Grouting steel pipe connection device structure and connection method

A technology for device structure and grouting pipe, which is applied in building construction, construction, and building material processing, etc., can solve the problems of high technical level requirements of construction personnel, large residual stress of welding at joints, and difficult on-site construction, etc. The construction quality is easy to guarantee, the construction difficulty is small, and the effect of improving the bearing capacity and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

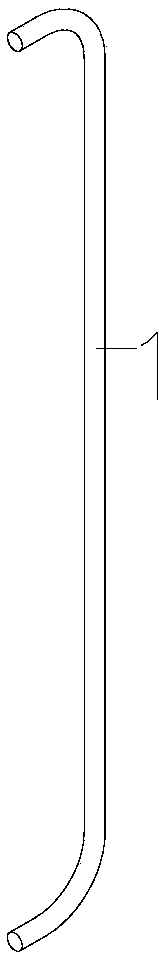

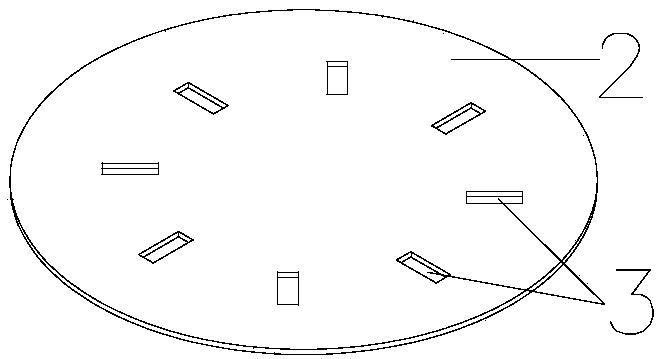

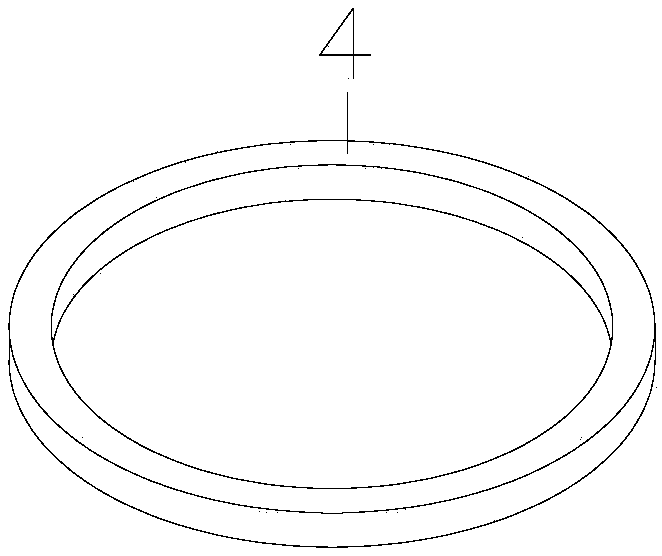

[0044] Such as Figure 1-Figure 19 As shown, the structure of the device for connecting steel pipes by grouting in the present invention mainly includes: high-strength steel bars with anchoring hooks 1, anchoring and positioning steel plates 2, steel bar passing holes 3, built-in snap rings 4, lower connected steel pipes 5, grouting holes 6, The upper part is connected with steel pipe 7, vent hole 8, PVC grouting pipe 9, adhesive tape 10, grouting material 11, etc. The specific structure is as follows:

[0045] Such as figure 1 As shown, both ends of the high-strength steel bar 1 with anchor hooks are bent, and the bent length is determined according to the requirements of relevant specifications.

[0046] Such as figure 2 As shown, the anchoring and positioning steel plate 2 is provided with a rectangular steel bar passing through the hole 3, and the diameter of the anchoring and positioning steel plate 2 is the same as the inner diameter of the connected steel pipe 7 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com