High selectivity chemically cross-linked rubbery membranes and their use for separations

a chemically crosslinked rubber and high selectivity technology, applied in the field of high selectivity chemically crosslinked rubbery membranes and their use for separation, can solve the problems of olefin recovery, liquefied, lpg) recovery, and the performance of membranes prepared from glassy polymers is not outstanding for organic vapor separation, and achieves the effects of improving the permeance and selectivity, increasing the plasticization of condensable olefins, and increasing the permeation ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of 5DMS-TDI / PES-a TFC Membrane

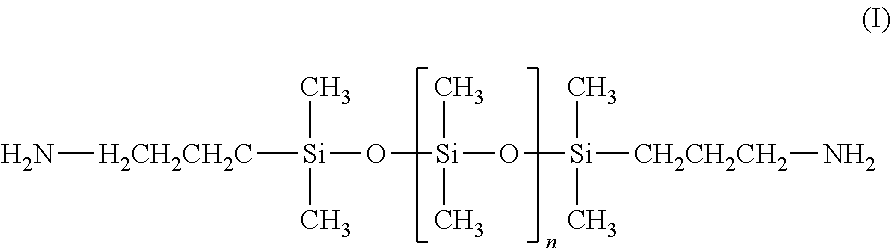

[0036]A porous, asymmetric PES gas separation support membrane was prepared via the phase-inversion process. A PES-a membrane casting dope comprising PES 18-25 wt %, NMP 60-65 wt %, 1,3-dioxolane 10-15 wt %, glycerol 1-10 wt % and n-decane 0.5-2 wt % was cast on a nylon fabric then gelled by immersion in a 1° C. water bath for about 10 minutes, and then annealed in a hot water bath at 85° C. for about 5 minutes. The wet membrane was dried at 70° C. A 5 wt % DMS-TDI pre-cross-linked rubbery polymer solution was prepared by dissolving 6.0 g of an aminopropyl-terminated polydimethylsiloxane (Gelest catalog number: DMS-A21) and 0.25 g of 2,4-toluene diisocyanate (TDI) in 118.8 g of hexane at room temperature for about 10 min. The dried PES-a porous support membrane was coated with the 5 wt % DMS-TDI pre-cross-linked rubbery polymer solution, dried at room temperature for about 5 min, and then heated at 85° C. for 2 h to form a thin, nonporous, d...

example 2

Preparation of 6.5DMS-TDI / PES-a TFC Membrane

[0037]A 6.5DMS-TDI / PES-a TFC membrane was prepared using the procedure described in Example 1 except that the PES-a support membrane was coated with a 6.5 wt % DMS-TDI pre-cross-linked rubbery polymer solution comprising 6.0 g of DMS-A21 and 0.25 g of 2,4-toluene diisocyanate (TDI) in 89.9 g of hexane at room temperature for about 10 min. The coated membrane was dried at room temperature for about 5 min, and then heated at 85° C. for 2 h to form a thin, nonporous, dense, chemically cross-linked DMS-TDI selective layer on the surface of the PES-a support membrane (abbreviated as 6.5DMS-TDI / PES-a). The 6.5DMS-TDI / PES-a TFC membrane was tested with a fuel gas mixture of 70% C1, 15% C2, 10% C3 and 5% CO2 at 3549 kPa (500 psig) and 25° C. The membrane was also tested with N2, H2, CH4, propylene, and propane single gases at 791 kPa (100 psig) and 25° C. The membrane permeances (P / L) and selectivities (α) are shown in Tables 1 and 2.

example 3

Preparation of 5DMS-TDI / 5DMS-TDI / PES-a Dual-Coated TFC Membrane

[0038]A 5DMS-TDI / 5DMS-TDI / PES-a dual-coated TFC membrane was prepared using the procedure described in Example 1 except that the PES-a support membrane was first coated with a 5 wt % DMS-TDI pre-cross-linked rubbery polymer solution comprising 6.0 g of DMS-A21 and 0.25 g of 2,4-toluene diisocyanate (TDI) in 118.8 g of hexane at room temperature for about 10 min. The coated membrane was dried at room temperature for about 5 min, and then heated at 85° C. for 2 h to form the first layer of thin, nonporous, dense, chemically cross-linked DMS-TDI on the surface of the PES-a support membrane. The DMS-TDI-coated PES-a TFC membrane was then coated with a 5 wt % DMS-TDI pre-cross-linked rubbery polymer solution again, dried at room temperature for about 5 min, and then heated at 85° C. for 2 h to form the second layer of thin, nonporous, dense, chemically cross-linked DMS-TDI on the surface of the DMS-TDI-coated PES-a TFC membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com