Coupling method for suspended-core optical fibers

A technology of coupling connection and suspension core, which is applied in the field of optical fiber and can solve the problems that do not involve single-core fiber coupling and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0033] Include the following steps:

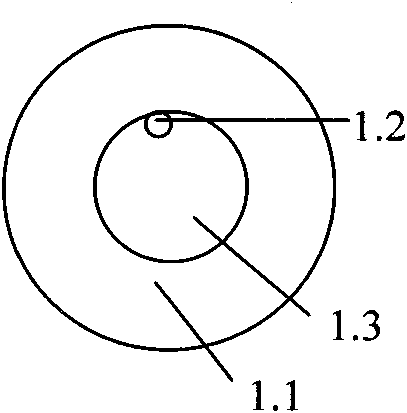

[0034] 1. If Figure 1-b For the suspended core optical fiber shown, peel off the coating layer at one end, and then clean it. During the cleaning process, prevent liquid from entering the hollow cavity of the suspended core optical fiber;

[0035] 2. Carefully cut out the flat suspension core fiber end face;

[0036] 3. Prepare the fiber end of the standard single-core fiber to be connected according to the same steps above;

[0037] 4. Put the prepared section of quartz protective tube on one end of standard single-core optical fiber or suspended core optical fiber;

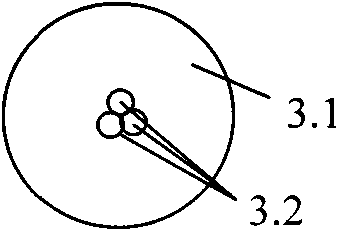

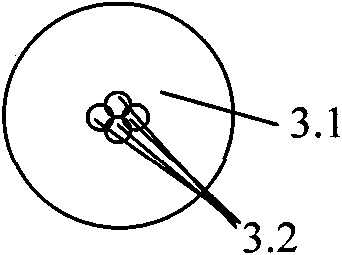

[0038] 5. Butt and weld the prepared two optical fiber ends on the optical fiber welding machine, such as figure 2 As shown; the electrode high-voltage discharge causes the air cavity of the suspended core fiber after welding to collapse under the action of surface tension, and the cross-section of the solder joint forms a double-core solid fiber with two cores located i...

Embodiment ( 2

[0041] The second embodiment of the present invention is realized in the process of making and implementing, including the following steps:

[0042] 1. Take as Figure 1-f For the suspended core optical fiber shown, peel off the coating layer at one end, and then clean it. During the cleaning process, prevent liquid from entering the hollow cavity of the suspended core optical fiber;

[0043] 2. Carefully cut out the flat suspension core fiber end face;

[0044] 3. Prepare the fiber end of the standard solid single-core fiber to be connected according to the same steps above;

[0045] 4. Put the prepared section of quartz protective tube on one end of standard single-core optical fiber or suspended core optical fiber;

[0046] 5. Butt and weld the prepared two optical fiber ends on the optical fiber welding machine, such as figure 2 As shown; the electrode high-voltage discharge causes the air cavity of the suspended core fiber after welding to collapse under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com