A preparation method and production device for producing fuel oil from bio-heavy oil

A bio-heavy oil and fuel oil technology, which is applied to fuels, chemical instruments and methods, and hydrocarbon oil treatment, can solve the problems of secondary heating and ignition difficulties, low calorific value of bio-heavy oil, high pour point, and flash point, and achieve The production process is green and environmentally friendly, with low cost and low flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

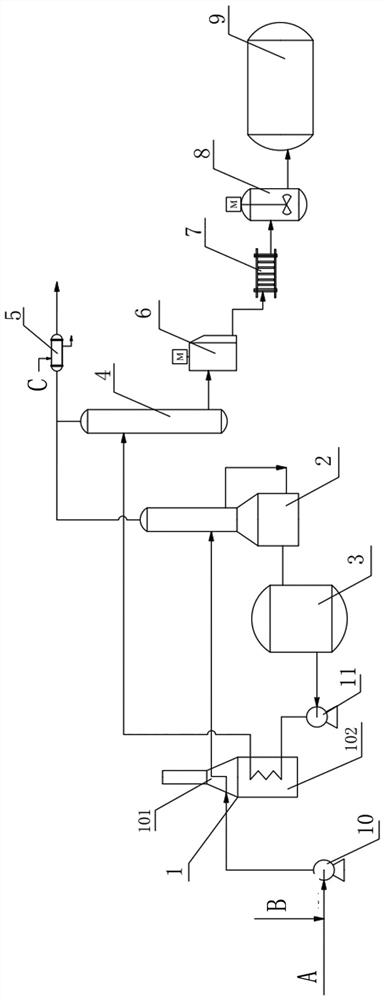

[0031] A method for producing fuel oil from bio-heavy oil, characterized in that the method comprises the following steps:

[0032] 1) Dehydration and desalination: After the biological heavy oil is fully mixed with 8wt% sodium carbonate solution, it is heated to 120°C in the convection zone of the tube furnace for dehydration and desalination, so that the water content in the biological heavy oil is reduced to below 0.5%.

[0033] 2) Catalyzed esterification: Add bio-heavy oil, absolute ethanol and solid alkali catalyst obtained in step 1) to the esterification reactor in sequence, and react at 50°C by total reflux, and take it every 20 minutes Again, stop the reaction when the pH is greater than 5.

[0034] 3) The product in step 2) is heated by a high-temperature centrifugal oil pump through the radiation zone of the tube furnace at 320-330°C and then enters the fractionation tower. The temperature at the top of the tower is controlled at 115-120°C. The oil is cooled by th...

Embodiment 2

[0045] A method for producing fuel oil from bio-heavy oil, characterized in that the method comprises the following steps:

[0046] 1) Dehydration and desalination: After the biological heavy oil is fully mixed with 9wt% sodium carbonate solution, it is heated to 125°C in the convection zone of the tube furnace for dehydration and desalination, so that the water content in the biological heavy oil is reduced to below 0.5%.

[0047] 2) Catalyzed esterification: Add the bio-heavy oil, absolute ethanol and solid alkali catalyst obtained in step 1) to the esterification reactor in sequence, and react at 70°C by total reflux, and take it every 25 minutes Again, stop the reaction when the pH is greater than 5.

[0048] 3) The product in step 2) is heated by a high-temperature centrifugal oil pump through the radiation zone of the tube furnace at 320-330°C and then enters the fractionation tower. The temperature at the top of the tower is controlled at 115-120°C. The oil is cooled by ...

Embodiment 3

[0059] A method for producing fuel oil from bio-heavy oil, characterized in that the method comprises the following steps:

[0060] 1) Dehydration and desalination: After the biological heavy oil is fully mixed with 12wt% sodium carbonate solution, it is heated to 130°C in the convection zone of the tube furnace for dehydration and desalination, so that the water content in the biological heavy oil is reduced to below 0.5%.

[0061] 2) Catalyzed esterification: Add bio-heavy oil, absolute ethanol and solid alkali catalyst obtained in step 1) to the esterification reactor in sequence, and react at 80°C by total reflux, and take it every 30 minutes Again, stop the reaction when the pH is greater than 5.

[0062] 3) The product in step 2) is heated by a high-temperature centrifugal oil pump through the radiation zone of the tube furnace at 320-330°C and then enters the fractionation tower. The temperature at the top of the tower is controlled at 115-120°C. The oil is cooled by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com