Patents

Literature

77results about "Fuels" patented technology

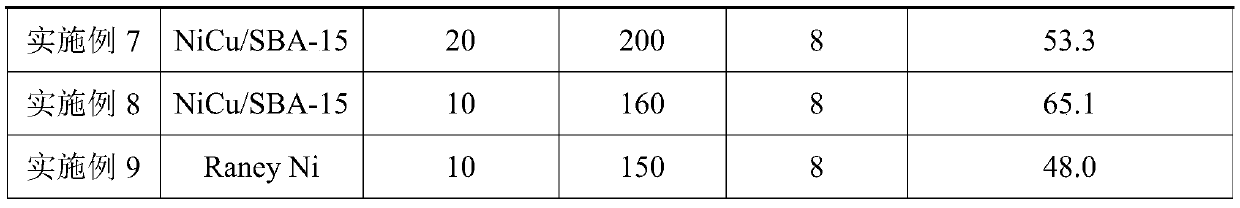

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

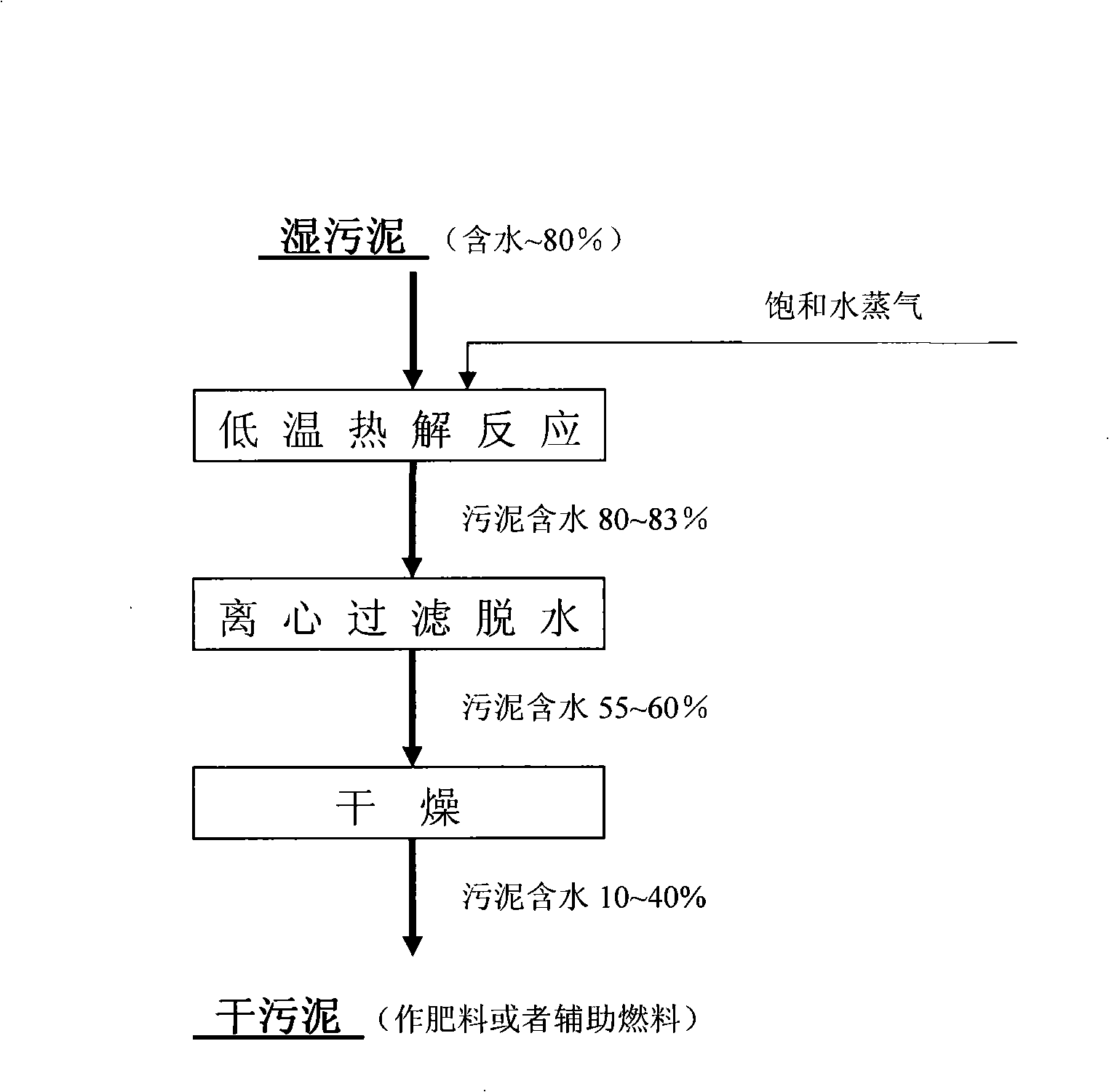

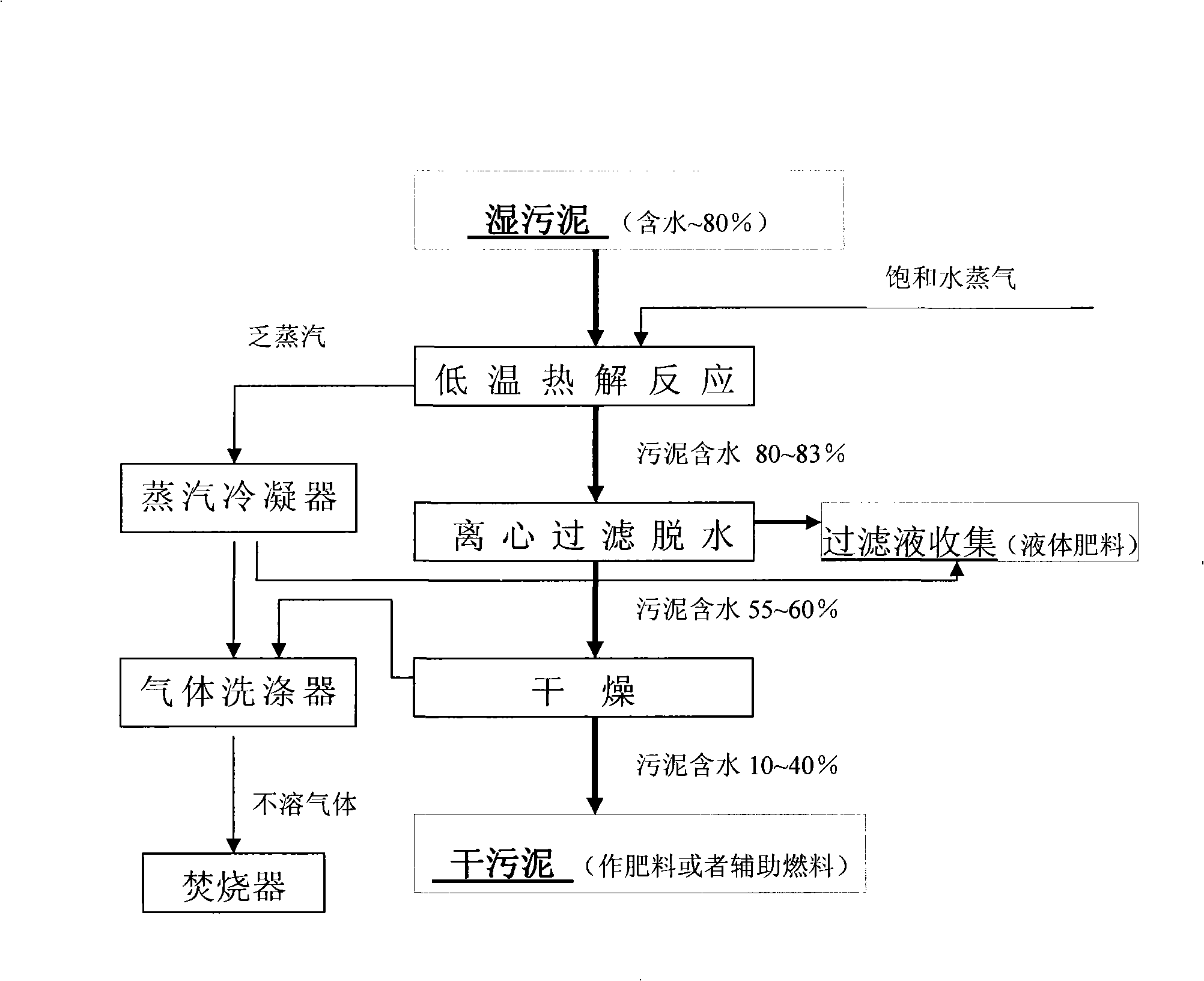

System and process for anhydration treatment of wet sludge

ActiveCN101289267AAvoid it happening againNo odorSludge treatment by de-watering/drying/thickeningWaste processingResource utilizationSludge

The invention relates to a wet sludge anhydration treatment system which comprises a low-temperature pyrolysis reaction device which is used for carrying out the low-temperature pyrolysis reaction of wet sludge and saturated water vapor to convert macromolecular organics in the wet sludge into low-molecular organics, a spiral centrifugal filtering device which is used for carrying out centrifugal filtering and dehydration to the wet sludge after the pyrolysis in a mechanical separation manner so as to obtain semi-dry sludge with the water content of 55 percent to 60 percent, and a drying device which is used for drying and removing the water in the semi-dry sludge after the filtering and hydration so as to obtain dried-sludge solid fuel with the water content of 10 percent to 40 percent. Meanwhile, the invention also relates to a wet sludge anhydration treatment technology by adopting the treatment system. The system and the technology of the invention can solve the problem of renewable resource of sludge in a method of environment protection, energy saving, high resource utilization and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

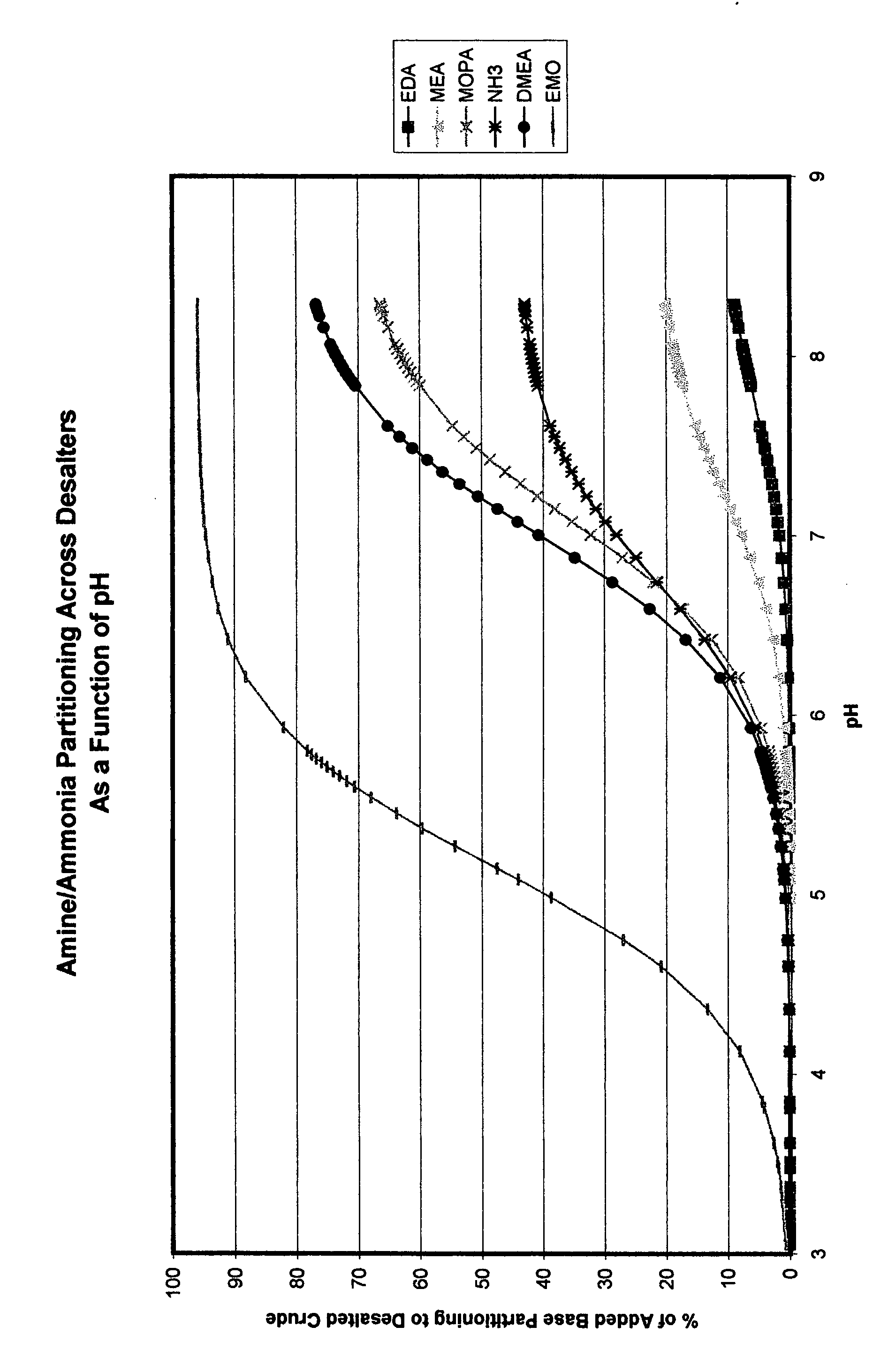

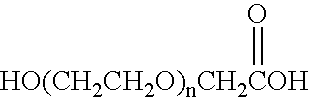

Additives to enhance phosphorus compound removal in refinery desalting processes

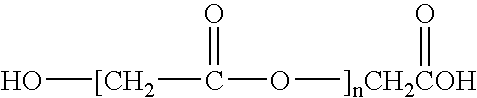

ActiveUS20050241997A1Dewatering/demulsification with chemical meansOther chemical processesAlkaneChloroacetic acids

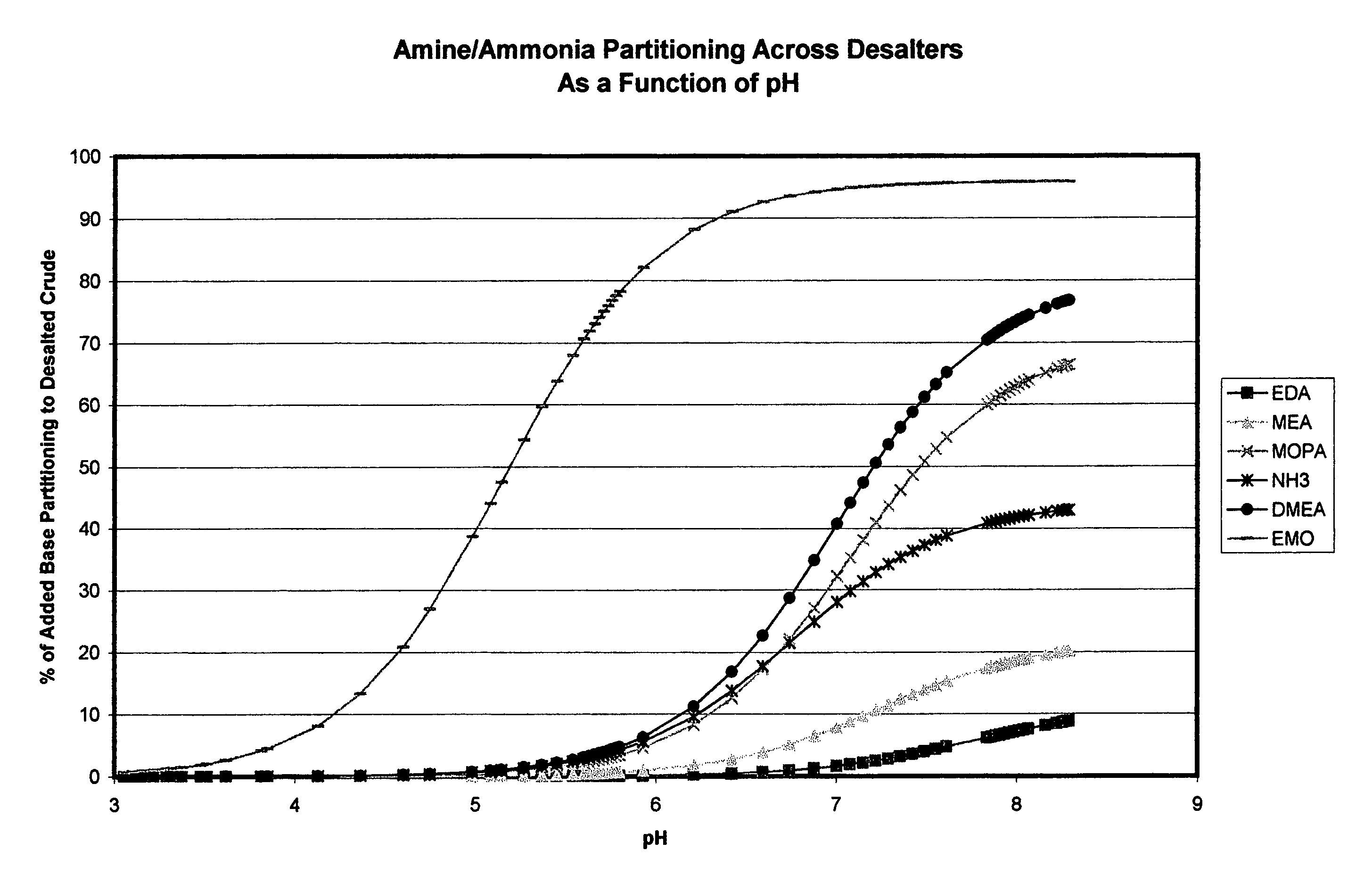

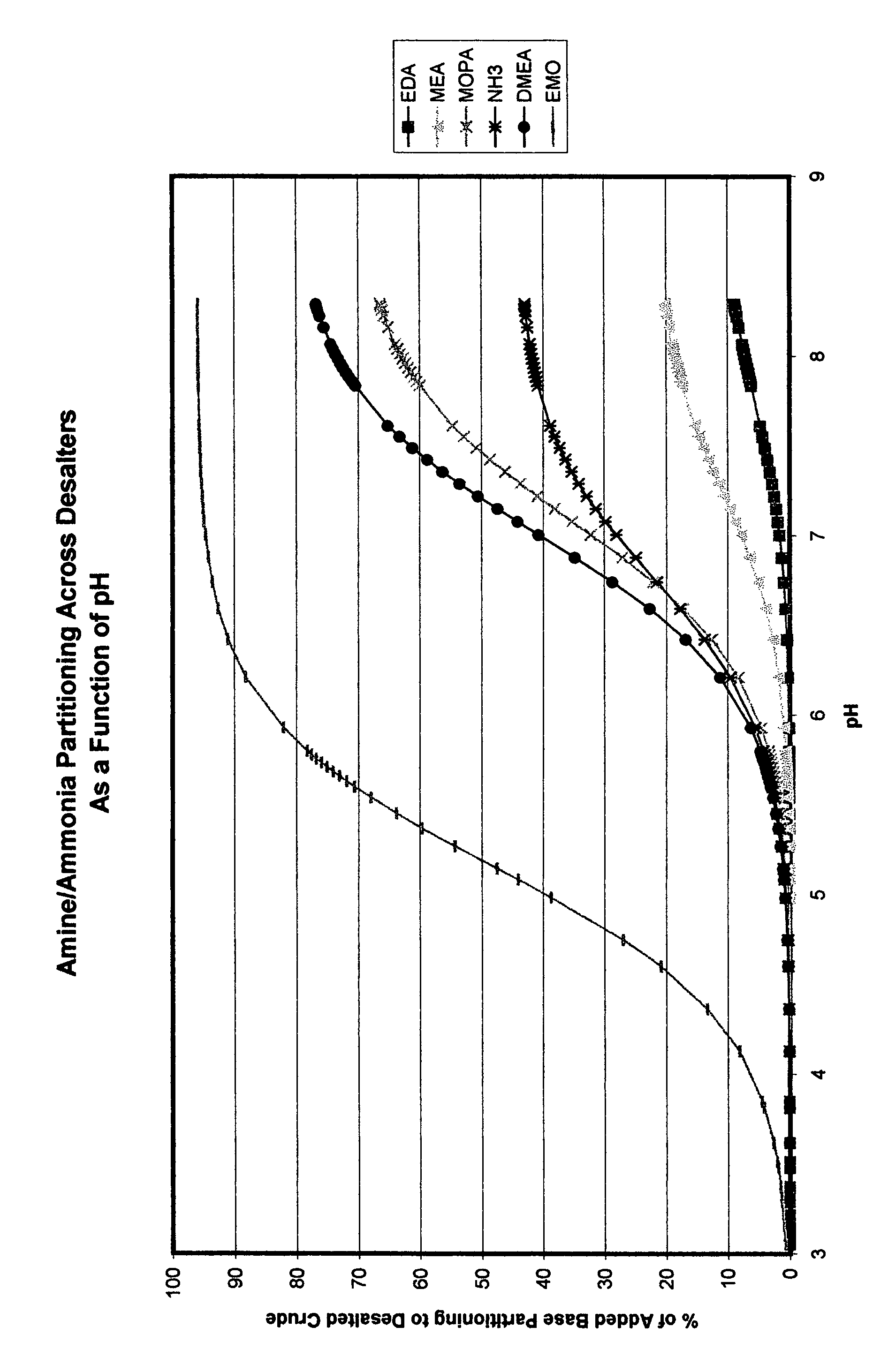

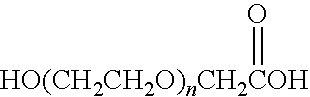

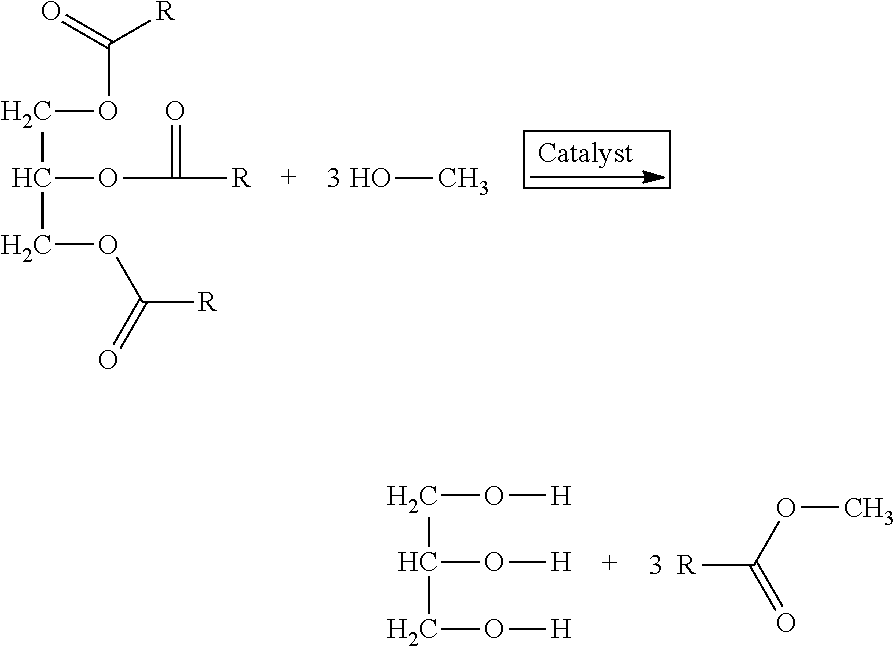

Reactive phosphorus species can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxy-acids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may optionally include a mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of reactive phosphorus species into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES INC

