Anti-air-leakage heat-preservation non-return aluminum titanate lift tube for aluminum alloy low-pressure casting

A technology of low-pressure casting and aluminum titanate, which is applied in the field of anti-leakage heat preservation check aluminum titanate riser for aluminum alloy low-pressure casting. Short life and other issues, to reduce turbulent flow, facilitate disassembly and cleaning, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

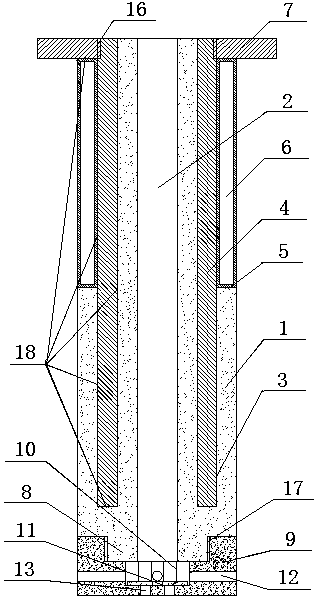

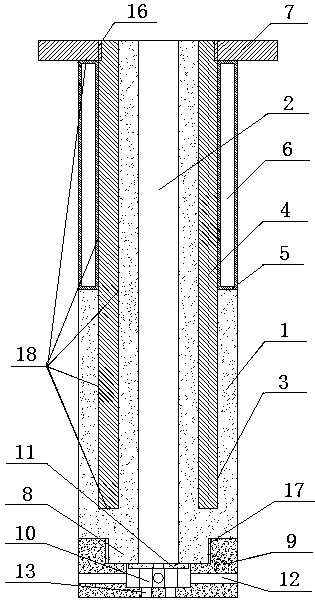

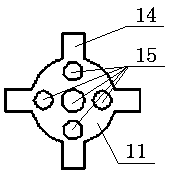

[0038] combine Figure 1~Figure 4 It can be seen that the present invention includes an aluminum titanate tube 1, the top end of the aluminum titanate tube 1 is coaxially fixed with a mounting disc 7, and the bottom end of the aluminum titanate tube 1 is coaxially fixed with an aluminum titanate filter disc 9, The top of the aluminum titanate filter disc 9 is coaxially provided with a groove 10, the groove wall of the groove 10 is provided with a side hole 12, and the groove bottom of the groove 10 is provided with a bottom hole 13, and the side hole 13 is arranged at the bottom of the groove 10. The hole 12 and the bottom hole 13 respectively connect the groove 10 with the outer side of the aluminum titanate filter disc 9, and the groove 10 is provided with a matching non-return piece 11, and the non-return piece 11 is arranged up and down along the inside of the groove 10. The non-return piece 11 is provided with a through hole 15, and the projection of the through hole 15 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com