Flexible board

A flexible substrate and flexible technology, applied in the direction of electrical connection of printed components, printed circuit components, electrical components, etc., can solve the problems of inability to correspond, inability to bend flexible substrates, unfavorable labor and cost, and achieve improved performance. Effects of mounting density, improved bonding, and reduced springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

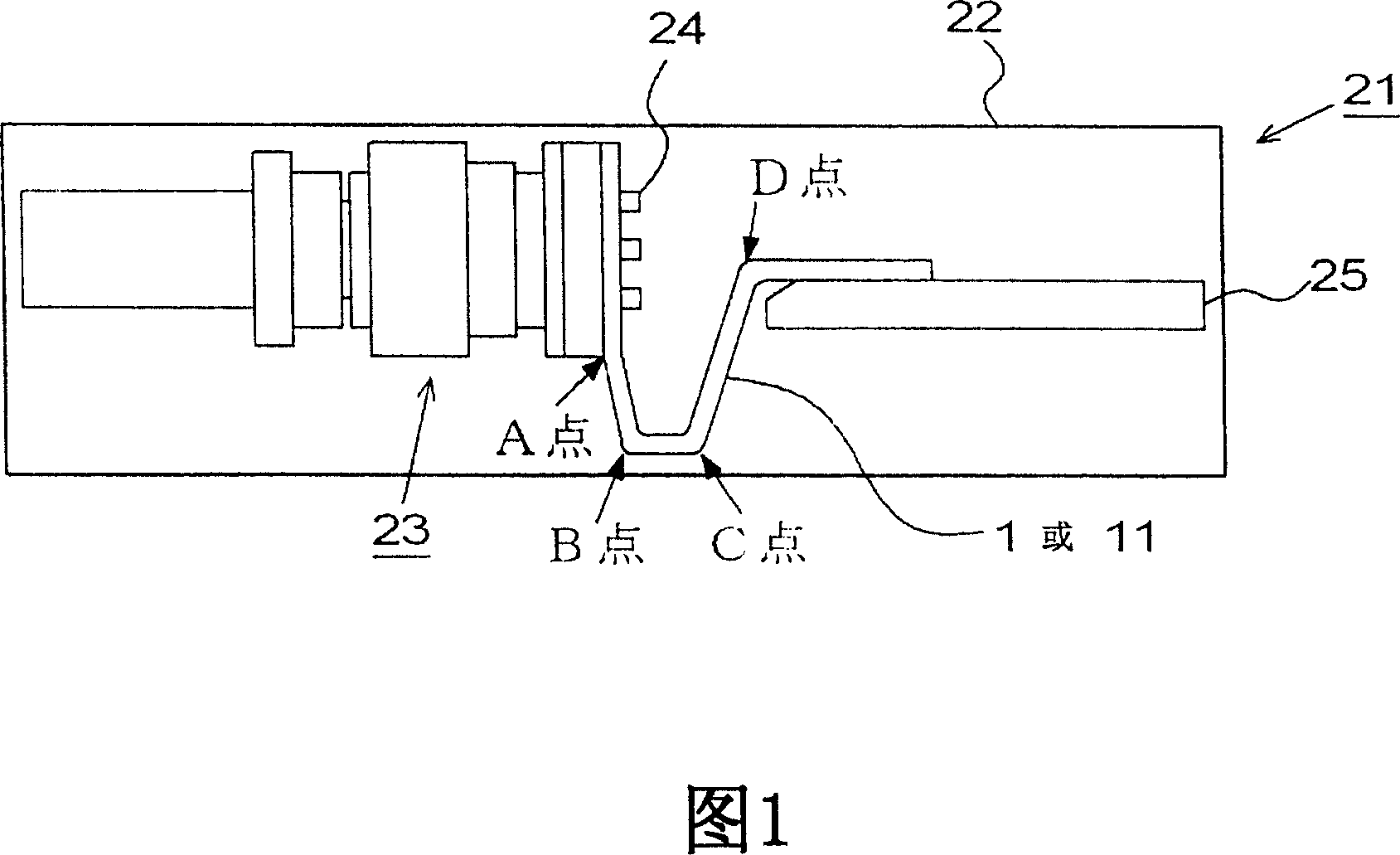

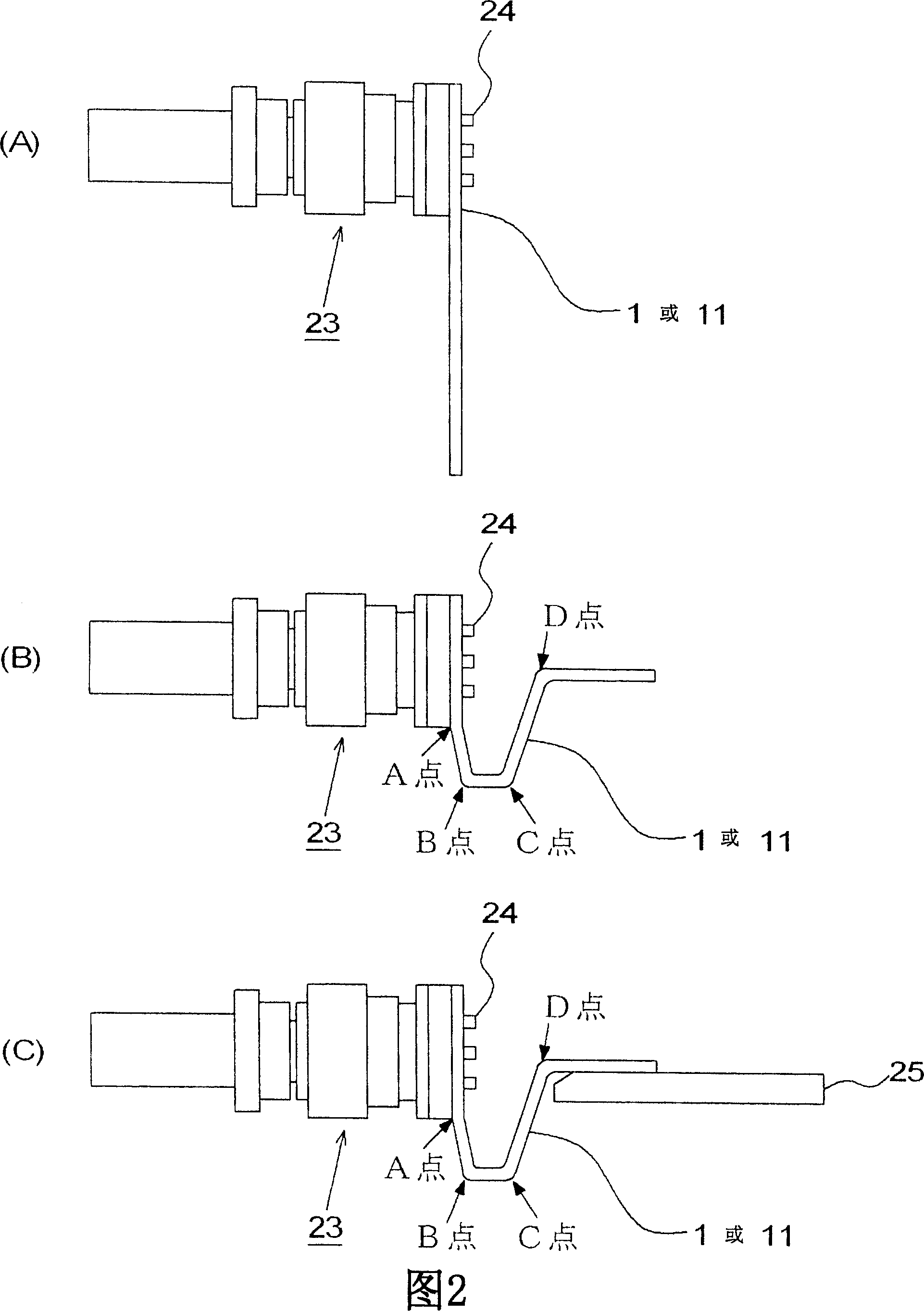

