A flexible mechanism topology optimization design method based on adaptive constraint

A topology optimization and flexible mechanism technology, applied in constraint-based CAD, design optimization/simulation, calculation, etc., can solve problems such as single hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The present invention provides a flexible mechanism topology optimization design method based on adaptive constraints, see Figure 11 , including the following steps:

[0075] S1: Given the initial design area, divide the finite element grid, and give boundary conditions, load cases and other conditions.

[0076] S2: Read the fixed finite element grid model file of the design area, read the current structure reserved element data file, form a layer of artificial material elements with small topological variable values around the structure and holes, and automatically form the current effective structure limited The meta-model generates and saves the mapping relationship data file between the grid model of the largest design area and the effective grid model of the current structure.

[0077] S3: Apply unit virtual load at the output end, and perform finite element analysis to obtain displacement vector data under actual load and unit virtual load. By reading the map...

Embodiment 2

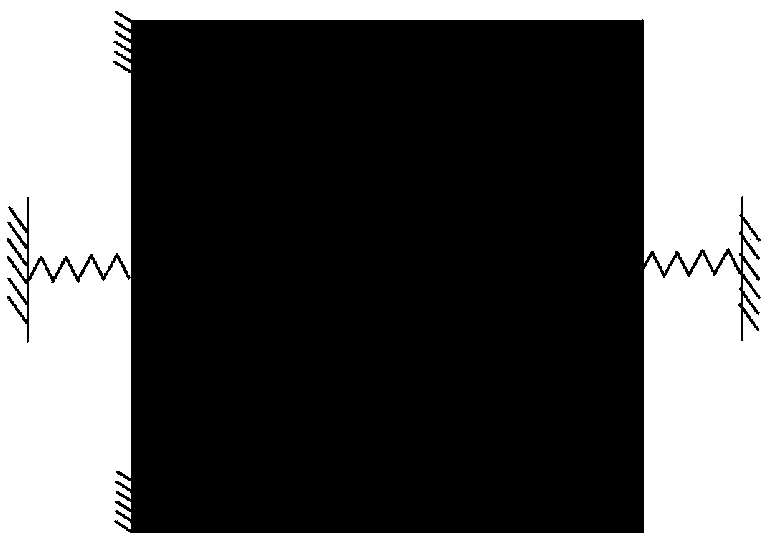

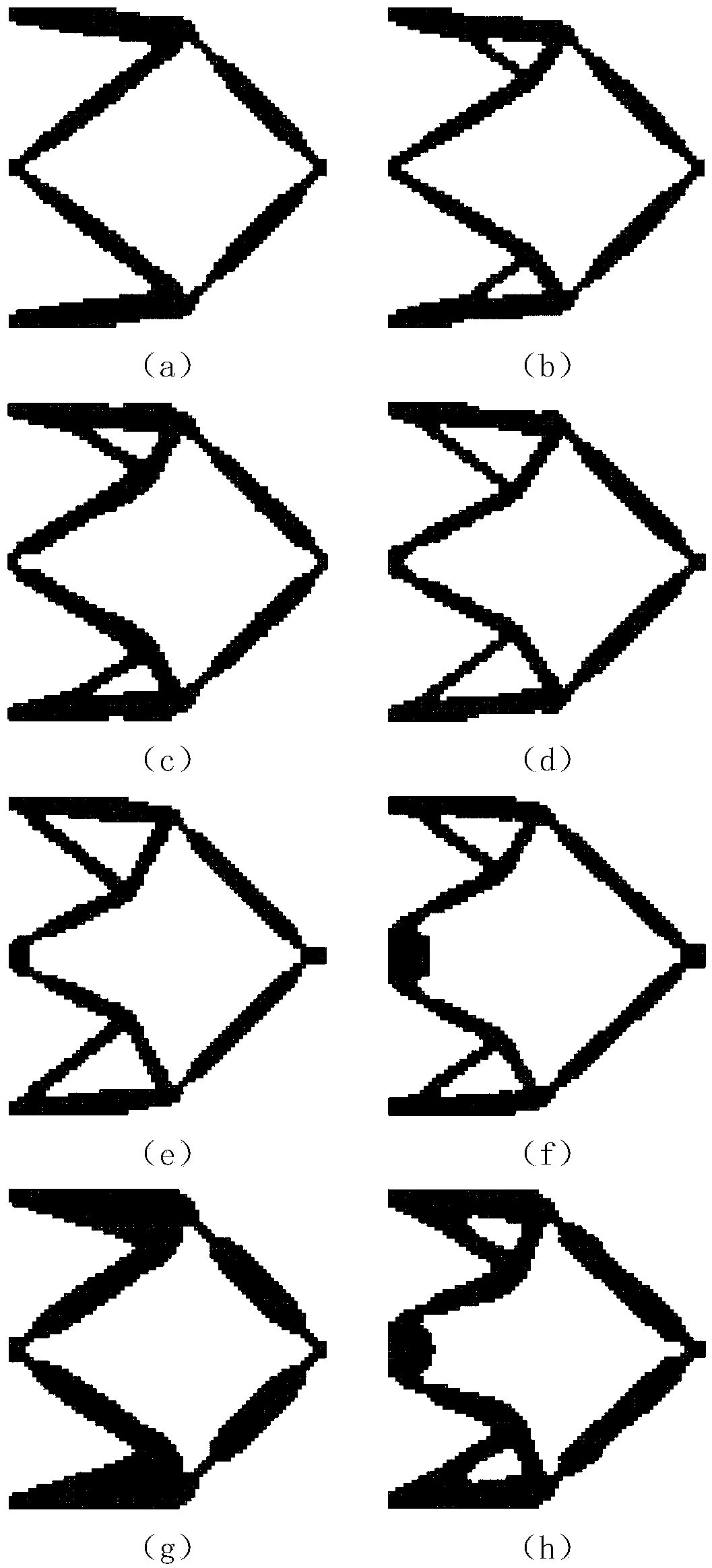

[0099] This embodiment proposes a single-input single-output displacement reverse flexible mechanism, the size of the initial mechanism is 0.4m×0.4m×0.05m, and the elastic modulus of the material is 2.09×10 14 pa, Poisson's ratio is 0.3. The upper and lower parts on the left side of the mechanism are fixed-end constraints, the input force acts on the