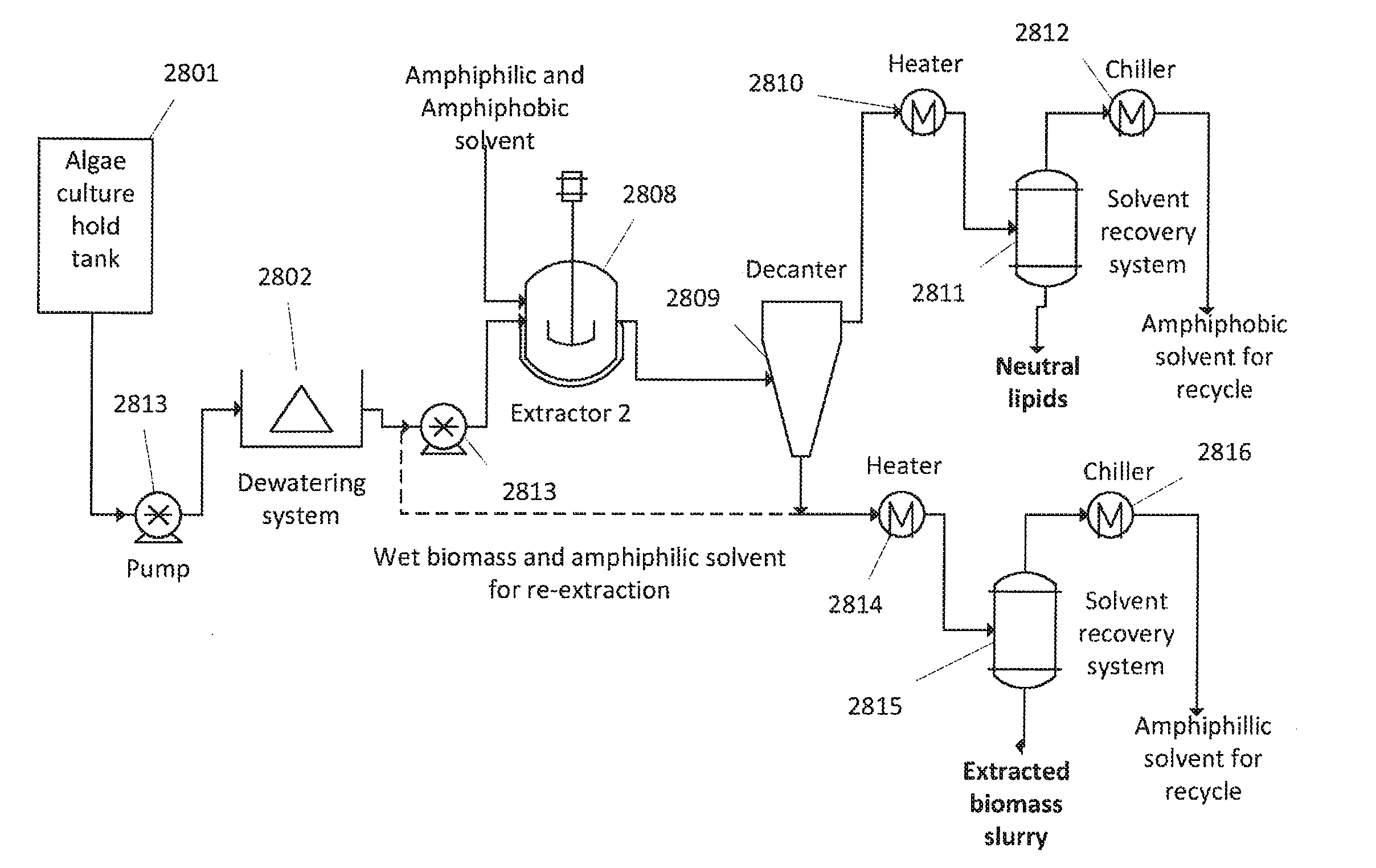

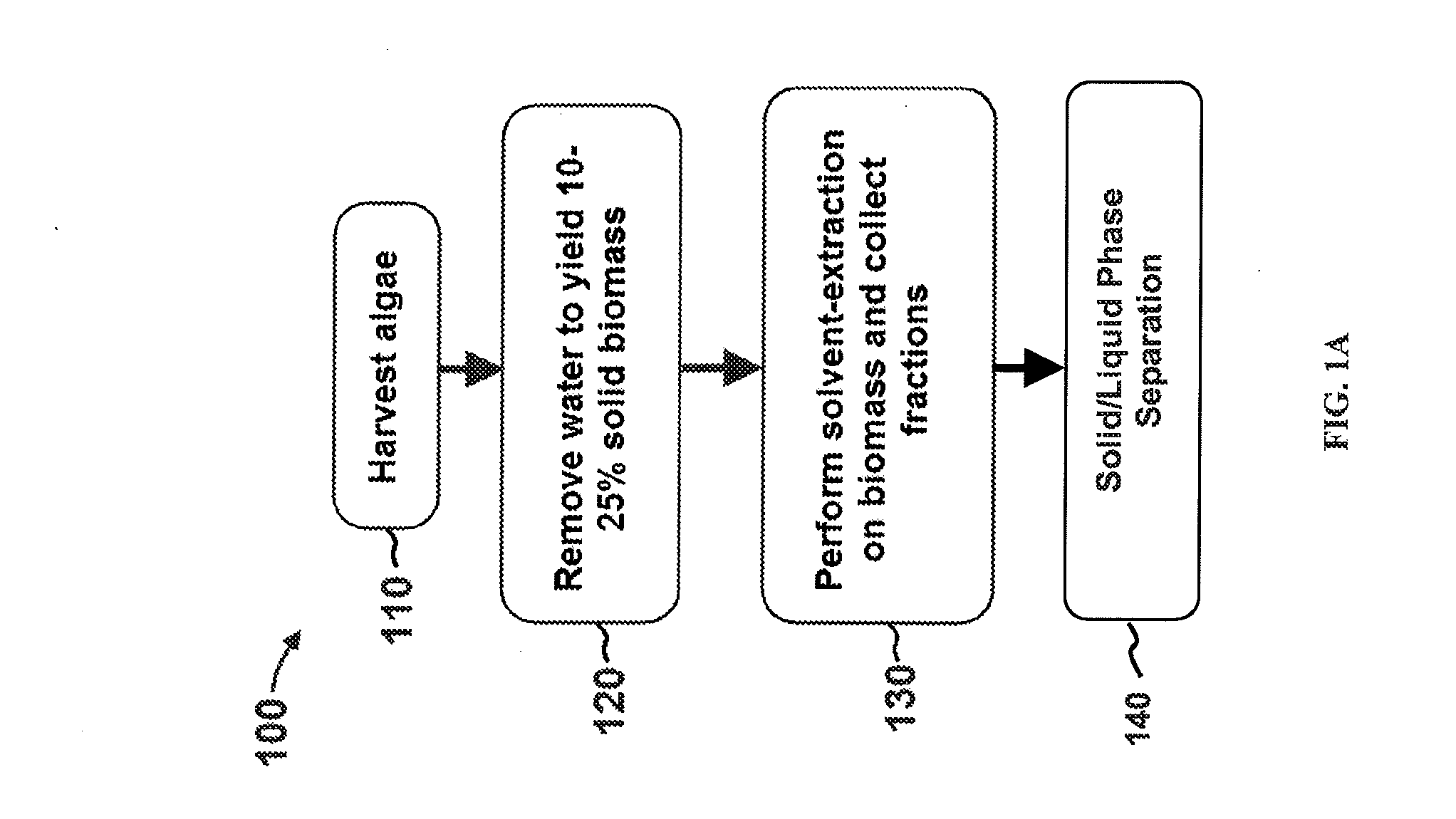

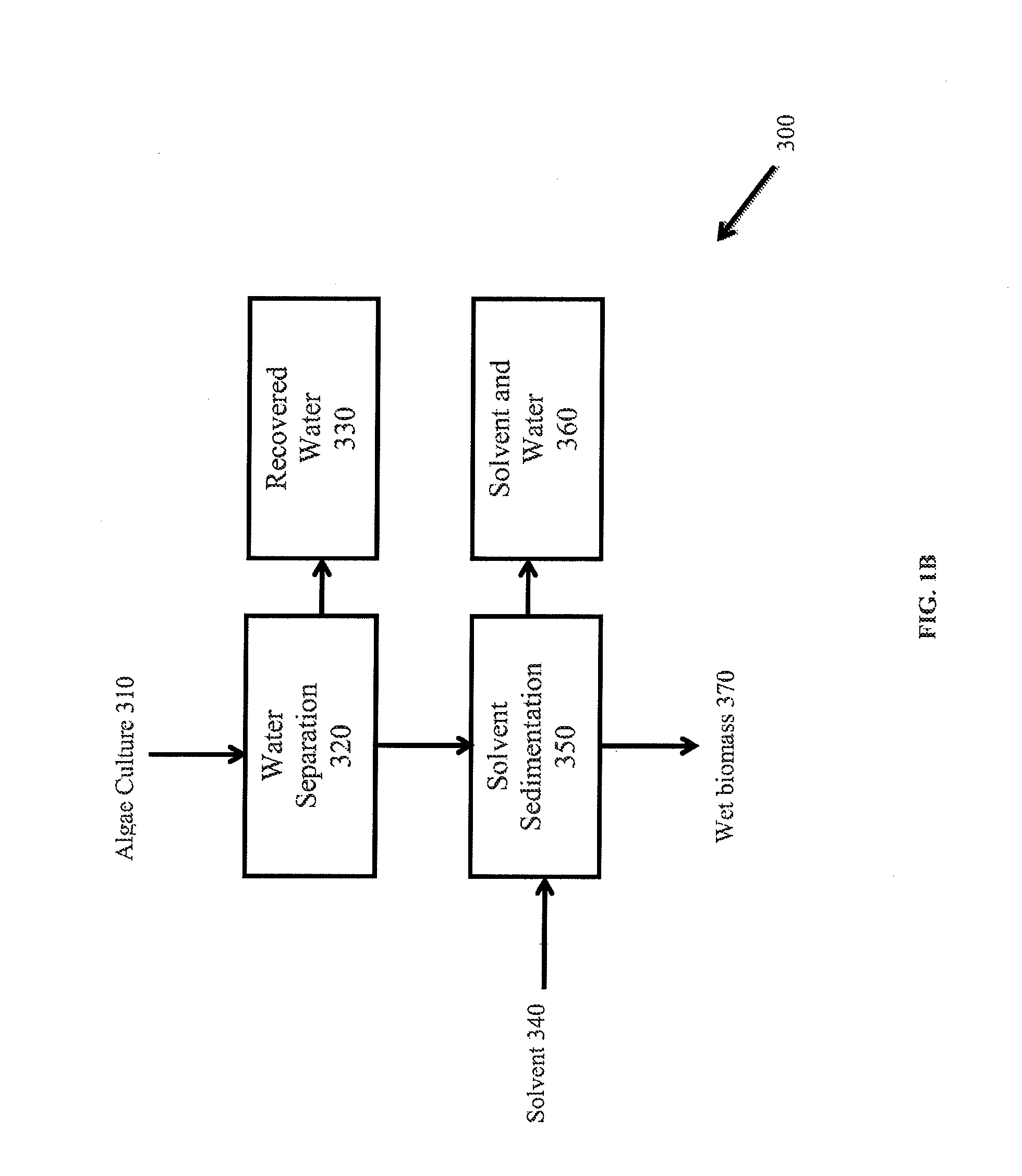

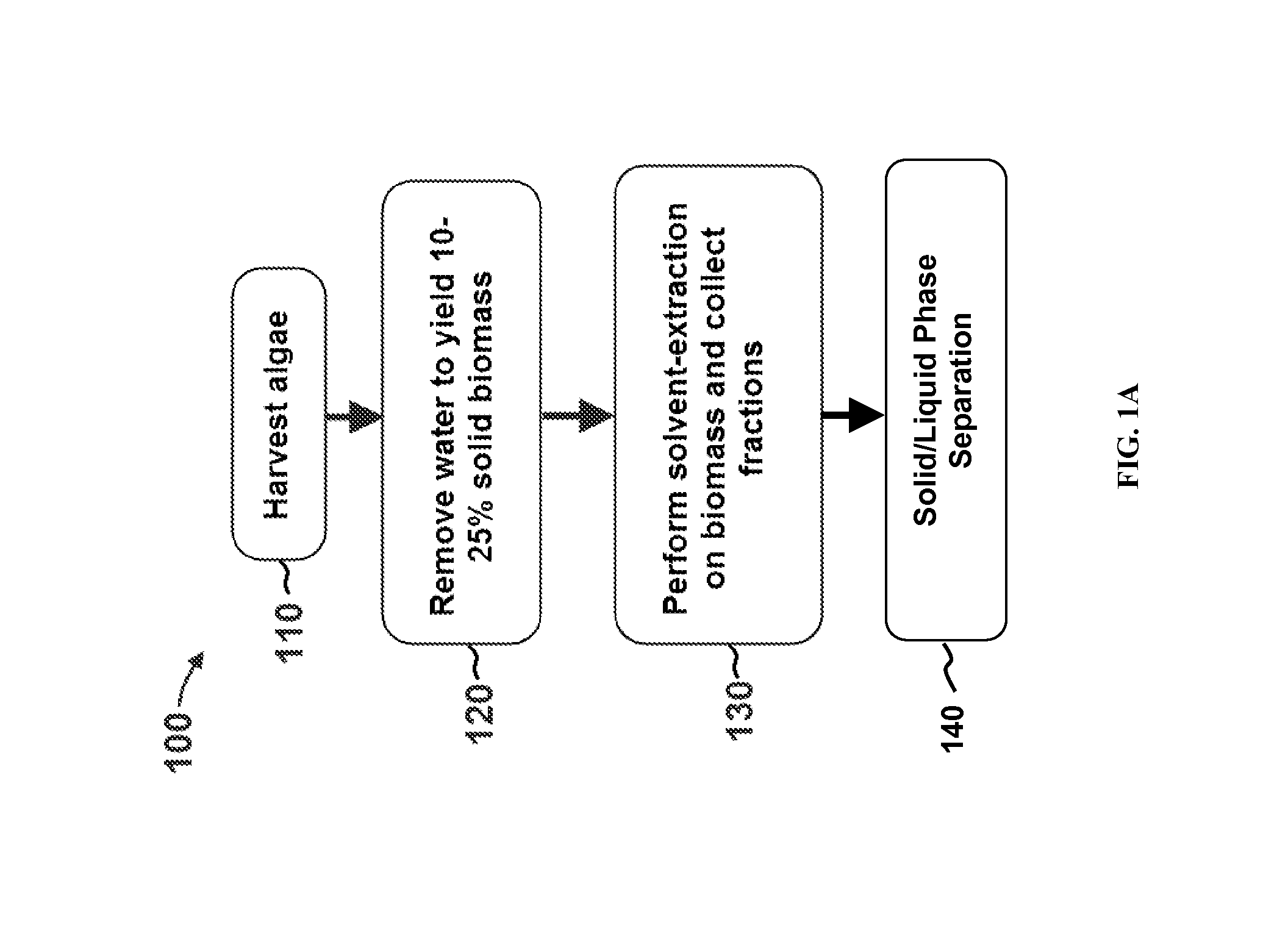

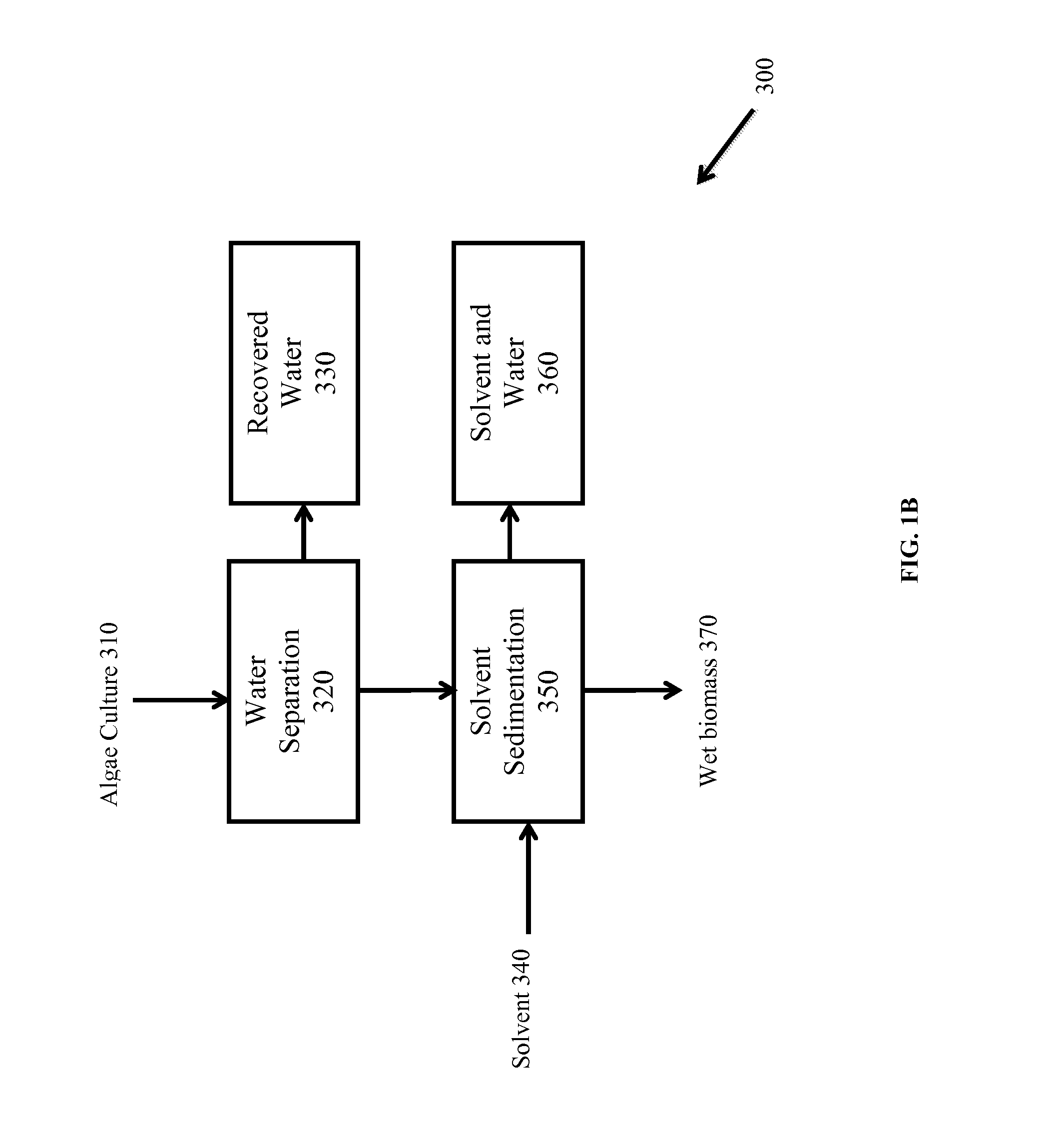

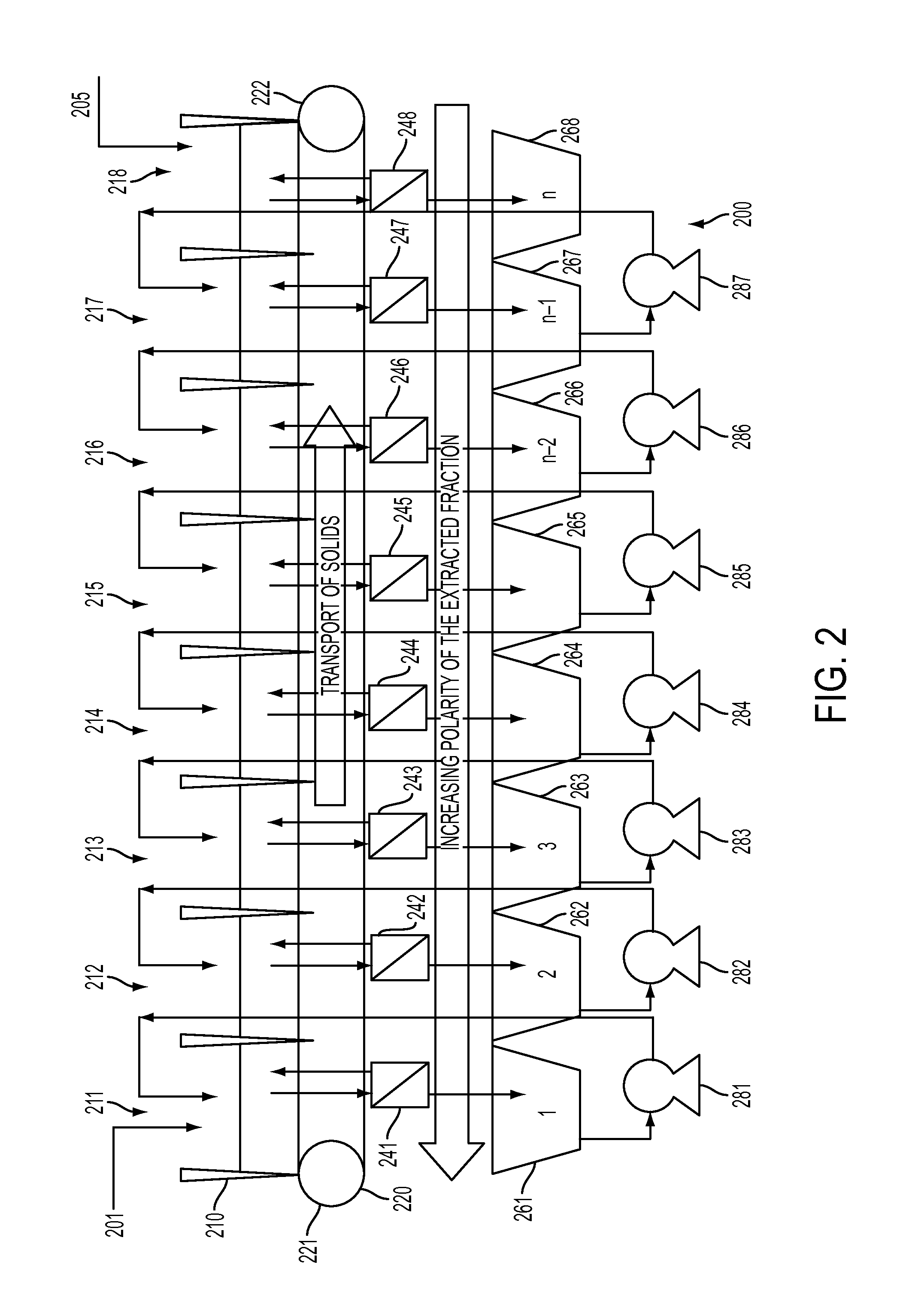

Method of extracting neutral lipids with two solvents

InactiveUS20140005422A1Reduce processing latencyQuantity minimizationFatty acid esterificationSolvent extractionSolventNeutral lipid

A method for separating neutral lipids from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting neutral lipids from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal neutral lipids from a wet algal biomass while avoiding emulsification of extraction mixtures. These neutral lipids are high value products which can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

Method of extracting polar lipids and neutral lipids with two solvents

InactiveUS20130217904A1Reduce processing latencyQuantity minimizationSolvent extractionFatty-oils/fats productionFood additiveSolvent

A method for separating polar lipids and neutral lipids from plant material, in particular, intact algal cells, using an amphipathic solvent set and a hydrophobic solvent set. Some embodiments include dewatering intact algal cells and then extracting polar lipids and neutral lipids from the algal cells. The methods provide for single and multistep extraction processes which allow for efficient separation of algal polar lipids and neutral lipids from a wet algal biomass while avoiding emulsification of extraction mixtures. These polar lipids are high value products which can be used as surfactants, detergents, and food additives. These neutral lipids are also high value products which can be used to generate renewable fuels.

Owner:HELIAE DEVMENT

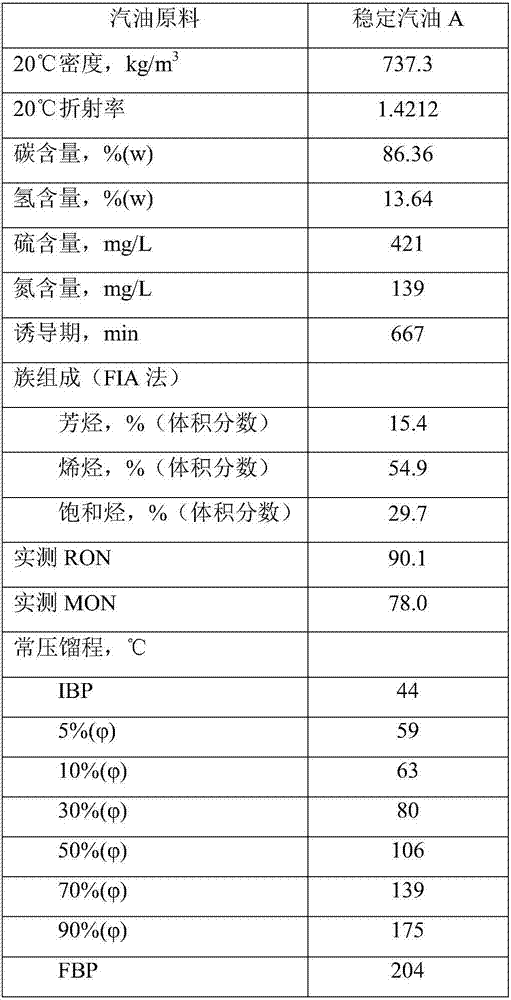

Gasoline treatment method

ActiveCN107974278AHigh yieldHigh sulfur and high yieldHydrocarbon oils refiningFuelsHydrogenNitrogen

The invention relates to a gasoline treatment method, which comprises: feeding a gasoline raw material into a fluidized reactor, contacting a mixed catalyst, and carrying out a desulfurization and aromatization reaction under a hydrogen present condition to obtain a desulfurization and aromatization product, wherein the mixed catalyst comprises an adsorption desulfurization catalyst and an olefinaromatization catalyst, the olefin aromatization catalyst comprises, by weight, 0.1-5.0 wt% of a passivation material, and the passivation material comprises at least an element selected from carbon,sulfur and nitrogen. With the method of the present invention, the sulfur content and the olefin content in gasoline can be reduced, and the octane number of gasoline can be increased while the high gasoline yield can be maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