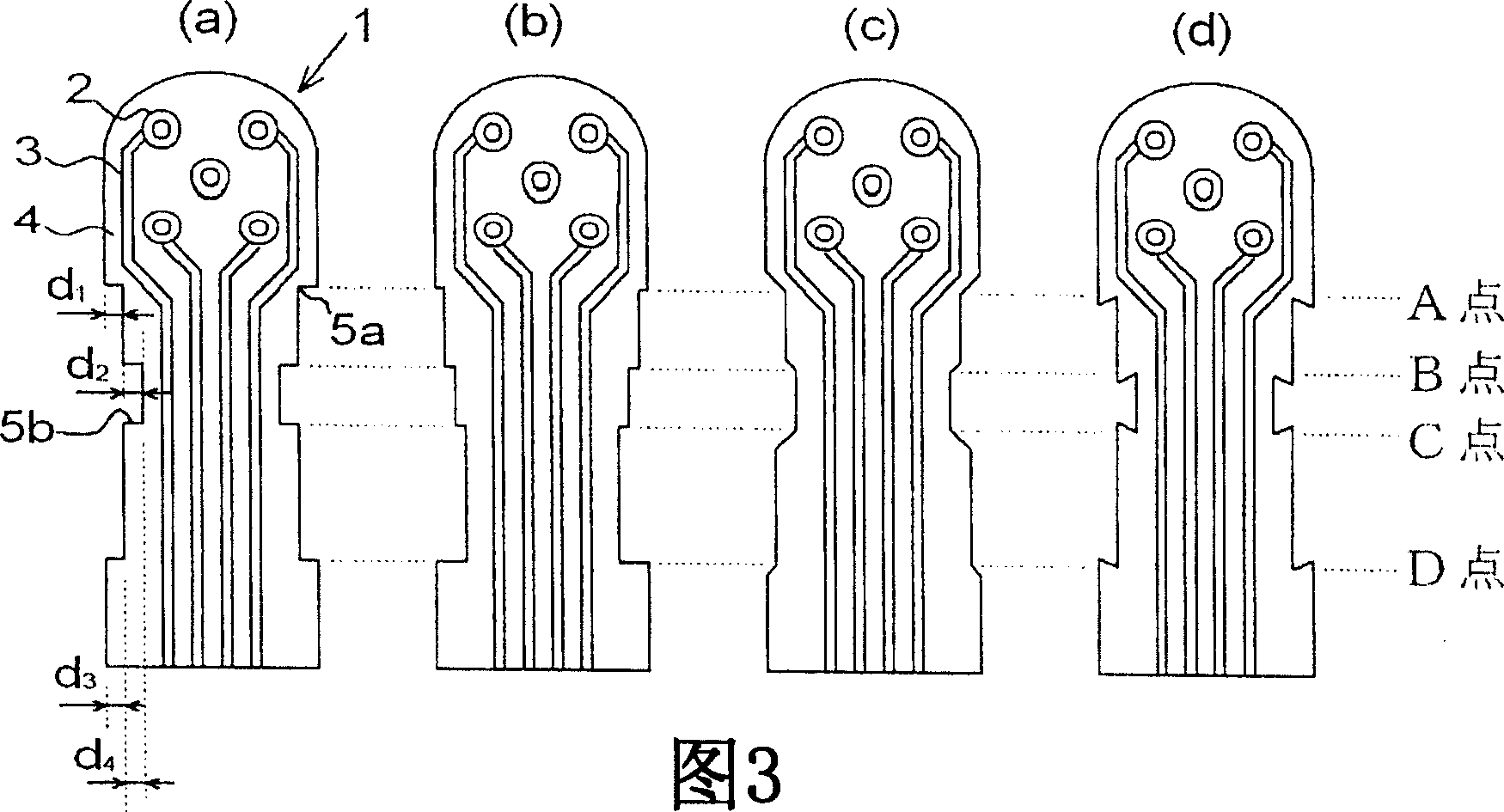

[0039] Polyimide was used for the insulating layer, and copper foil was used for the conductor layer, thereby fabricating flexible substrate 1 as shown in FIG. 6 . Neck with 4 pairs of re-entrant corners to have 4 inflection points, full width t 5 = 5.6mm on both sides of the flexible substrate, the maximum width of each segment is t 1 = 1.2mm (ratio to full width: about 21%), t 2 = 0.2mm (about 3.6%), t 3 = 0.5mm (about 8.9%), and t 4 =0.6mm (approximately 11%) 4 segments are formed so that the width of the central segment is the narrowest. Each segment is tapered upward, and has a concave corner at the bent position. From another point of view, the constricted portion may also be considered to be composed of four continuously formed notches. In order to assemble the flexible substrate into the optical transceiver as shown in Figure 1, after soldering on the transceiver module, the flexible substrate can be bent in the manner shown in Figure 1, then the predetermined ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com