Wire bending device

A bending device and wire technology, applied in the field of wire processing, can solve problems such as affecting plug assembly, low efficiency, and difficulty in ensuring cable alignment, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

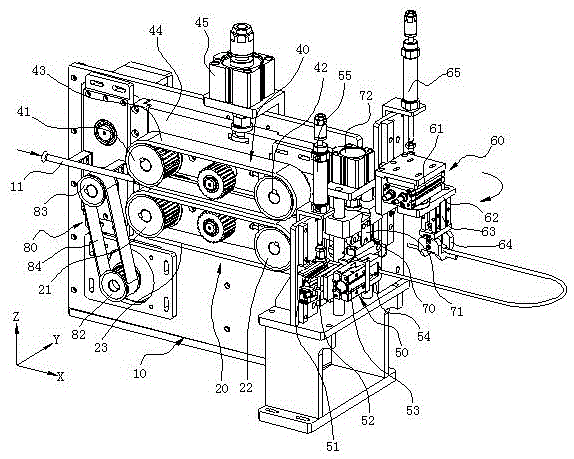

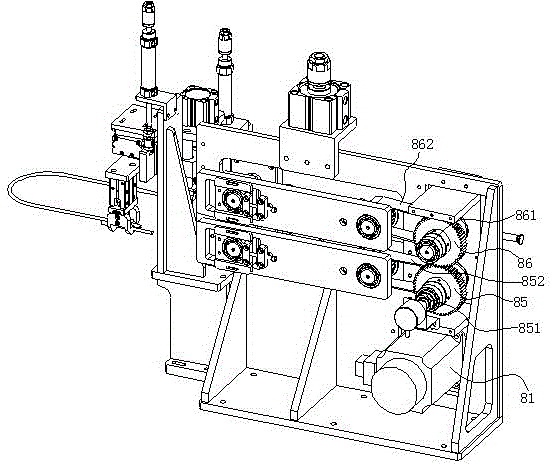

[0024] Such as figure 1 , 2 As shown, it is a wire bending device of the present invention, which includes a frame 10, a first belt conveying assembly 20, a second belt conveying assembly 40, a driving assembly 80, a wire bending assembly 60, a wire clamping assembly 50, a cutter Cut assembly 70.

[0025] Wherein the frame 10 is used as the installation base of the whole device, and the first belt conveying assembly 20 is installed on the frame 10, specifically, the first belt conveying assembly 20 includes a first driving pulley 21 pivotally connected on the frame 10 , the first driven pulley 22 pivotally connected on the frame 10, the first drive belt 23 that is wound around the first drive pulley 21 and the first driven pulley 22 outside synchronously, the first drive belt 23 Extend along the length direction of the rack 10 (that is, the X directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com