Fuel-oil refining device

a technology of fuel oil and refining device, which is applied in the field of fuel oil refining device, can solve the problems of poor fluidity at ambient temperature, low grade quality of petroleum products, and high viscosity, and achieve the effects of reducing moisture removal processing capacity and processing time, easy recovery of physical properties of fuel oil, and maximizing moisture removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

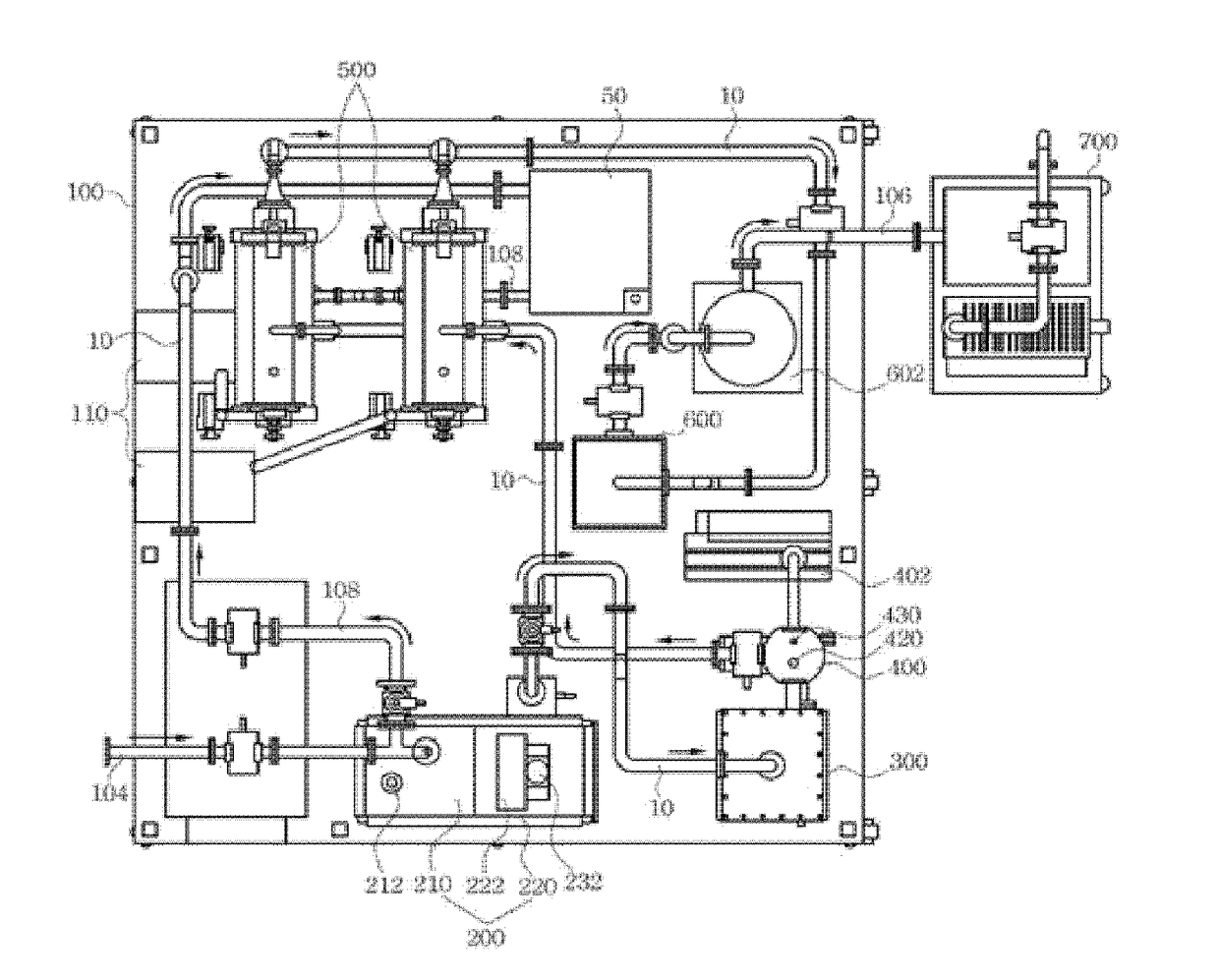

