Micro-lattice mismatch quantum well solar cell and manufacturing method therefor

A technology of solar cells and quantum wells, applied in the field of solar cells, can solve problems such as difficult control of cell defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific examples.

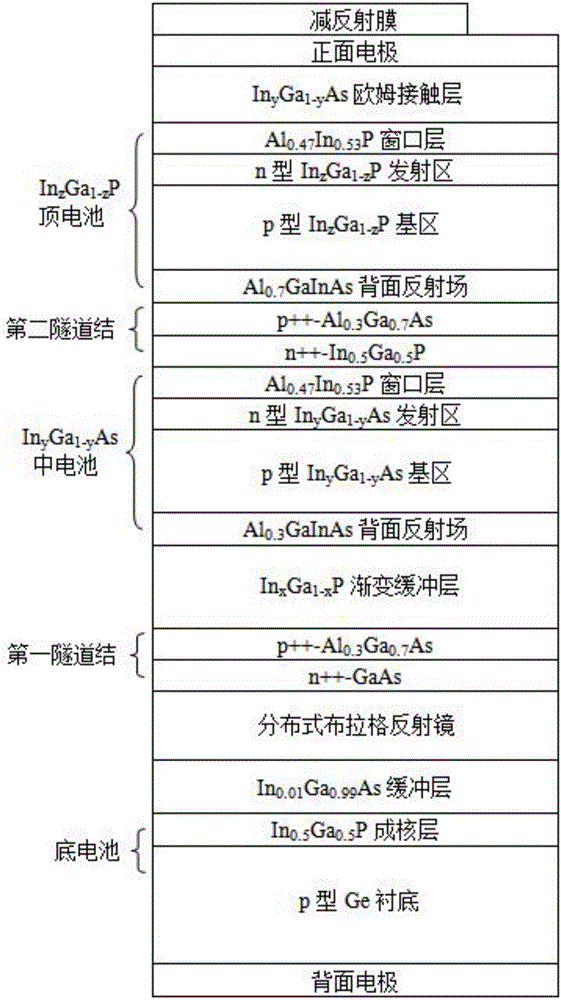

[0049] Such as figure 1 As shown, the microlattice mismatch quantum well solar cell described in this embodiment is mainly composed of "Ge / In y Ga 1- y As / In z Ga 1-z P" triple junction structure, can also be "Ge / In y Ga 1-y As / AlGaInAs / AlGaInP" four-junction structure. In this embodiment, the microlattice-mismatched quantum well solar cell uses p-type Ge as the substrate, and is stacked sequentially from bottom to top from the upper surface of the substrate lined up In 0.5 Ga 0.5 P nucleation layer, In 0.01 Ga 0.99 As buffer layer, distributed Bragg reflector, first tunnel junction, In x Ga 1-x P gradient buffer layer, In y Ga 1-y As middle cell, second tunnel junction, In z Ga 1-z P top battery, In y Ga 1-y An As ohmic contact layer, a front electrode, and an anti-reflection film; a back electrode is prepared on the lower surface of the p-type Ge substrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com