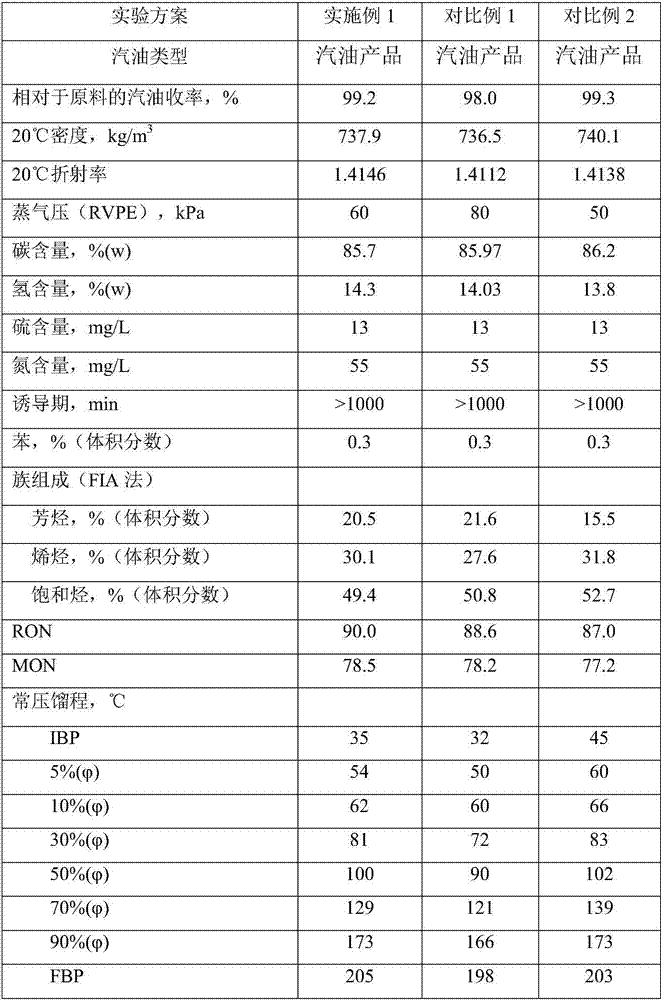

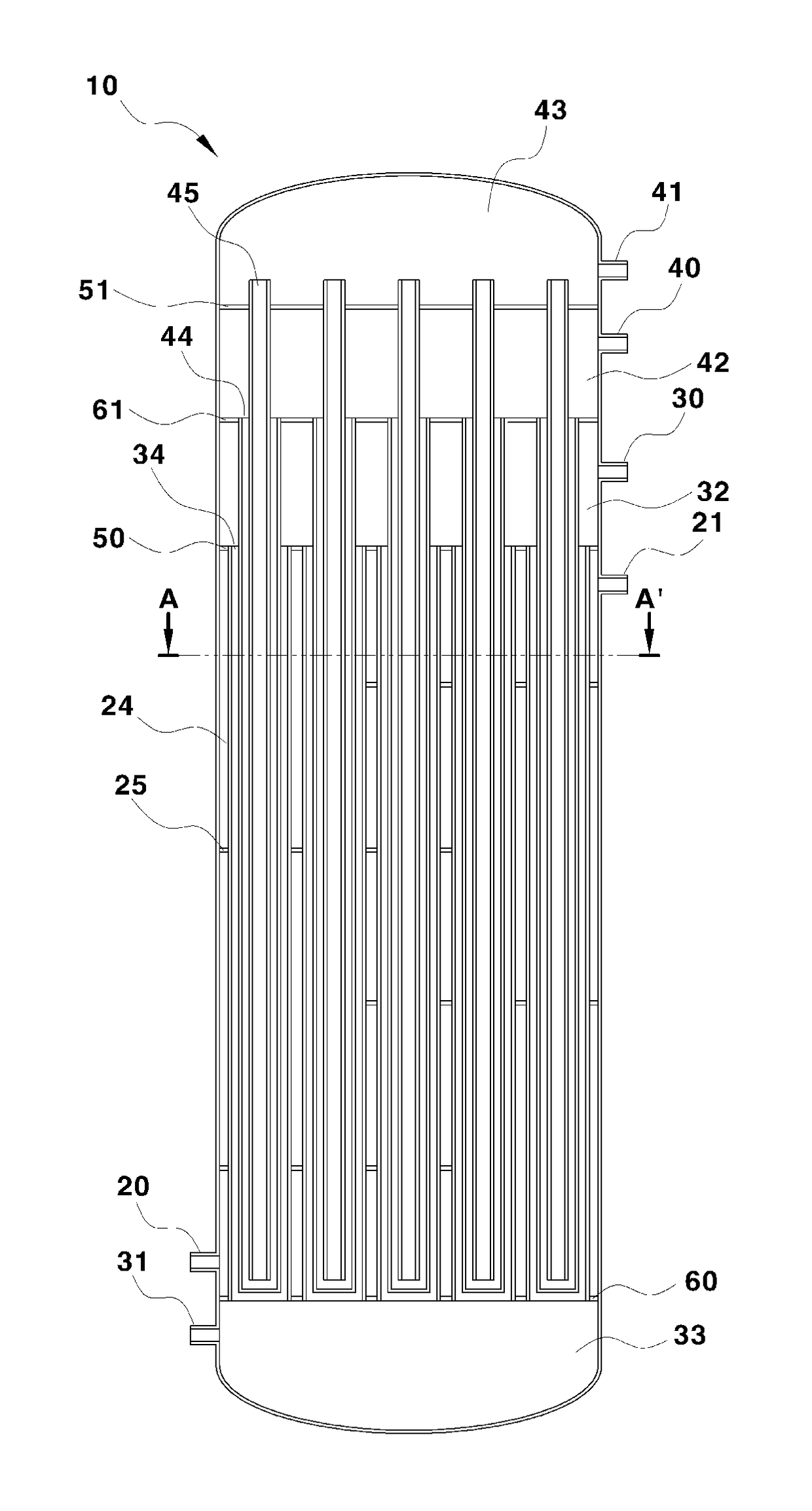

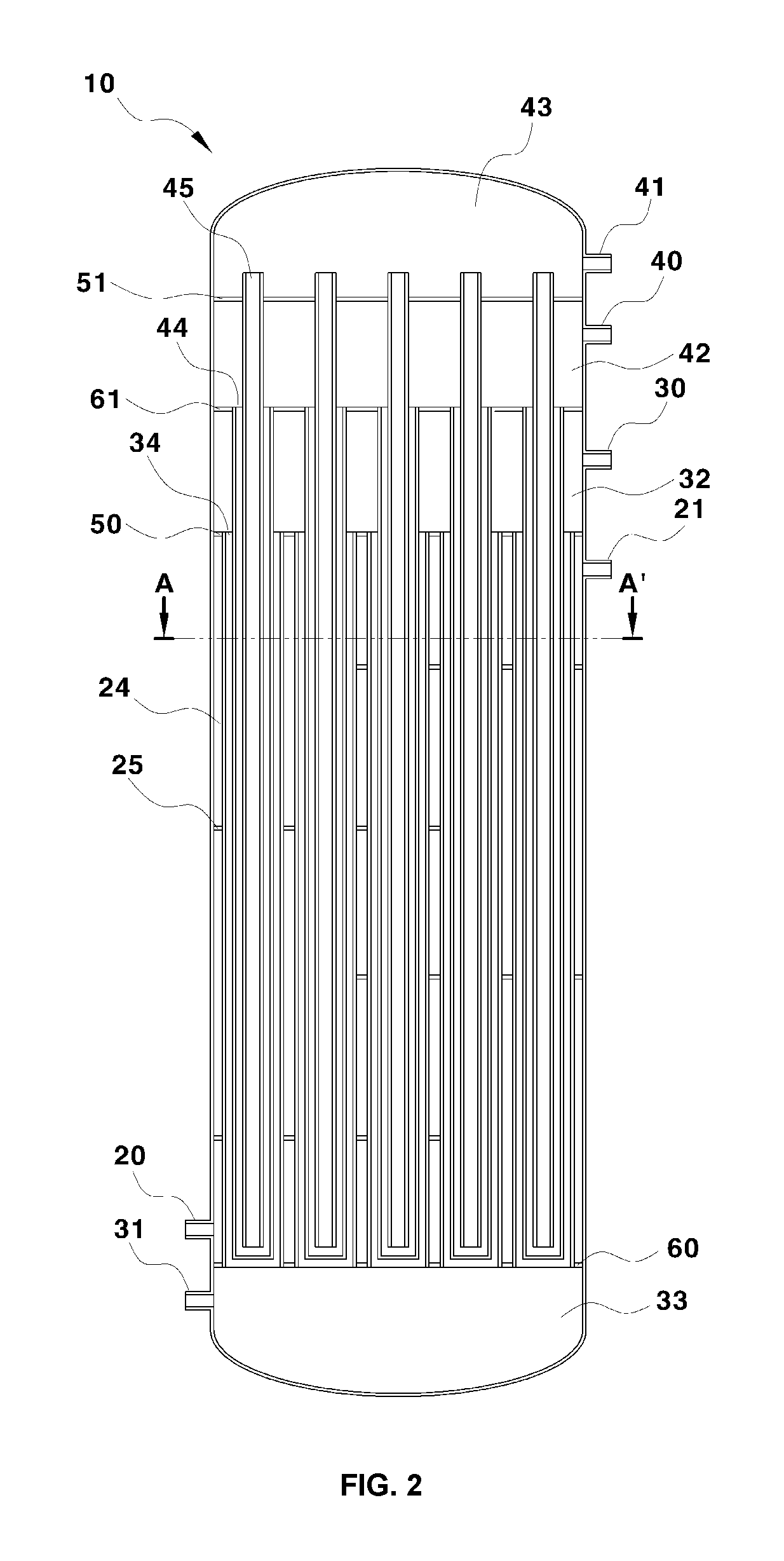

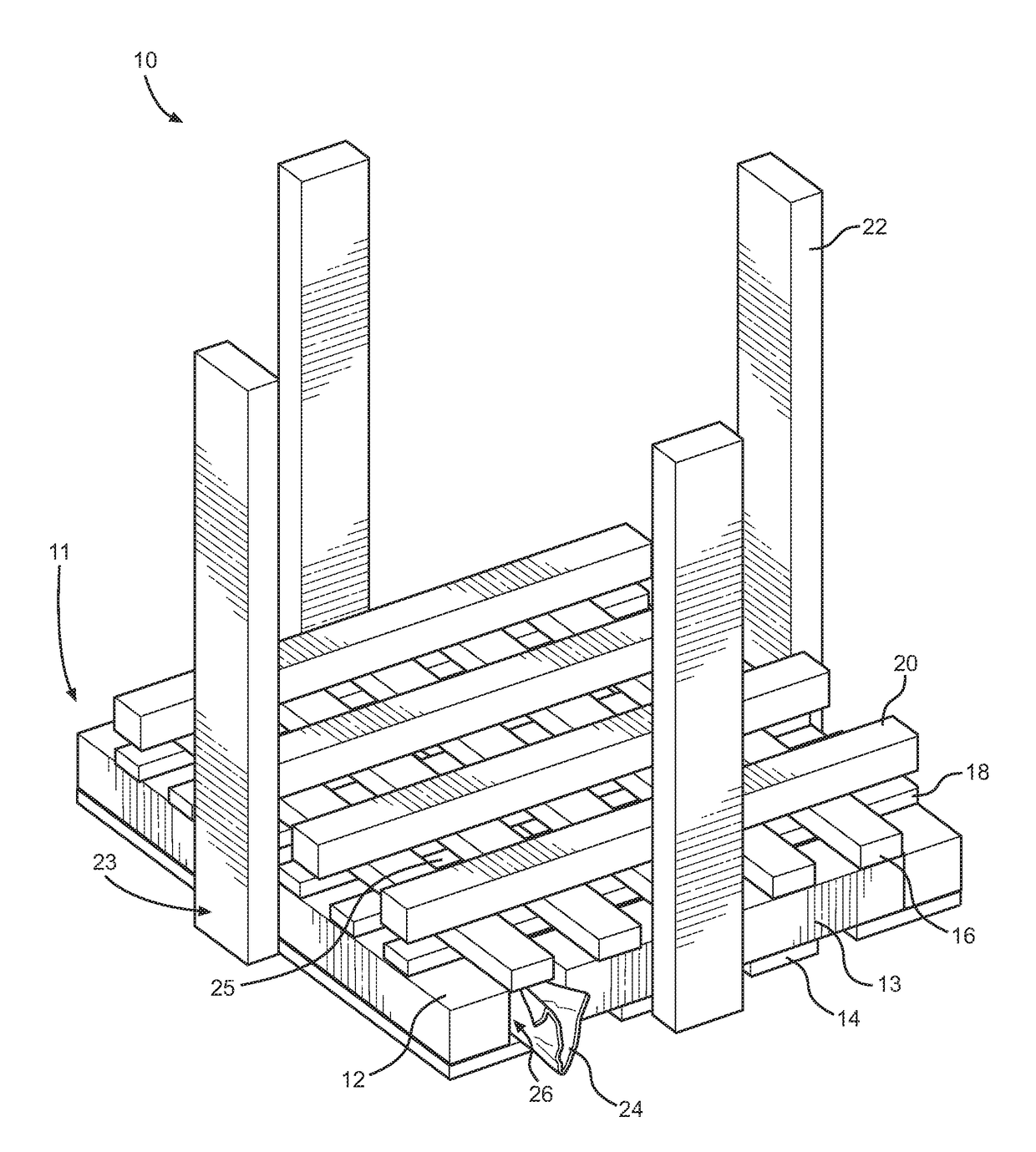

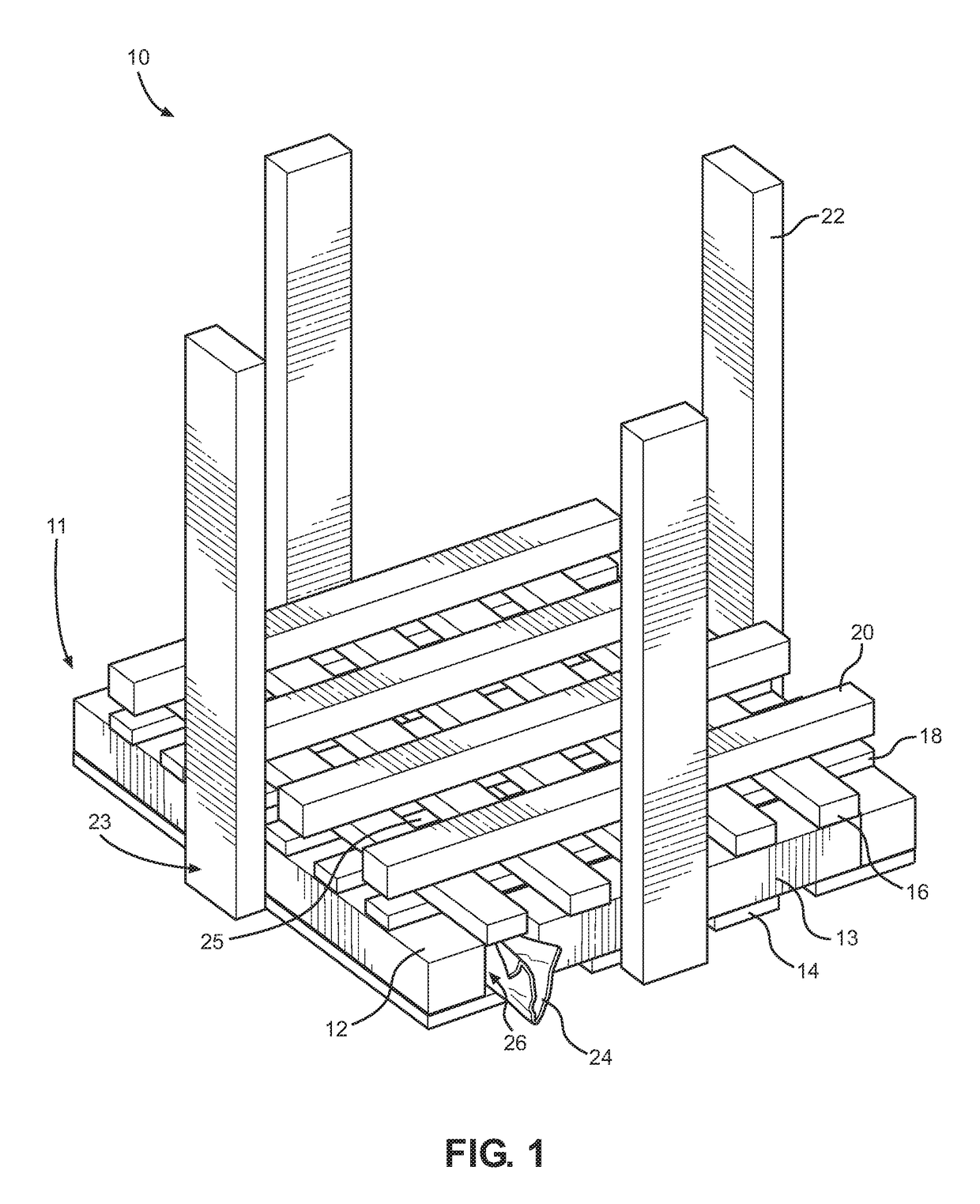

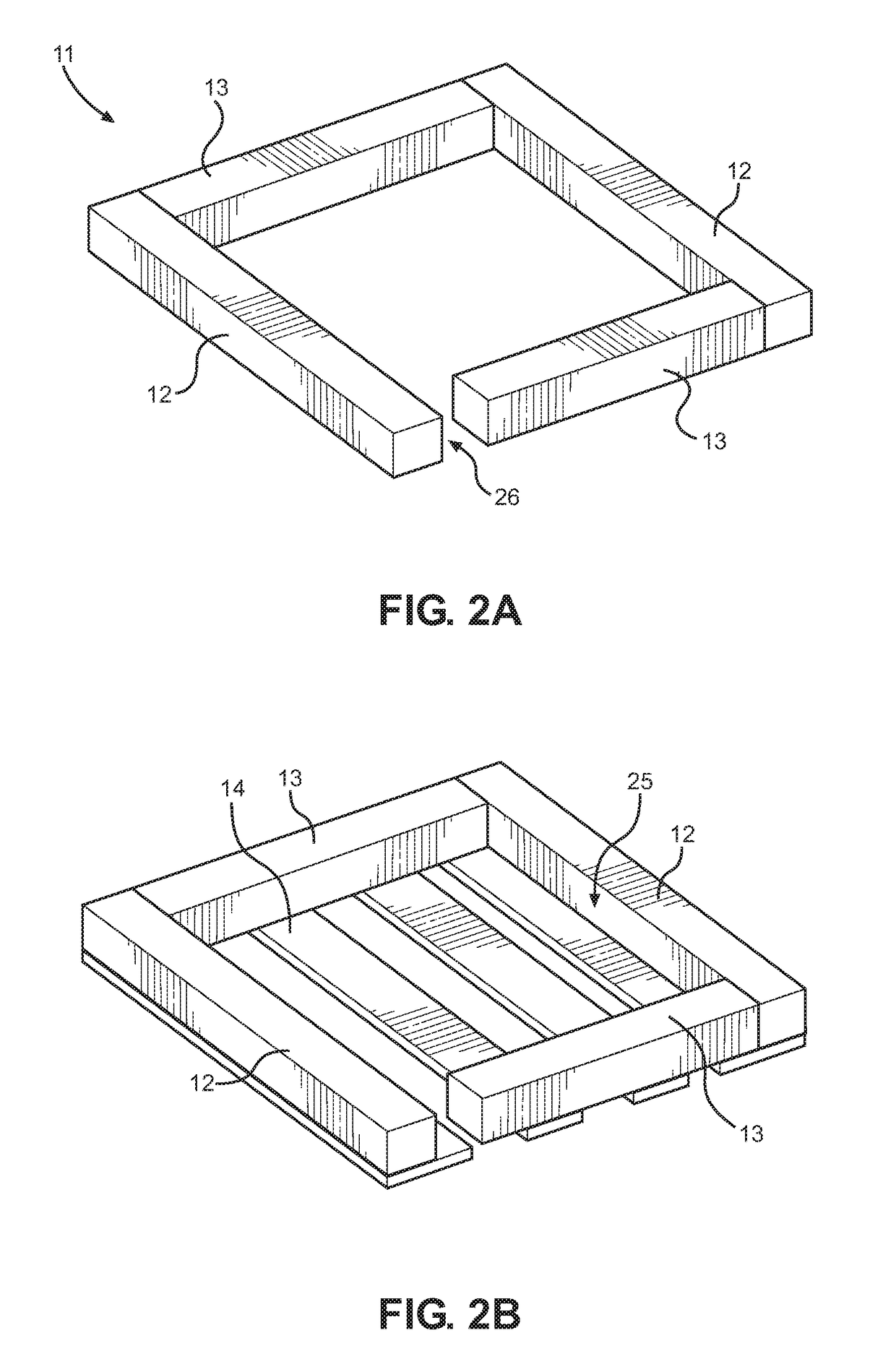

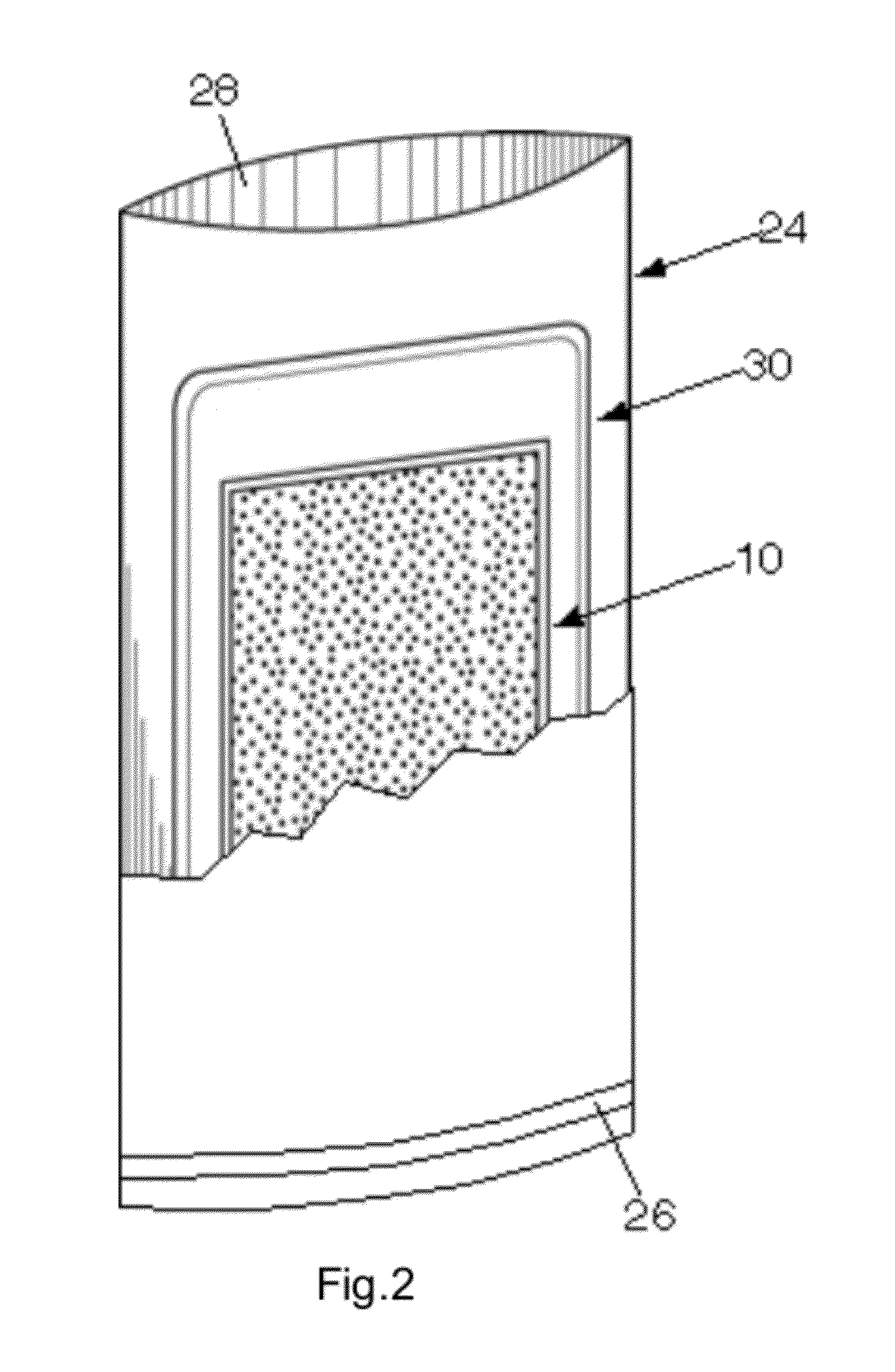

Shell-and-multi-triple concentric-tube reactor and heat exchanger

ActiveUS20170274339A1Improve catalytic performanceMaximize heat exchange efficiencyStationary tubular conduit assembliesFuelsPtru catalystHeat flow

The present disclosure relates to a shell-and-multi-triple concentric-tube reactor and a shell-and-multi-triple concentric-tube heat exchanger, and to a shell-and-multi-triple concentric-tube reactor and a shell-and-multi-triple concentric-tube heat exchanger which provide a new type of reactor and heat exchanger, thereby maximizing catalyst performance and improving performance of the reactor by optimizing heat exchange efficiency and a heat flow, uniformly distributing a reactant, and increasing a flow rate of the reactant, and accordingly making the reactor and the heat exchanger compact.

Owner:KOREA INST OF SCI & TECH

Combustible Fire Starting Kit

A combustible fire starting kit for conveniently stacking and burning fuel. The combustible fire starting kit includes a rectangular base frame having four side members and an aperture placed along an exterior wall. A bottom layer and a top layer are secured to the base frame, each layer having a plurality of parallel slats positioned at regular intervals. The side members, top layer and bottom layer form an interior volume where kindling material is placed. Vertical side support members are secured to the base frame in order allow for easy stacking of fuel. A wick is placed in the aperture, extending from the interior volume to beyond the exterior wall of the base frame. The base frame, top and bottom layers, and side support members are made from combustible material, allowing a user to burn the combustible fire starting kit along with the fuel.

