Modularizing transformation method of convection section of ethylene cracking furnace and convection section module of the ethylene cracking furnace

A technology of ethylene cracking furnace and convection section, which is used in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of poor installation quality and long installation period, shorten the construction period, reduce construction difficulty, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

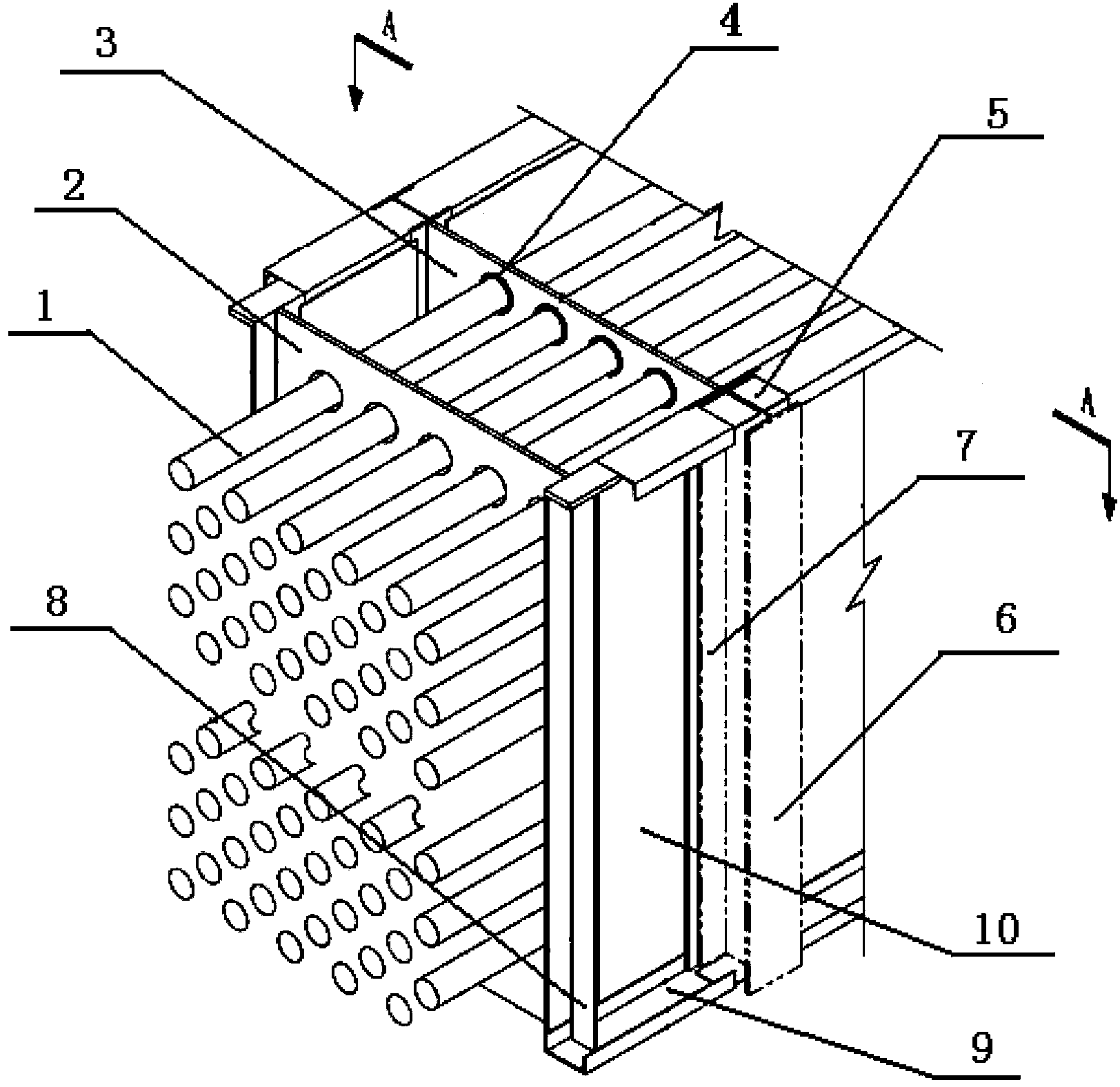

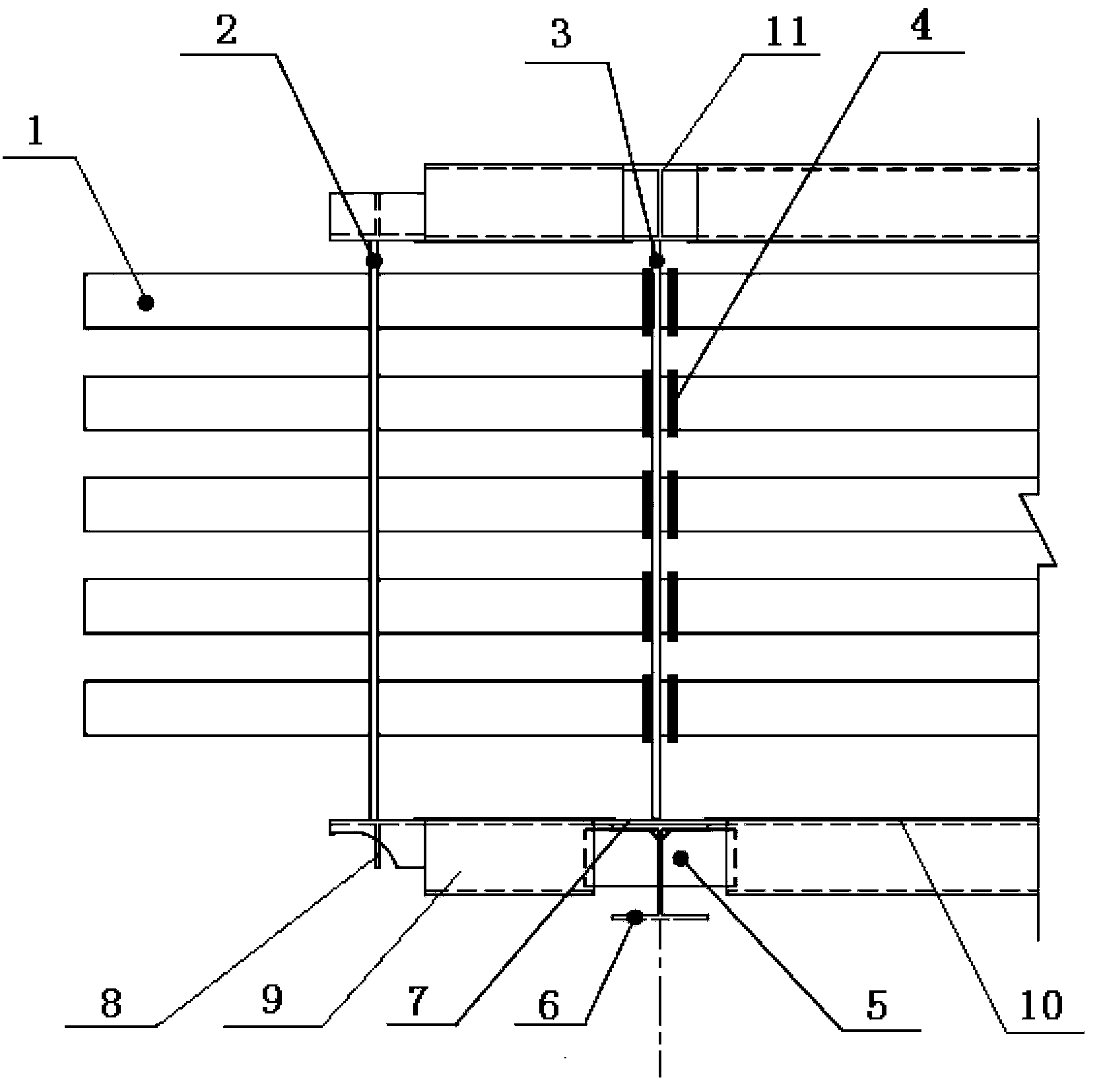

[0058] Such as figure 1 , figure 2 As shown, the figure only shows a part of the modular structure of the convection section, and there are other recycling modules in the upper and lower parts; and, the figure is a simplified drawing, and the heat exchange tube bundles 1 are not connected in the figure. In fact, Each heat exchange tube bundle 1 is connected by an elbow, that is, the material flows in the coil.

[0059] A method for modular transformation of the convection section of an ethylene cracking furnace. The method prefabricates each component in the convection section of an ethylene cracking furnace into an integrated convection section module according to the design requirements by recycling the first bearing column 6, and The convection section module is fixedly connected to the first bearing column 6 on site to complete the modular transformation of the convection section of the ethylene cracking furnace.

[0060] The concrete steps of described method are:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com