False cable joint

A cable dummy and cable technology, applied in the field of cable laying and installation, can solve the problems of inability to realize and the number of cable joints cannot be arbitrarily reduced, and achieve the effect of reducing the influence of induced voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

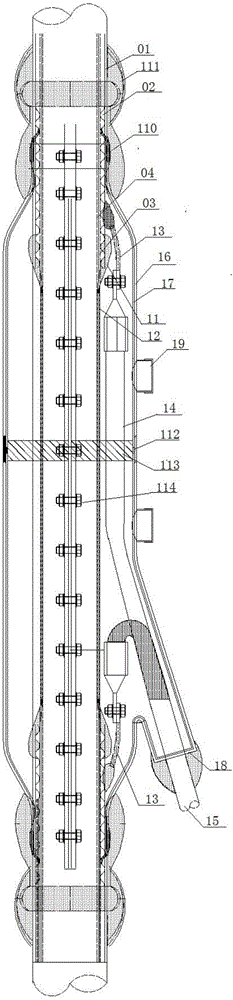

[0077] Such as figure 1 As shown, the present invention adopts the method of stripping from the outer insulating layer of the cable to the semiconductive buffer zone to make a false joint. The manufacturing method of this cable dummy joint comprises the following steps,

[0078] 1.1) Strip the part where the cable needs to be equipped with joints, and break the outer insulating layer 01, shielding sheath 02 and semi-conductive buffer strip 03; the breaking length of the outer insulating layer 01 is greater than the breaking length of the shielding sheath 02; each cable The breaking length of the layer structure depends on the voltage level. The breaking length of the outer insulating layer 01 is about 1750-2000mm, the breaking length of the shielding sheath 02 is about 1100-1750mm, and the breaking length of the semiconducting buffer belt 03 is about 700-1600mm;

[0079] 1.2) Close the breakage of the shielding sheath 02: use the semi-conductive tape 11 to wrap half-fold from...

Embodiment 2

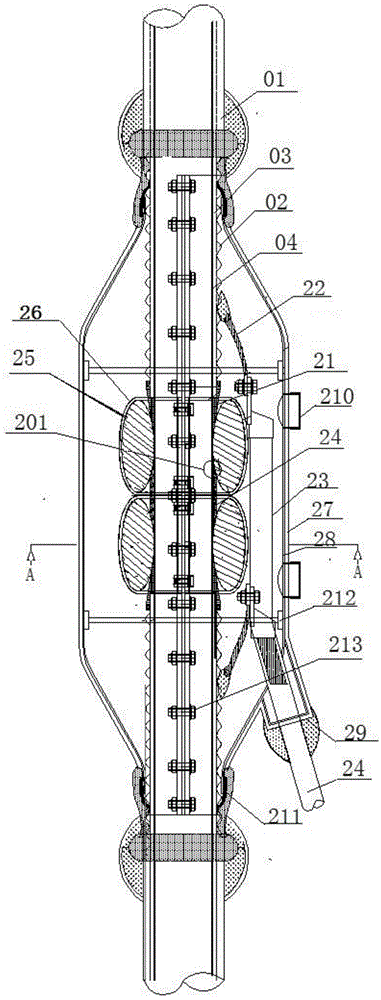

[0087] figure 2 The manufacturing method of the cable dummy joint shown includes the following steps:

[0088] 2.1) Strip the part where the cable needs to be equipped with joints, and break the outer insulating layer 01, shielding sheath 02, semi-conductive buffer strip 03 and outer semi-conductive layer 04 in sequence; the breaking length of the outer insulating layer 01 is greater than the shielding sheath The breaking length of 02, the breaking length of the shielding sheath 02 is greater than the breaking length of the semiconducting buffer zone 03, the breaking length of the semiconducting buffer zone 03 is greater than the breaking length of the outer semiconducting layer 04; the broken length of each layer of the cable depends on different voltages The grade varies, usually the breaking length of the outer insulating layer 01 is 800-1200mm, the breaking length of the shielding sheath is 350-400mm, the breaking length of the semi-conductive buffer zone is 300-350mm, an...

Embodiment 3

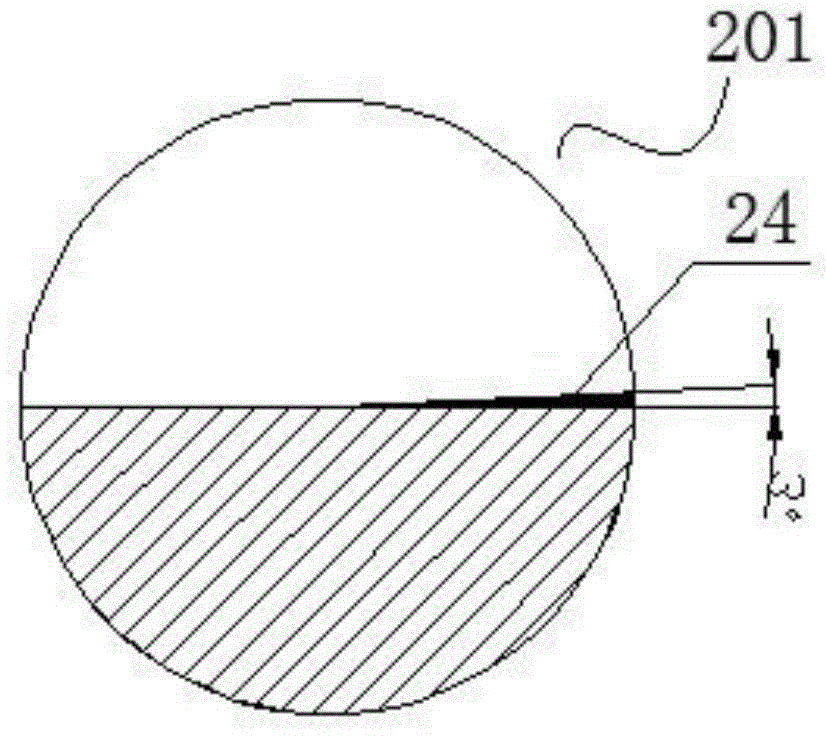

[0100] image 3 The cable dummy joints shown can be used in cable laying construction with low voltage level, generally 110KV and below systems. Its preparation method comprises the following steps:

[0101] 3.1) Strip the part where the cable needs to be equipped with joints, and break the outer insulating layer, shielding sheath, semi-conductive buffer zone and outer semi-conductive layer in sequence; the breaking length of the outer insulating layer is greater than the breaking length of the shielding sheath, and the shielding The breaking length of the sheath 02 is greater than that of the semiconducting buffer zone, and the breaking length of the semiconducting buffer zone is greater than that of the outer semiconducting layer; the breaking length of each layer of the cable is adjusted according to the voltage level. The breaking length is 800-1200mm, the breaking length of the shielding sheath is 350-400mm, the breaking length of the semi-conductive buffer belt is 300-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com