Method for preparing special fuel with low freezing point, high density and high thermal stability from lignocellulose biomass

A technology for lignocellulose and biomass raw materials, which is applied in the preparation of liquid hydrocarbon mixtures, fuels, and refined hydrocarbon oils, etc., can solve the problem of limited space for improving fuel density, calorific value, stability and freezing point, and insufficient fuel molecular structure regulation. , unable to meet the rapid development of aerospace vehicles and other problems, to achieve the effect of promoting national defense construction, realizing diversification, and ensuring supply security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

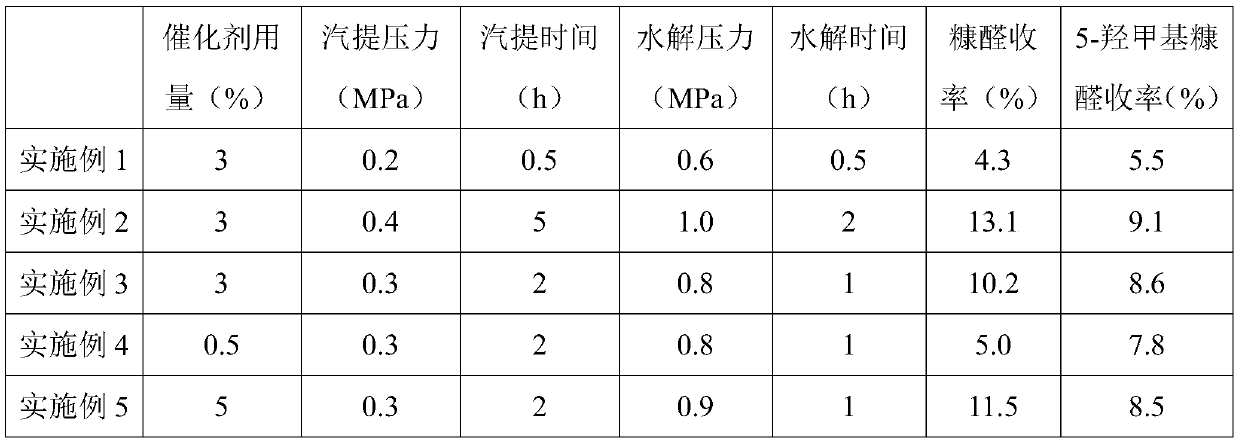

[0032] Examples 1-5: Preparation of Platform Compounds

[0033] The sulfuric acid-zinc sulfate catalyst (molar ratio of sulfuric acid and zinc sulfate is 1:1) and the biomass raw material (corn stover) are mixed and filled into the kettle type reactor, and then steam is introduced into the raw material through steam stripping operation. Hemicellulose is converted into furfural platform compounds and taken out of the reactor; then the steam pressure is increased to hydrolyze the cellulose components in the lignocellulosic biomass feedstock to 5-hydroxymethylfurfural. The specific parameters and target product yield are shown in Table 1.

[0034] Table 1

[0035]

Embodiment 6-9

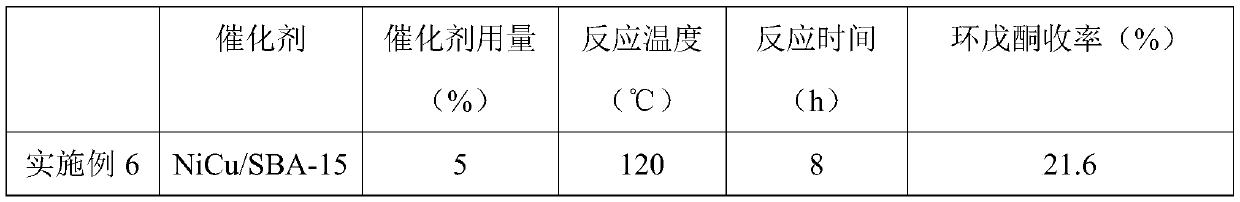

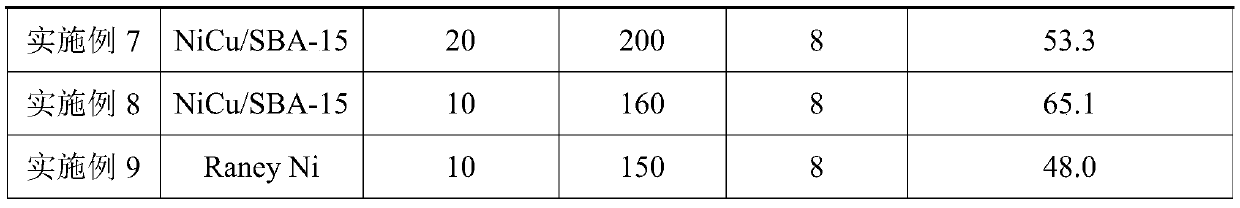

[0036] Example 6-9: Preparation of cyclopentanone

[0037] In the autoclave, using water as solvent, furfural in Raney Ni (CAS: 7440-02-0) or NiCu / SBA-15 (the mass content of Ni is 10%, the NiCu / SBA-15 with equal metal molar concentration was prepared by impregnation method. Under the action of SBA-15 catalyst), it is converted into cyclopentanone by selective hydrogenation rearrangement reaction. The specific parameters and the yield of the target product cyclopentanone are shown in Table 2.

[0038] Table 2

[0039]

[0040]

Embodiment 10-13

[0041] Examples 10-13: Preparation of 1-hydroxy-2,5-hexanedione

[0042] In an autoclave, using water as a solvent, 5-hydroxymethylfurfural was selectively hydrogenated to 1-hydroxy-2,5-hexane under the action of a Pd / C or Ru / C catalyst with a metal loading of 5%. diketone. The specific parameters and the yield of the target product 1-hydroxy-2,5-hexanedione are shown in Table 3.

[0043] table 3

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com