Frame type unit curtain wall adopting auxiliary installing rack, tooth profile angle and tooth profile support

A unit curtain wall, toothed angle technology, applied in the direction of walls, building components, covering/lining, etc., can solve the problems of large consumption of profiles and sealants, high cost, limited service life of rubber strips, etc. The effect of connecting materials, reducing adjustment difficulty, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

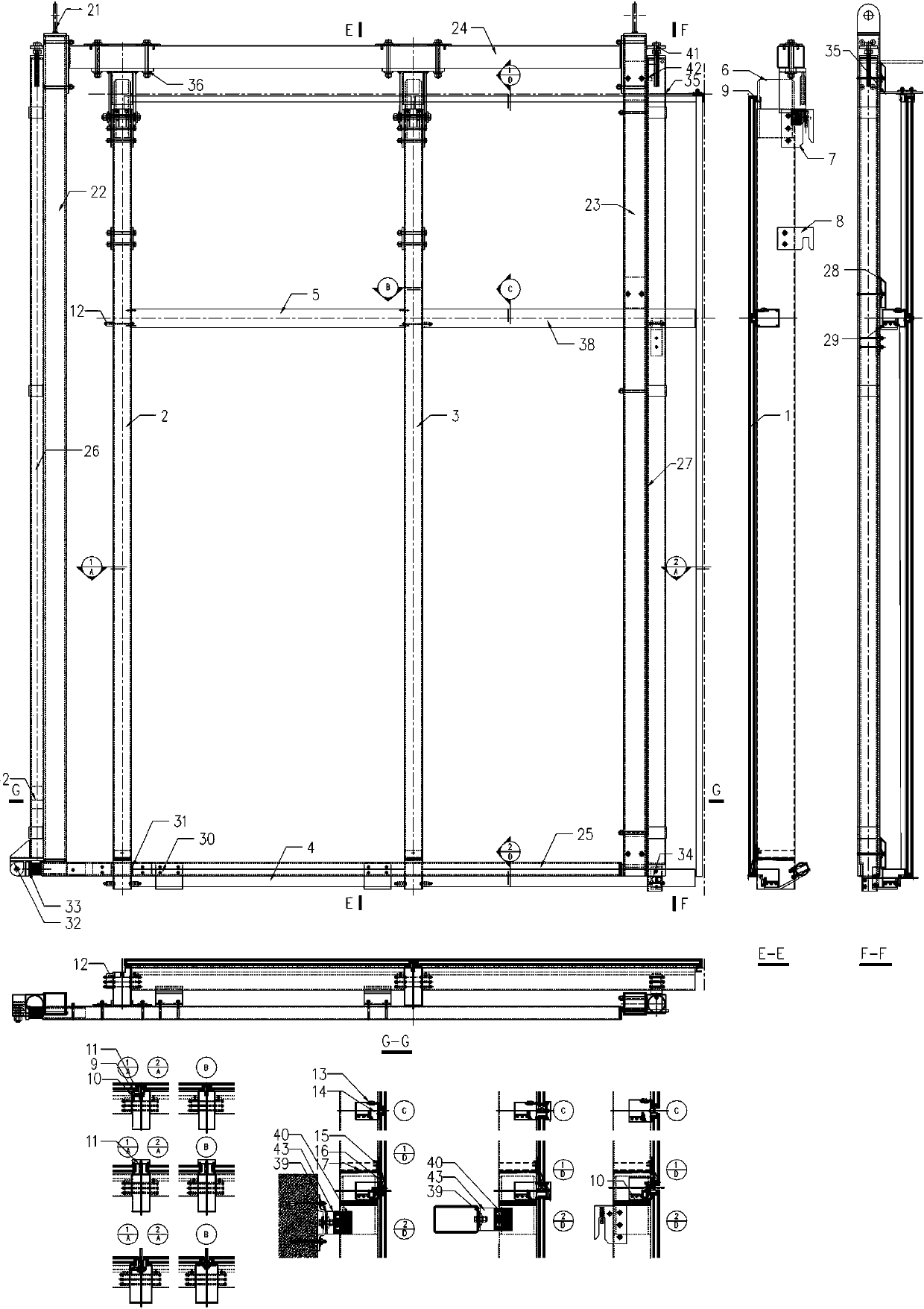

