Electric discharge device and method for treatment of fluids

A discharge device and fluid technology, applied in the direction of ozone preparation by discharge method, chemical instruments and methods, water/sewage treatment, etc., can solve the system complexity and sensitivity of compressors, coolers and dryers, cumbersome assembly, can not Prevents issues such as leakage into the area housing the electrodes, resulting in reduced complexity and part count, improved cooling, and ease of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

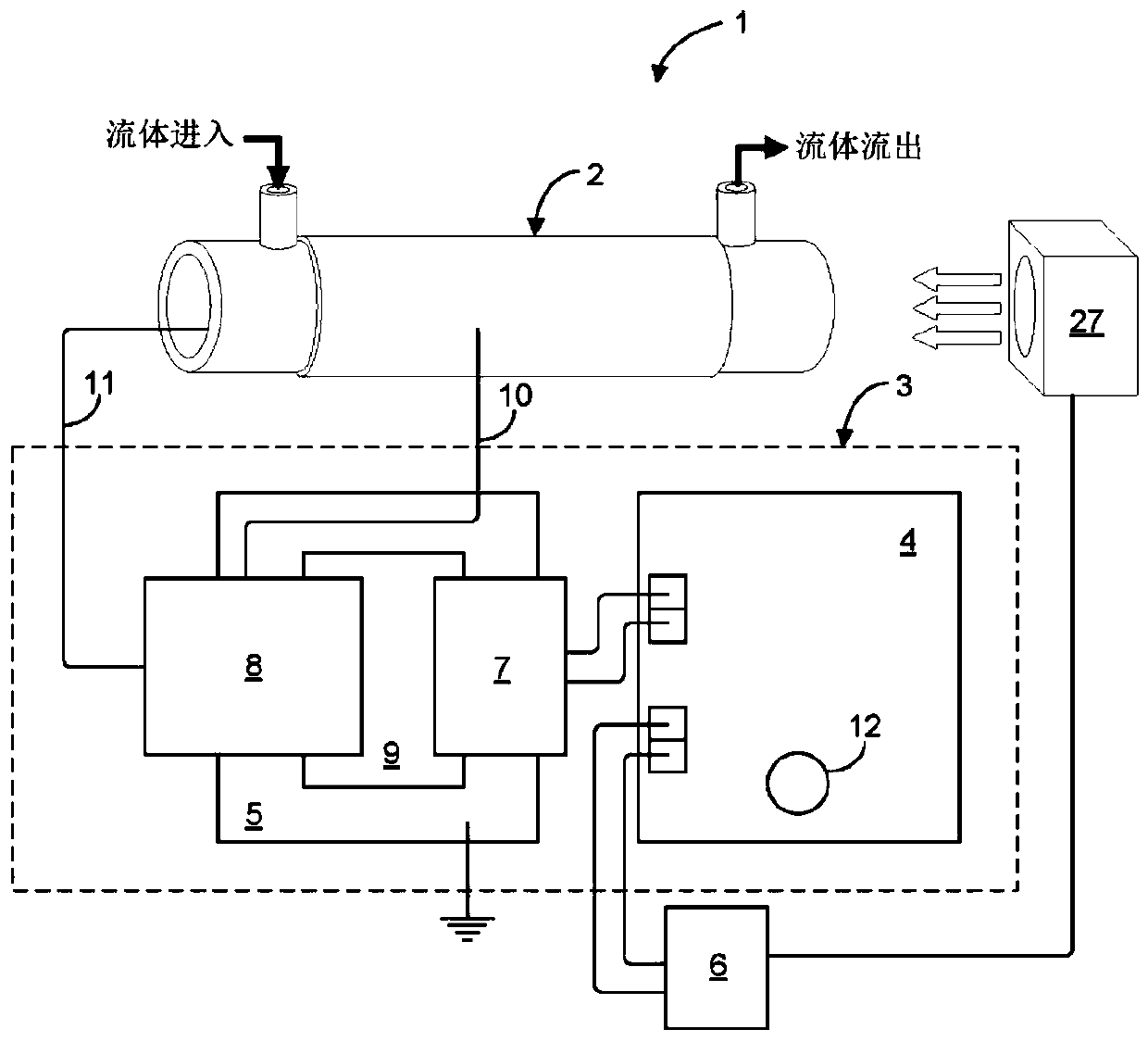

[0077] figure 1 A discharge device 1 for molecular recombination of fluids according to an exemplary embodiment of the present disclosure is shown.

[0078] The discharge device 1 is a corona discharge device configured to split fluid molecules by subjecting the fluid to a corona discharge. To this end, the discharge device 1 includes a discharge unit 2 for corona discharge, and a driving circuit 3 for applying a high voltage between electrodes of the discharge unit to generate corona discharge. The drive circuit 3 includes a converter 4 connected to a transformer 5 . The converter 4 is also connected to a power source 6, such as a mains power supply delivering approximately 230V alternating current (AC) at 50Hz or 60Hz, a 12V direct current (DC) car battery, or a 24V or 48V DC battery. Transformer 5 includes a primary winding 7 coupled to a secondary winding 8 via a transformer core 9 . The secondary winding 9 is connected via a first cable 10 to a first electrode of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com