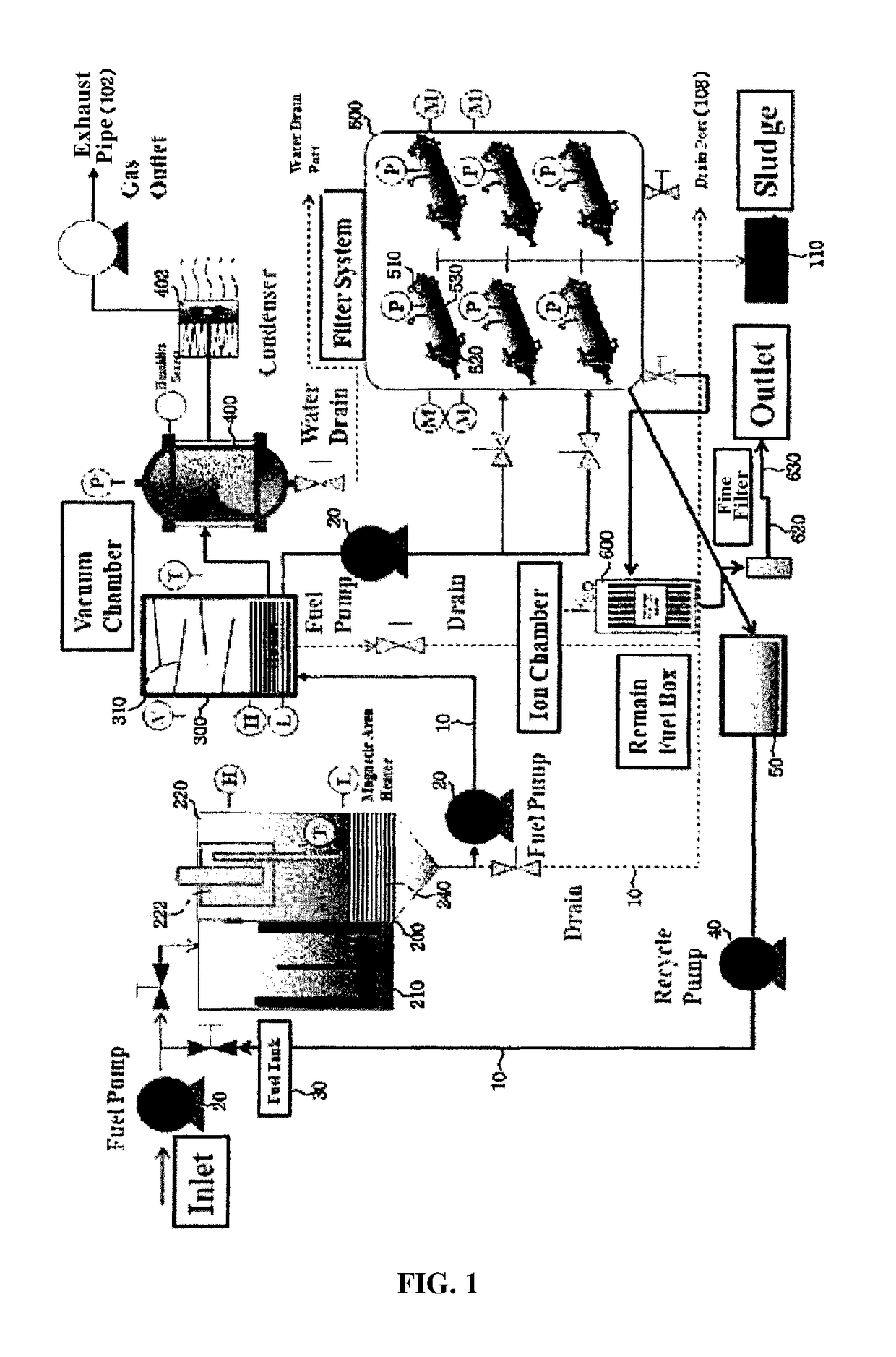

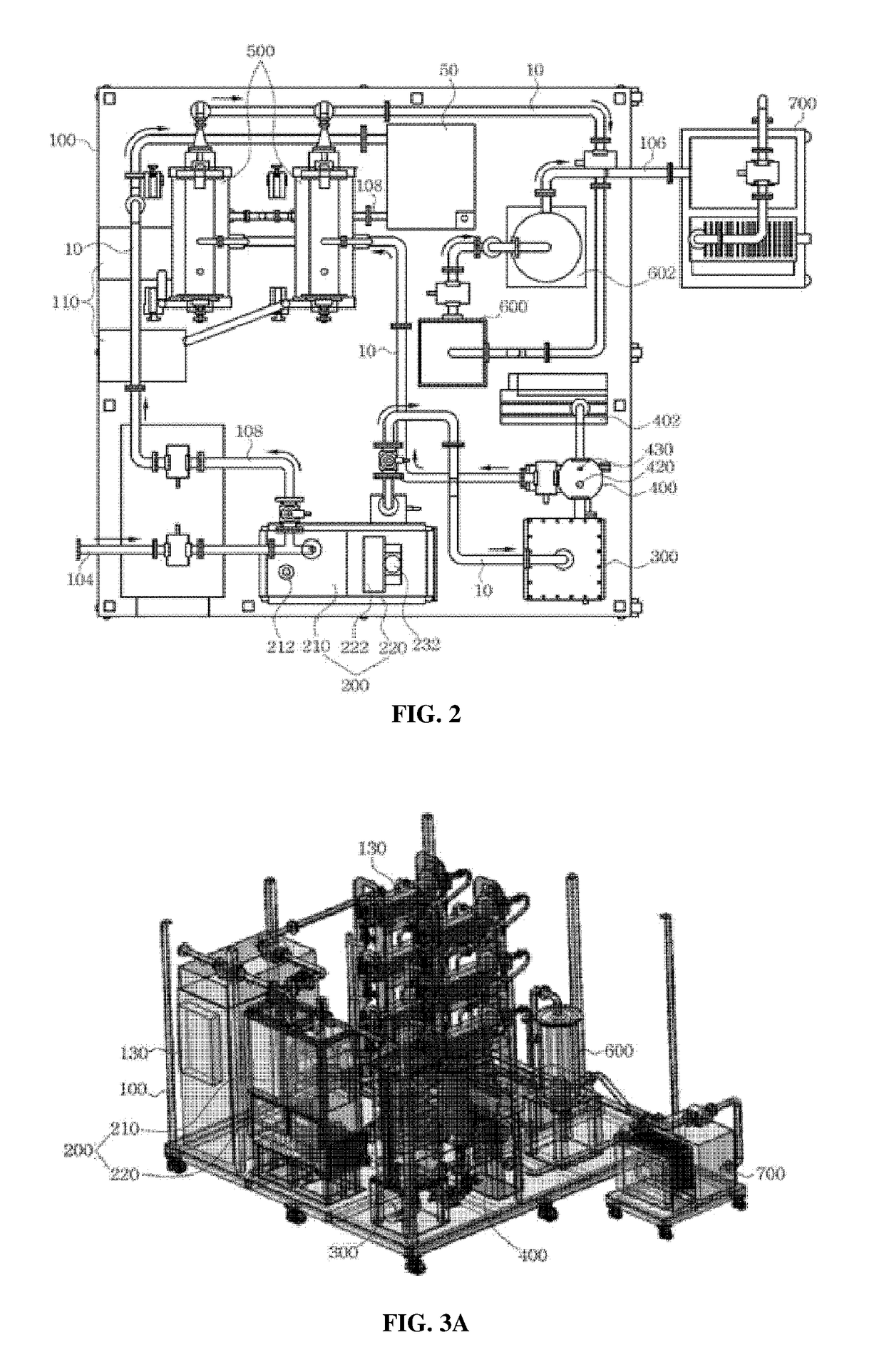

Image

Examples

Embodiment Construction

[0032]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In adding reference numerals to constituent elements in respective drawings, the same reference numerals are used for the same constituent elements across various figures. Further, in explaining the present invention, detailed description of well-known technology and typical technology incorporated herein may be omitted to avoid obscuring the subject matter of the present invention.

[0033]Further, in explaining the constituent elements of the present invention, the terms “first, second, A, B, (a), and (b)” may be used. The terms are used only to discriminate a constituent element from other constituent elements, and the essence, turn, or order of the corresponding constituent element is not limited by the terms. It should be understood that the term “connected to”, “coupled to”, or “contact with” that is used to designate a connection, coupling, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com