Aeroengine rotor-stator clamping device combined with hydraulic drive and double working belt

A technology of aero-engines and clamping devices, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems such as unsolved problems, achieve the effects of reducing clamping damage and deformation, improving accuracy, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

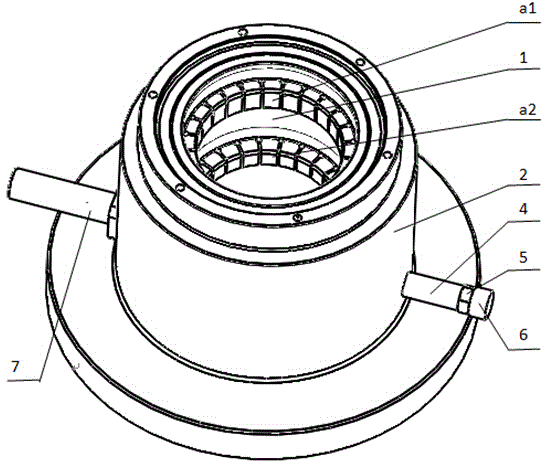

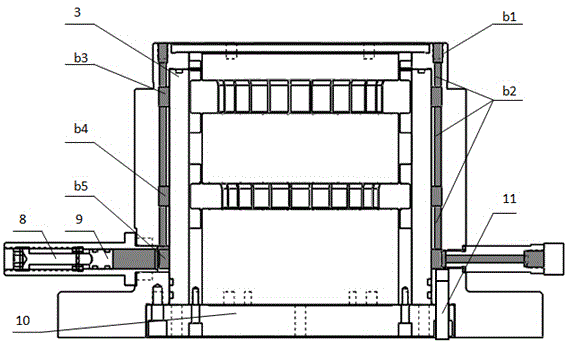

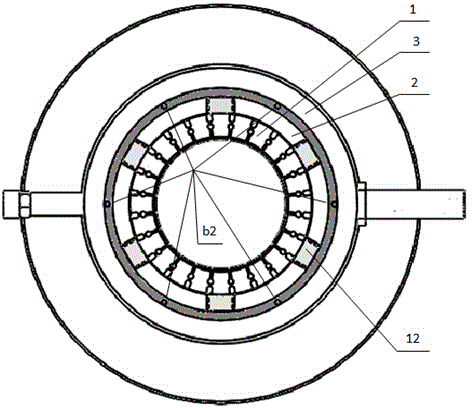

[0029] Such as figure 1 As shown, the aero-engine rotor-stator clamping device combined with hydraulic drive and double working belt, the device includes an inner sleeve 1, a middle sleeve 2, an outer sleeve 3, an extension pipe 4, a connecting piece 5, a pressure detector 6, and a pressurizer 7 , the bottom plate 10, the sealing mouth 11 and the piston 12, the inner sleeve 1, the middle sleeve 2 and the outer sleeve 3 are all fixed on the base plate 10; it is characterized in that: the inner sleeve 1 includes the upper annular working belt a1 and the lower annular working belt a2; The jacket 3 includes an oil injection hole b1, a connecting channel b2, an upper annular oil passage b3, a middle annular oil passage b4 and a lower annular oil passage b5;

[0030] The middle sleeve 2 is arranged between the outer sleeve 3 and the inner sleeve 1; the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com