Method of preparing baking-free load-bearing bricks through steam curing of semidry desulfurization residues

A semi-dry desulfurization, load-bearing brick technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc. Risks can not be ignored and other issues to achieve the effect of avoiding adverse effects, short maintenance time, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific experimental examples.

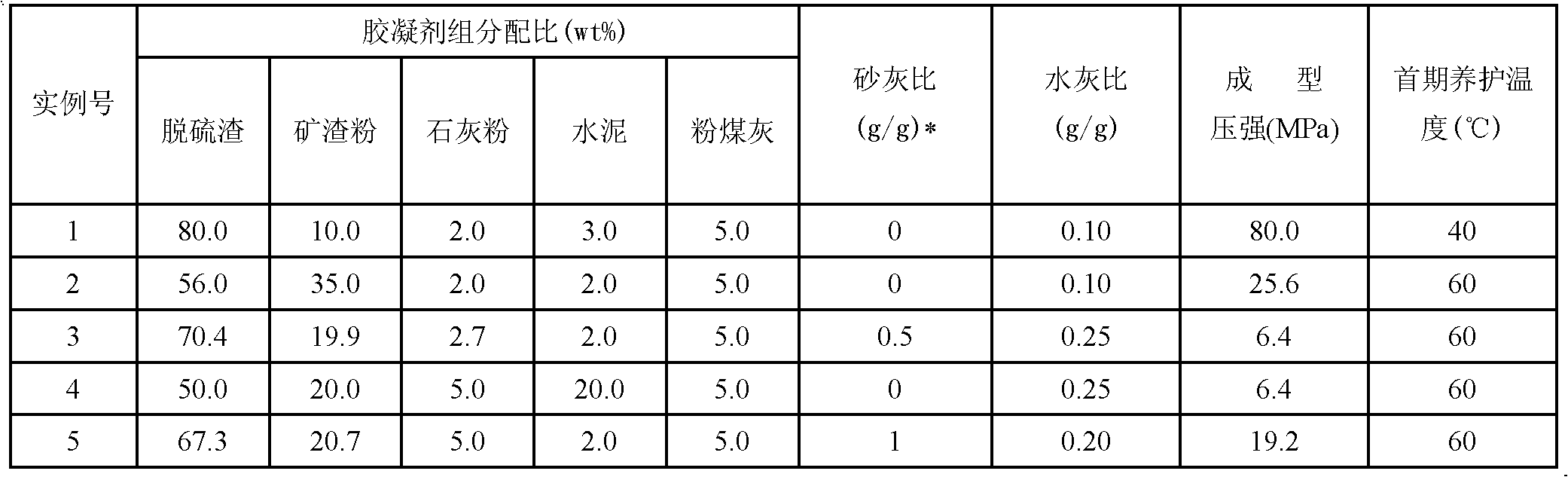

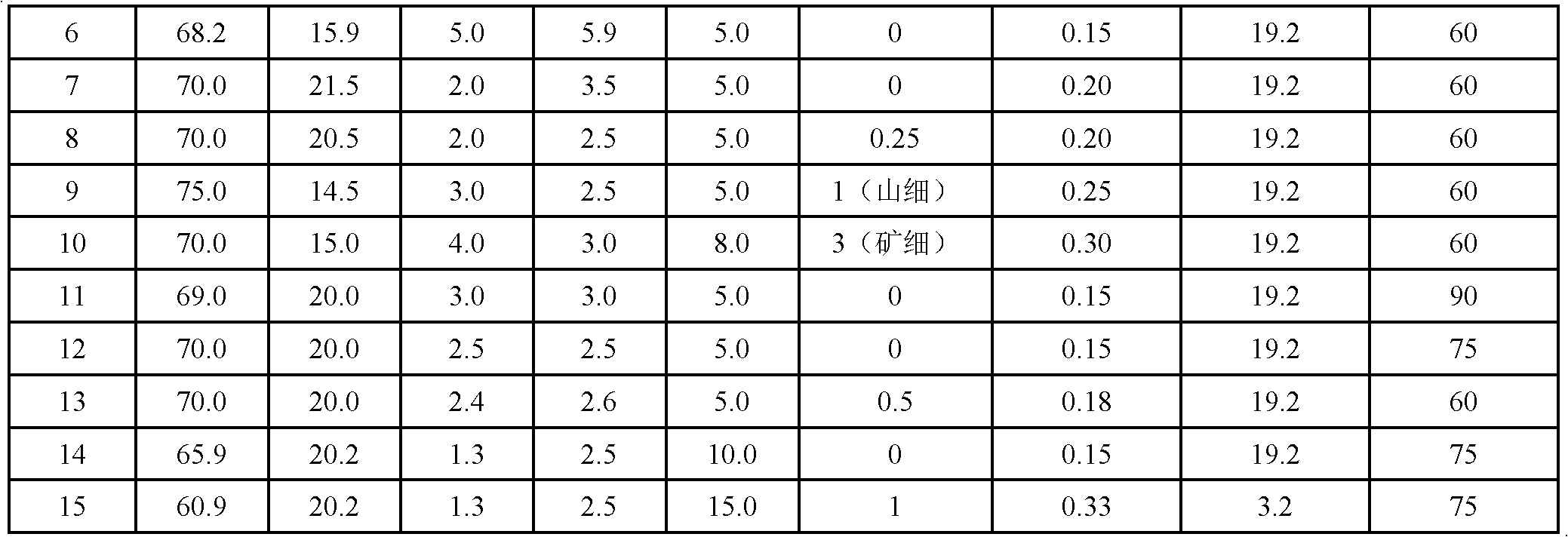

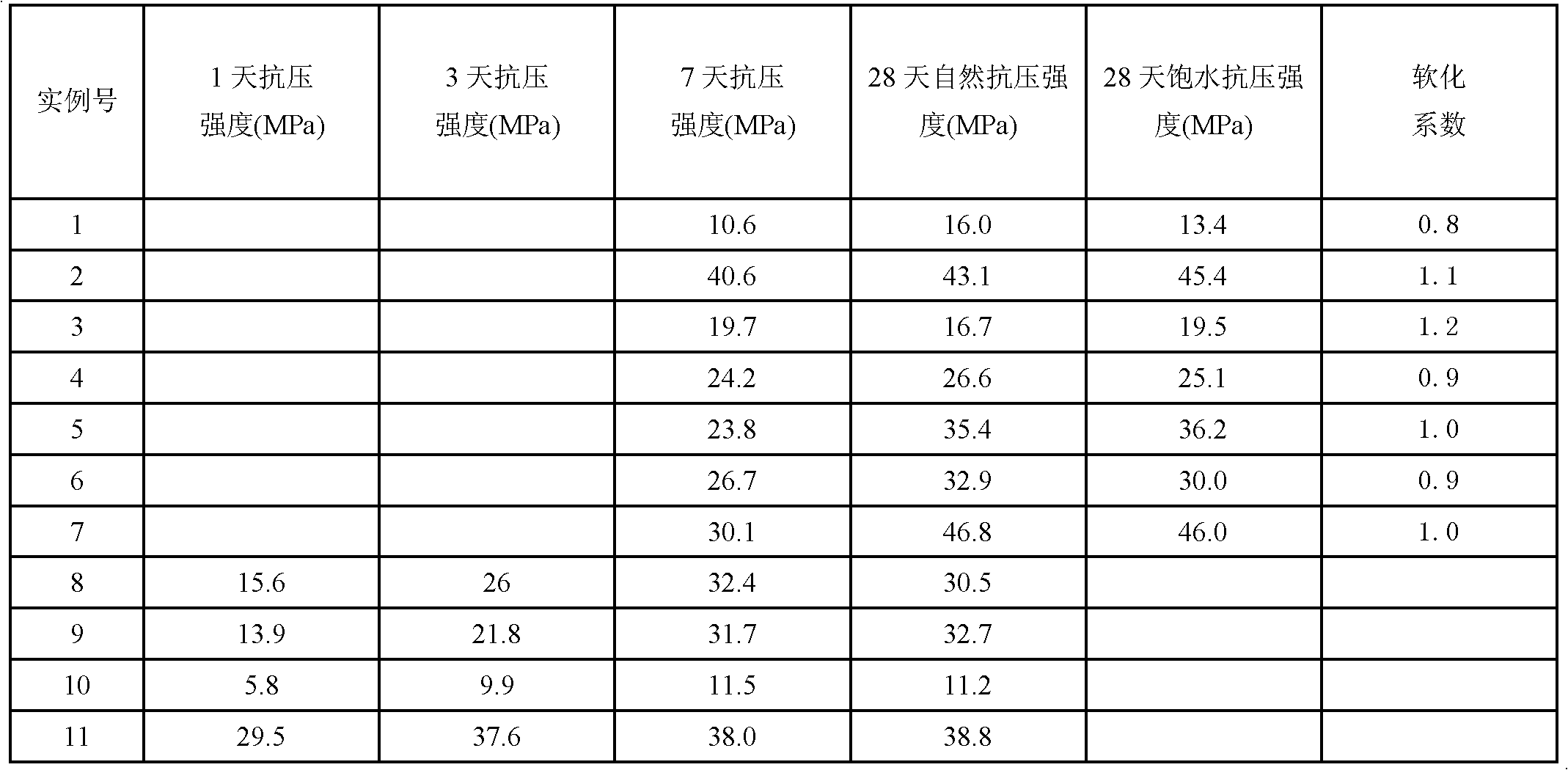

[0019] (1) Example of semi-dry static pressing: Table 1 lists the technical parameters of the preparation example of semi-dry static pressing at a water-cement ratio of 0.1-0.33. Raw materials used in the experiment: semi-dry desulfurization slag, the desulfurization slag is off-white to light gray-yellow fine powder, with good dispersibility and fluidity, the average particle size is 4-10um, and the BET specific surface area is 2-10m 2 / g, its composition is: the mass percent content is the CaO of 40-50%, the SO of 8-16% 3 , 10-18% SO 2 , 1-3% MgO, 1-2% TFe, 0.2-1.0% SiO 2 , 0.4-0.6% Al 2 o 3 , 1-5% K 2 O, 0.1-0.5% Na 2 O, 1-5% chloride, 15-25% loss on ignition, its radionuclide content complies with GB6566-2010 building main material nuclide content index, namely I Ra ≤1.0B q / Kg, I γ ≤1.0B q / Kg (testing method is GB11743-89) requirements; S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com