Owner:JONES STANLEY

Preparation method and application of azobenzene-based light energy storage phase change material

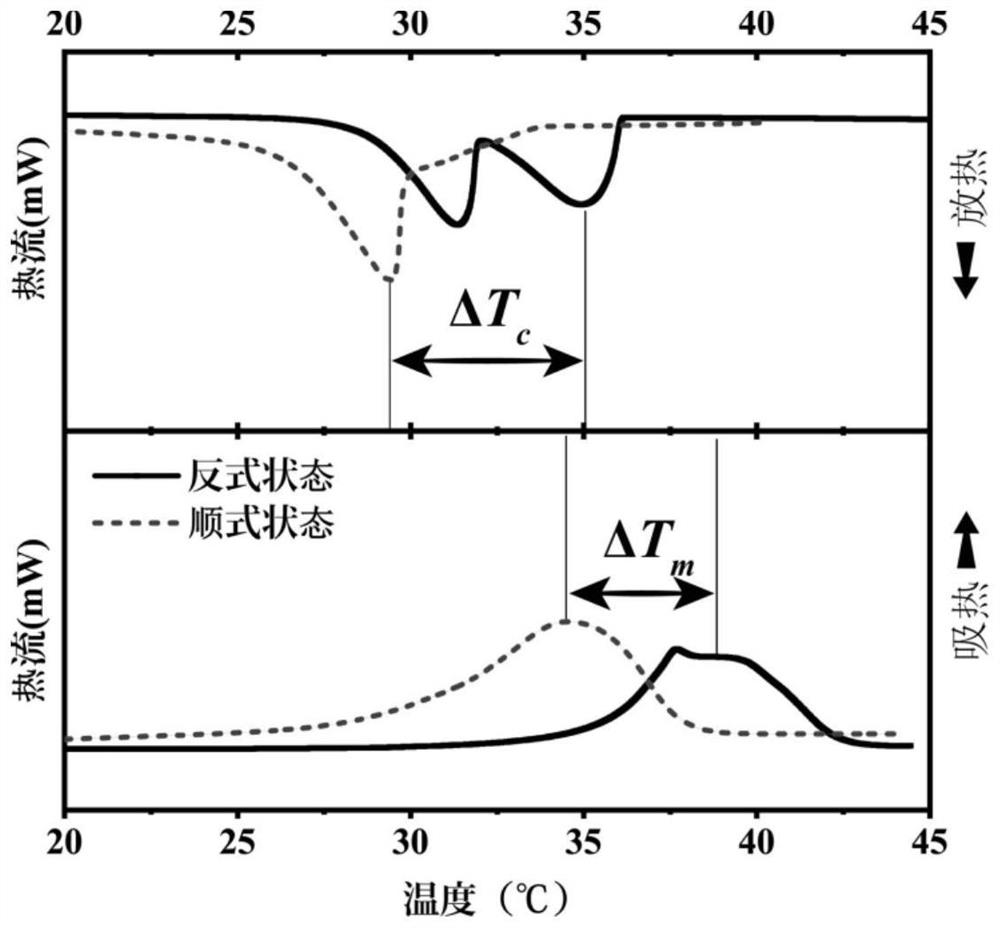

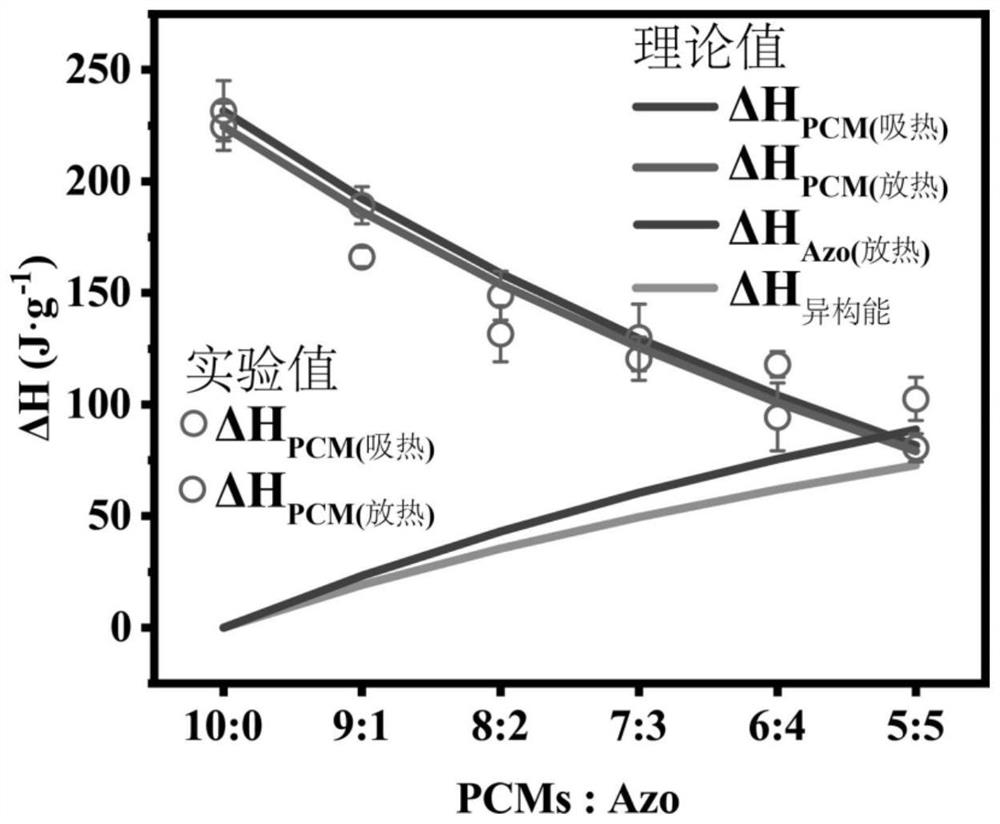

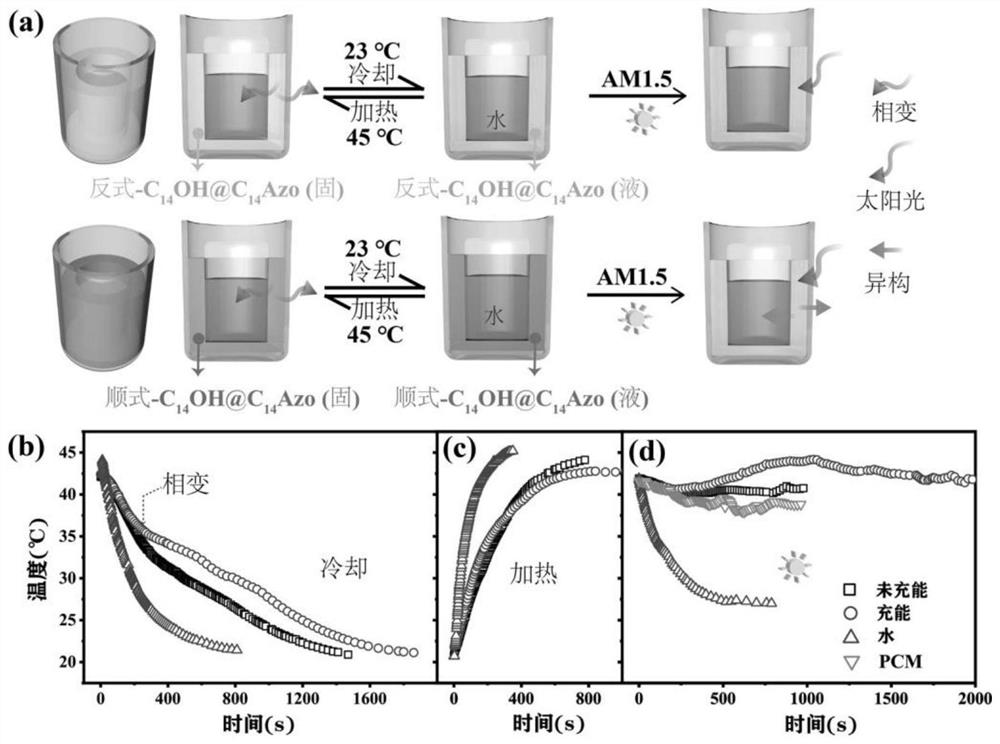

PendingCN111748323AAchieve reversible releaseHigh speedOrganic chemistryMaterial analysis by observing effect on chemical indicatorAlkanePtru catalyst

The invention discloses a preparation method of an azobenzene-based light energy storage phase change material. The method comprises the following steps that: (1) preparing photoresponse azobenzene molecules: carrying out a reaction on 4-hydroxyazobenzene and 1-bromoalkane by using N, N-dimethylformamide as a solvent under an alkali and iodine-containing catalyst condition to obtain 4-alkoxy azobenzene energy storage molecules; and (2) preparing the azobenzene light energy storage phase change material: carrying out melt blending on the 4-alkoxy azobenzene energy storage molecules prepared inthe step (1) and an organic phase change material, fully stirring the molecules and the organic phase change material to obtain the azobenzene light energy storage phase change material. The phase change point of the phase change material decreases under ultraviolet irradiation, the phase change point of the phase change material rises under visible light irradiation, light response phase change control exists. The azobenzene light energy storage molecules have photochromic performance; the change of the color can indicate the change of an isomerism degree; and based on the corresponding relation, an energy storage state can be monitored, and the utilization efficiency of energy is improved.

Owner:JIANGNAN UNIV

Hydrogen elimination and thermal energy generation in water-activated chemical heaters

InactiveUS20120030992A1Eliminate and suppress cogenerationInhibition releaseHydrogen separation by selective and reversible uptakeExothermal chemical reaction heat productionThermal energyParticulates

A hydrogen suppressing, flameless, heat generating chemical composition including magnesium, a hydrogen suppressor or eliminator, particulate carbon, an alloying metal selected from the group consisting of: iron, cobalt, nickel, zinc, aluminum and mixtures thereof, a metallic salt including a cation and an anion, wherein the anion is selected from the group consisting of silicate, carbonate, bicarbonate, phosphate, borate, perborate, percarbonate, perphosphate, persulfate, nitrate, nitrite, ferrate, permanganate, and stannate and combinations thereof, and water. The magnesium or magnesium-containing alloy, hydrogen suppressor or eliminator, particulate carbon, alloying metal, metallic salt and water are each present in a proportional amount to generate sufficient heat to heat water, medical supplies and / or consumable rations.

Owner:BOMMARAJU TILAK V

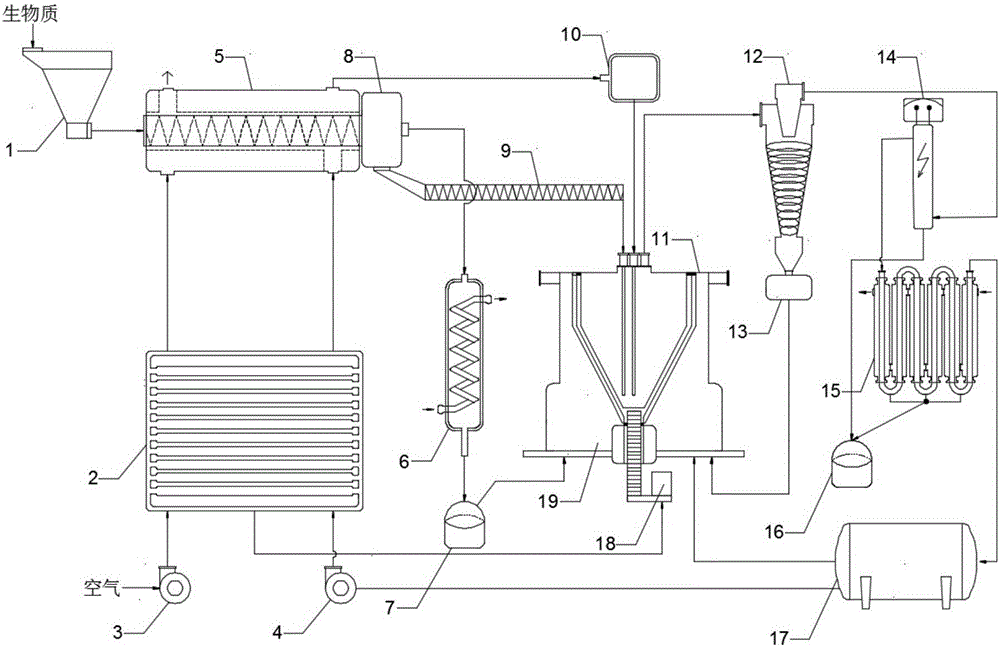

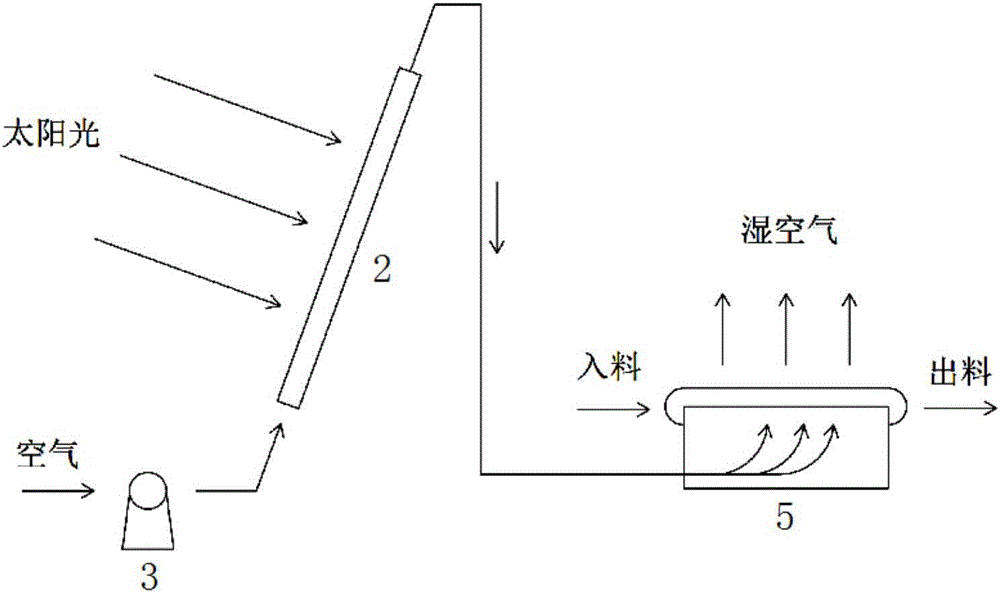

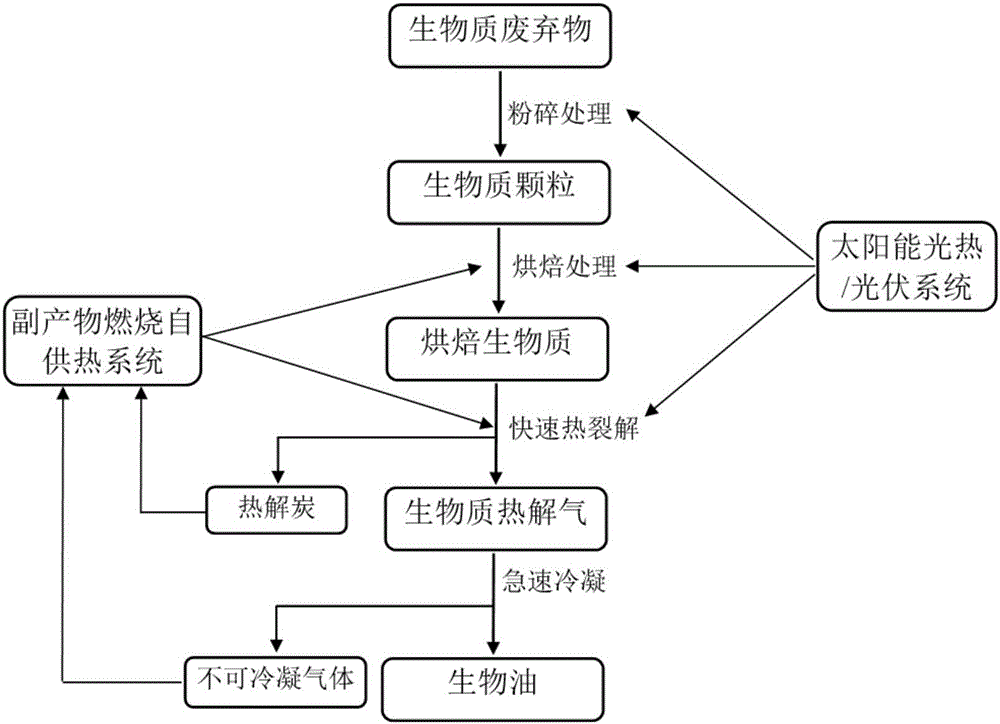

Solar heat collection and auto heating-based outdoor biomass thermal cracking oil refining device

InactiveCN106281397AReduce processingReduce usageSolar heating energySolar heat devicesBiomass carbonEngineering

The invention relates to a solar heat collection and auto heating-based outdoor biomass thermal cracking oil refining device which comprises a smashing machine, solar optothermal / photovoltaic equipment, a high-temperature baking chamber, a preheating sand box, rotary conical biomass thermal cracking equipment and a condensation system. The main technological process is that a raw material enters the high-temperature baking chamber after being smashed; under the condition that the solar optothermal / photovoltaic equipment supplies energy, the raw material is baked, and biological vinegar which is a byproduct is collected; biomass particles subjected to baking treatment enter a rotary conical reactor for thermal cracking reaction and are subjected to condensation collection, so that bio-oil, biomass carbon powder and non-condensable gas are generated; the biomass carbon powder and the non-condensable gas are used as fuel combusted for heating. According to the solar heat collection and auto heating-based outdoor biomass thermal cracking oil refining device, solar energy and the byproduct are used for realizing baking pretreatment and cracking reaction for supplying heat, so that energy and production cost are reduced, and the operation demand for outdoor auto energy supplying is met; a bio-oil product refined by the baking treatment is high in energy density and stability; the oil refining process is clean and efficient.

Owner:BEIJING FORESTRY UNIVERSITY

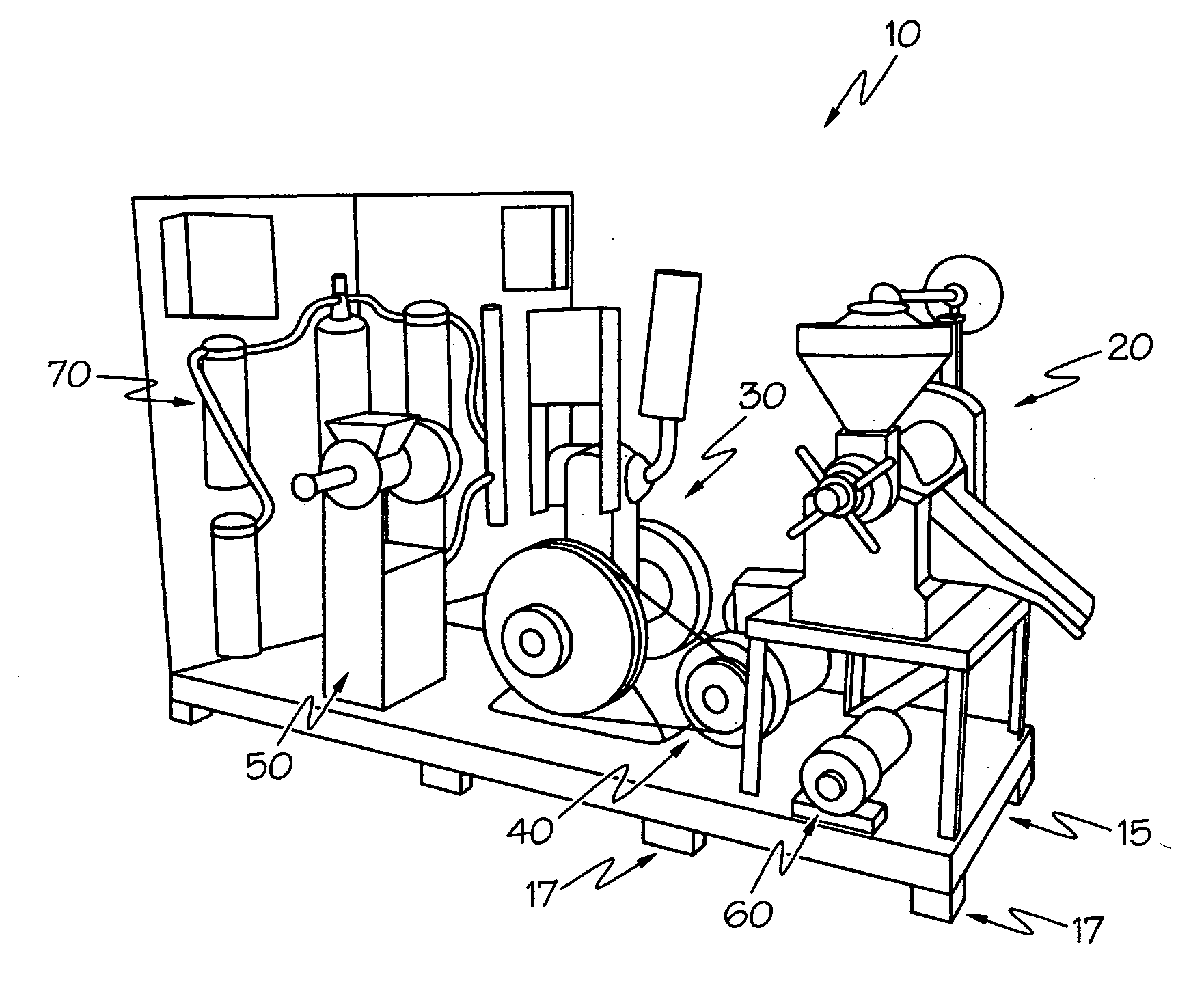

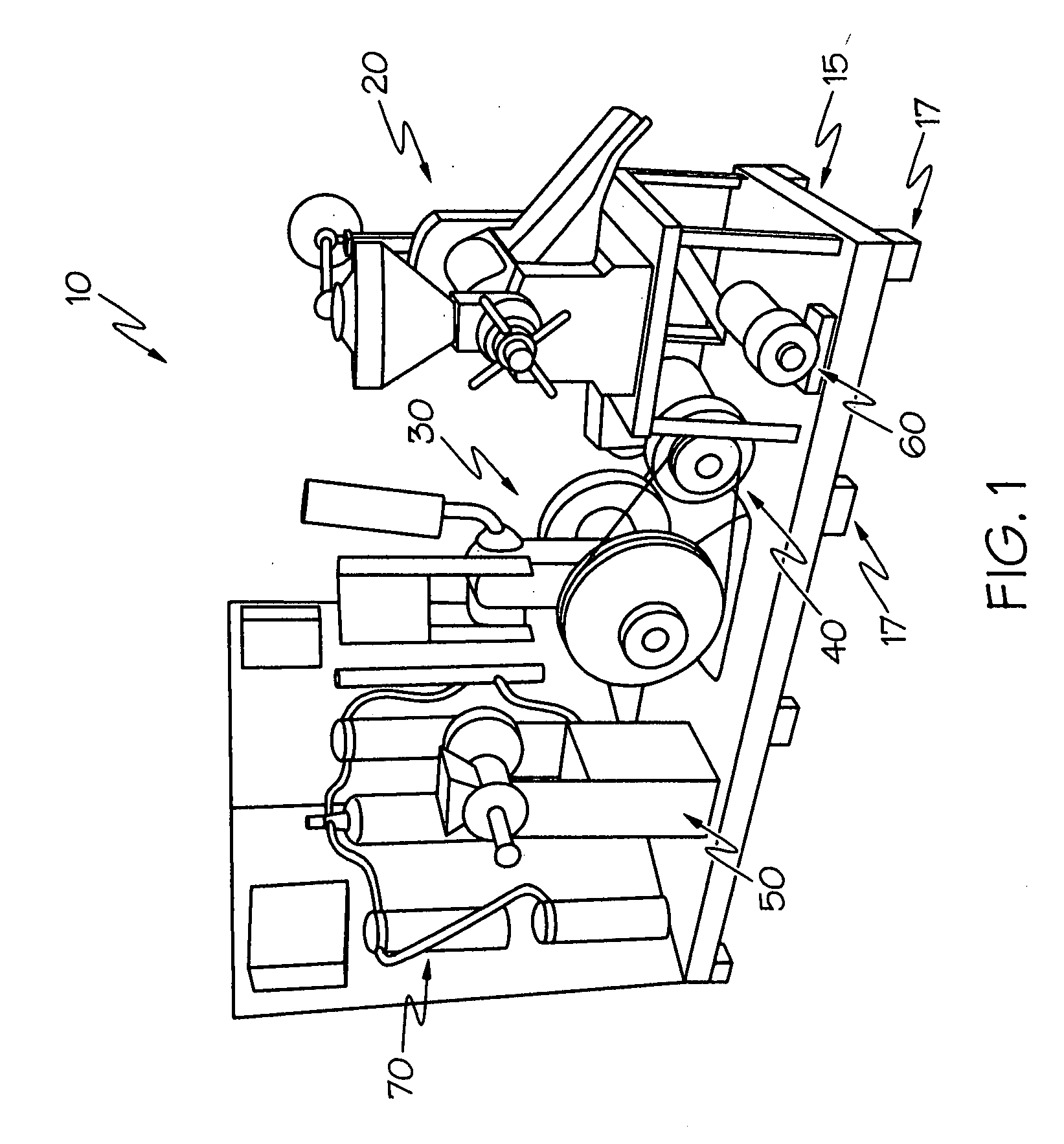

Multi-function rural fuel platform

A multi function rural fuel platform has a biofuel production unit and a diesel engine incorporated onto a transportable platform, wherein said biofuel production unit produces fuel for said diesel engine.

