Adhesive tape with fabric carrier for cable wrapping

A non-woven carrier, tape technology, applied in the direction of fabrics, textiles, adhesives, etc., can solve the problem that the unwinding force is not in the optimal range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

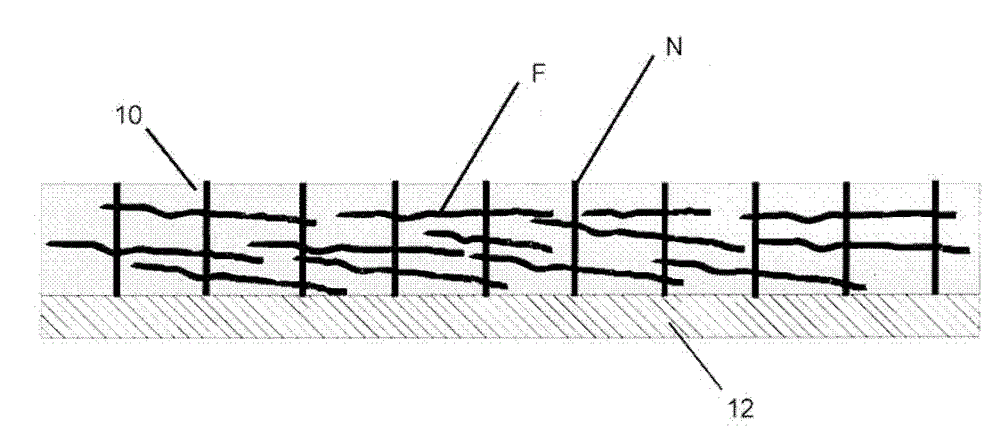

[0046] Staple fibers are individual fibers of finite length. Filaments (infinitely long fibers) are the opposite of staple fibers. All natural fibers are short fibers in that they only exhibit up to a certain length. All man-made fibers can be chopped into staple fibers. Hereinafter, short fibers are also referred to as fibers for convenience.

[0047] According to the invention, the solution of an adhesive tape with adhesive on only one side is preferred.

[0048] Preferably, the web consists of polyester fibres, polypropylene fibres, polyethylene fibres, or polyamide fibres.

[0049] The fiber thickness is preferably 1 to 5 dtex (1 tex: 1 gram per 1000 m) and preferably 1.7 to 3.64 dtex.

[0050] The fiber length is preferably 50 to 100 mm and more preferably 60 to 85 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com