Process device for extracting high-purity carbon dioxide from landfill gas, marsh gas and chemical exhaust

A high-purity carbon dioxide and landfill gas technology, which is applied in the field of biogas or chemical tail gas extraction of high-purity carbon dioxide, and in the field of landfill gas, can solve problems such as destroying the ozone layer, reduce environmental pollution, improve utilization, and reduce total The effect of tonnage mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments and accompanying drawings.

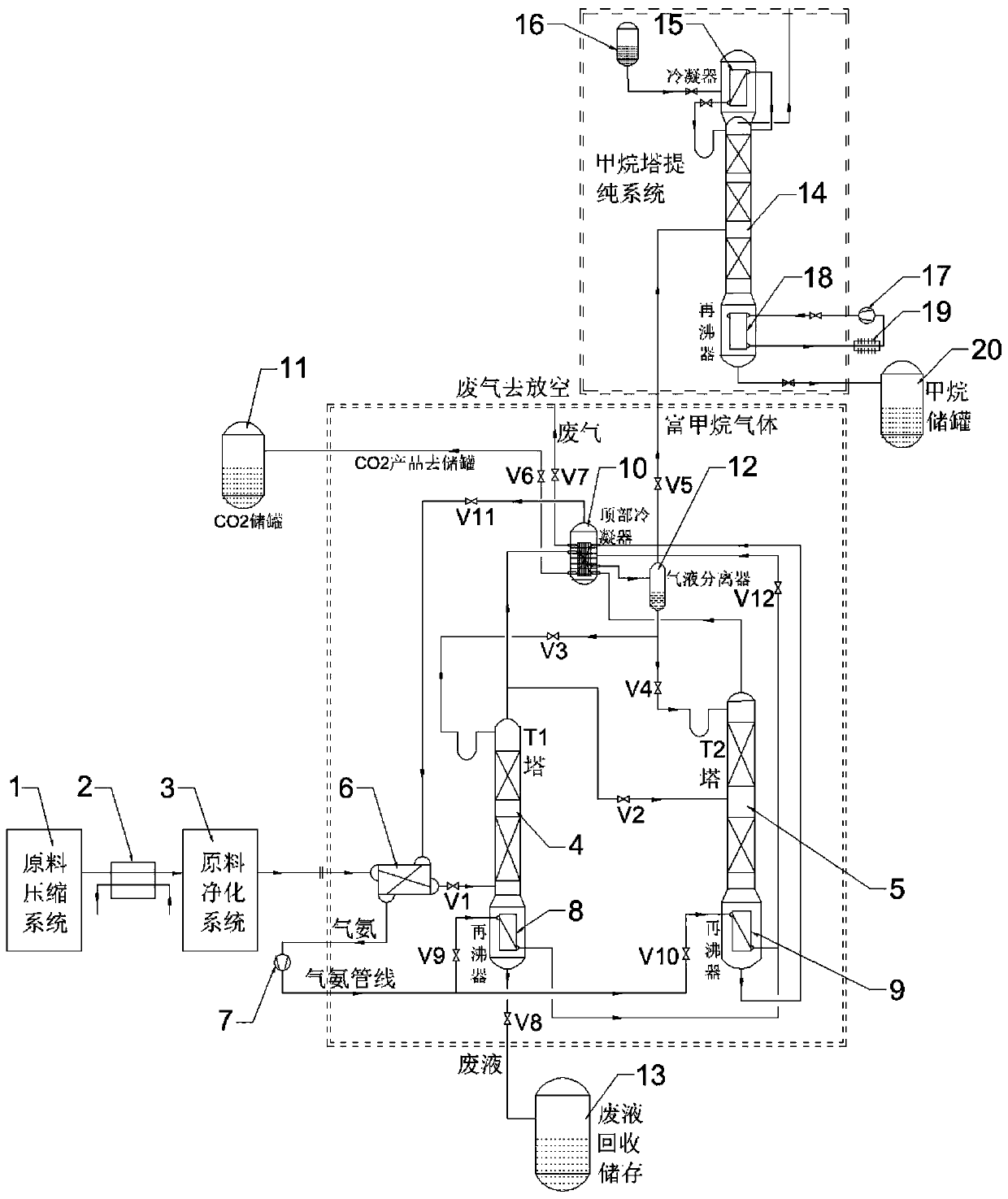

[0024] The specific implementation is as follows: figure 1 As shown, the process equipment for extracting high-purity carbon dioxide from landfill gas, biogas or chemical tail gas includes pretreatment system, cryogenic rectification system, refrigeration system and methane purification system. The pretreatment system includes a raw material compressor 1 , a precooler 2 and a desulfurization tower 3 in sequence. The cryogenic rectification system includes a first rectification tower 4 , a second rectification tower 5 , a carbon dioxide storage tank 11 , a gas-liquid separator 12 and a waste liquid recovery storage tank 13 . The refrigeration system includes an ammonia compressor 7, a parallel first reboiler 8 and a second reboiler 9, a top condenser 10 and a recooler 6, and the first reboiler 8 and the second reboiler 9 are respectively located in The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com