Owner:BELL PETER J

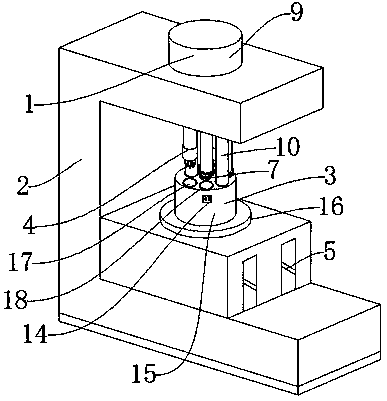

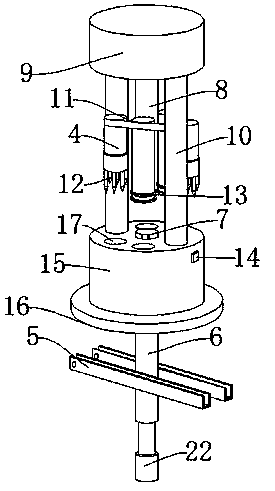

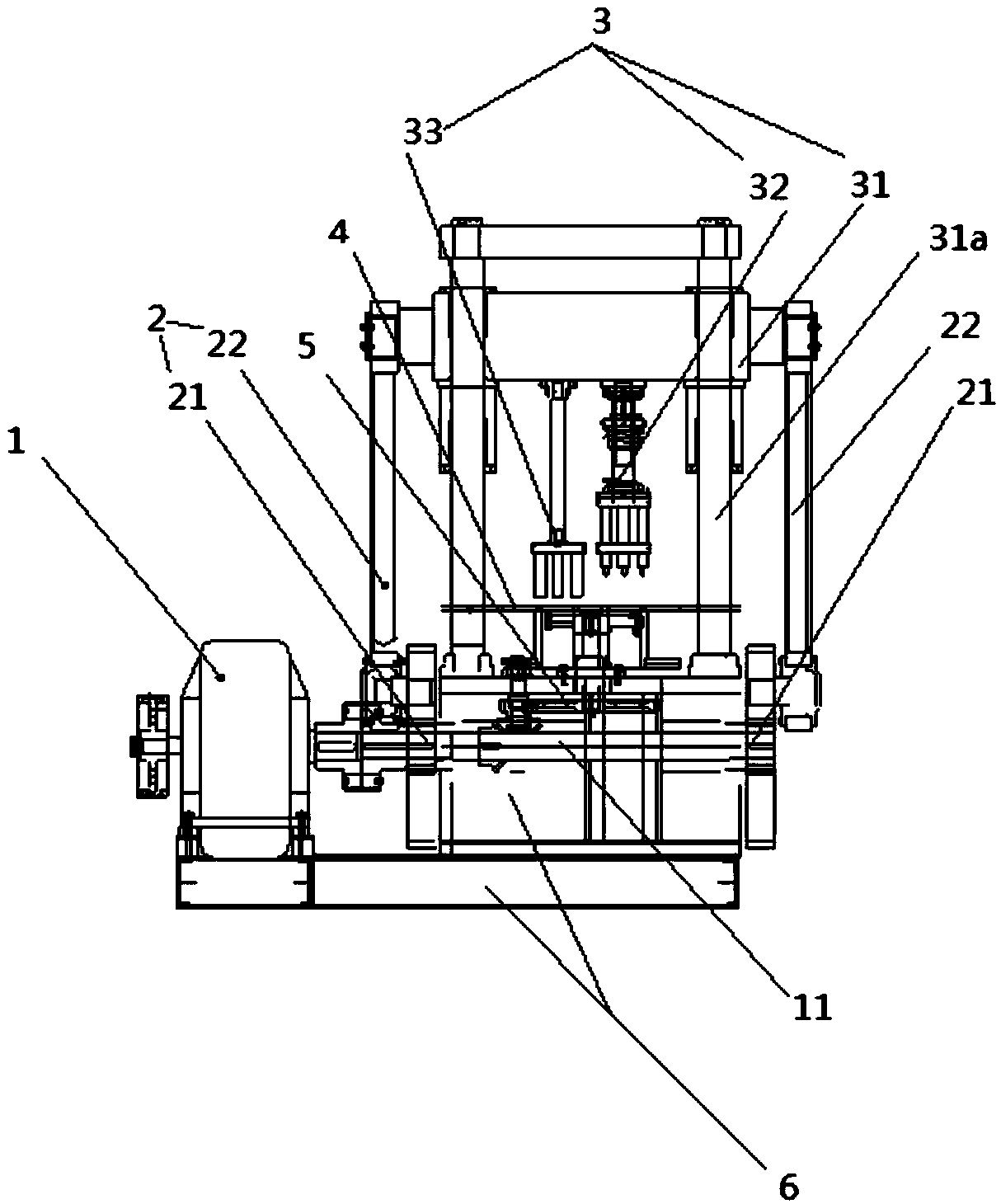

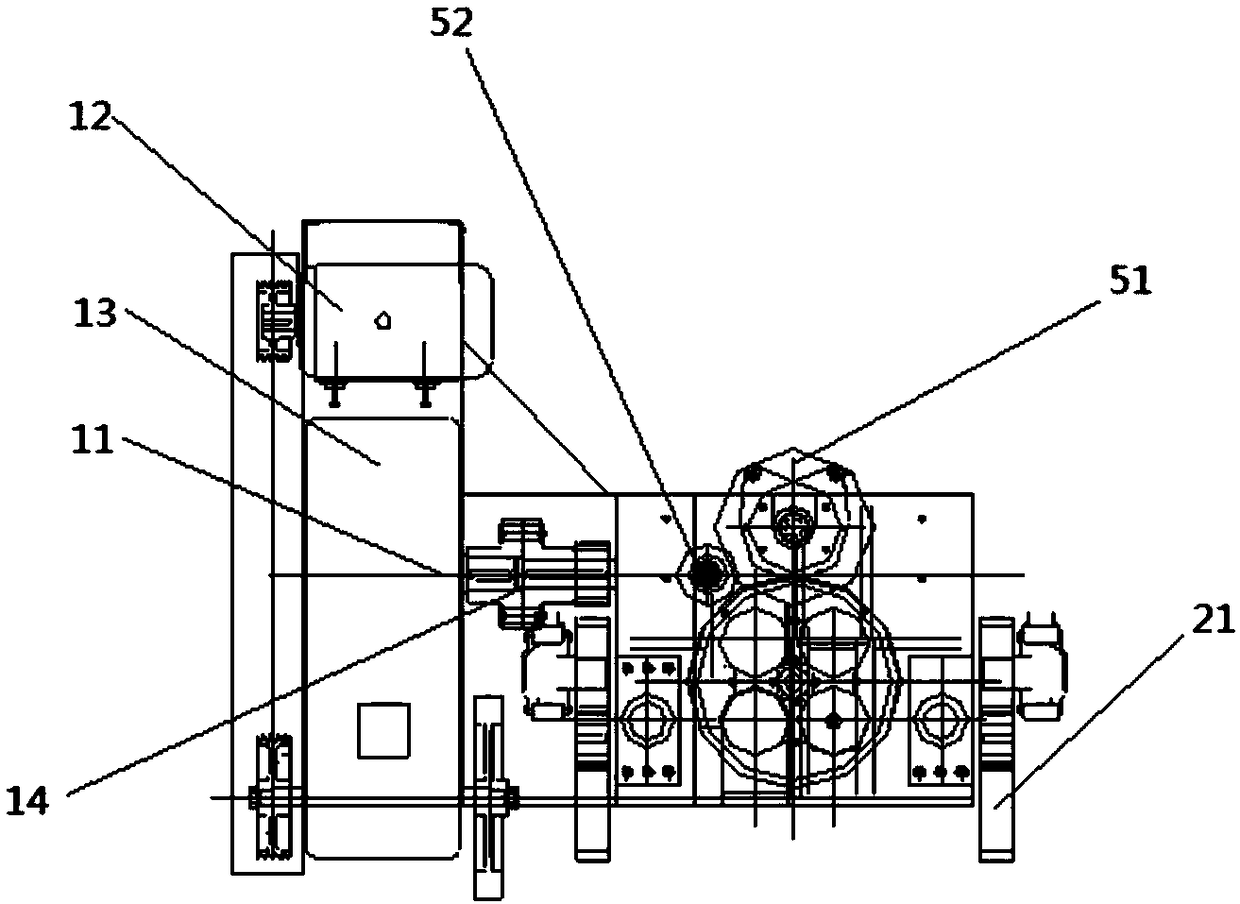

Heating forming machine for honeycomb biomass cured fuel

The invention discloses a heating forming machine for a honeycomb biomass cured fuel. The heating forming machine for the honeycomb biomass cured fuel comprises a charge device, a box body, a formingdevice, a stamping chipping-sweeping device, a finished product conveying device and a power transmission device, wherein the charge device comprises a charge hopper and a material barrel; the material barrel is arranged below the charge hopper; the forming device is arranged below the material barrel; a piston rod is arranged at the inner side of the material barrel and at the lower end of the box body; and the forming device comprises a forming die, a tray, a spiral heating wire and a power connector. The heating forming machine for the honeycomb biomass cured fuel has the following beneficial effects: the biomass cured fuel produced by the cured fuel forming machine is honeycomb, and high in burn-off rate and calorific value; the cured fuel forming machine is simple in structure, stablein mechanism running, reliable in working, low in noise in a production process, and capable of meeting the environmental protection requirement; the overall system is high in adaptive capacity, andcapable of meeting different process requirements; wearing parts are easy to install, detach and change; and equipment parts are simple to machine.

Owner:ZAOZHUANG UNIV

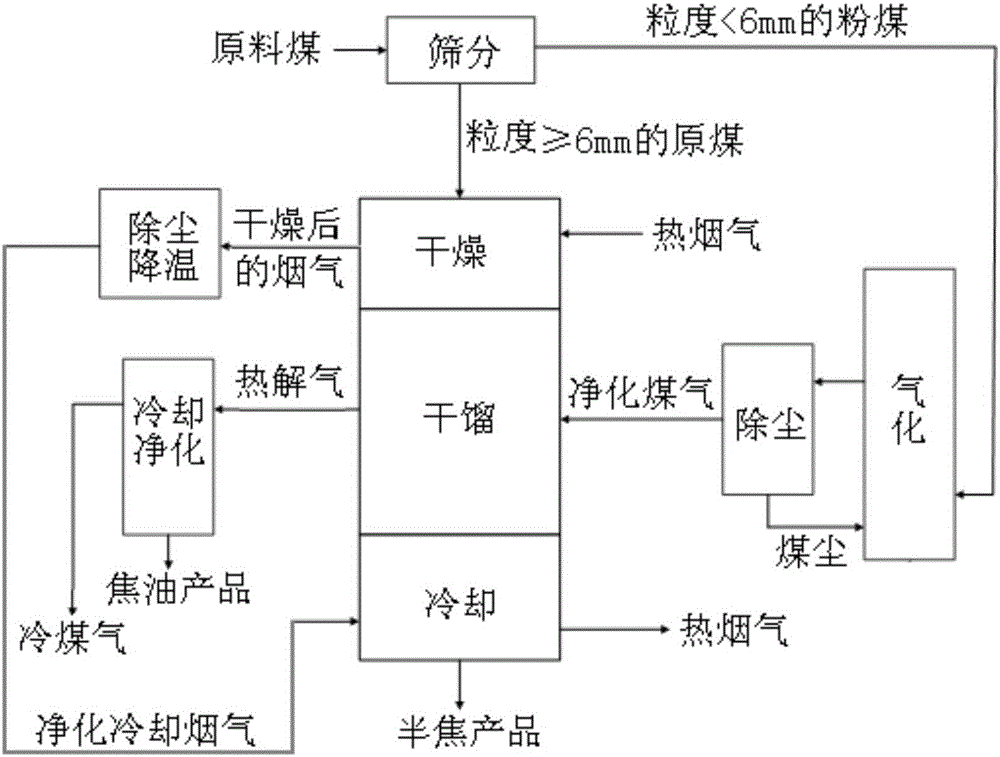

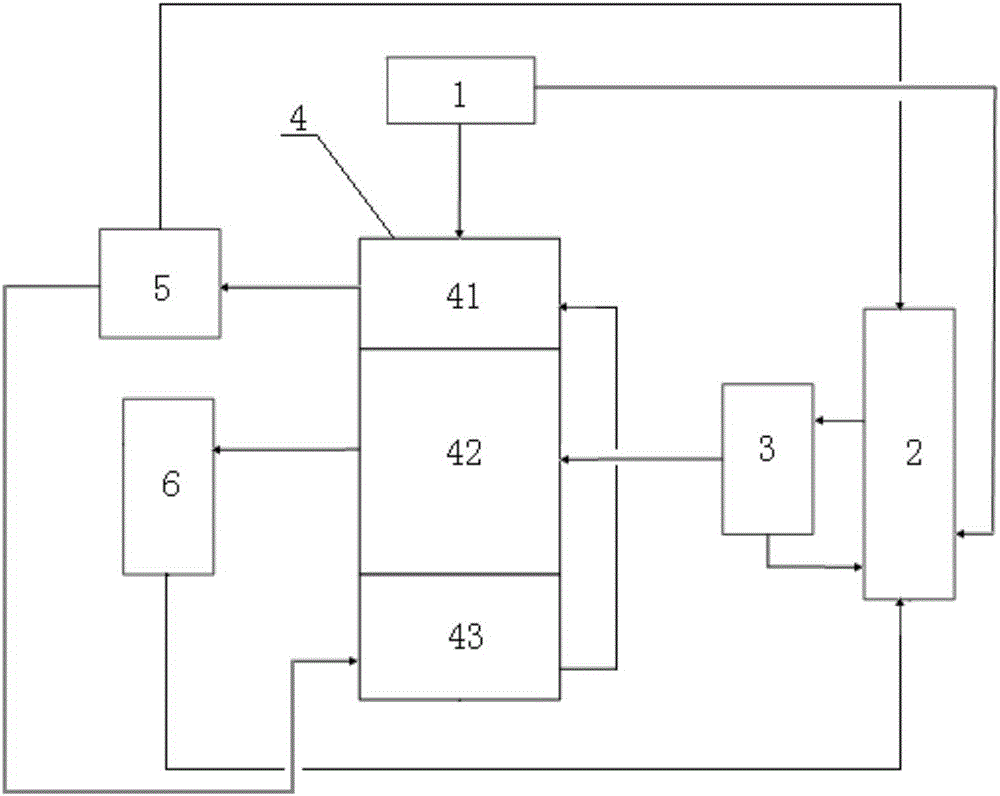

Coal pyrolysis and gasification coupling technology and device

InactiveCN106010607AHigh yieldImprove qualitySpecial form destructive distillationGas purification by non-gaseous materials condensationCoal pyrolysisLarge particle

The invention provides a coal pyrolysis and gasification coupling technology and device. According to the technology, hot coal gas generated through coal gasification makes direct contact with dry coal, and the dry coal is subjected to dry distillation with the high-temperature sensible heat of the hot coal gas so that on one hand, the high-temperature sensible heat of the hot coal gas can be fully utilized, the heat exchange efficiency can be improved, and thus the energy consumption of the whole technology can be greatly reduced; on the other head, due to the fact that hydrogen in the gasified hot coal gas is high in content and concentration, the yield of tar can be increased through the hydrogen-rice atmosphere; furthermore, only large particle size raw coal is subjected to dry distillation, and thus the quality of the tar is improved; besides, in the technology, raw material coal is screened to be divided into small particle size pulverized coal and large particle size raw coal, and then gasification and dry distillation treatment are carried out on the pulverized coal and the raw coal respectively, so that the raw material coal within the full particle size range can be treated with the technology, and full particle size feeding of the raw material coal is achieved. According to the device, a purification device for the hot coal gas does not need to be independently arranged, and thus the energy consumption of the system can be easily reduced.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

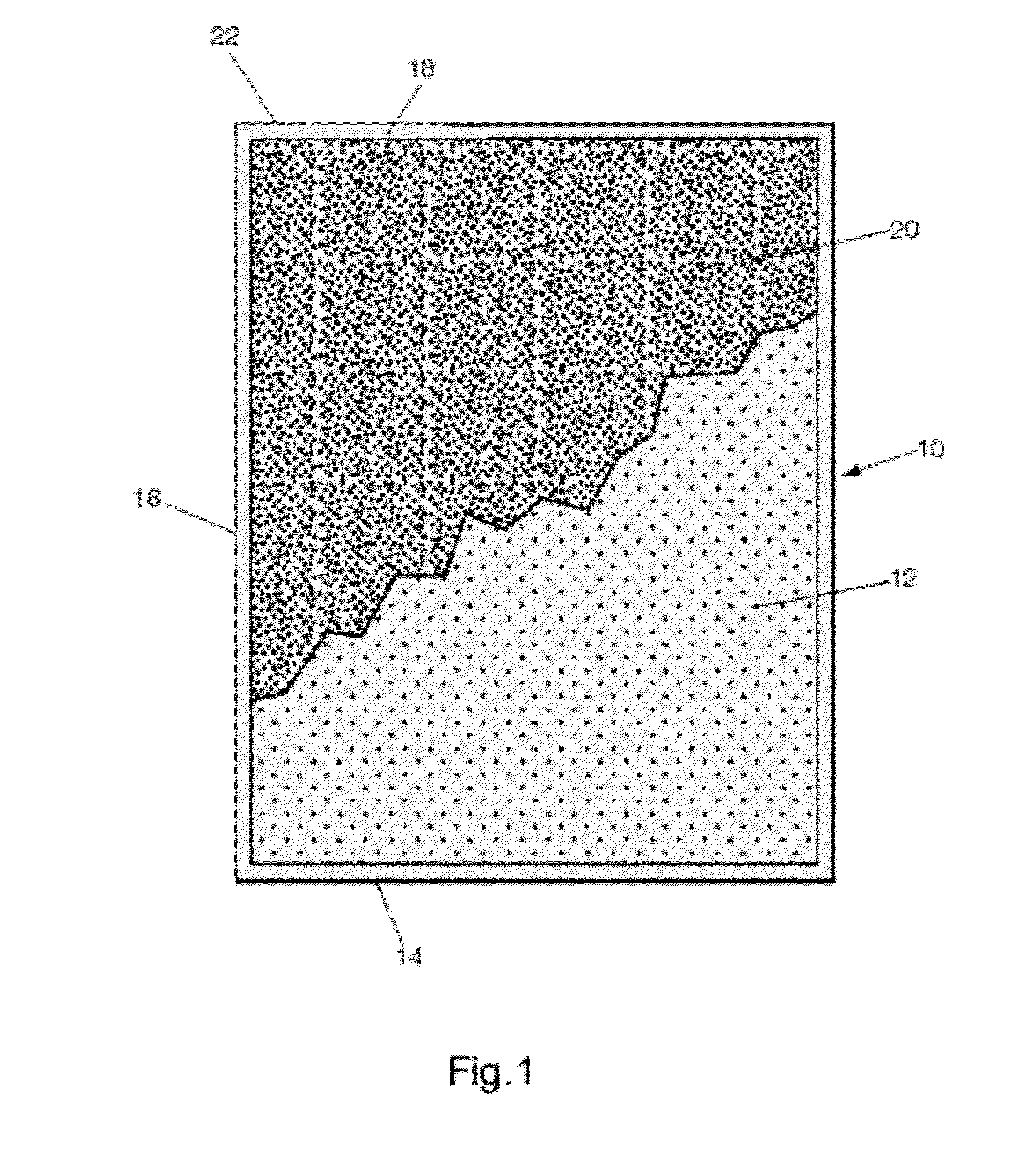

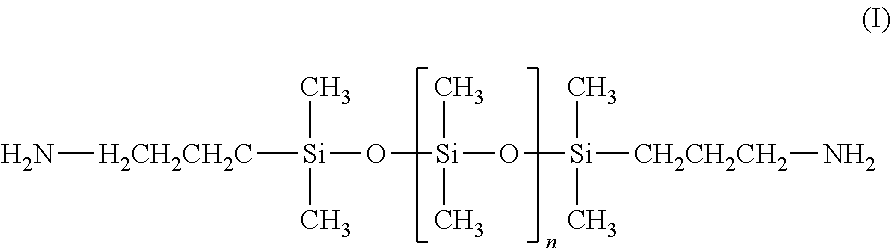

High selectivity chemically cross-linked rubbery membranes and their use for separations

InactiveUS20180133663A1High selectivityExtended operating timeSemi-permeable membranesMembranesCross-linkPolymer thin films

A novel chemically cross-linked rubbery polymeric thin film composite (TFC) membrane comprising a selective layer of a chemically cross-linked rubbery polymer supported by a porous support membrane formed from a glassy polymer has been developed. The chemically cross-linked rubbery polymeric thin film composite (TFC) membrane comprising a selective layer of a chemically cross-linked rubbery polymer supported by a porous support membrane formed from a glassy polymer may be used to separate at least one component from another.

Owner:UOP LLC

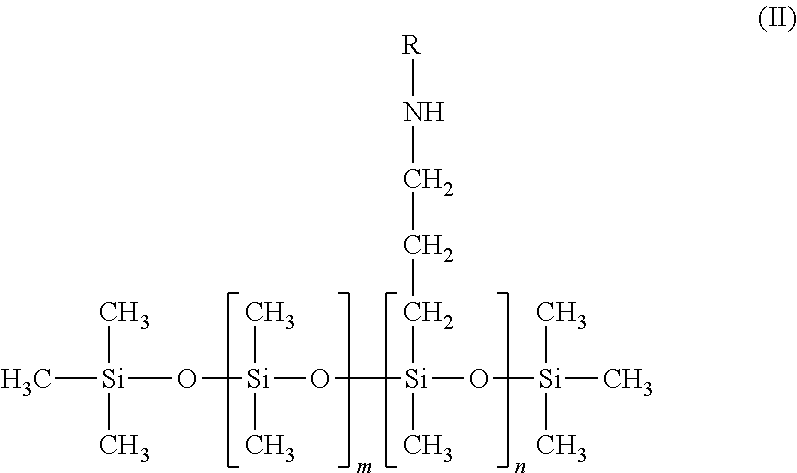

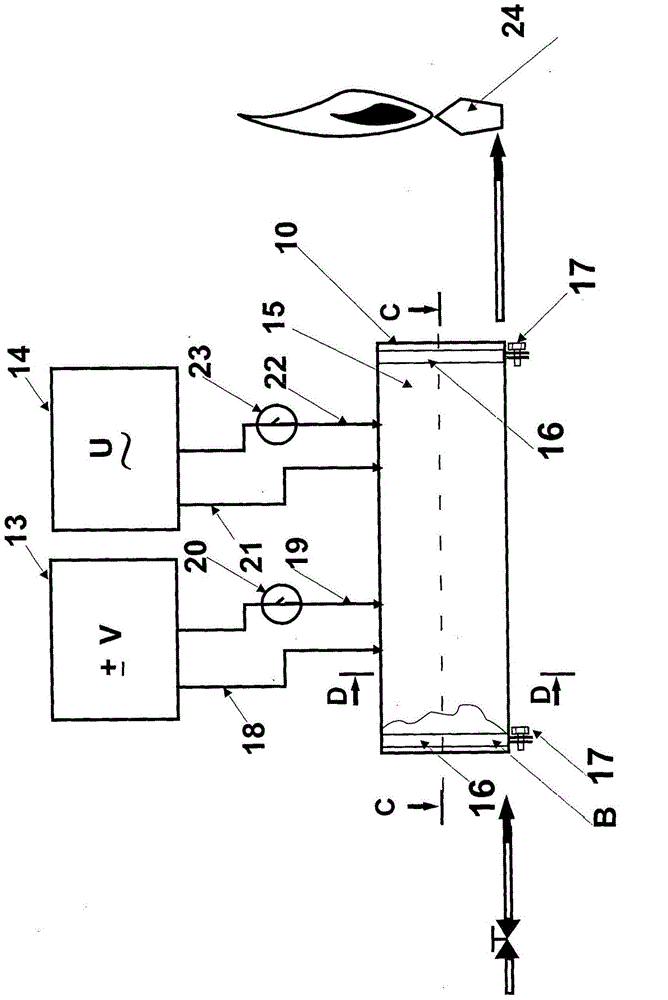

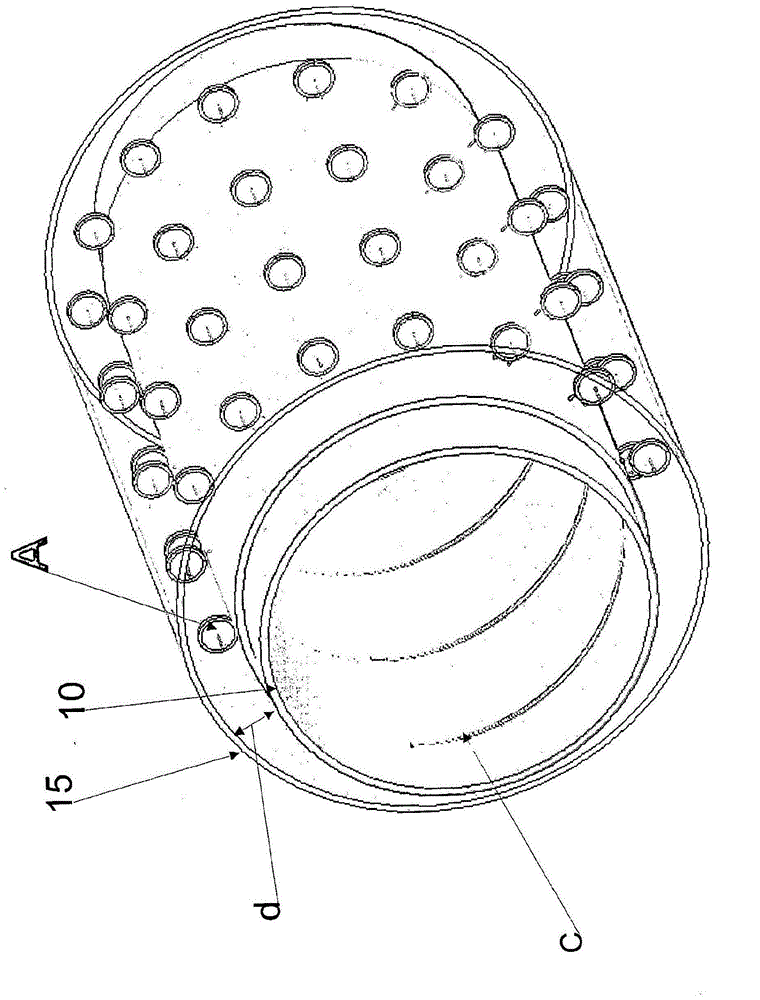

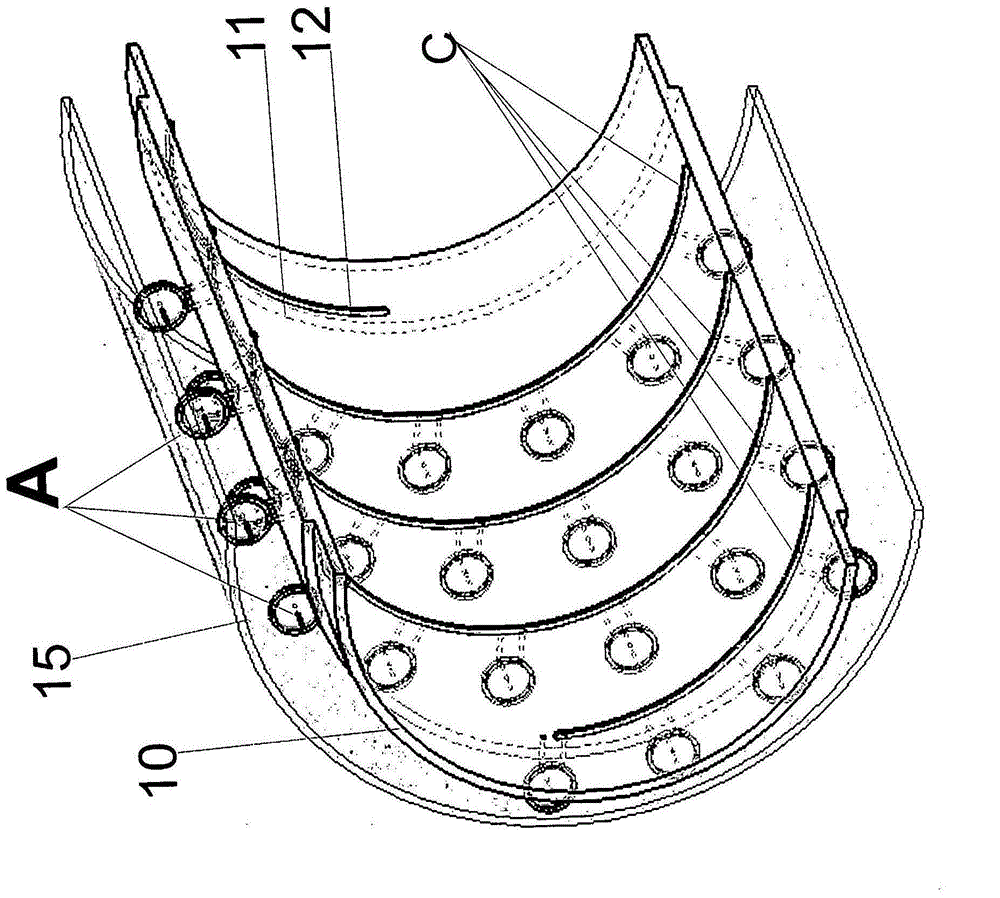

Electric discharge device and method for treatment of fluids

PendingCN110178447AReduce complexityReduced parts countCombustion-air/fuel-air treatmentElectrical discharge ozone preparationElectric dischargeEngineering

