Efficient label printing equipment

A label printing and equipment technology, applied in printing, printing presses, rotary printing presses, etc., can solve problems such as reducing the production quality and production efficiency of printing base paper tapes, loosening label stickers, and separating and warping the corners of label stickers. The effect of production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

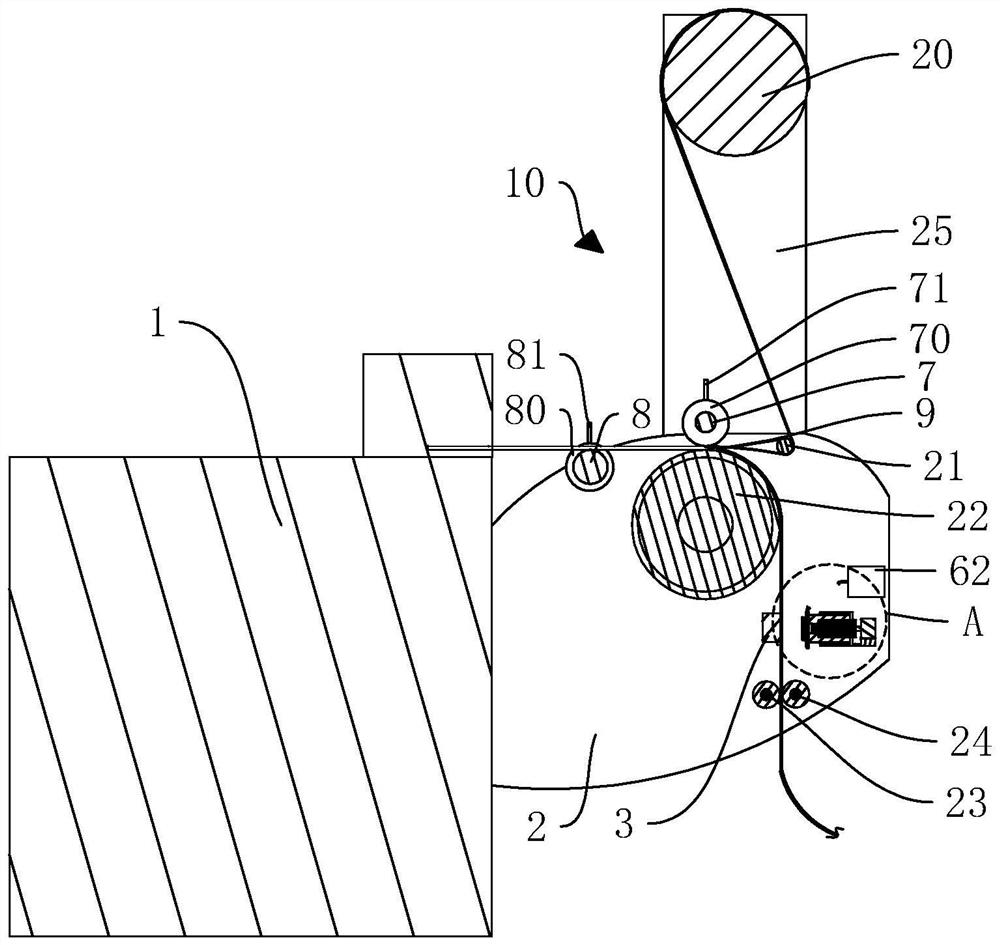

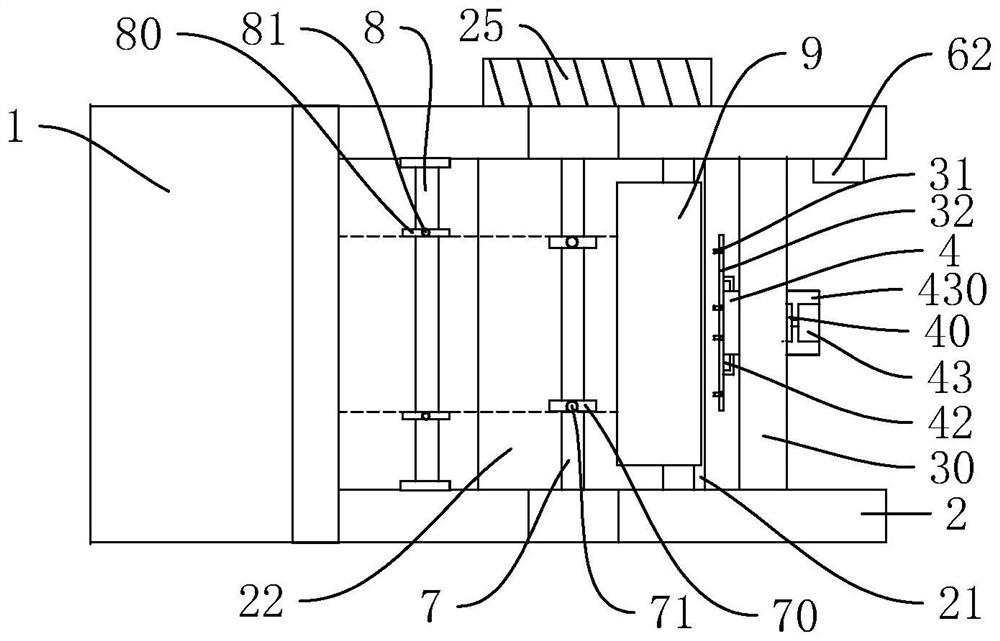

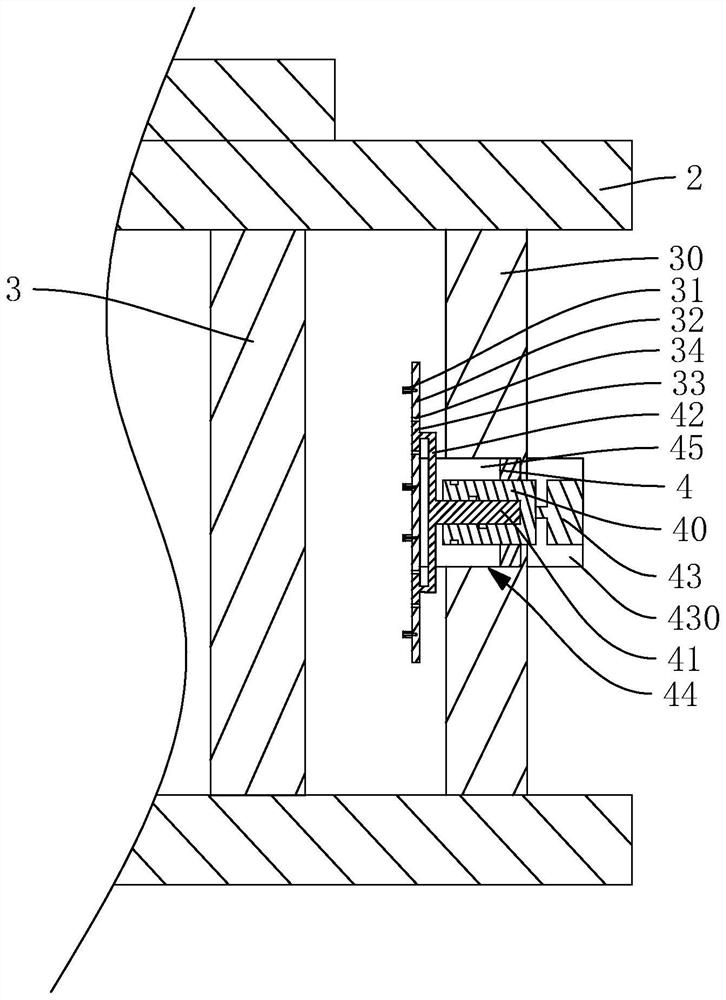

[0037] The following is attached Figure 1-7 The application is described in further detail.

[0038] The embodiment of the present application discloses an efficient label printing device. refer to figure 1 , the label printing equipment includes a glue cutting device 1 and a glue tearing device 10, the glue tearing device 10 and the glue cutting device 1 are integrated, and the driving equipment provided in the glue tearing device 10 and the glue cutting device 1 are all synchronous intermittent drives, Wherein, glue tearing device 10 comprises two installation boards 2, and two installation boards 2 and glue cutting device 1 casing are integrally formed and are respectively arranged at the two sides of end of glue cutting device 1 along printing base paper tape conveying direction. The two mounting plates 2 are respectively horizontally provided with a winder 20 , an abutting rod 21 , a transmission roller 22 , a driving clamping roller 23 and a passive clamping roller 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com