A system for transporting biomass material and a method for preventing blow back in said system

a biomass material and system technology, applied in the field of biomass material transportation system and a method for preventing blowback in the system, can solve the problem that minor amounts of gas will always be able to penetrate the plug, and achieve the effect of reducing the risk of blowback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

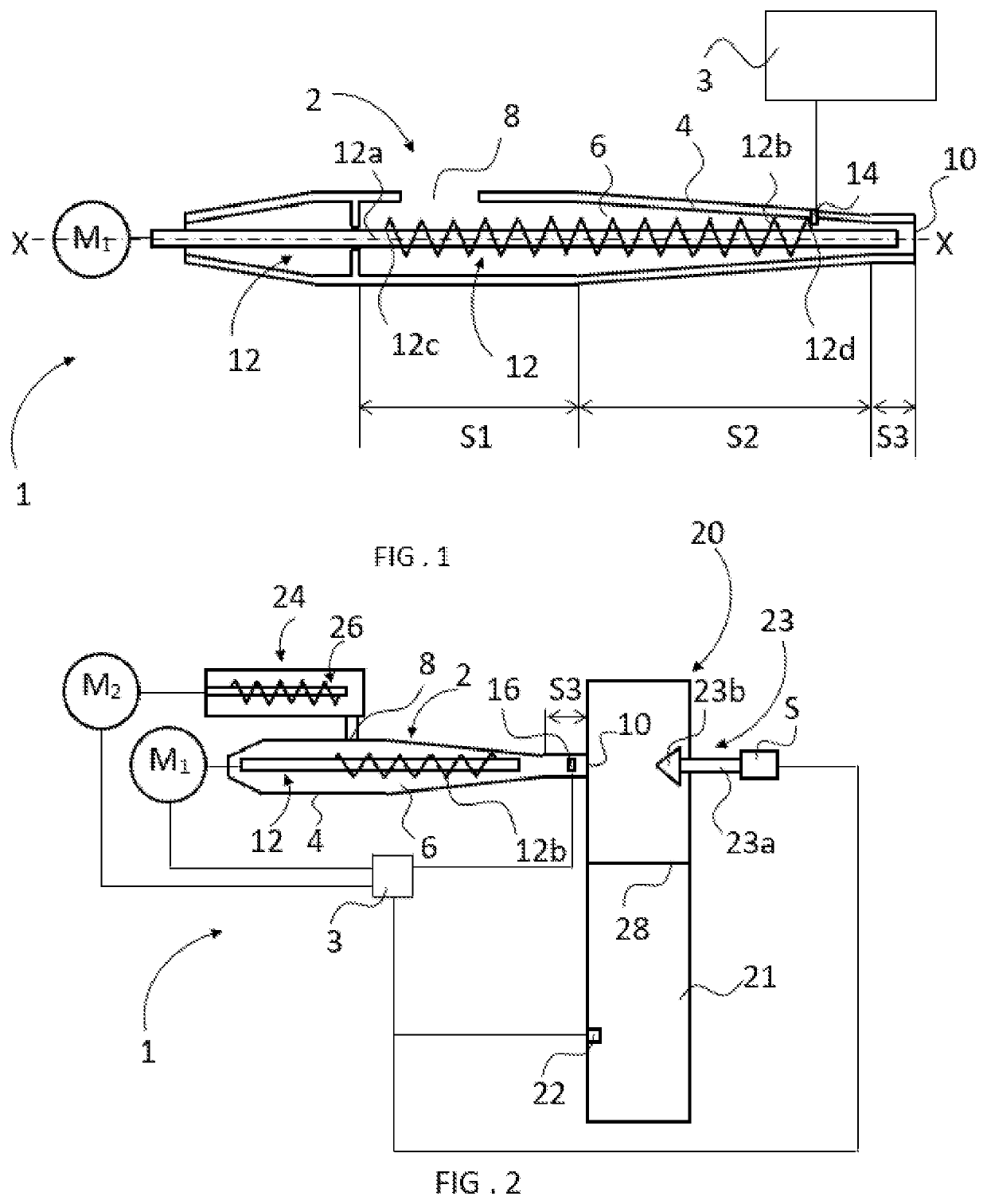

[0045]FIG. 1 illustrates a system 1 according to the invention comprising a feeding device 2 in the form of a plug screw feeder and a control unit 3.

[0046]The feeding device 2 comprises a housing 4 that defines a channel 6 that extends along a longitudinal axis X of the feeding device 2. The channel 6 is divided into an inlet section 51, an intermediate section S2 and an outlet section S3. The inlet section 51 comprises an inlet 8 for biomass material and the outlet section S3 comprises an outlet 10 for biomass material. The inlet 8 is adapted to be connected to a feeding device (not shown) for feeding 25 biomass into the channel 6. Such a feeding device may, for example, comprise a force feed screw adapted to transport the biomass towards the inlet 8. The outlet 10 is adapted to be connected to a charger (not shown) to allow the biomass to be discharged from the channel 6 and into said charger.

[0047]A feed screw 12 extends into the housing 4 along the longitudinal axis X of the fee...

second embodiment

[0053]FIG. 2 is a schematic view of a system 1 according to the invention. The system 1 comprises a feeding device 2 similar to the feeding device 2 in FIG. 1, the only difference being that the primary measuring unit 16 in FIG. 2 is a strain gauge (schematically shown) attached to an outside of the housing 4 of the feeding device 2. The electric resistance of the primary measuring unit 16 varies with the length of the primary measuring unit 16 and thus the length of the corresponding part of the housing 4, and the length of the corresponding part of the housing 4 varies with the radial pressure that the plug of biomass exerts on the inside of the channel 6, wherefore the electric resistance is a variable that is indicative of the radial force applied by the plug of biomass and thus also the gas permeability of the plug of biomass. The primary measuring unit 16 in FIG. 2 is arranged within the outlet section S3 close to the outlet 10.

[0054]The system 1 also comprises a feeding devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com