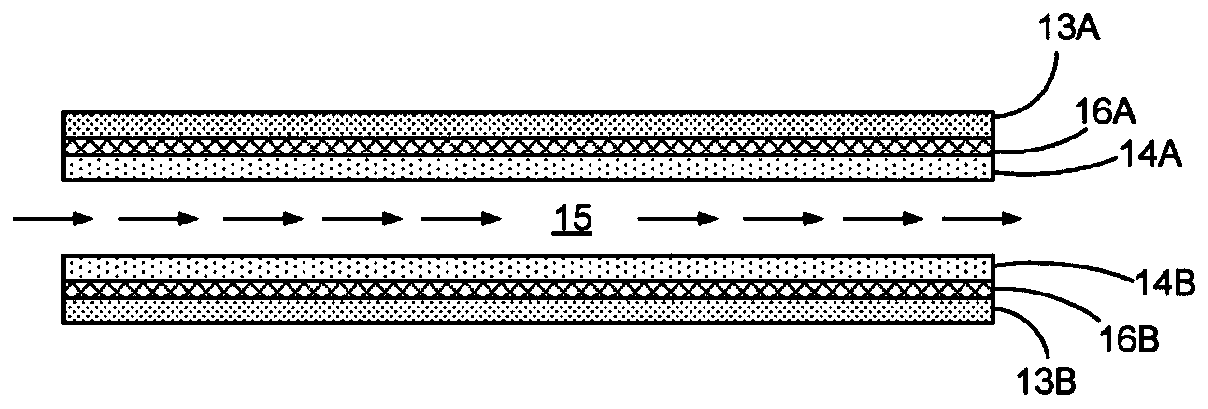

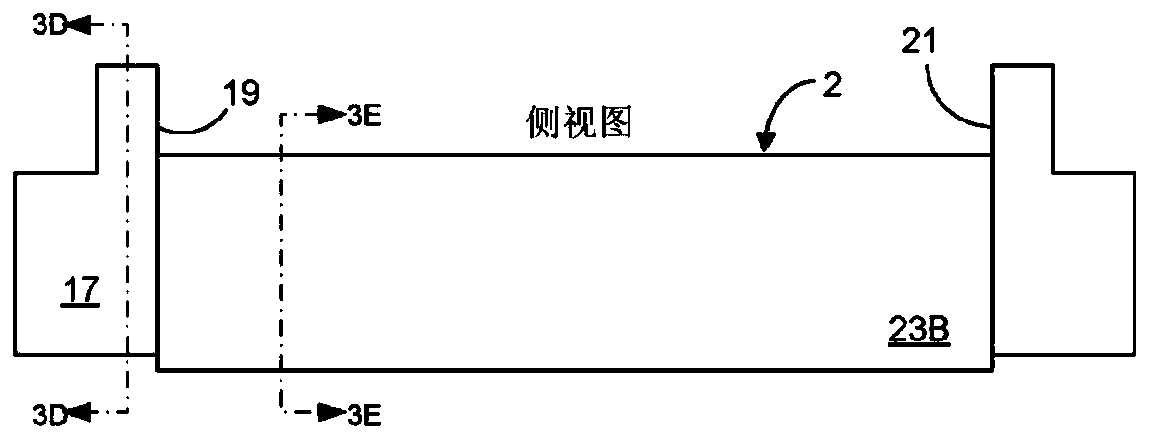

The present disclosure relates to an electric discharge device (1) and associated method for molecular restructuring of a fluid. The electric discharge device (1) comprises a discharge cell (2) including a first dielectric layer (14A) and a second dielectric layer (14B) that are spaced apart by a gap constituting a flow channel (15) for a feed fluid to be molecularly restructured,. The dielectriclayers (14A, 14B) and the flow channel (15) are arranged between a first electrode (13A) and a second electrode (13B) for generating electric discharge in the flow channel (15) when voltage is appliedbetween the electrodes (13A, 13B). The discharge cell (2) comprises a double-walled dielectric tube (17) having an inner wall (17A) and an outer wall (17B) that come together at both ends of the tubeto form a double-walled dielectric tube (17) made in one piece, the inner and outer walls (17A, 17B) of the double-walled dielectric tube (17) constituting the first (14A) and second (14B) dielectriclayers of the discharge cell (2).

Owner:PURE BIO SYNERGY SWEDEN AB

Method for Increasing the Yield When Chlorinating Titaniferous Raw Materials

A method for reprocessing cyclone dust occurring during the carbochlorination of titaniferous raw materials, which essentially consists of titanium dioxide, coke and other inert metal oxides, such as silicon dioxide, and for returning a coke-rich and / or a TiO2-rich fraction to the chlorination reactor includes:preparing an aqueous suspension of the cyclone dust;separating a coke-rich fraction (1) from the aqueous suspension by flotation;adding hydrofluoric acid to the remaining suspension; andseparating a TiO2-rich fraction (2) by flotation from the remaining suspension.

Owner:KRONOS INTERNATIONAL INC

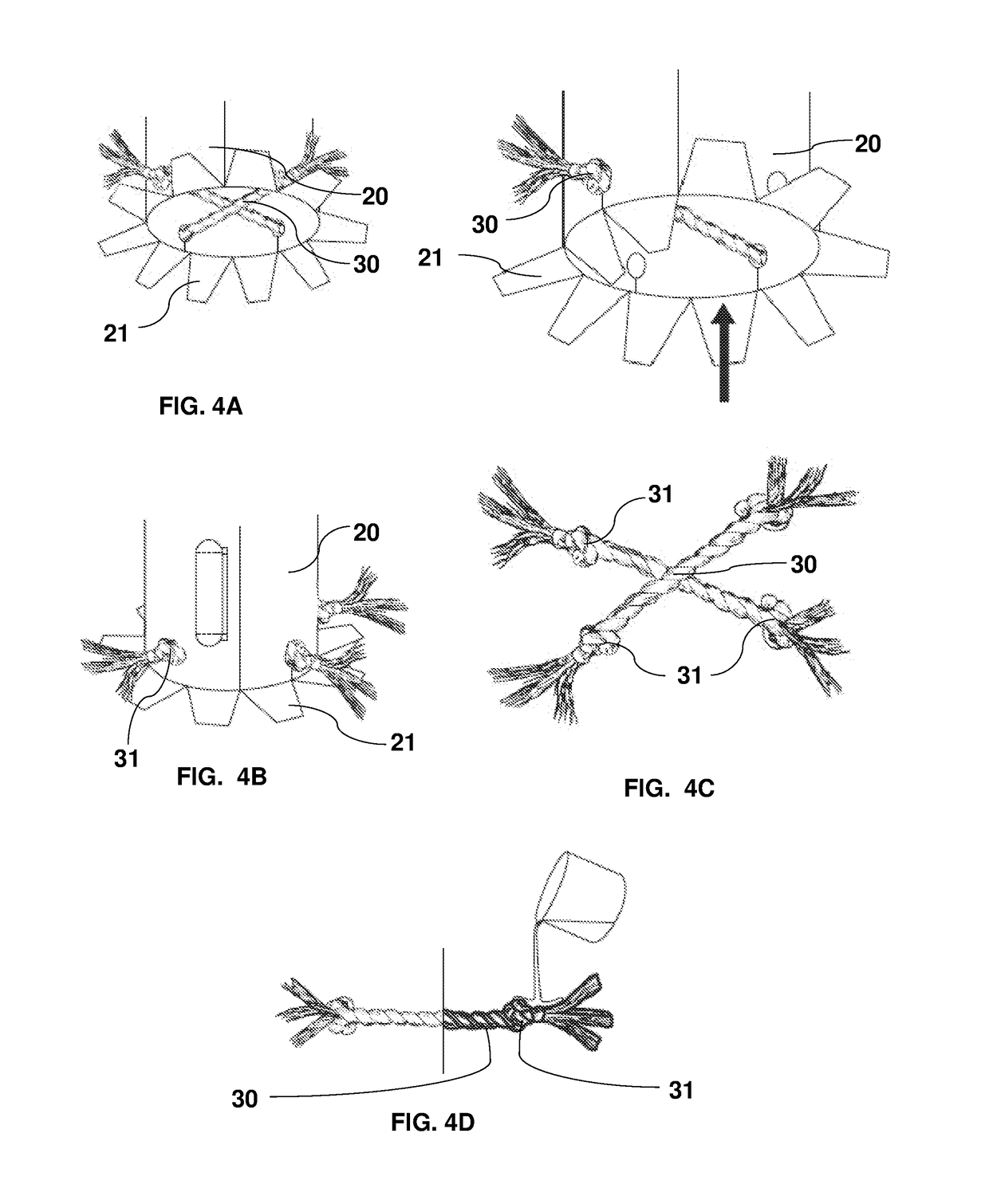

Fuel-containg fire-starting device

A fire start fuel container device including a container defined by side walls forming walls which contains a plurality of holes marked with suction, the holes arranged on at least one of the side faces with alternating arrangement in the central part and below the middle on an equatorial axis for each lateral face; and also has a face that forms the base and another face that makes the cover, which have a hole cut in the middle, which is larger diameter than the side holes, where all the faces define a space that it stores combustible material inside, including a fire initiating mechanism inside it, which is composed of a medium based on cellulose located in the central part of the container whose height reaches the entire height of the container, additionally the walls of the container. Fire initiating mechanism has a plurality of holes spaced equidistantly and arranged alternately one below or above the other on its entire surface, additionally has at its base two wax-coated wicks that cross each other and are fixed to the mechanism fire starter through four holes through which the ends of the wicks pass and by a stop preventing them from coming off, said stop made Referentially by a knot of the same wick.

Owner:VILLARREAL VIVES JOSE ALEJANDRO +1

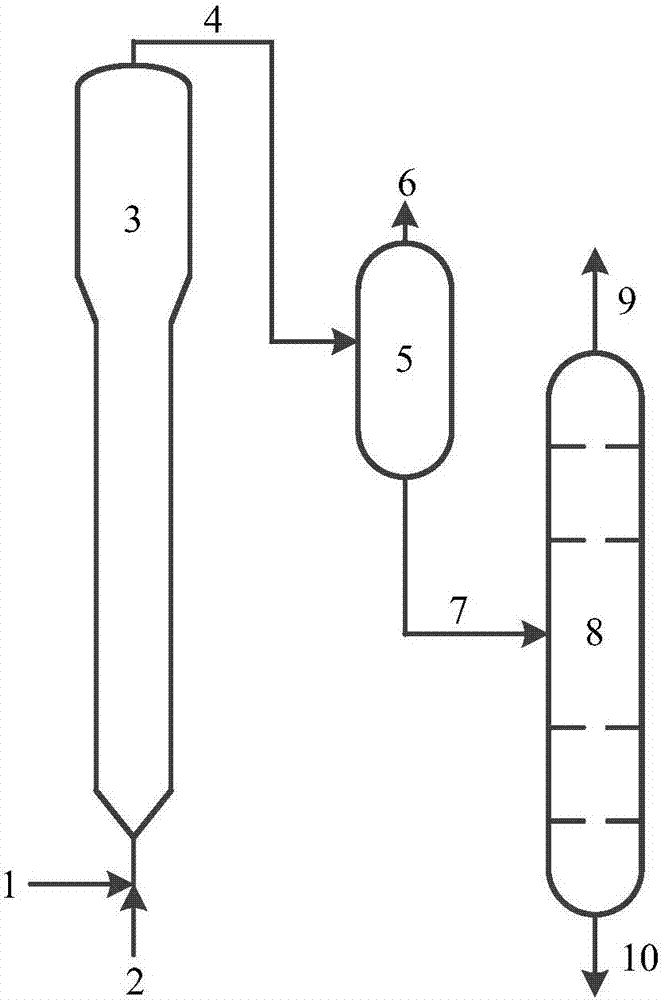

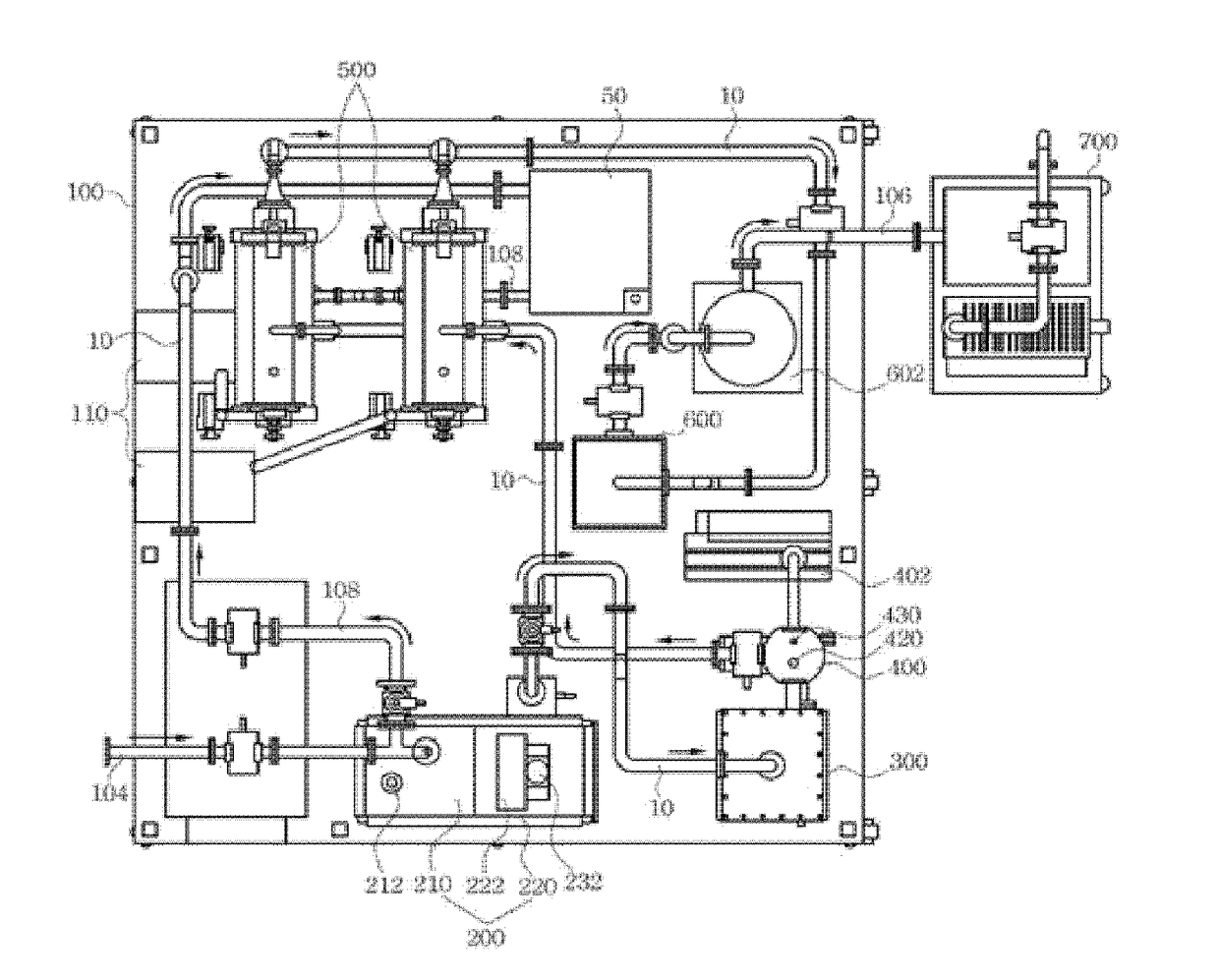

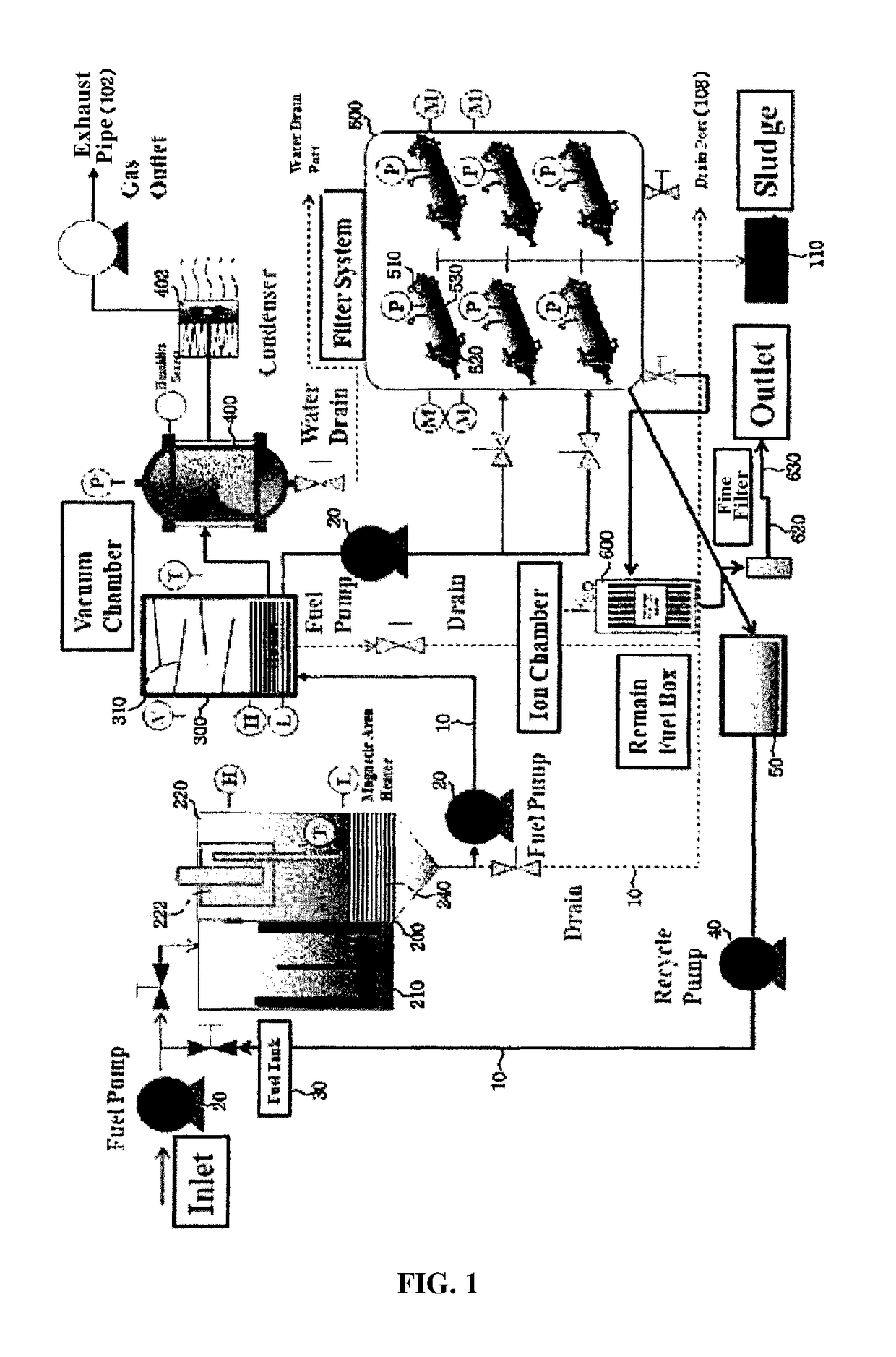

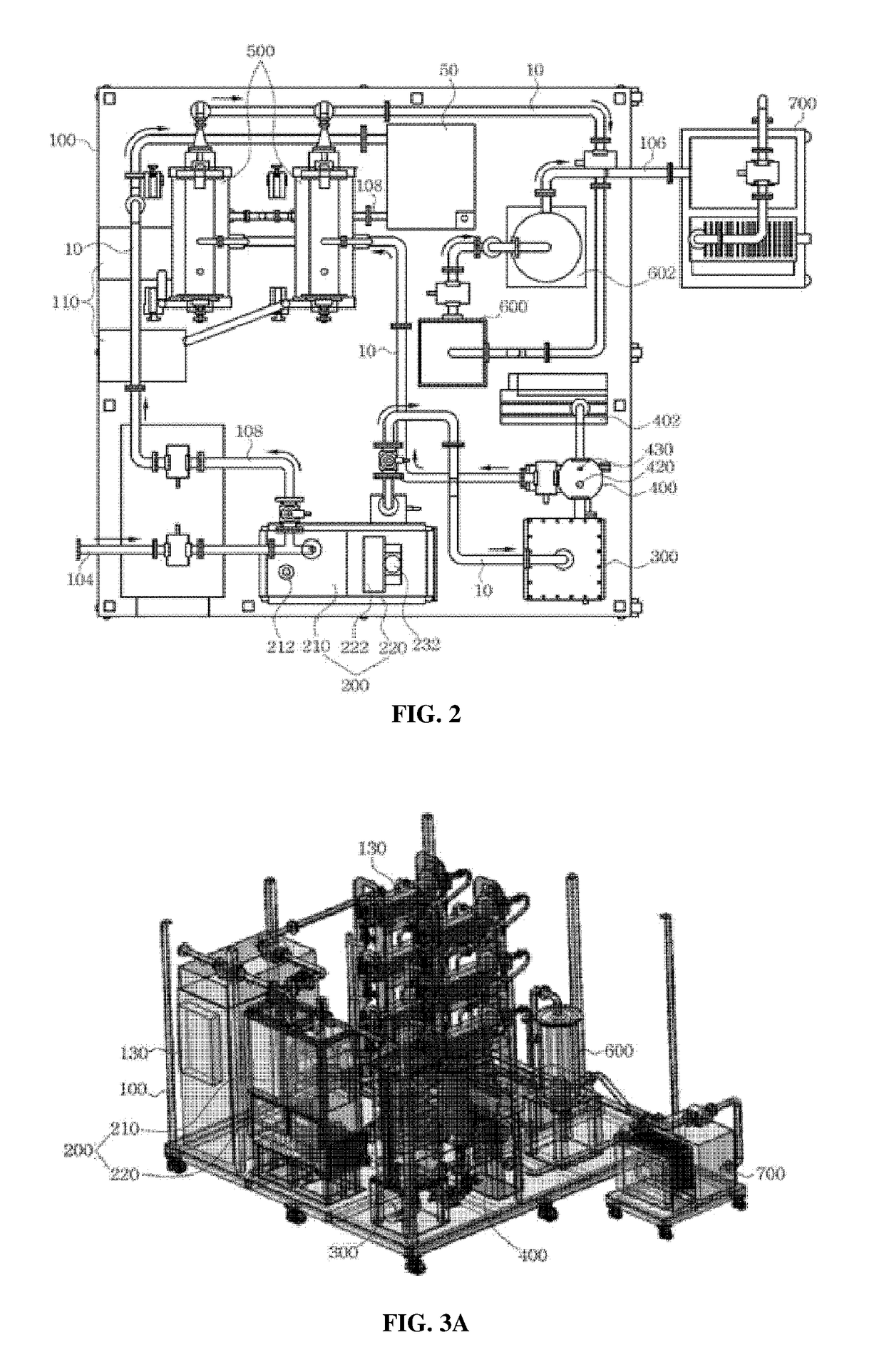

Fuel-oil refining device

InactiveUS20170226432A1Reduce capacityShorten the timeRefining by heating/coolingTreatment with plural serial refining stagesForeign matterSludge

The present invention is characterized by comprising: a main unit which incorporates a fuel-inflow port for fuel oil supply, a fuel-discharge port for discharging fuel oil that has finished being refined and a drainage discharge pipe for collecting and discharging untreated fuel oil, and a sludge box for storing sludge that has been separated out from the fuel oil; an ultrasound tank which receives fuel oil supplied from the fuel-inflow port, and adjusts the particle size of the fuel oil and the viscosity and surface tension of the fuel oil by means of ultrasound; a vacuum chamber which receives fuel oil supplied from the ultrasound tank, and of which the inside is maintained in a vacuum state such that the specific volume and the surface area of the fuel oil are maximized via a baffle panel; a water-fraction elimination tank of which one side is connected to the vacuum chamber and the other side is connected to a vacuum pump, and which eliminates the water fraction from the fuel oil by using air heated to a high temperature and the reduced pressure of the vacuum state created due to the vacuum chamber; an oil-refining filter which receives fuel oil supplied from the vacuum chamber and filters the received supply of fuel oil by means of centrifugation so as to trap sludge contained in the fuel oil; an ion chamber which eliminates and bums particles including fine foreign matter remaining in the fuel oil in the state after the sludge has been eliminated; and a control panel which is constituted on one surface of the main unit, sets the operating conditions of the ultrasound tank, vacuum chamber and water-fraction elimination tank, and controls whether to provide power for refining the fuel oil.

