Assembly type framework beam anchor cable supporting structure and construction method thereof

A supporting structure and assembled technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., to achieve the effect of speeding up construction, reducing construction difficulty and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

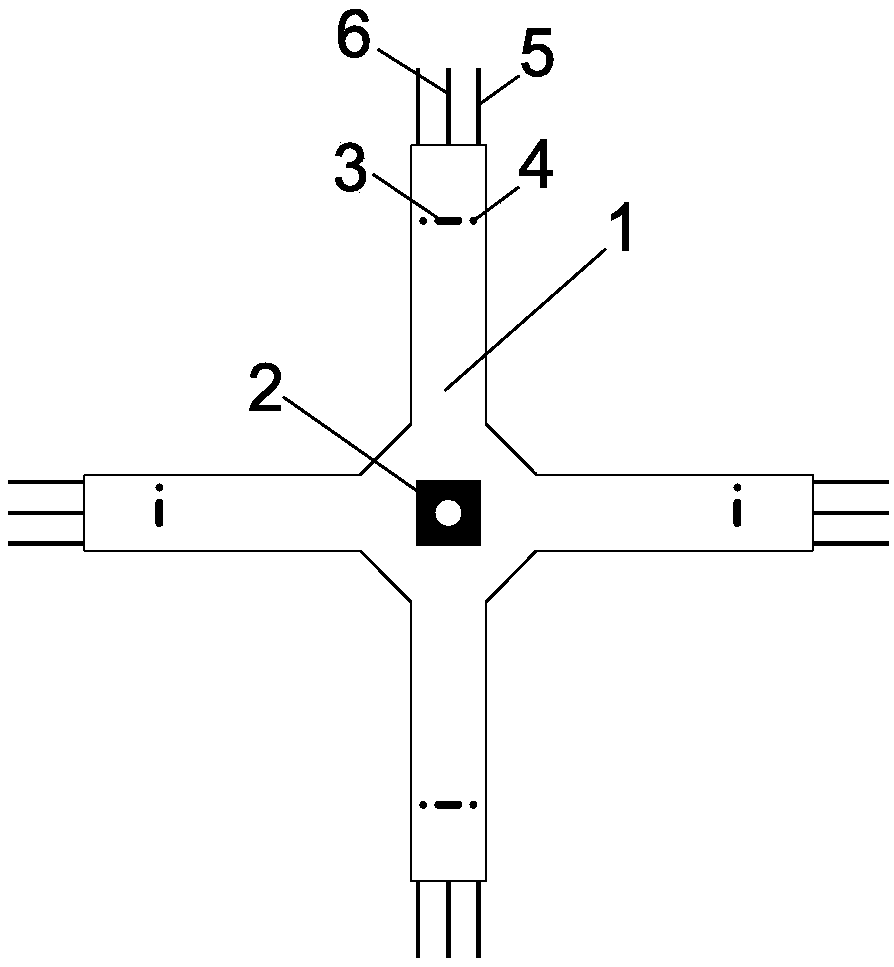

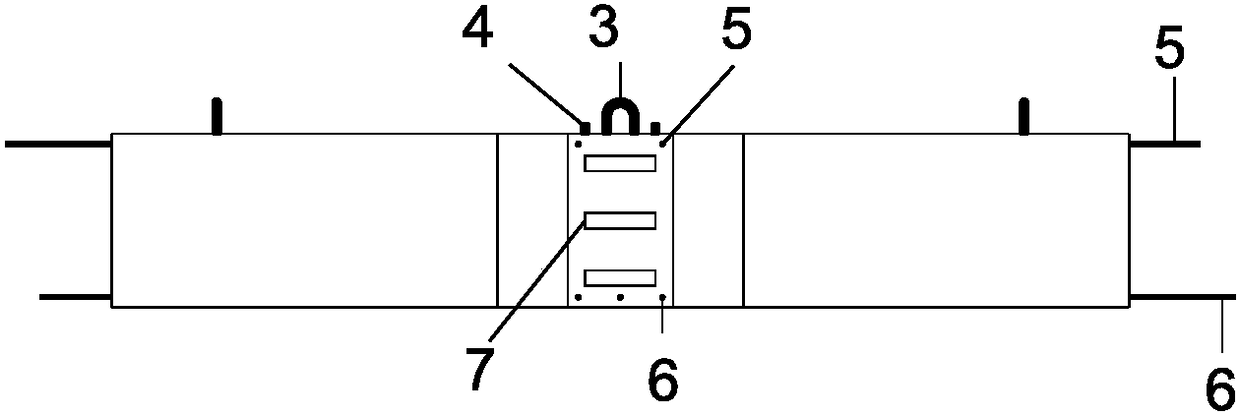

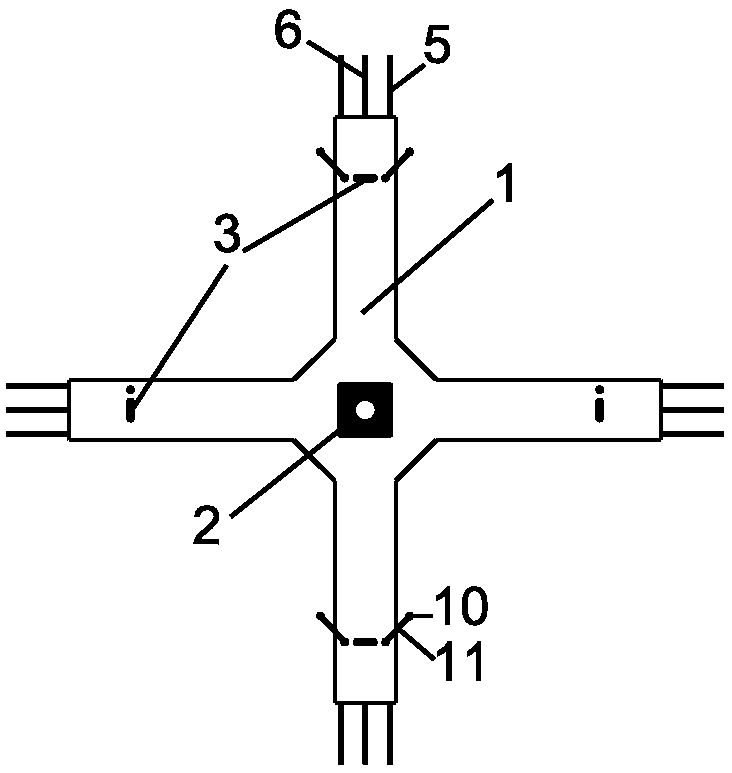

[0043] Such as Figure 1-8 As shown, a prefabricated frame beam anchor cable support structure includes a prefabricated frame beam 1, prestressed anchor cables 17, soil nails 12 evenly distributed on the support surface layer and guest soil spraying surface 16; the prefabricated frame The beam 1 is composed of several interconnected prefabricated cross beams, the upper and lower full-length steel bars 5 and 6 are arranged inside the cross beams and vertical beams of the prefabricated cross beams, and the two ends of the cross beams and the vertical beams are pre-embedded with The hook 3 and the fixed steel bar 4 are provided with an anchor cable hole in the center of each prefabricated cross beam; the upper full-length steel bar joints between the prefabricated cross beams are connected to each other through a mechanical connection joint 8, and the lower full-length steel bar joints are connected to each other through a mechanical connection joint 8 Connection, concrete is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com