Beneficiation method applied to superconduction magnetic separation of rare earth ore

A mineral processing method and superconducting magnetic technology, applied in chemical instruments and methods, magnetic separation, high-gradient magnetic separation, etc., can solve the problems of economic loss and waste of resources, high cost of separation, low rare earth resources, etc., and achieve energy reduction Reduce consumption and operation cost, improve sorting accuracy and efficiency, and achieve comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the specific embodiments of the present invention are clearly and completely described below to further illustrate the present invention. Obviously, the described specific implementation The form is only a part of embodiment of this invention, and it is not all form.

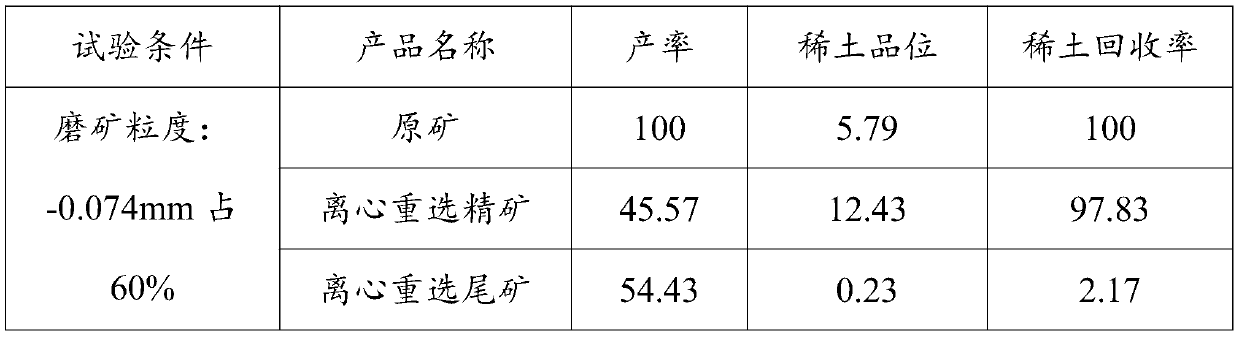

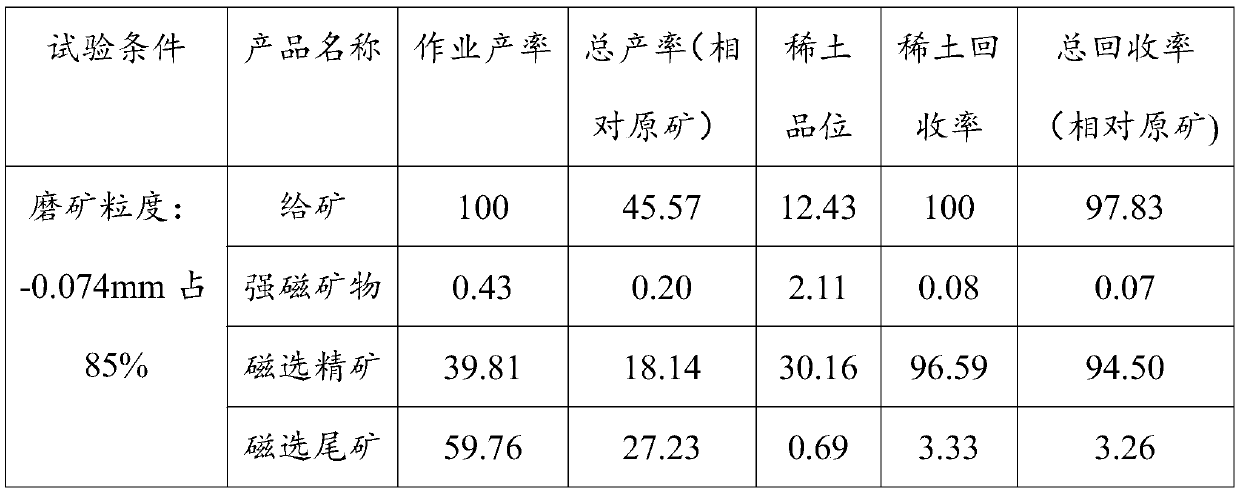

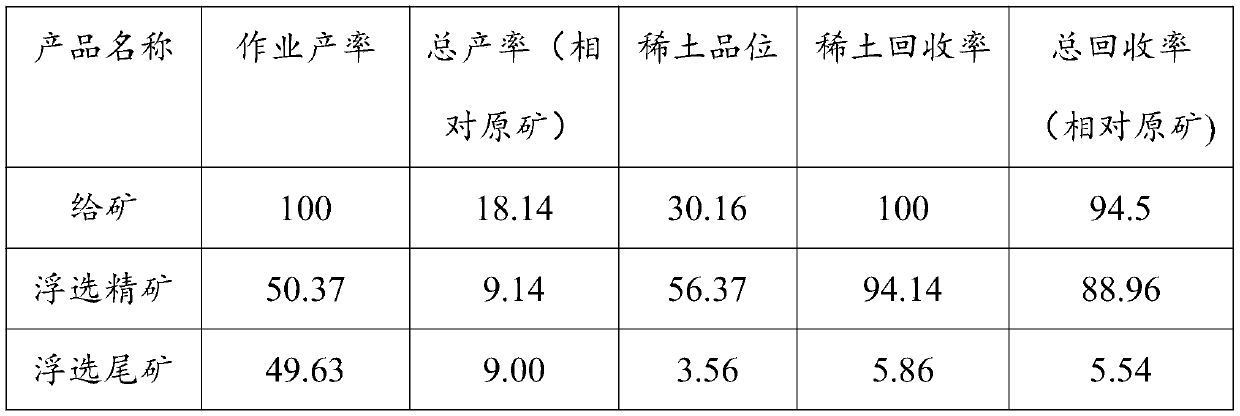

[0028]This specific embodiment adopts the method of gravity separation-superconducting magnetic separation-flotation separation to separate rare earth ores. The raw material used in this embodiment is raw rare earth ore, the grade of rare earth in the raw ore is 5.79%, and the contents of other main elements are as follows (All are mass percentages): Ca: 10.38%, Si: 15.38%, F: 8.17%, Fe: 5.52%, Sr: 12.49%, Al: 5.56%, K: 4.90%, Na: 2.33%, S : 0.18%, Pb: 2.95%.

[0029] Raw ore minerals are composed of rare earth minerals bastnaesite, monazite, bastnaes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com