Through-hole connection method and connection structure of titanium aluminum turbine impeller and rotating shaft

A turbine impeller and through-hole connection technology, which is applied in the direction of blade support components, engine components, machines/engines, etc., to achieve the effects of easy mass production, reduced core stress, and durable and reliable connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

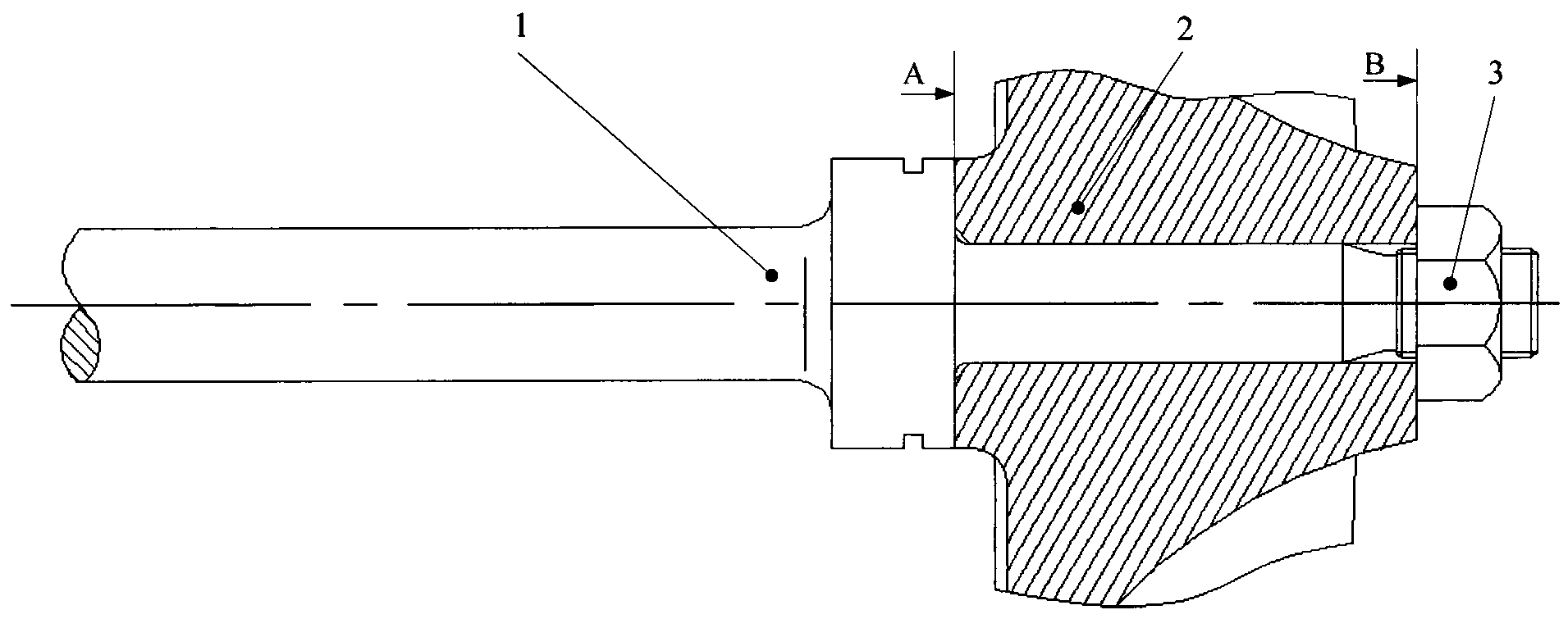

[0019] A through-hole connection structure between a titanium-aluminum supercharger turbine impeller and a rotating shaft, including a titanium-aluminum turbine impeller, a rotating shaft, and a high-temperature-resistant homogeneous lock nut, the rotating shaft and the titanium-aluminum turbine impeller are connected through a through-hole, and the titanium-aluminum turbine impeller There is a through hole in the center, and there is a transition fit or clearance fit between the shaft and the through hole of the turbine impeller. The high temperature homogeneous nut is locked on the turbine end.

[0020] In order to increase the reliability of the connection between the impeller and the rotating shaft, it is preferable that the thread at the end of the rotating shaft go deep into the through hole of the turbine impeller for 3-5 pitches, which can make the lock nut and the rotating shaft more tightly clamp the turbine impeller and ensure the connection between the turbine impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com