Owner:ENERBIG

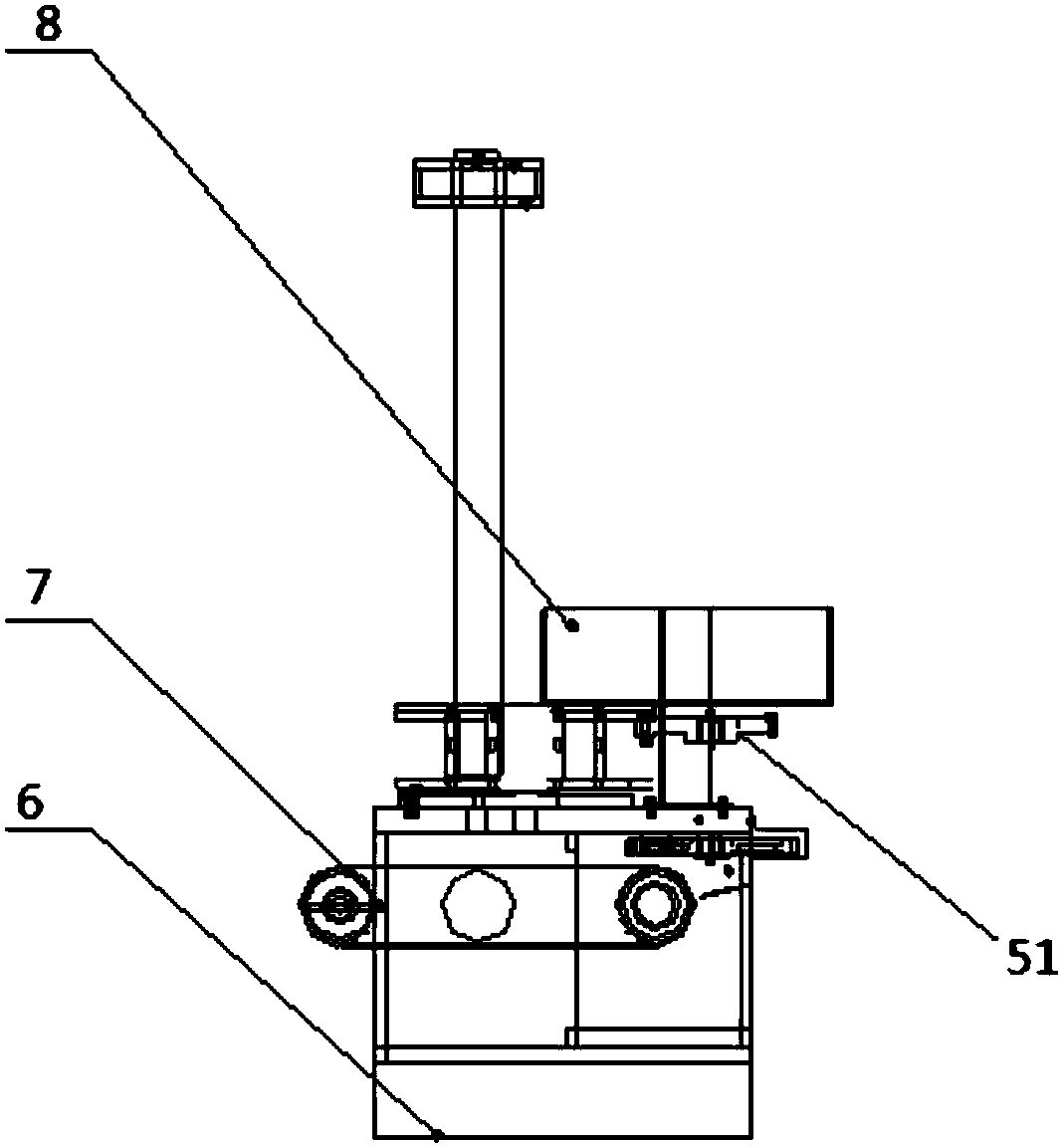

Rod making machine and rod making machine system

InactiveCN108422696AHigh molding strengthImprove breathabilityFuelsShaping pressPulp and paper industryMachining system

The invention relates to the technical field of molding of carbon powder and discloses a rod making machine and a rod making machine system. The rod making machine includes a driving mechanism, a stamping mechanism and a turntable mechanism. By means of the rod making machine and the rod making machine system, carbon powder can be extruded into a rod shape, and molded rod bodies have high moldingstrength, are not scattered and smashed during drying, have high air permeability and can be burnt thoroughly. The technical problems that barbecue carbon of Ramsbottom carbon in the prior art is noteasy to mold and ignite, likely to be scattered and difficult to apply to an industrial production process are solved.

Owner:王圣君

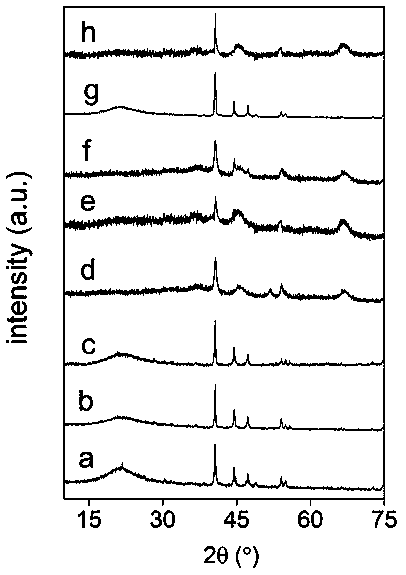

Preparation method of middle-low temperature coal tar hydrotreating catalyst Ni2P/SiO2 or Ni2P/Al2O3

InactiveCN108714430ALow preparation temperatureLow costPhysical/chemical process catalystsFuelsHydrogenNitrogen

The invention discloses a preparation method of a middle-low temperature coal tar hydrotreating catalyst Ni2P / SiO2 or Ni2P / Al2O3. The preparation method comprises the following steps: impregnating nickel nitrate onto an SiO2 or Al2O3 carrier at equal volume; drying, calcining in air; reducing with hydrogen; reacting a reduction product and red phosphorus at 390-410 DEG C for 30-120 min; after finishing the reaction, cooling a reactor to room temperature; and then, feeding a nitrogen-oxygen gas mixture having an oxygen concentration of 0.5 vol% to 2 vol% for passivation. The preparation methodprovided by the invention has advantages of low cost, no toxicity, environmental protection and low phosphorus consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

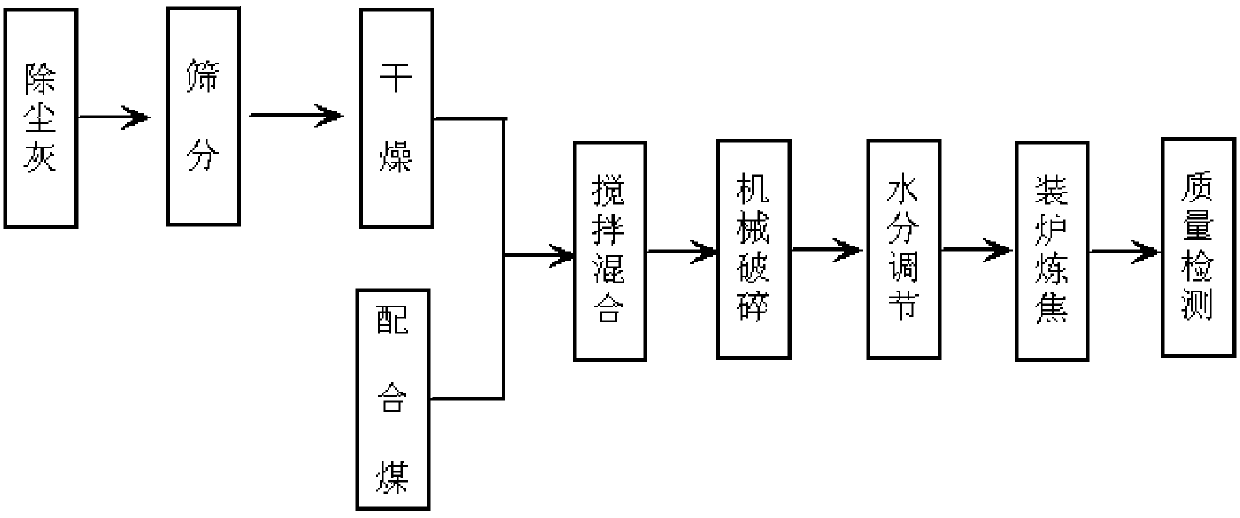

Method for producing high-reactivity coke by co-coking fly ash and coal

InactiveCN110283614ARelieve pressureQuality improvementRetortsSpecial form destructive distillationIron powderCarbonization

The invention discloses a method for producing high-reactivity coke by co-coking fly ash and coal. The method comprises the following steps: screening blast furnace fly ash, and screening out fly ash having a particle size of below 0.28 mm; drying and dewatering the screened fly ash in a drying box; mechanically mixing and crushing the dried fly ash and basic blended coal; adjusting the water to ensure that the moisture content of the obtained mixture is 4-6%; and adding the mixture into a coke oven, carrying out high temperature carbonization, and cooling the obtained maturated coke through a dry quenching process to obtain the high-reactivity coke. The new method for preparing the high-reactivity coke is provided to solve the problem that the blast furnace fly ash only can be used for sintering and pelletizing or for the flotation preparation of carbon powder and iron powder, and has the advantages of full utilization of high-content carbon and iron in the fly ash, effective utilization of waste fly ash generated in the blast furnace, and reduction of the pressure to the environment.

Owner:BAOSHAN IRON & STEEL CO LTD

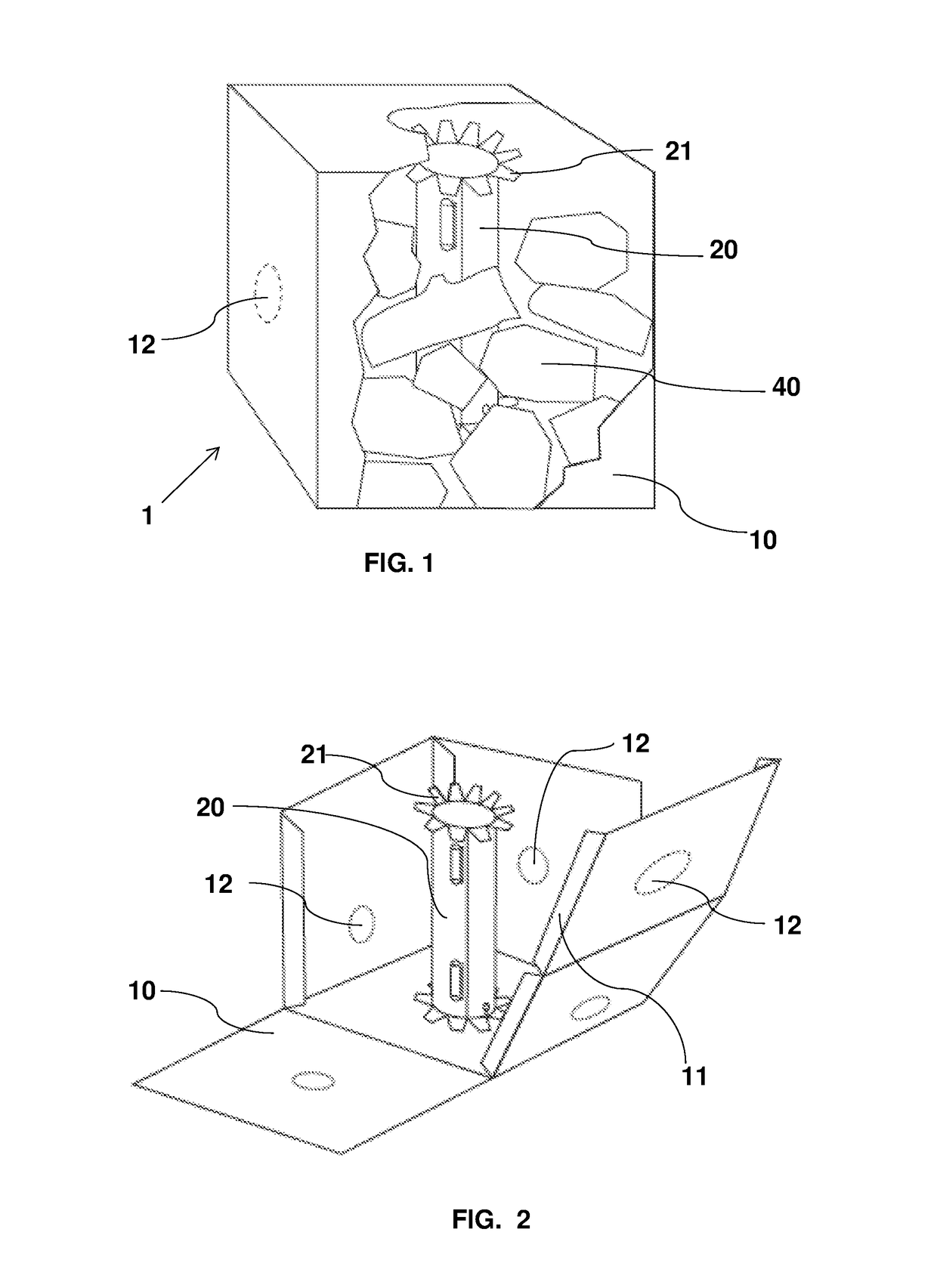

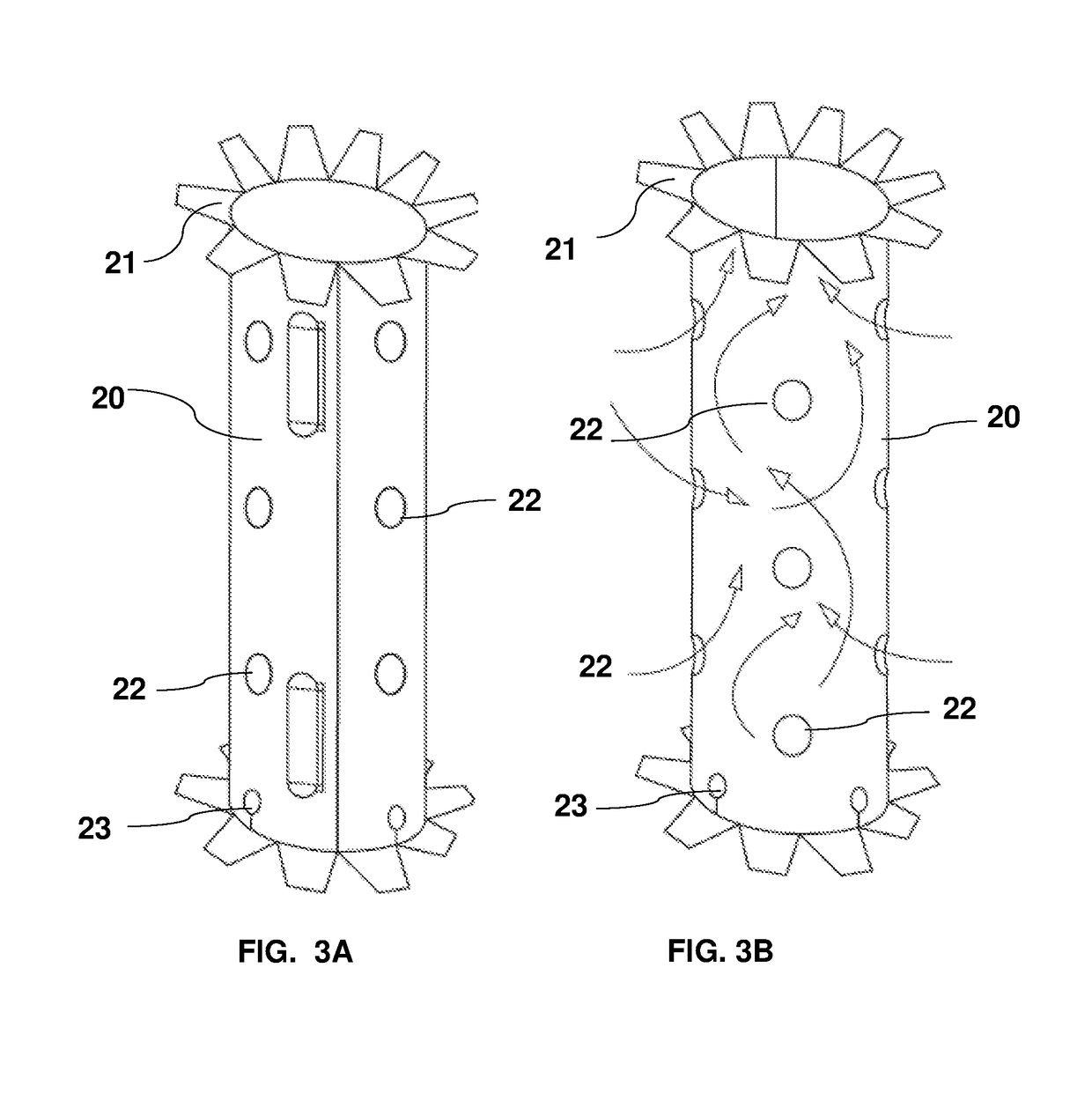

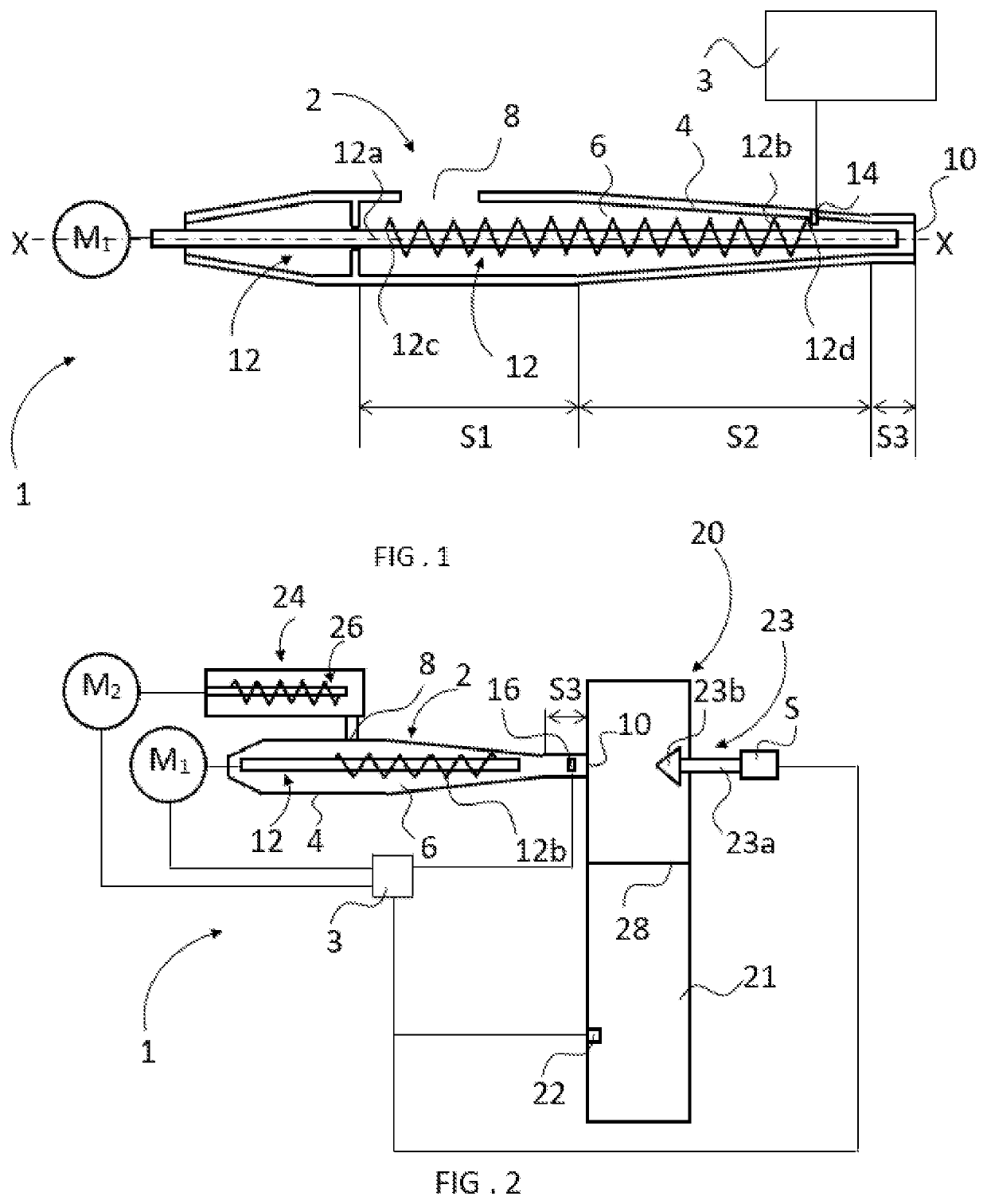

A system for transporting biomass material and a method for preventing blow back in said system

InactiveUS20210039893A1Reduce riskDigestersControl devices for conveyorsControl cellEnvironmental engineering

The invention relates to a system (1) comprising a feeding device (2) comprising a channel (6) having an inlet (8) and an outlet (10) and a feed screw (12) for conveying biomass material through the channel. The feed screw comprises a screw flight (12b) that extends from a first end (12c) to a second end (12d) and is adapted to form a gas impermeable plug of biomass. The system comprises at least one primary measuring unit (14; 16) adapted to continuously measure a primary variable indicative of the gas permeability of the plug, which primary measuring unit is connected to said feeding device between the first end of the screw flight and the outlet; and a control unit (3) adapted to use said primary variable values to monitor the gas permeability of the plug. The invention also relates to a method for preventing blow back in the above described system.

Owner:VALMET AB

Liquid fuel

InactiveCN104726163ARich deuterium atom contentWill not polluteSeawater treatmentWater/sewage treatment by electrochemical methodsSolubilityNuclear power

The invention provides liquid fuel. The liquid fuel is extracted from seawater and comprises deuterium, total dissolved solids (TDS) are equal to or larger than 30,000 milligrams / liter, whether total deuterium in concentrated solution is up to the preset value or not is judged by measuring TDS in the seawater concentrated solution, and if the total deuterium is up to the preset value, the seawater concentrated solution can be used as liquid fuel. The liquid fuel has the advantages of no pollution in reaction, no side products and radiation, deuterium is cracked by cold fusion and releases energy, energy conversion efficiency is high, sources are wide and extraction process is simple and the like. In addition, the liquid fuel is widely applicable to the fields of nuclear power automobiles, airplanes, ships, power plants and the like, gradually phases out existing gasoline and diesel cars, solves the problem of coal power pollution and is a breakthrough in energy exploitation.

Owner:GUANGZHOU TONGHE ENERGY TECH

Coal tar hydrodemetallization catalyst and preparation method thereof

InactiveCN108722454AAvoid uneven heatingAvoid intensityCatalyst activation/preparationFuelsPore distributionFreeze-drying

Owner:一重集团大连工程建设有限公司

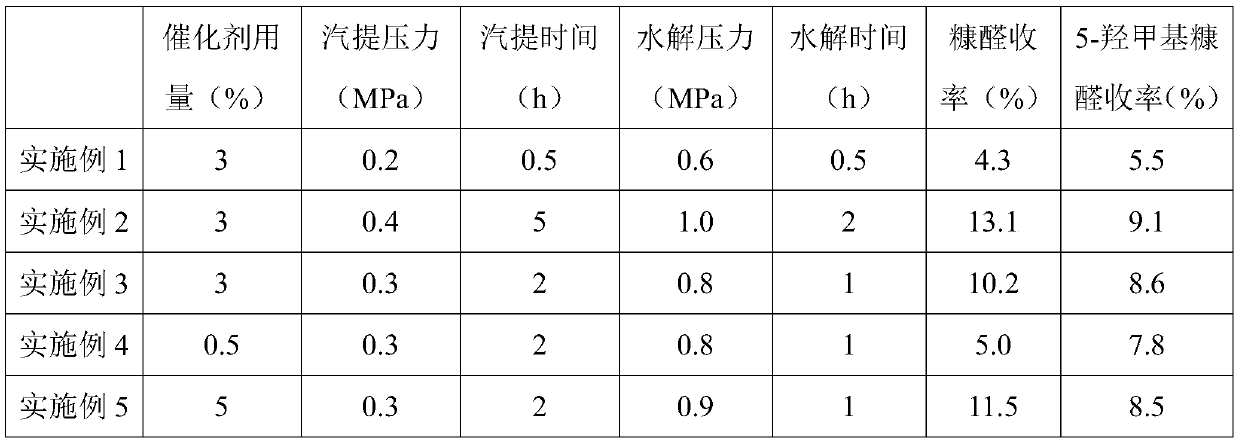

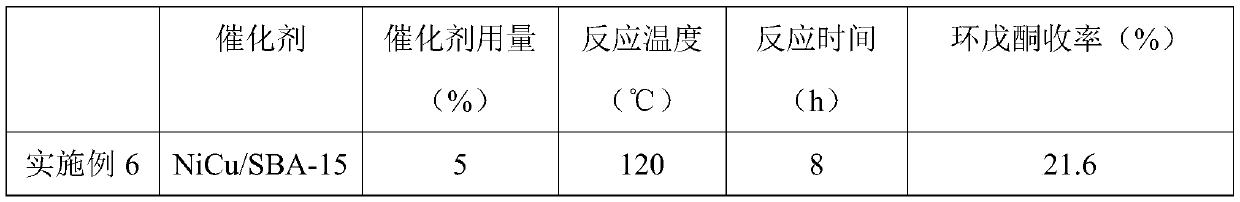

Method for preparing special fuel with low freezing point, high density and high thermal stability from lignocellulose biomass

ActiveCN110923001ALowering the freezing pointHigh densityLiquid hydrocarbon mixture productionFuelsAviationDepolymerization

The invention provides a method for preparing special fuel with low freezing point, high density and high thermal stability from lignocellulose biomass. The method mainly comprises the following threesteps: 1) converting hemicellulose and cellulose in a biomass raw material into aldehydes and ketones (containing cyclic ketone substances) platform compounds through steam stripping and hydrolysis and then carrying out directional cross condensation and hydrodeoxygenation among platform compounds to synthesize low-freezing-point aviation oil components mainly comprising components such as direct-connection hydrocarbon, branched-chain isohydrocarbon and loop-chain isohydrocarbon of which the carbon chain length is 8-17; 2) synthesizing a high-density aviation oil component through cyclic ketone platform compound self-condensation and hydrodeoxygenation; and 3) preparing a cyclohexane component with high chemical heat sink characteristic and an additive component with thermal oxidation resistance through oriented depolymerization and conversion of lignin and obtaining the biomass special fuel with low freezing point, high density and high heat sink characteristic through component blending and hydrofining accordingly, thereby meeting the requirement of rapid development of high-performance aircrafts in China.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Installation for treating a fuel to increase its caloric power

InactiveCN104160132AReduce capacityReduce quality problemsLiquid fuel feeder/distributionTurbine/propulsion fuel supply systemsEngineering

Owner:奥雷尔·埃纳凯

Additives to enhance phosphorus compound removal in refinery desalting processes

ActiveUS7799213B2Dewatering/demulsification with chemical meansOther chemical processesWash waterChloroacetic acids

Reactive phosphorus species can be removed or transferred from a hydrocarbon phase to a water phase in an emulsion breaking process by using a composition that contains water-soluble hydroxyacids. Suitable water-soluble hydroxyacids include, but are not necessarily limited to glycolic acid, gluconic acid, C2-C4 alpha-hydroxy acids, poly-hydroxy carboxylic acids, thioglycolic acid, chloroacetic acid, polymeric forms of the above hydroxyacids, poly-glycolic esters, glycolate ethers, and ammonium salt and alkali metal salts of these hydroxyacids, and mixtures thereof. The composition may optionally include a mineral acid to reduce the pH of the desalter wash water. A solvent may be optionally included in the composition. The invention permits transfer of reactive phosphorus species into the aqueous phase with little or no hydrocarbon phase undercarry into the aqueous phase. The composition is particularly useful in treating crude oil emulsions, and in removing calcium and other metals therefrom.

