Wet processing system and method of operating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

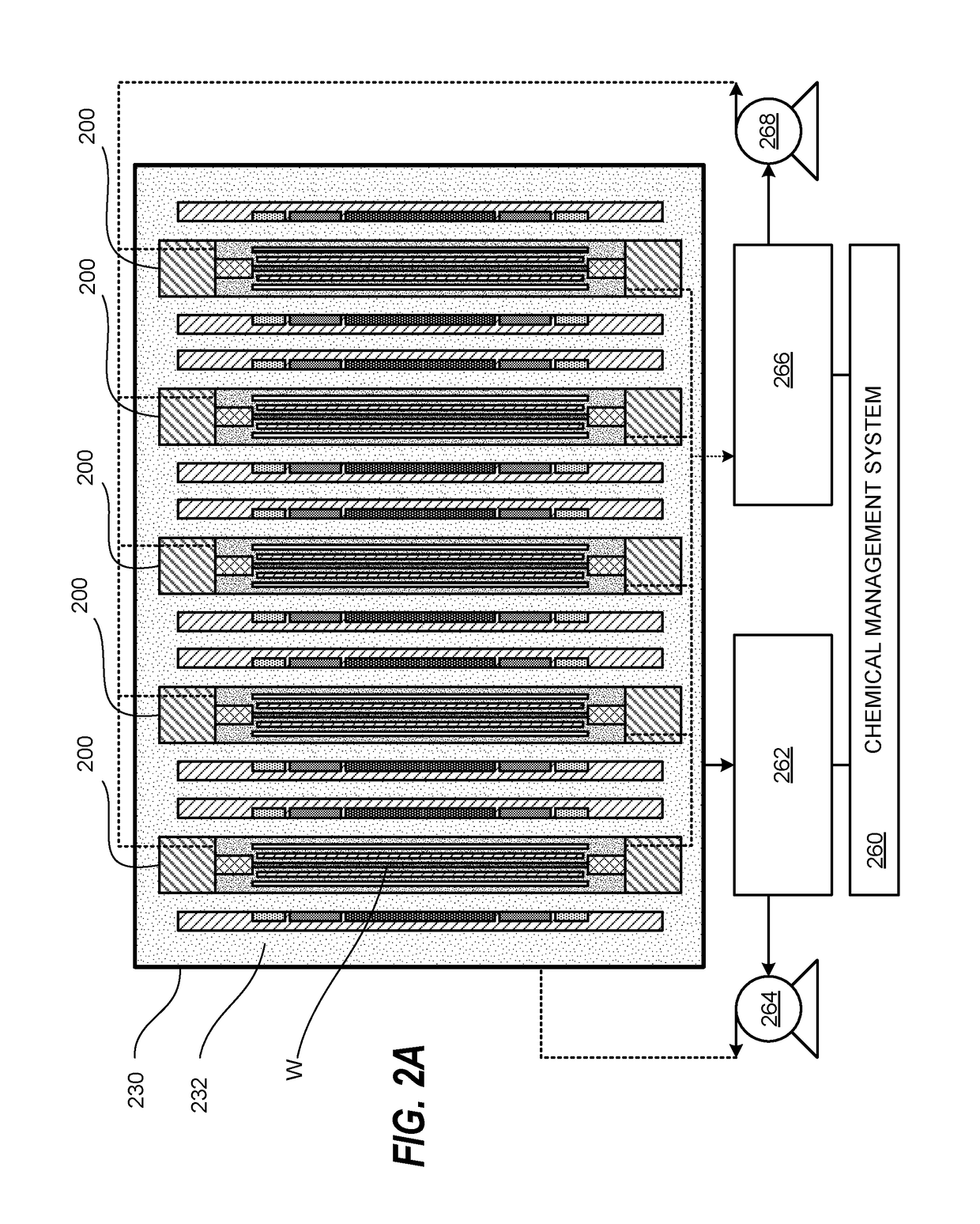

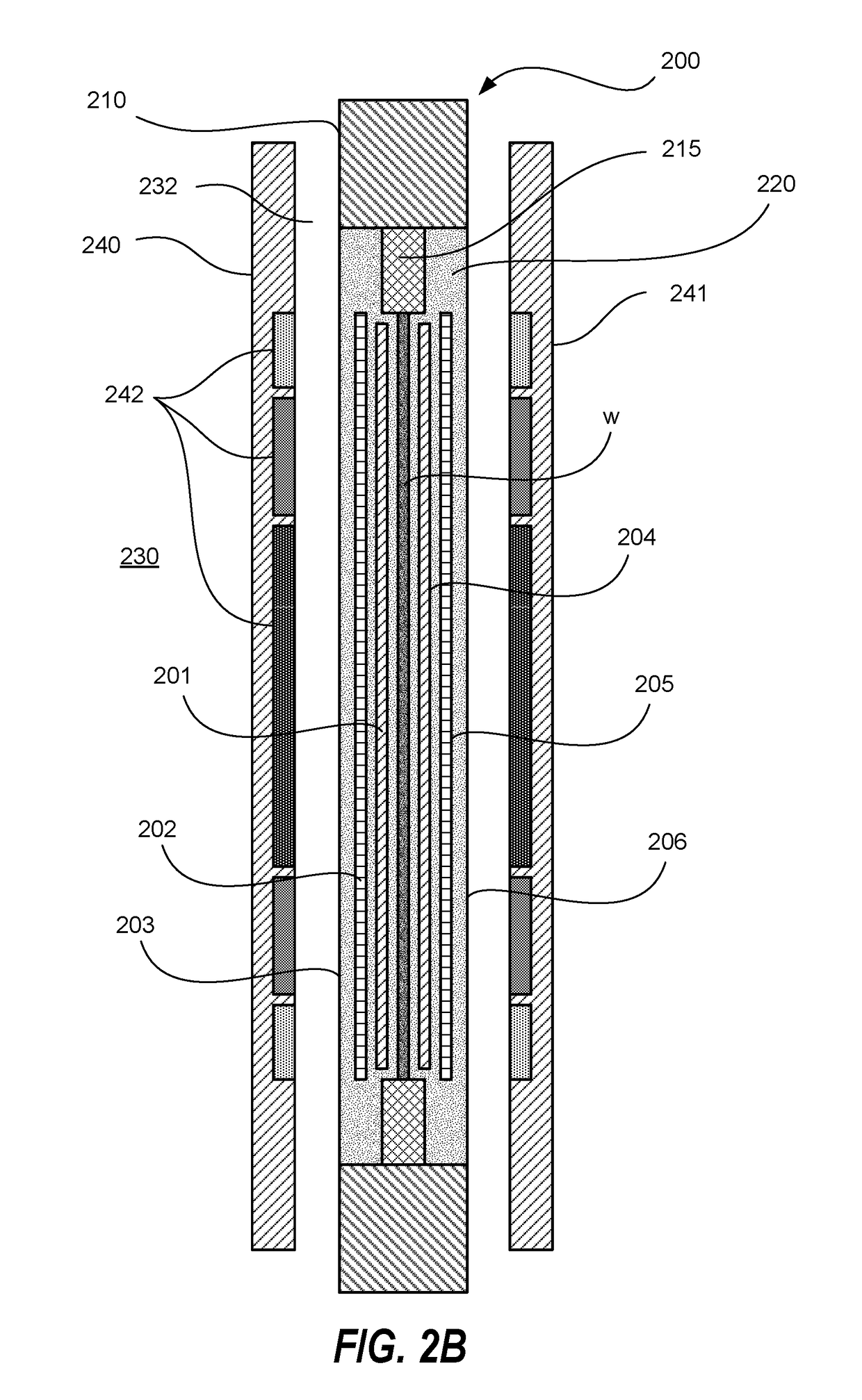

[0017]Techniques disclosed herein include an electrochemical deposition apparatus that provides a robust workpiece handling system, a simplified circulation system, an improved chemical management system for more reliable and uniform plating, as well as short maintenance times for greater tool availability

