Dolomite-barite type lead zinc ore separation flotation method

The technology of barite and dolomite is applied in the field of separation and flotation of dolomite-barite lead-zinc ore, which can solve the problems of affecting the separation index of lead and zinc, over-crushing of barite, difficulty in recycling and the like, Achieve the effect of solving the problem of low flotation index, reducing the amount of ore and reducing the content of minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

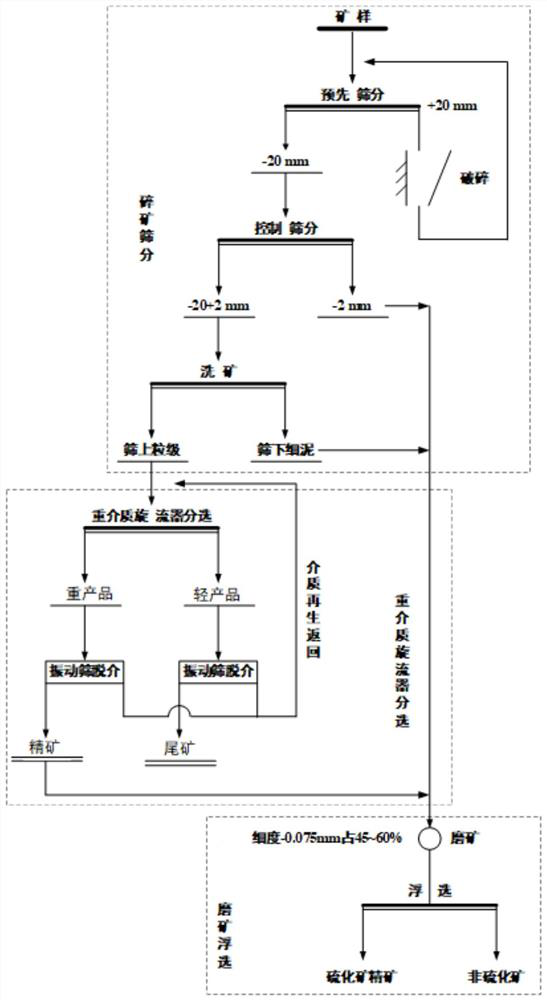

[0031] The dolomite-barite type lead-zinc ore treated in this embodiment contains 0.97% lead, 3.33% zinc, about 16% barite mineral content, and about 63% gangue mineral dolomite content. The separation flotation method that this embodiment provides refers to figure 1 The flow shown is carried out and includes the following steps:

[0032] S1: crushing-screening

[0033] The dolomite-barite type lead-zinc ore is crushed to -15mm, and the mass ratio of the ore with a particle size between -15+4mm is 78%, and the fine minerals with a particle size of -4mm enter the powder ore bin of the concentrator. As the feed material of the ore grinding machine, the -15mm+4mm grain grade minerals enter the ore washing; the -15mm+4mm ore is washed with a vibrating screen with a 2mm screen hole and high-pressure water washing, and the fine-grained grade under the screen is concentrated and used as a mill The ore feed, the size on the sieve enters the dense medium cyclone for sorting, and the ...

Embodiment 2

[0045] The dolomite-barite type lead-zinc ore processed in this embodiment contains 0.97% lead, 3.33% zinc, about 16% barite mineral content, and about 67% gangue dolomite mineral content. The separation flotation method that this embodiment provides refers to figure 1 The flow shown is carried out and includes the following steps:

[0046] S1: crushing-screening

[0047] Dolomite-barite type lead-zinc ore is crushed to -15mm, and the mass ratio of ore with a particle size between -15+2mm is 84.5%, and the fine minerals with a particle size of -2mm are used as a grinding machine Feeding, -15+2mm grain grade minerals enter the ore washing; the -15+2mm ore is washed with a vibrating screen with 2mm sieve holes and high-pressure water washing, and the fine-grained grades under the screen are concentrated and used as grinding feedstock. The above-screen particle size enters the heavy medium cyclone for separation, and the above-screen particle size obtained by ore washing has a ...

Embodiment 3

[0059] The dolomite-barite type lead-zinc ore processed in this embodiment contains 0.97% lead and 3.33% zinc, the mineral content of barite is about 16%, and the mineral content of gangue dolomite is about 67%. The separation flotation method that this embodiment provides refers to figure 1 The flow shown is carried out and includes the following steps:

[0060] S1: crushing-screening

[0061] The dolomite-barite type lead-zinc ore ore is crushed to -20mm, and the mass ratio of the ore with a particle size in the range of -20+2mm is 84.9%, and the fine minerals with a particle size of -2mm are used as the feed material for the grinding machine. Minerals of -20+2mm grain size enter the ore washing; the -20+2mm ore is washed by a vibrating screen with 2mm mesh and high-pressure water washing, and the fine-grained grade under the sieve is concentrated and used as grinding feed, and the sieve is used as a grinding feed. The grade enters the dense medium cyclone for separation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com