Runoff type supercharger turbine rotating shaft structure and molding process thereof

A turbocharger turbine and shaft structure technology, which is applied in the direction of machines/engines, blade support components, engine components, etc., can solve the difficult problems of reliable connection of turbocharger turbine shafts, so as to improve the allowable operating speed, reliable Connection, the effect of improving the connection rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

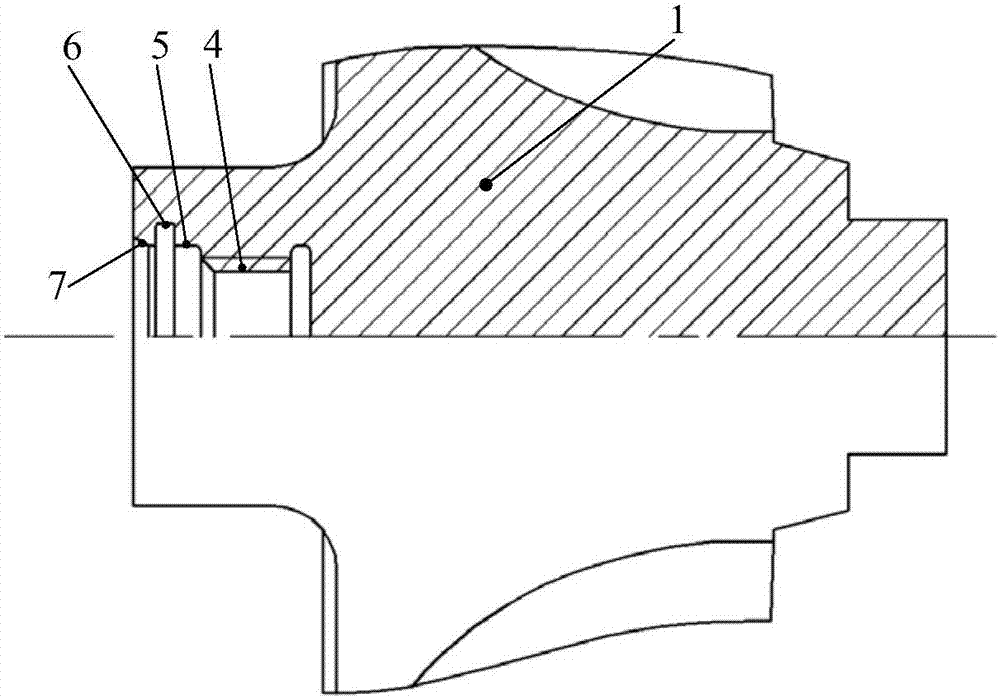

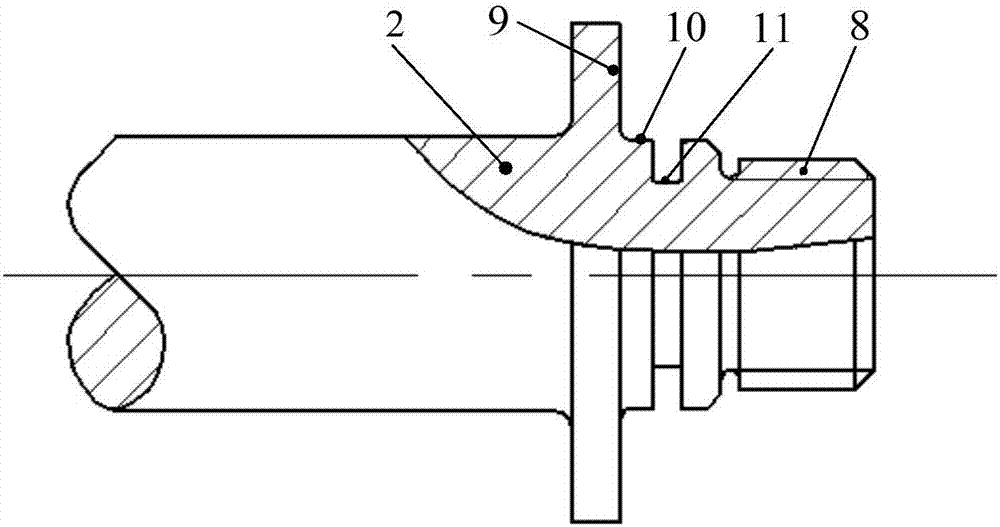

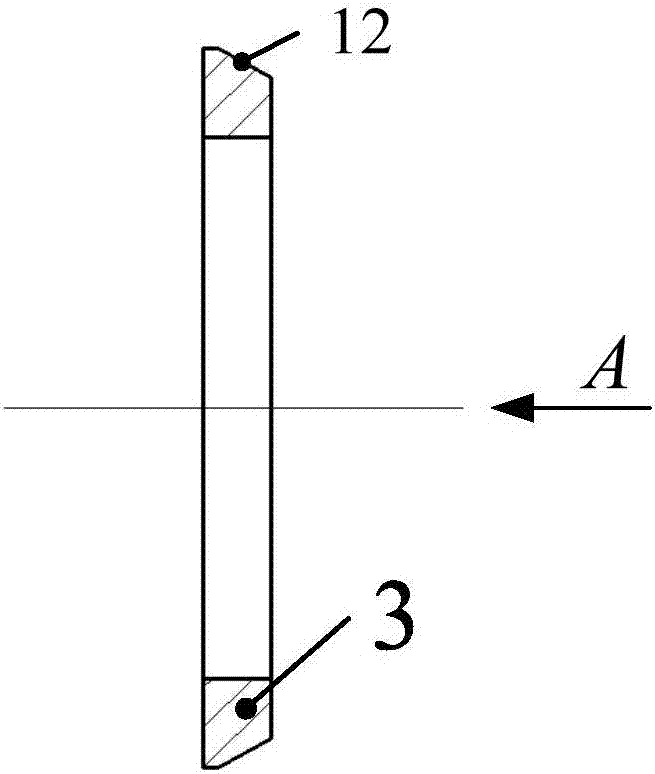

[0028] A radial supercharger turbine shaft structure, including a turbine 1, a shaft 2 and a self-locking ring 3, such as figure 1 As shown, one end of the turbine 1 connected to the rotating shaft 2 is provided with a turbine internal thread blind hole 4, and the bottom of the turbine internal thread blind hole 4 is provided with a process ring groove, and the thread of the internal thread blind hole 4 of the turbine 1 The direction of rotation is opposite to the direction of rotation when the turbine shaft works; a section of turbine light hole 5 is provided between the end surface of the turbine 1 close to the shaft 2 and the blind hole 4 of the internal thread of the turbine, and the turbine light hole 5 is provided with a hole for assembling The turbine ring groove 6 of the lock ring 3, the diameter of the turbine light hole 5 is larger than the internal thread bottom diameter of the turbine internal thread blind hole 4, and the end surface of the turbine light hole 5 nea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com