A treatment method for dewatered sludge in a domestic sewage treatment plant

A technology for dewatering sludge and domestic sewage, used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems of long maintenance time, low efficiency, and limited sources, and achieve short maintenance time, high strength, and sludge solidification. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

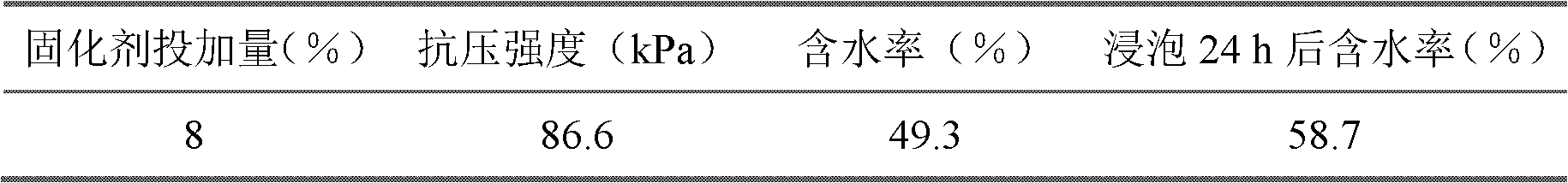

[0030] A pilot test of sludge solidification treatment was carried out at a large domestic waste landfill in Shanghai.

[0031]In the first step, the three mineral powders of limestone, magnesite and bauxite taken from Chaohu Lake in Anhui Province are mixed according to the weight percentage of 55%: 20%: 25%, and then mixed evenly and then burned. The burning temperature is 1000 ° C. The burning time is 2 hours, and the sludge solidification agent is obtained after cooling. After testing, the weight percentage of each component in the sludge solidifying agent is MgO=10%~30%, Al 2 o 3 =15%~20%, CaO=40%~45%, SiO 2 =4%~8%, Fe 2 o 3 = 2% ~ 3%, SO 3 = 1% ~ 2%, ash = 8% ~ 12%;

[0032] The main components of the above limestone are CaO 82.1%, MgO 0.5%, Al 2 o 3 0.05%, SiO 2 3.6%, Fe 2 o 3 1.25%, SO 3 1.1% and 11.4% ash.

[0033] The main components of the above-mentioned magnesite are MgO 73.5%, CaO 2.2%, SiO 2 9%, Fe 2 o 3 2.5%, SO 3 0.8%, ash 12%.

[0034] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com