High-performance epoxy bitumen mixture easy to construct and maintain and preparation method thereof

A technology of epoxy asphalt and mixture, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of long reaction time, complicated construction technology, and degradation of bridge deck performance, and achieve excellent mechanical properties and simple construction technology , the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

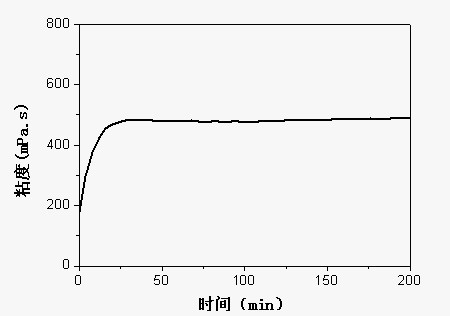

Method used

Image

Examples

Embodiment 1

[0054]Embodiment 1: Weigh 100 parts (parts by mass, the same below) hydroxyl-terminated polybutadiene liquid rubber (HTPB) (provided by Zibo Qilu Ethylene Chemical Co., Ltd.), and add 20 parts of toluene diisocyanate (TDI) respectively (German BASF company ) and 0.5 parts of butyl ditin laurate (provided by Shanghai Yutian Chemical Co., Ltd.), start stirring, and under the protection of nitrogen, gradually increase the temperature to 120 ° C, react for 2 hours and cool to room temperature to obtain epoxy asphalt mixture Modified toughener for A component.

Embodiment 2

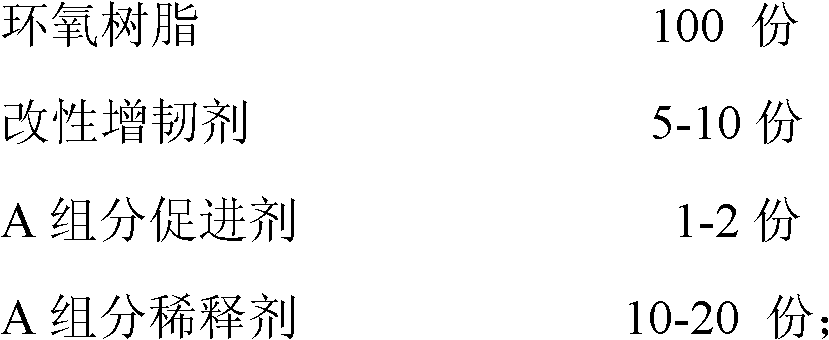

[0055] Embodiment 2: Take by weighing 100 parts of bisphenol A type glycidyl ether epoxy resin (E51) (provided by Wuxi Resin Factory), add respectively 5 parts of modified tougheners prepared in Example 1 and 1 part of tetrabutyl iodide Ammonium chloride (TBAI) (provided by Yixing Kailida Chemical Co., Ltd.), start stirring, and gradually increase the temperature to 160 ° C, after 2 hours of reaction, cool at room temperature for 24 hours, add 10 parts of phenyl glycidyl ether (provided by Wuxi Resin Factory ) to obtain component A of the epoxy asphalt mixture.

Embodiment 3

[0056] Embodiment 3: take by weighing 100 parts of bisphenol A type glycidyl ether epoxy resins (E51), add respectively 10 parts of modified tougheners prepared in Example 1 and 2 parts of tetrabutylammonium iodide (TBAI), Start stirring, and gradually increase the temperature to 160°C. After reacting for 2 hours, cool at room temperature for 24 hours, and add 20 parts of benzyl glycidyl ether (provided by Wuxi Resin Factory) to obtain component A of the epoxy asphalt mixture.

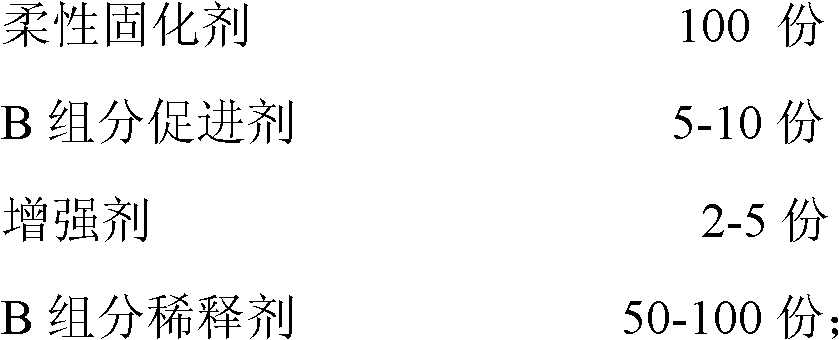

[0057] The preparation method of component B of high-performance epoxy asphalt mixture is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com