Offshore wind power fabricated type bearing table foundation and construction method thereof

An offshore wind power, prefabricated technology, applied in infrastructure engineering, construction, etc., can solve problems such as the difficulty of leveling, and achieve the effects of saving construction costs, reducing difficulty, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

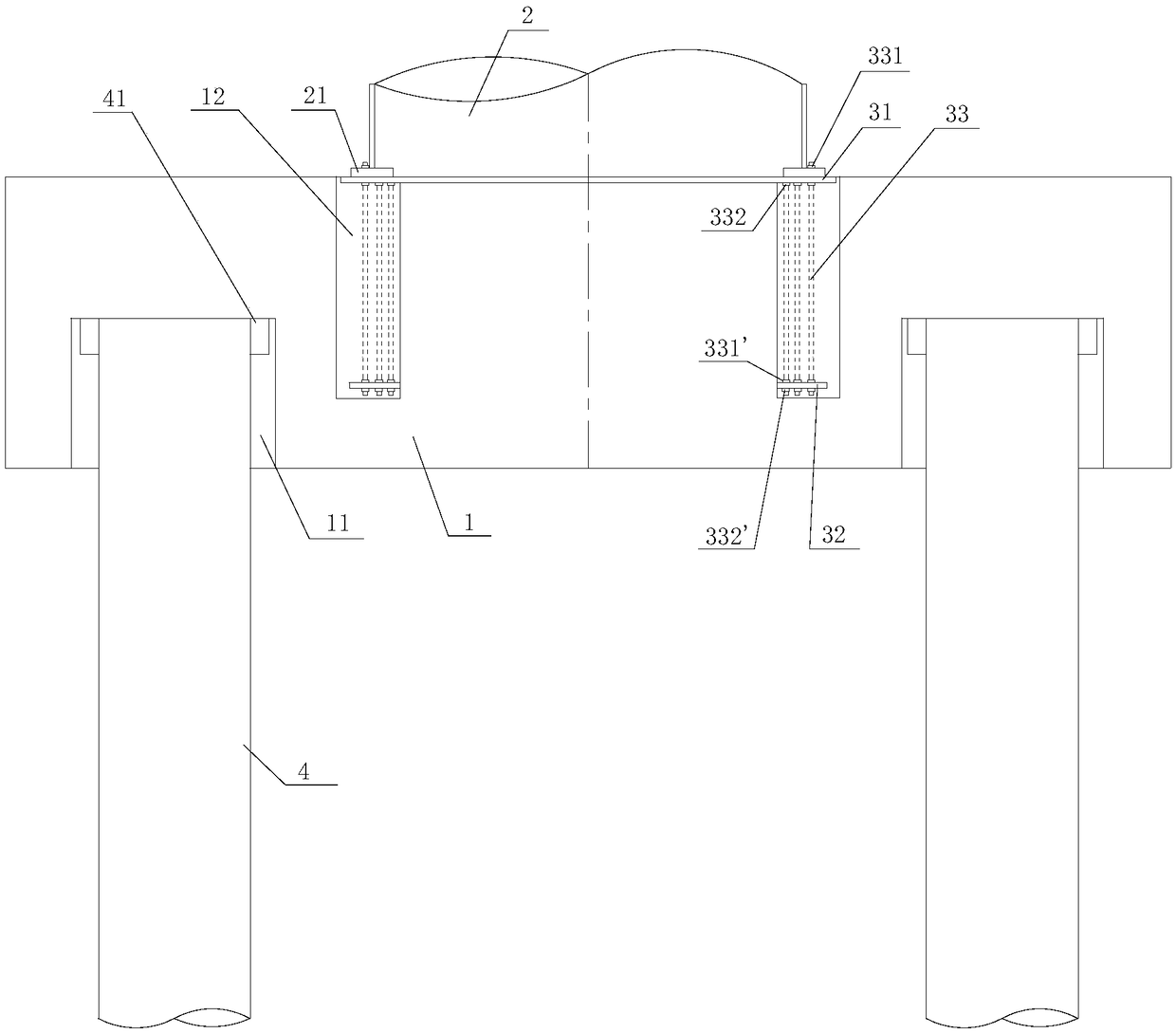

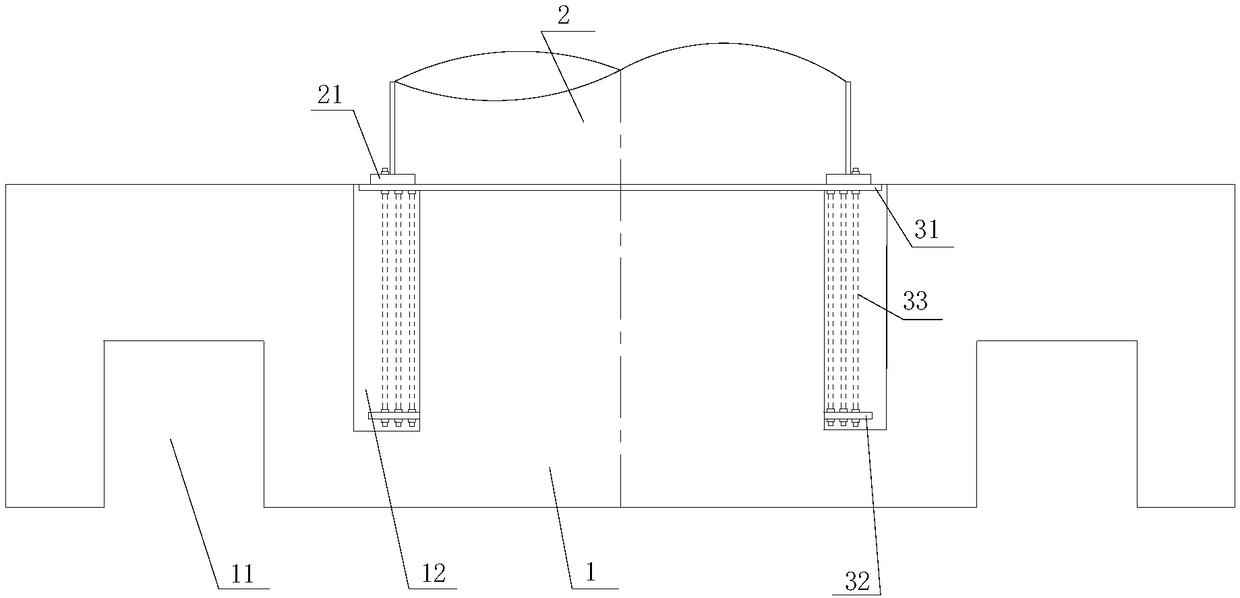

[0034] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

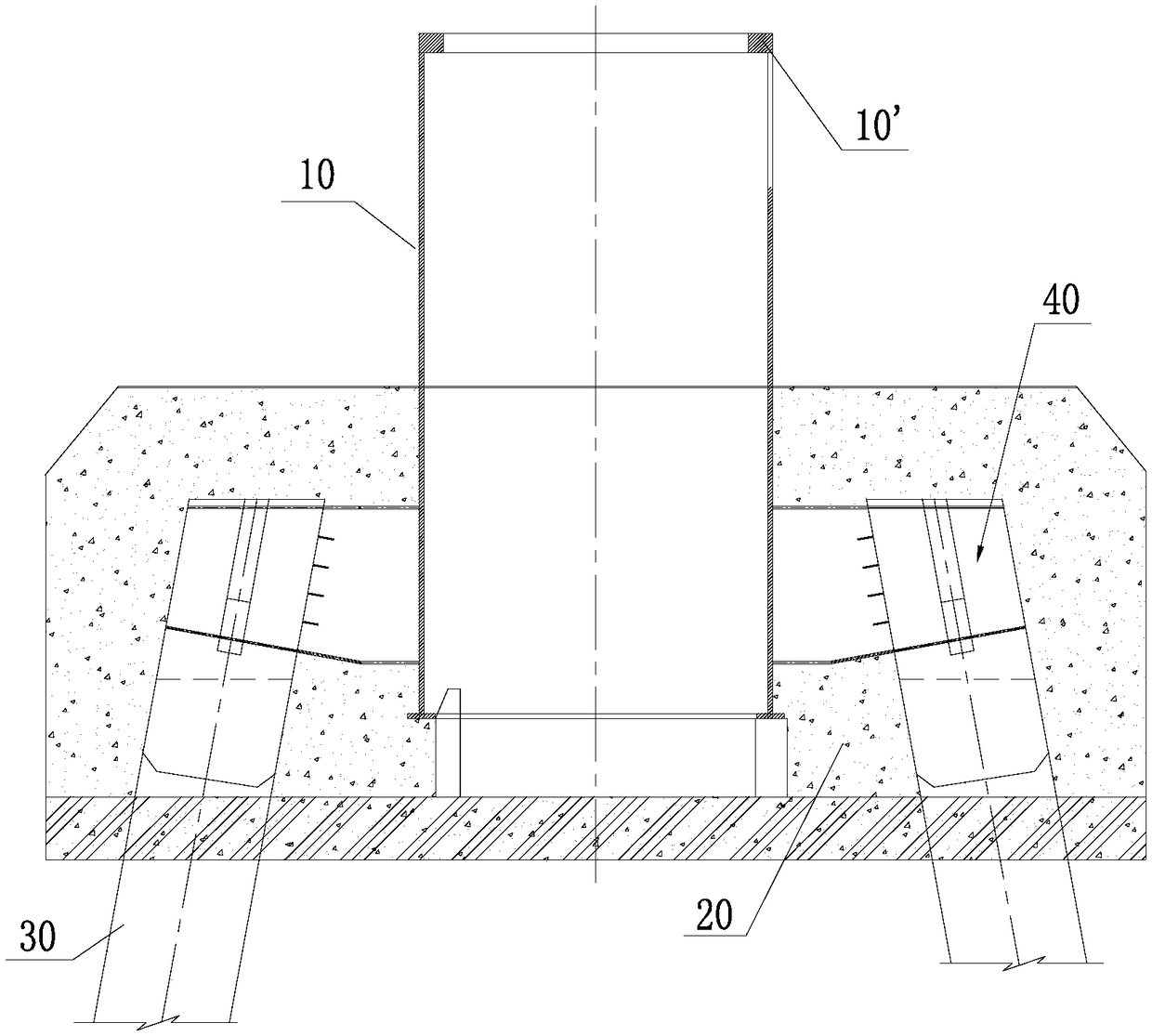

[0035] see Figure 2 to Figure 4 , the offshore wind power assembly cap foundation of the present invention includes a cap 1, an anchor mechanism 3 and several foundation steel pipe piles 4.

[0036] The cap 1 is a cylindrical prefabricated concrete cap. On the bottom surface of the cap 1, a number of cylindrical pile holes 11 are reserved evenly along a circle concentric with the cap 1. On the top surface of each pile hole 11 There is a grouting hole penetrating the top surface of the cap 1, and an annular anchor groove 12 is reserved in the center of the top surface of the cap 1;

[0037] The anchor mechanism 3 is a prestressed anchor cage, the height of the prestressed anchor cage is adapted to the depth of the anchor groove 12 on the cap 1, and the diameter is adapted to the diameter of the transition section 2 of the fan tower; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com