Owner:BAKER HUGHES HLDG LLC

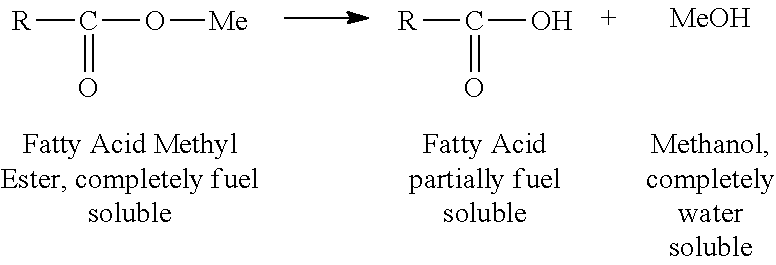

Determination of fame content in fuel

InactiveUS20170241974A1Material analysis by observing effect on chemical indicatorMaterial testing goodsLiquid hydrocarbonsFatty acid methyl ester

A method for determining whether a liquid hydrocarbon fuel, contained in a reservoir, comprises no more than a specified maximum permissible amount of fatty acid methyl ester (FAME) for the fuel to be accepted as being suitable for use in a specified engine.

Owner:PALOX OFFSHORE L +1

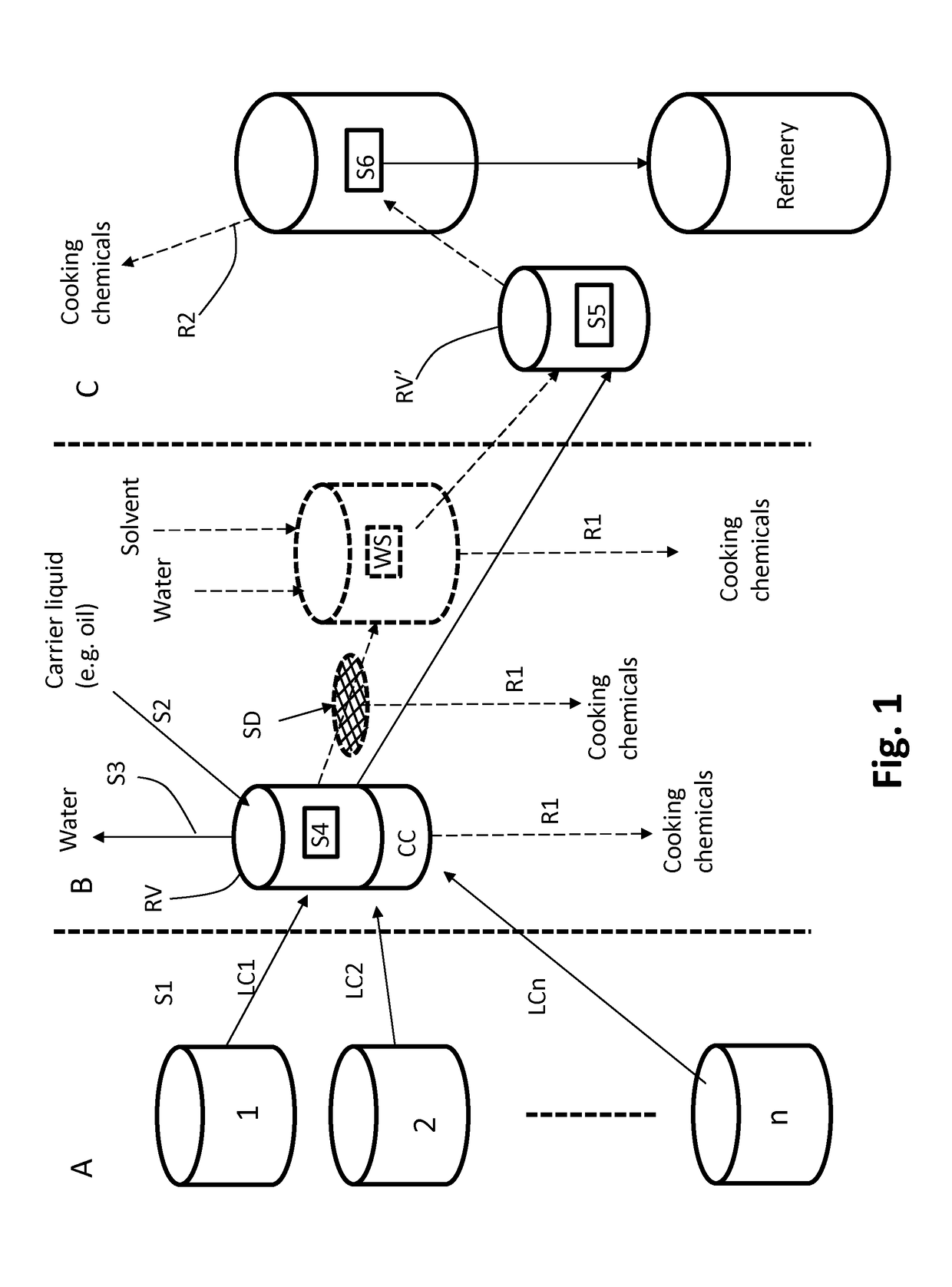

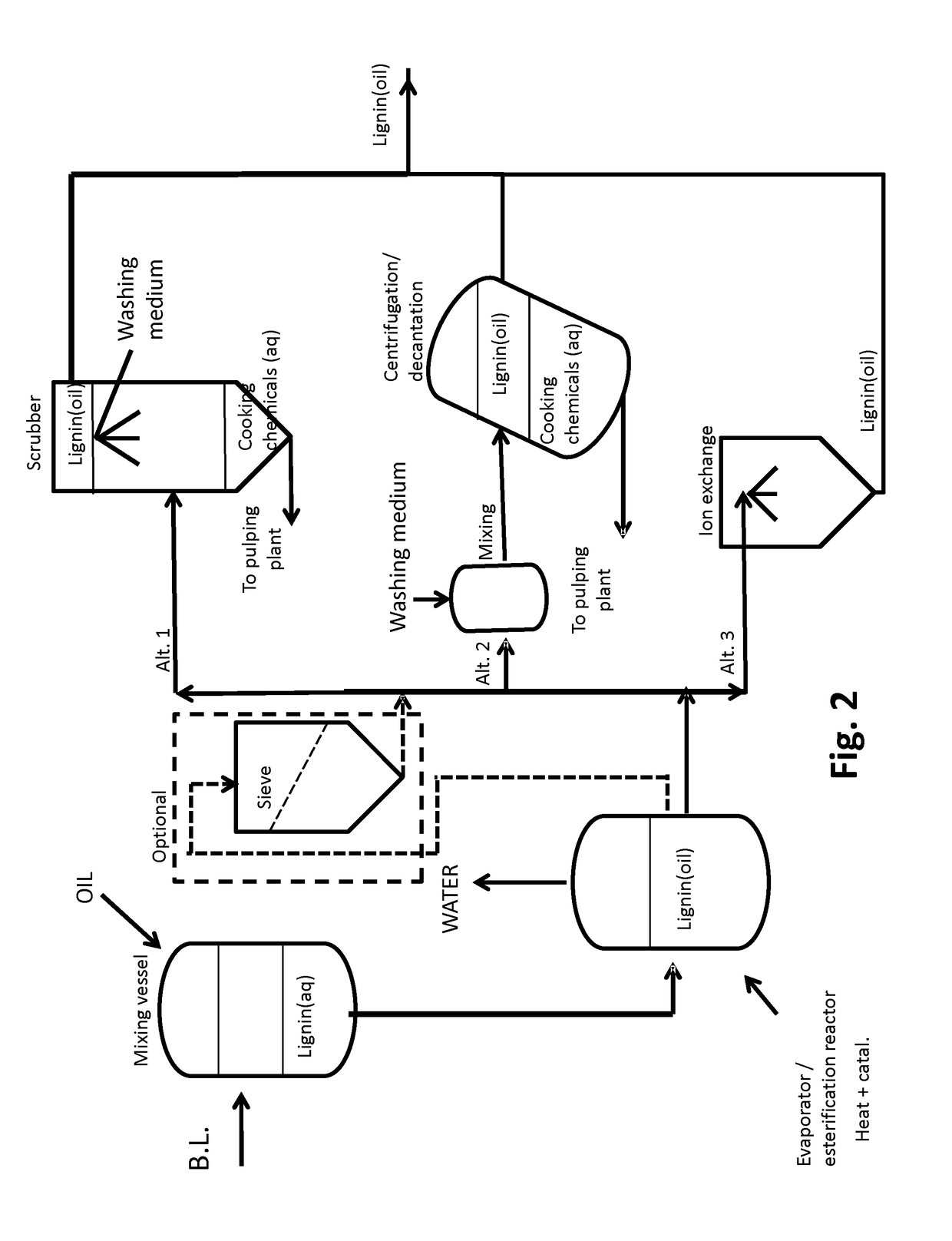

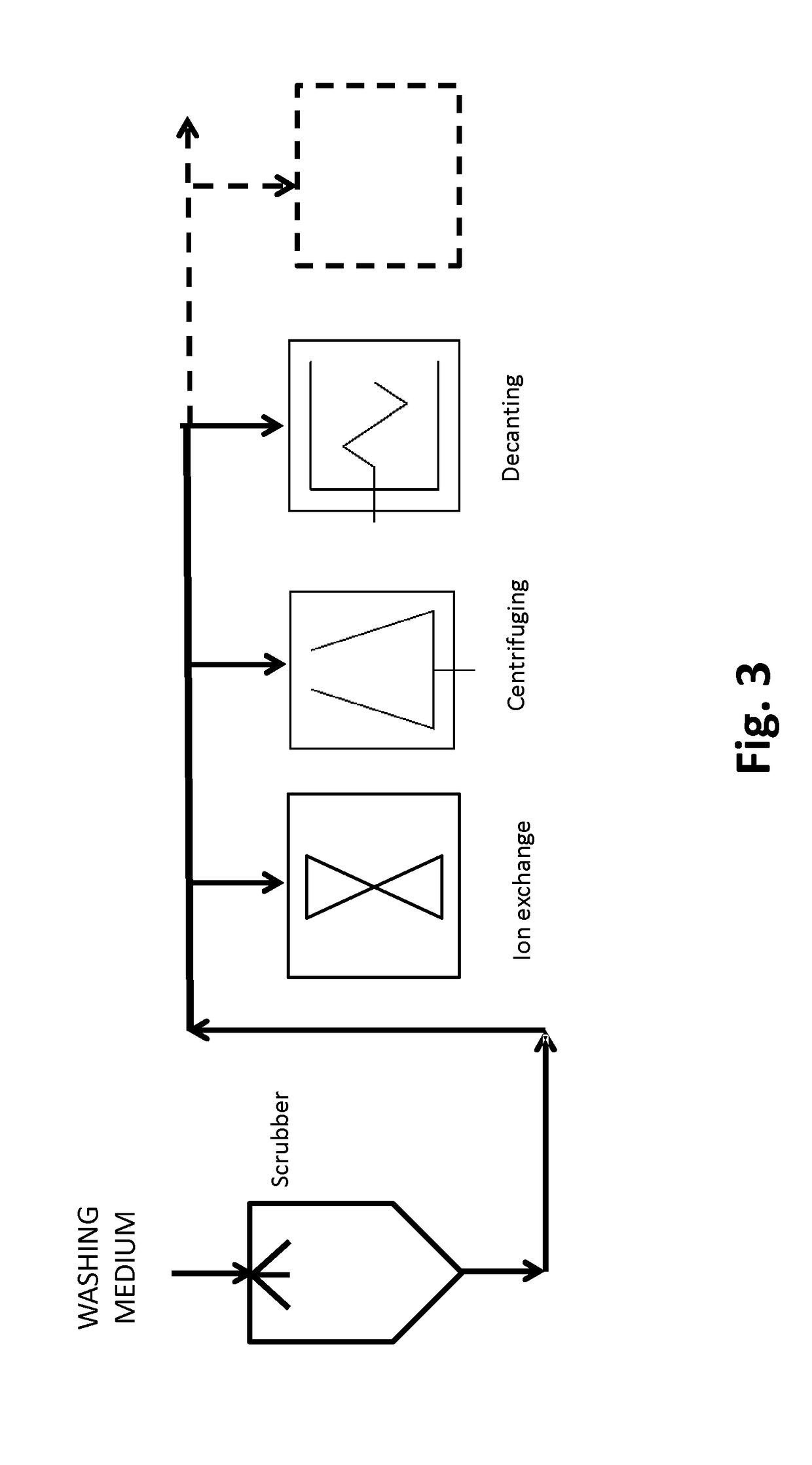

Process for making lignin composition

InactiveUS20180371252A1Lignin derivativesLiquid solutions solvent extractionCompound (substance)Refinery

The invention relates to a process for making a purified lignin composition comprising a carrier liquid suitable for processing in a refinery. It comprises providing an aqueous lignin composition comprising lignin, cooking chemicals and water and adding a carrier liquid to the aqueous lignin to provide an organic phase. Then all or substantially all the water is removed from the composition. The lignin composition is processed to make the lignin more soluble in the carrier liquid in order to transfer more of the lignin to the organic phase. Cooking chemicals are removed, suitably by of washing by liquid / liquid extraction using a washing liquid. Finally washing liquid is removed.

Owner:REN FUEL K2B

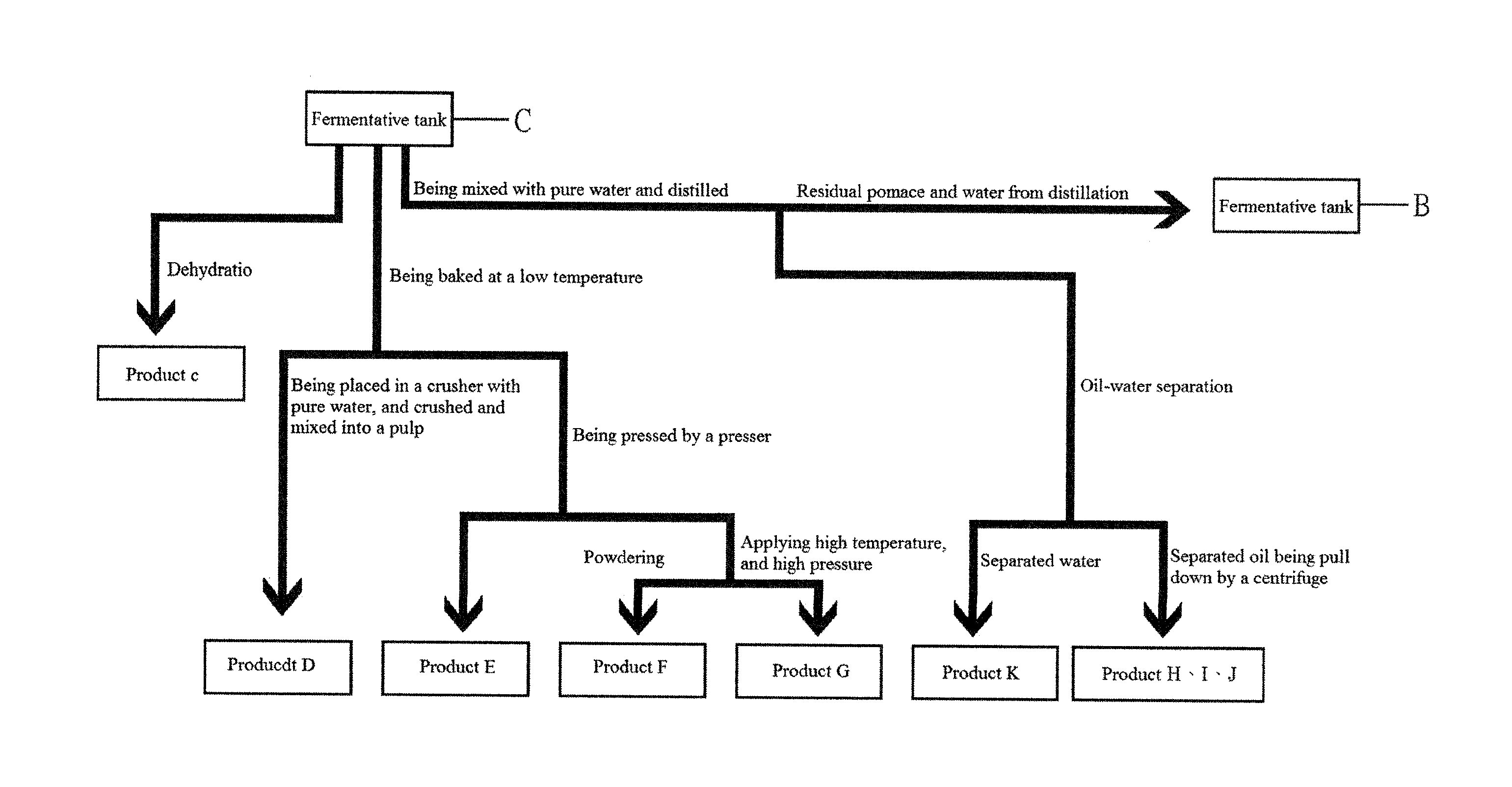

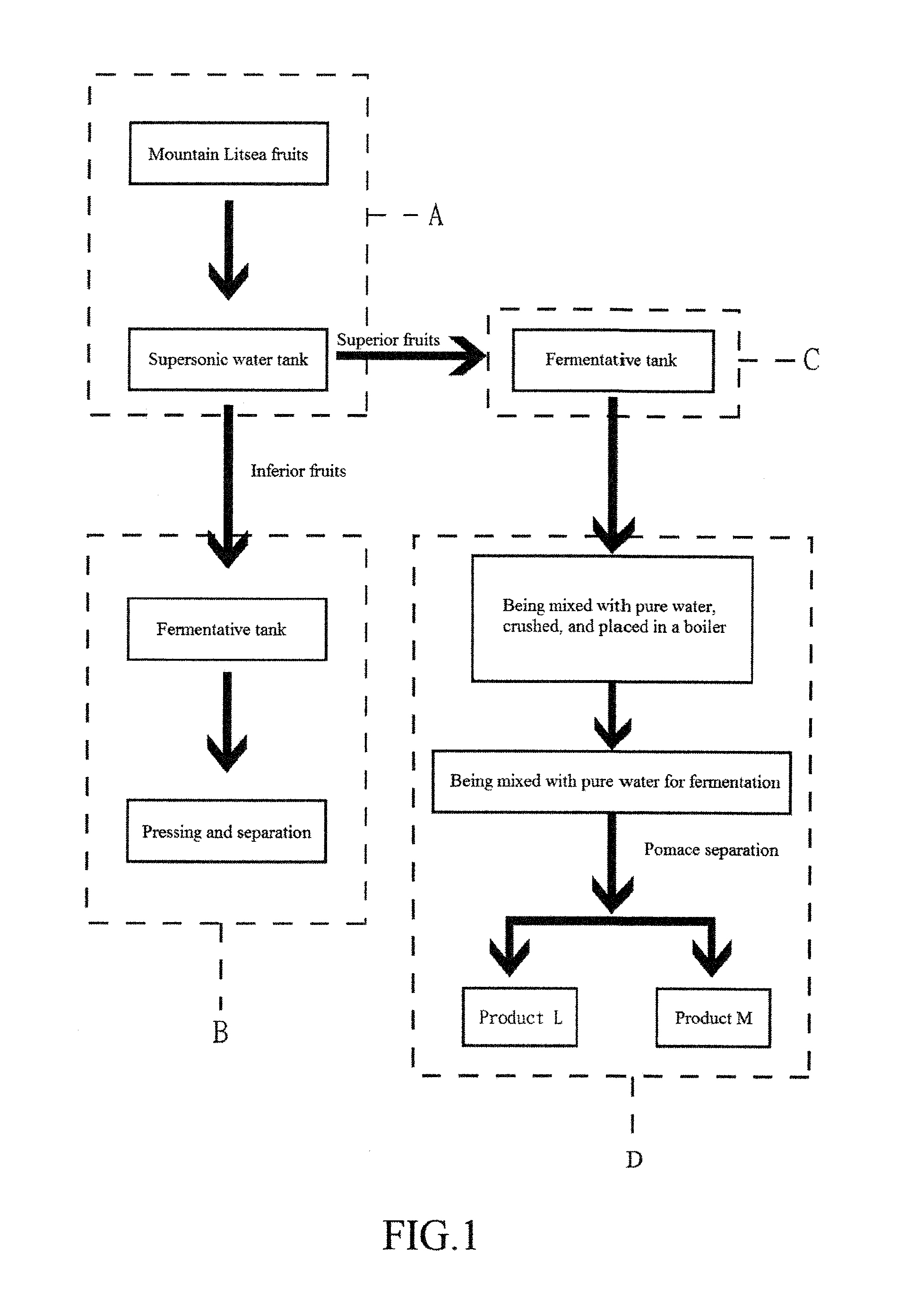

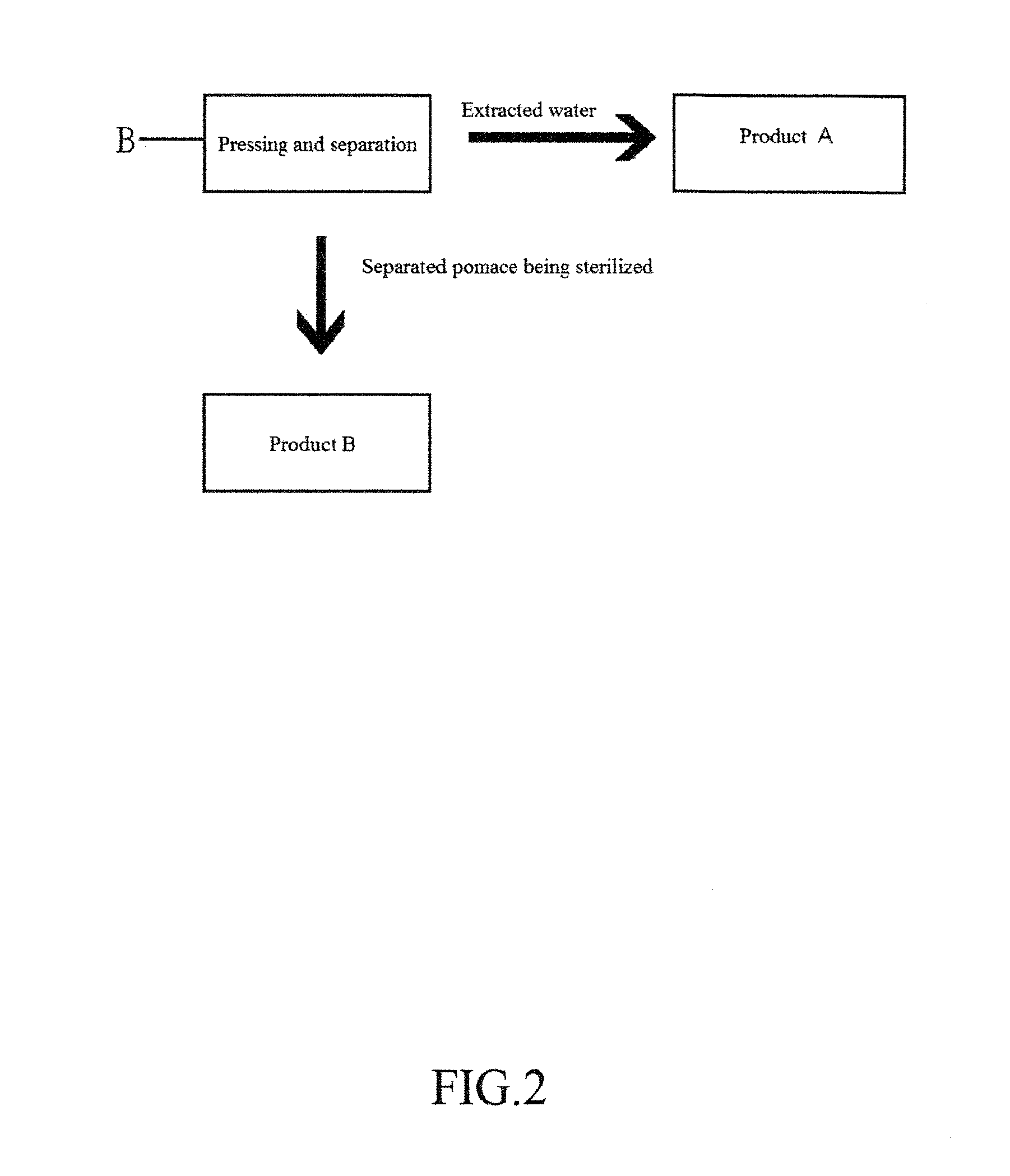

Method of producing organic product from mountain litsea

The method contains the following steps. In step A, supersonic waves are applied to Mountain Litsea fruits for excitation and sterilization. In step B, the inferior fruits and the cleaning water are removed from the water tank, placed in a fermentative tank, and left for fermentation. After the fermentation, a pressing and separation process is conducted. In step C, the superior fruits are placed in a separate fermentative tank for fermentation into mofetil alcohol. In step D, the superior fruits are alternatively mixed with pure water, crushed, and placed in a boiler for aging and sterilization. Then the crushed and aged fruits are placed in yet another fermentative tank with pure water for fermentation. After the fermentation, a pomace separation process is conducted. The separated pomace becomes a Mountain Litsea wine lees, whereas the separated water becomes a Mountain Litsea enzymatic liquid.

Owner:HSU HENG JUI +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com