PIN bent plugging and taking device

A technology of bending and inserting and bending blocks, which is applied in the field of electronic component processing equipment, can solve the problems of high cost and low production efficiency of assembly process, and achieve the effects of improving production efficiency, reducing production processes and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

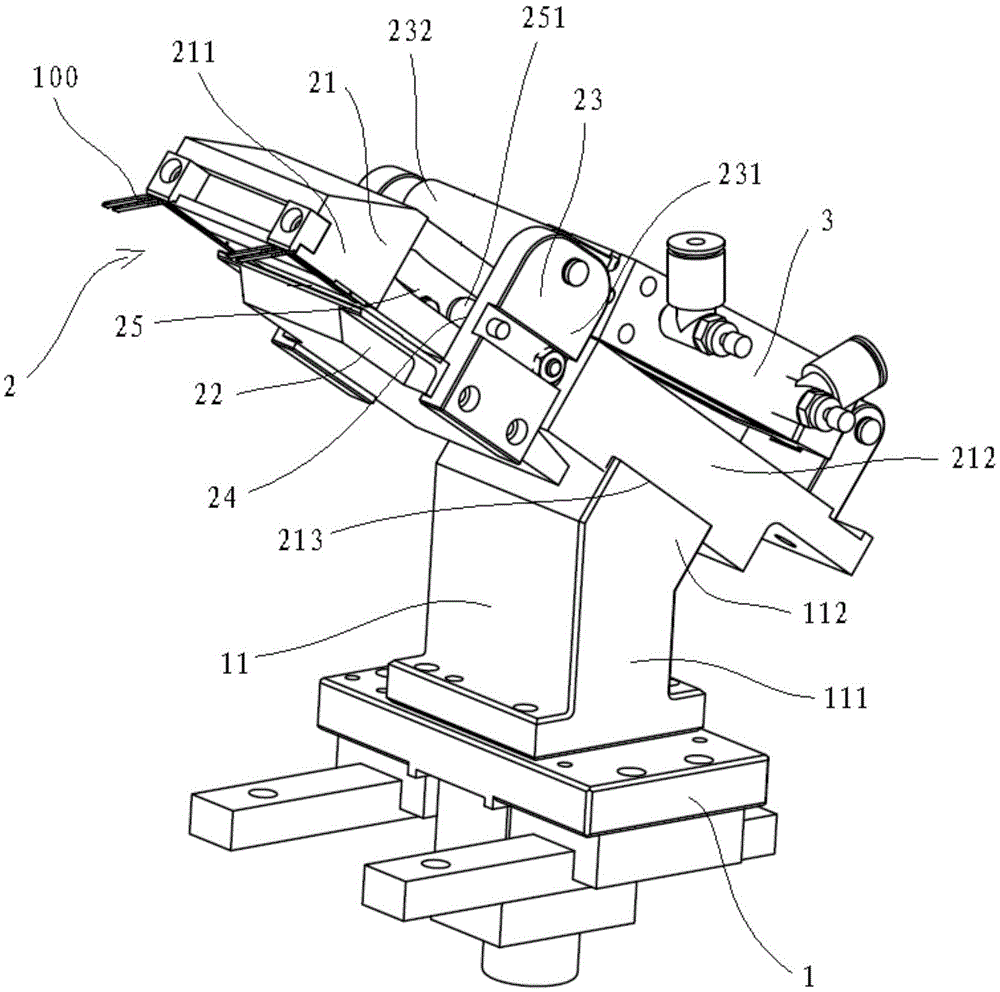

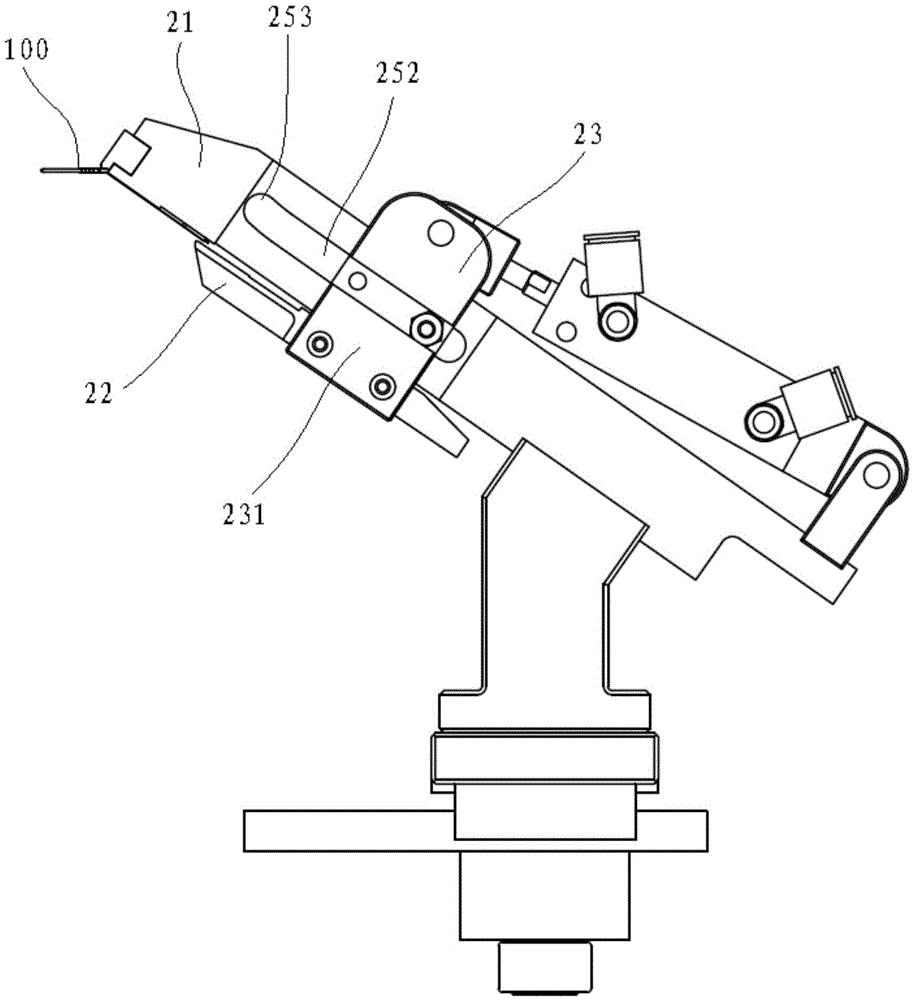

[0074] As a specific implementation, the transmission structure is a parallelogram hinged structure 7, including:

[0075] The vertical frame 71 is fixed on the mounting frame 5;

[0076] Crank 72, one end is hinged on described vertical frame 71;

[0077] Connecting frame rod 73, one end is hinged on described vertical frame 71, and in vertical direction, the hinge point of described connecting frame rod 72 and described vertical frame 71 is positioned at described crank 72 and described vertical frame. Above the hinge point of the straight frame 71;

[0078] The connecting rod 74 is arranged in parallel with the vertical frame 71, and the two ends of the connecting rod 74 are respectively hinged with the crank 72 and the connecting frame rod 73;

[0079] The bending block 6 is installed on the connecting rod 73 or the connecting rod 74 .

[0080] The bending block 6 installed on the connecting frame rod 73 or the connecting rod 74 can realize that when the power device dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com