Novel method for reinforcing deep soft foundition-cencrete core sand stone pile compound foundition method

A composite foundation and gravel pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of less investment in reinforcement equipment, difficult construction, poor pile continuity, etc., to achieve convenient and fast construction, save maintenance time, The effect of easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawings and examples.

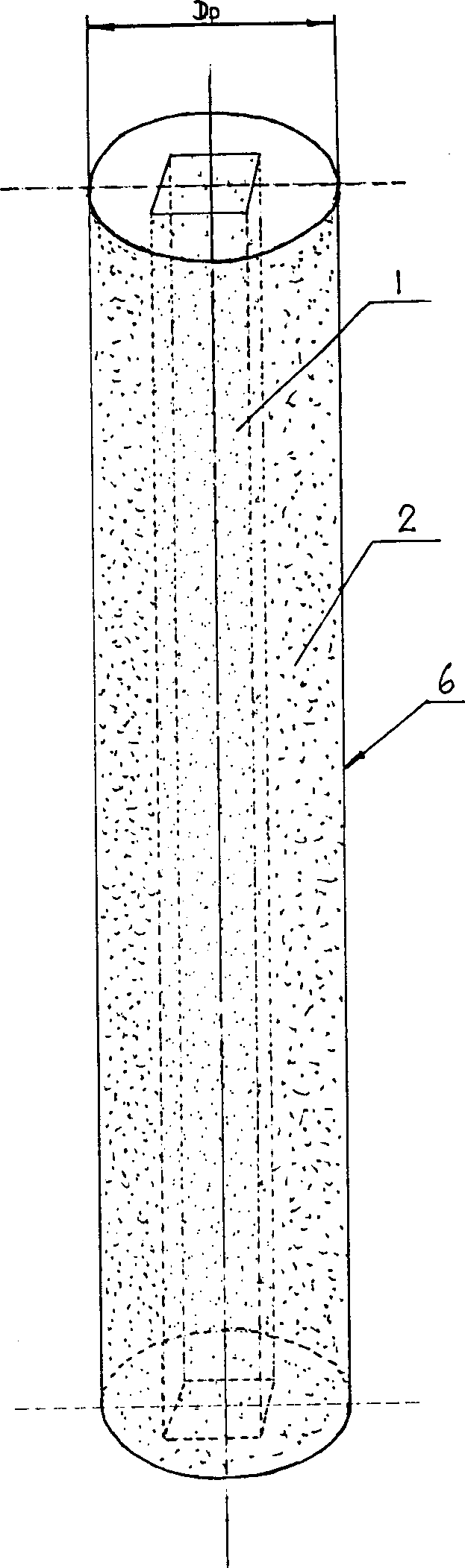

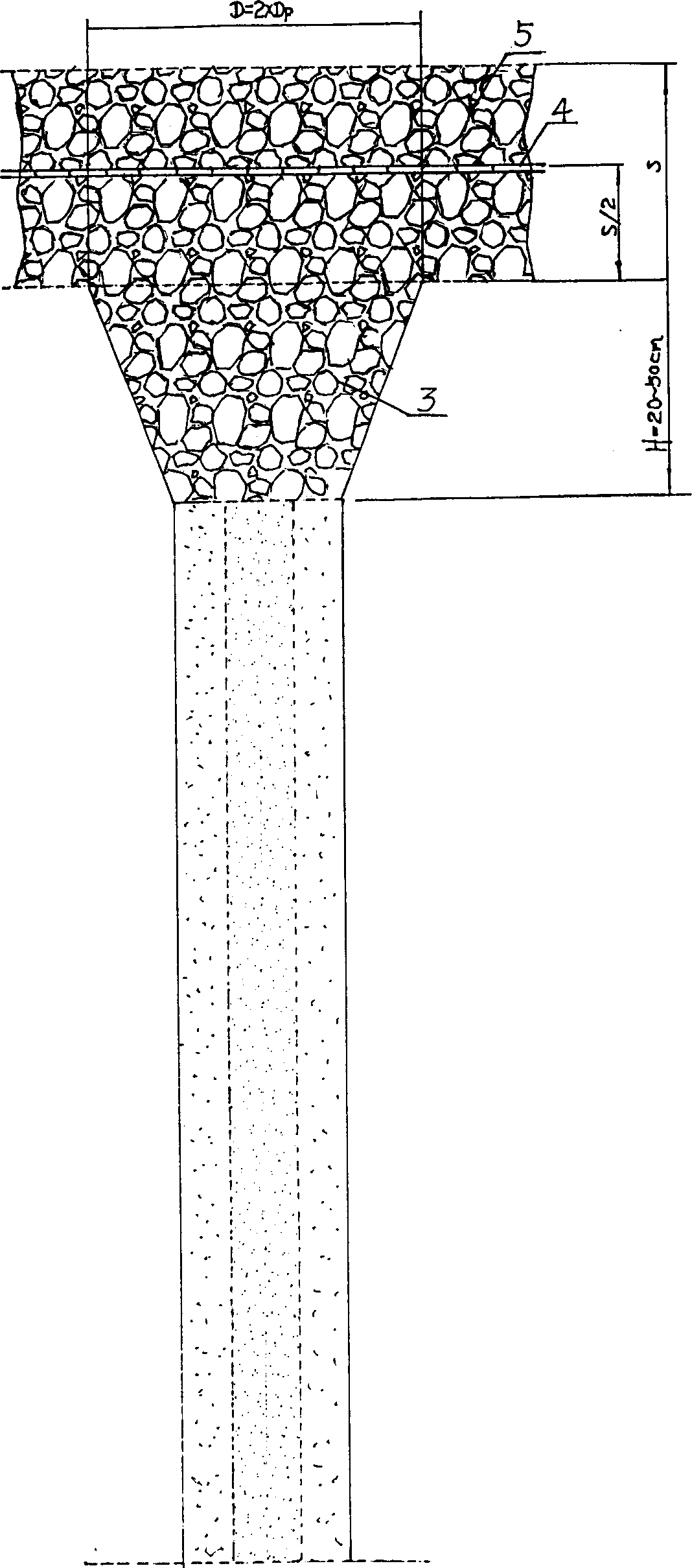

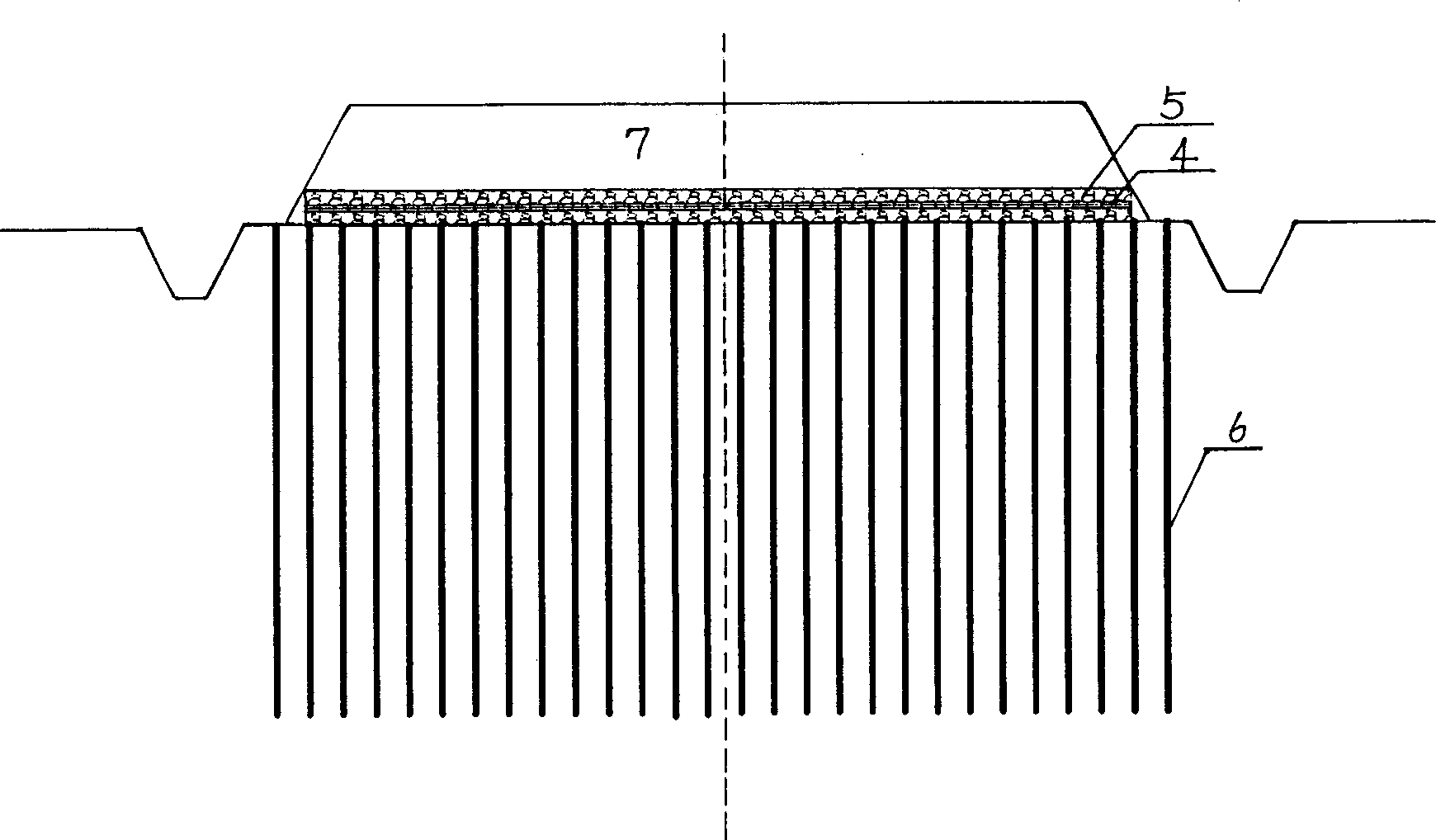

[0024] Such as figure 1 , 2 , 3 shown.

[0025] Concrete operation process of the present invention is:

[0026] (1) Pile position setting out: Arrange the pile position (that is, the position of the installation hole) according to the requirements of the design plan.

[0027] (2) The pile driver is in place: the pile driver is moved to the pre-pile position, the center of the immersed tube is aligned with the center of the pile position, and the immersed tube is adjusted to be perpendicular to the ground to ensure that the verticality deviation is not greater than 1%.

[0028] (3) Immersed tube: Start the motor, the immersed tube reaches the predetermined elevation, and stop. When there is a hard interlayer, start the motor to vibrate and load until the hard interlayer is penetrated. Holes are formed by vibrating immersed tubes (suitable for foundations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com