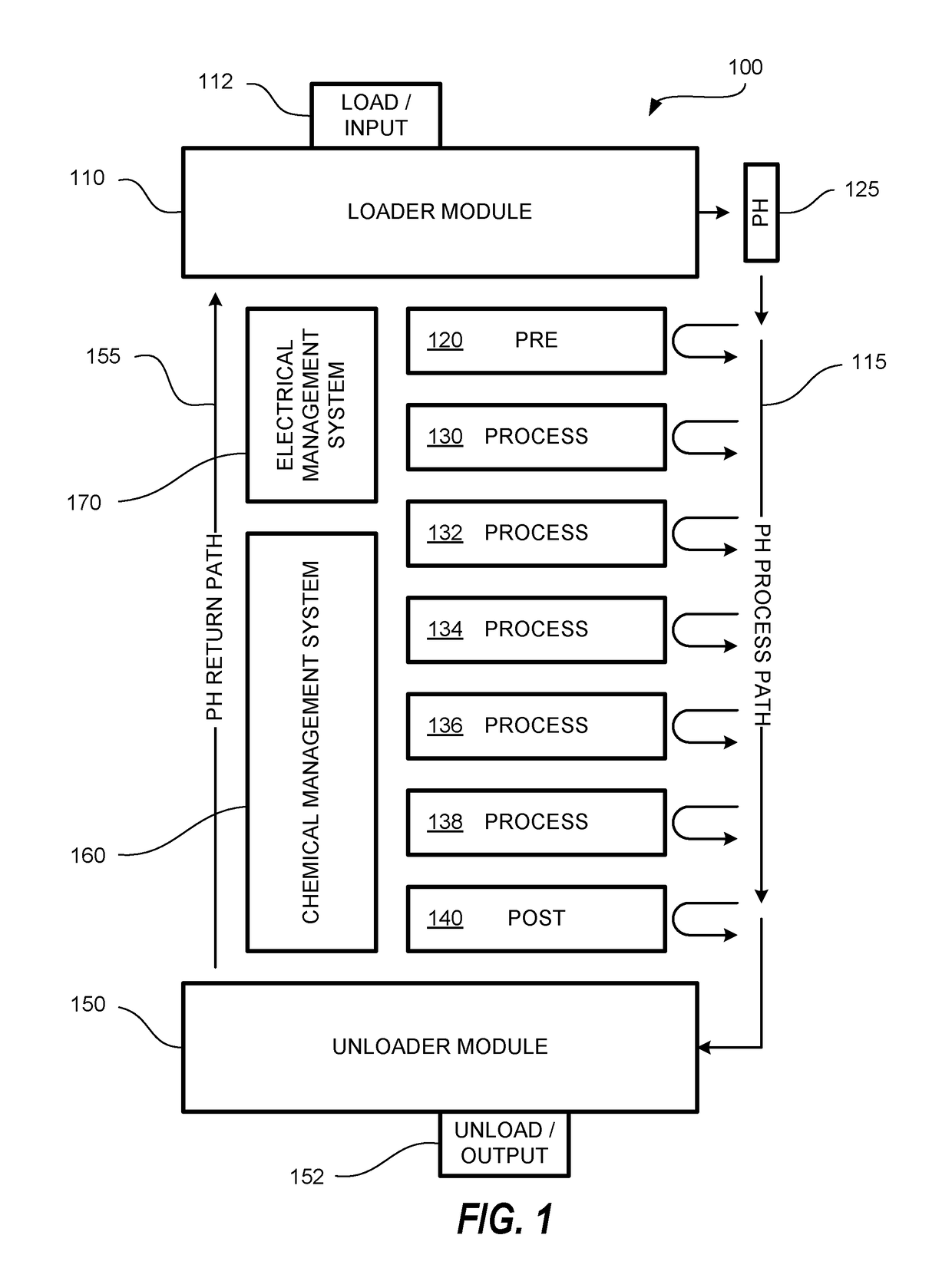

[0018]Systems and techniques disclosed herein can be embodied as an electrochemical deposition systems or module of a system, or workpiece surface wet process conditioning system. Example systems include a wet processing system capable of treating or conditioning workpieces of various types and sizes, including both wafer type geometries (e.g., semiconductor wafers), characterized by relatively rigid silicon circular disks, and panel type geometries, characterized by much larger and more flexible rectangular shaped substrates. One embodiment includes an electrochemical deposition apparatus for depositing metal onto a substrate. FIG. 1 illustrates a schematic representation of an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com