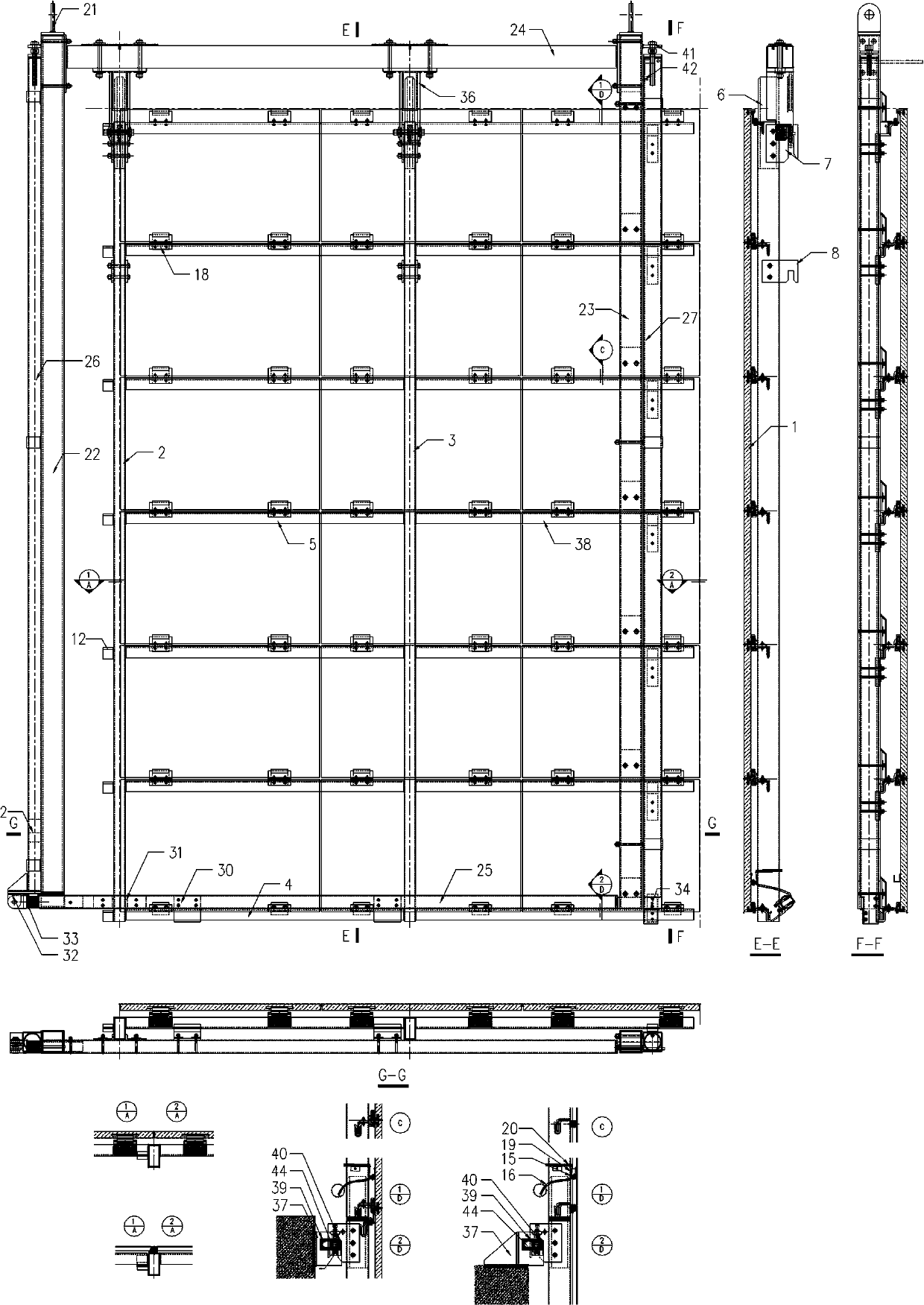

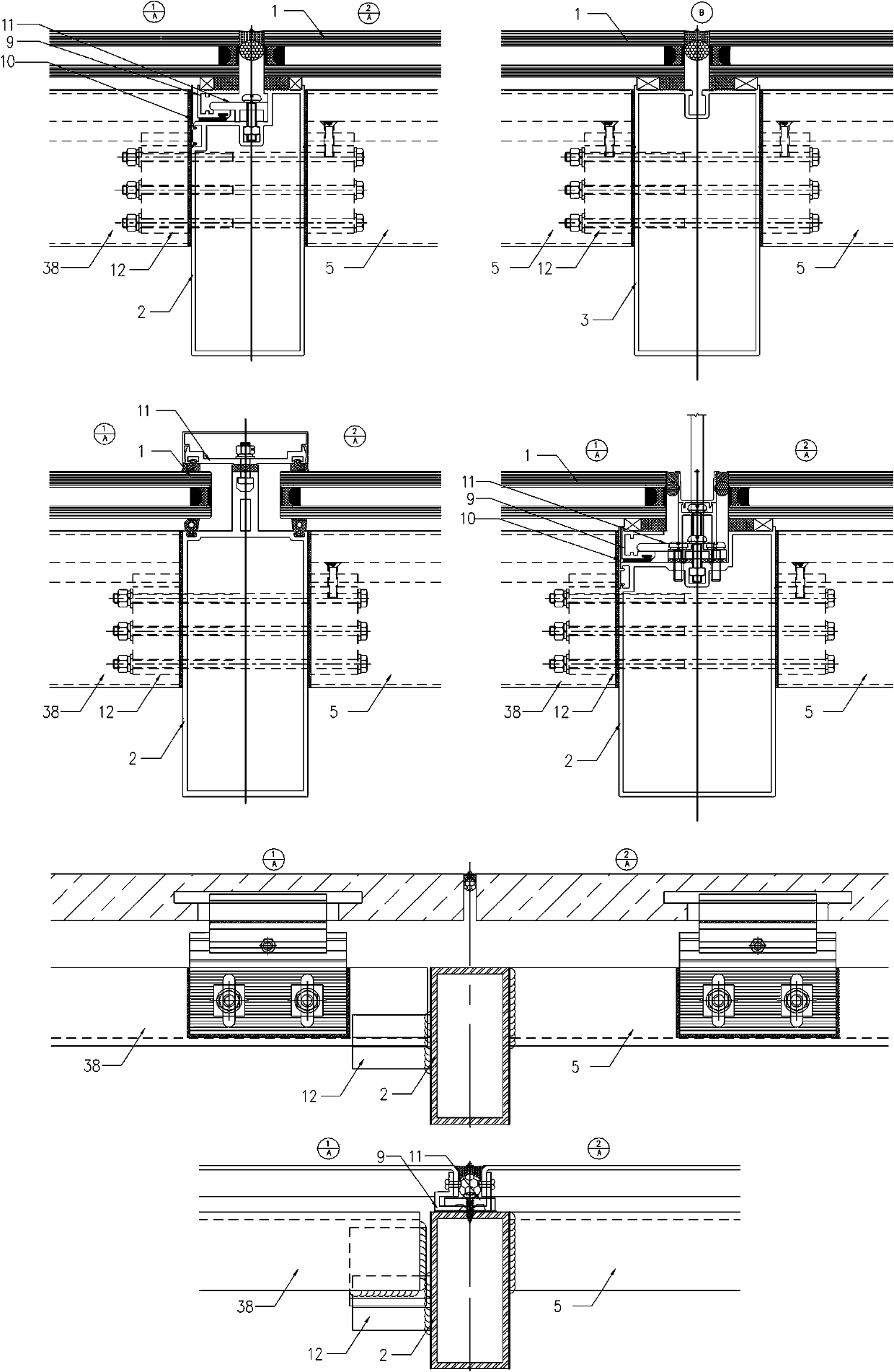

[0058] A frame-type unit curtain wall and a toothed corner code and a toothed support using an auxiliary mounting frame, including: a panel 1, an end column 2, a middle column 3, an end beam 4, a middle beam 5, a ferrule 6, an attachment Frame 9, cover plate 10, pressure block 11, beam hook 12, column side water hole 13, column front water collection hole 14, drainer 15, water guide pipe 16, water retaining plate 17, stone hook system 18, water collection tank 19. Water receiving bucket 20, cantilevered beam 38, adjustable positioning tooth 39, toothed pressure block 40, lateral positioning block 44, and toothed corner code and toothed support suitable for building curtain walls. like Figure 1 to Figure 8 As shown, the specific structure is:

[0059] The end column 2 and the cantilevered beam 38 of another unit plate are connected vertically through the beam hook 12, and the cantilevered beam 38 and the end column 2 slide relatively through the beam hook 12; the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com