left midpoint, its magnitude is 20000N, the direction is rightward, and the stiffness is 2.0×10 8 The N / m spring replaces the workpiece that the input end is in contact with the mechanism; the middle point on the right is the displacement output end, and the stiffness is 2.0×10 8 The N / m spring replaces the workpiece where the output end is in contact with the mechanism, figure 1 It is a schematic diagram of the initial design domain, force and boundary conditions of the displacement inversion mechanism. figure 1 where F is the force acting on the input. The goal of the optimal design of this example is to maximize the displace...

Embodiment 3

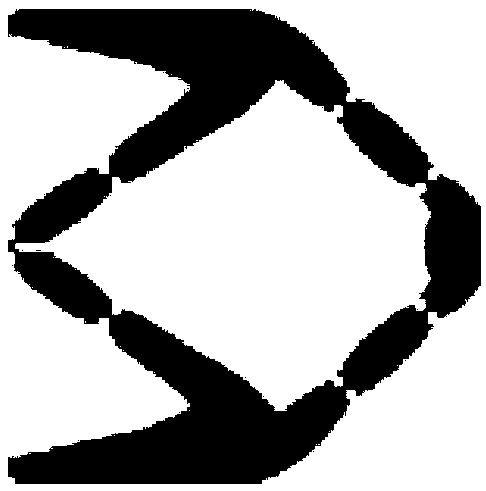

[0101] This embodiment proposes a micro-clamping mechanism, the design domain size of the mechanism is 500 μm × 500 μm × 10 μm, and the elastic modulus of the material is 1.9 × 10 11 pa, Poisson's ratio is 0.3. The upper and lower parts on the left side of the mechanism are fixed-end restraints, the input force acts on the midpoint on the left side, the size is 0.1mN, and the workpiece with the input end and the mechanism is replaced by a spring with a stiffness of 10.0N / m; the size of the gap on the right side is 100μm ×100μm, the upper and lower points of the notch are the displacement output ends, and the springs with a stiffness of 1000.0N / m are used to replace the workpieces in contact with the mechanism at the output end. Figure 4 It is a schematic diagram of the initial design domain, force and boundary conditions of the micro-clamping mechanism. The optimal design goal of this example is to maximize the absolute value of the difference between the two displacements a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com