Patents

Literature

68 results about "Cost of ownership" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent condition-based engine/equipment management system

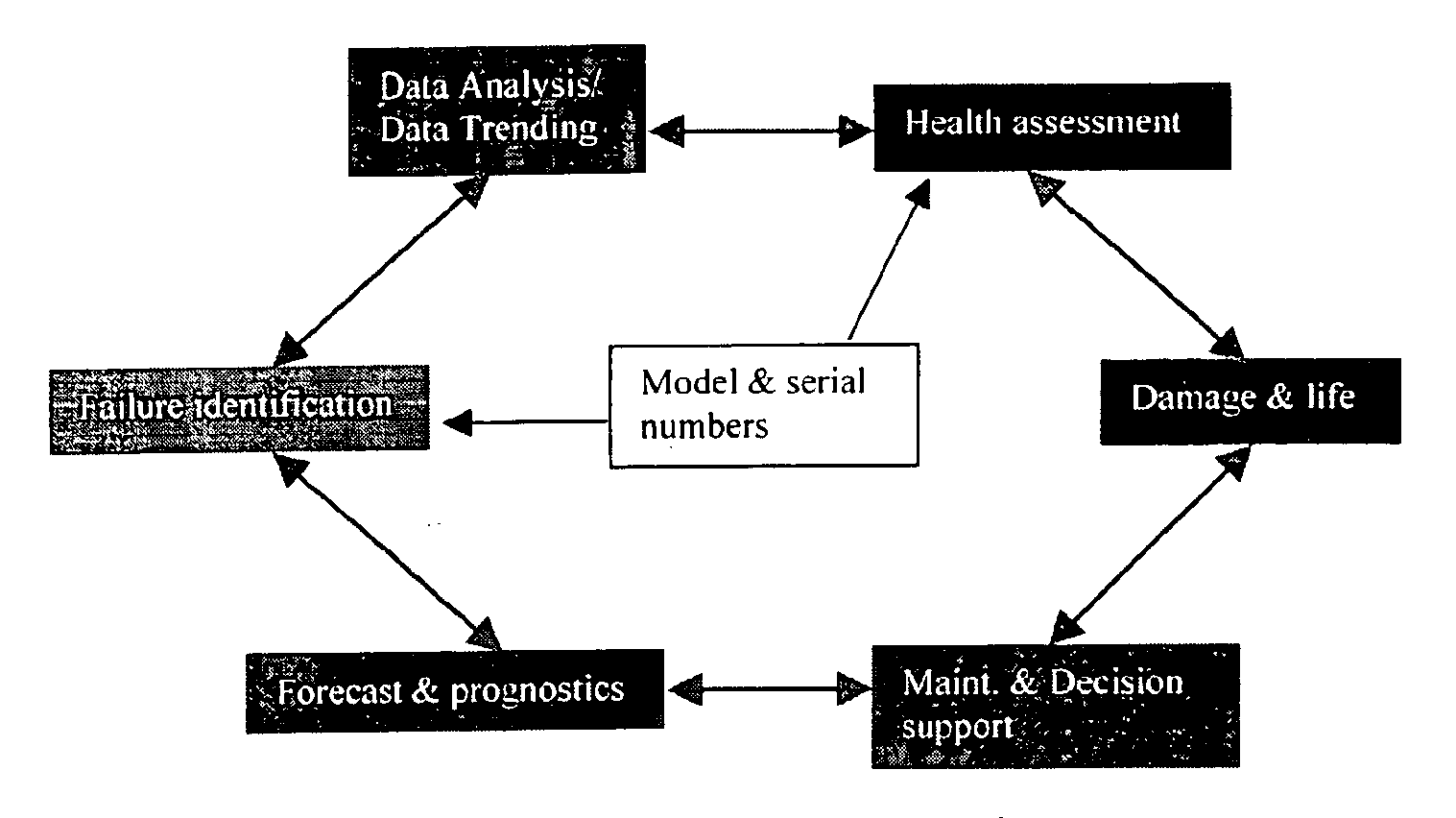

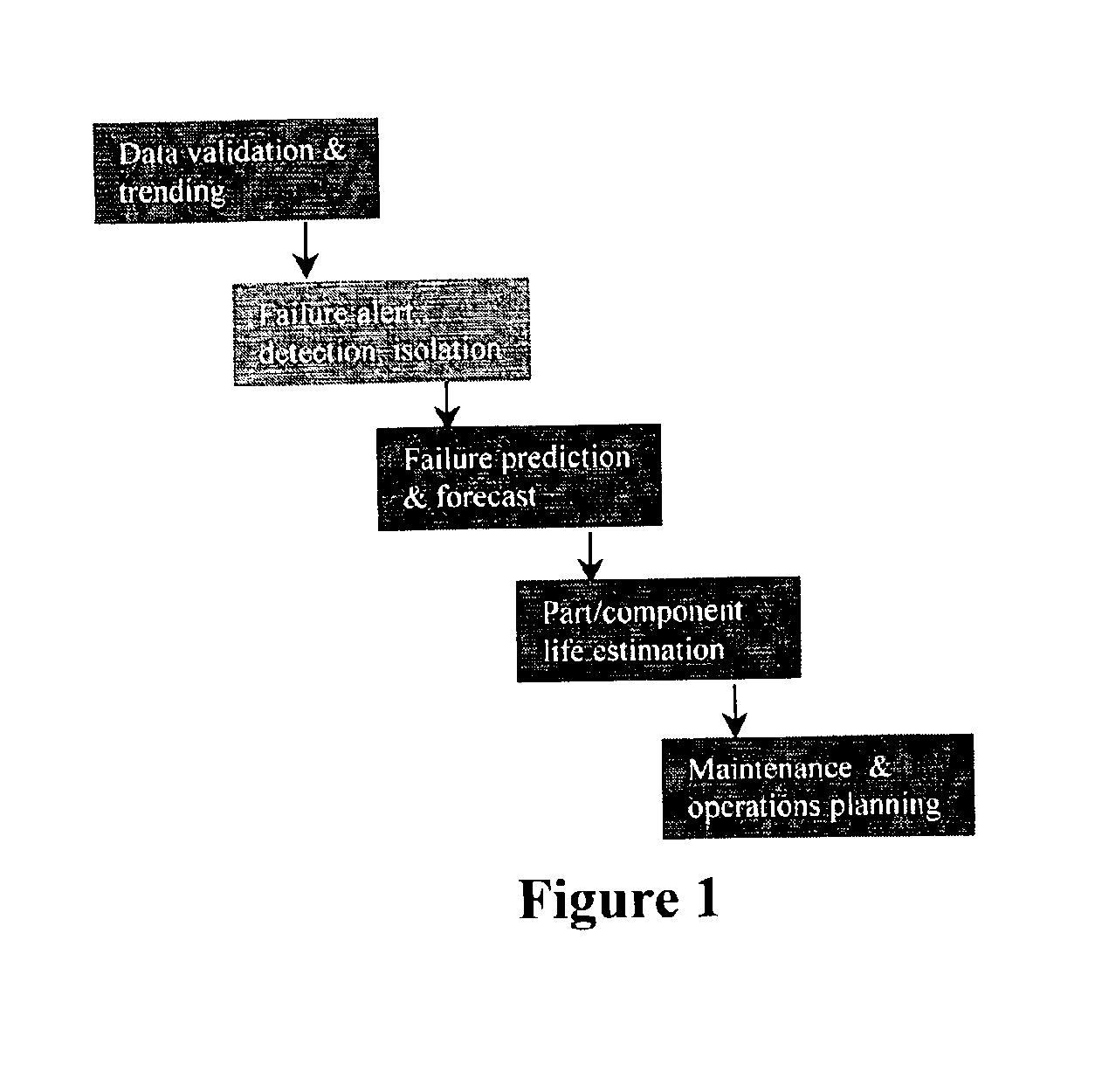

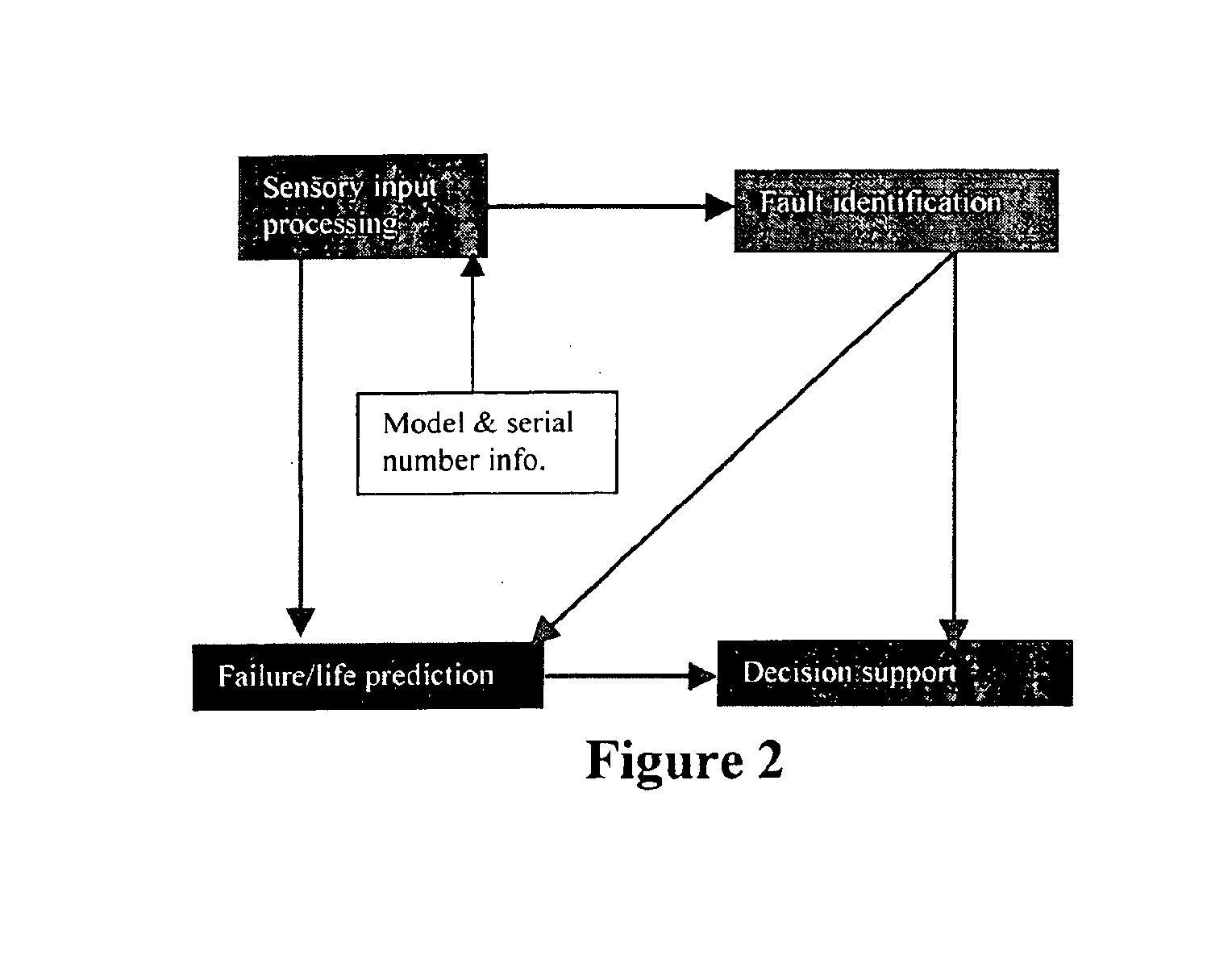

Health management of machines, such as gas turbine engines and industrial equipment, offers the potential benefits of efficient operations and reduced cost of ownership. Machine health management goes beyond monitoring operating conditions, it assimilates available information and makes the most favorable decisions to maximize the value of the machine. These decisions are usually related to predicted failure modes and their corresponding failure time, recommended corrective actions, repair / maintenance actions, and planning and scheduling options. Hence machine health management provides a number of functions that are interconnected and cooperative to form a comprehensive health management system. While these interconnected functions may have different names (or terminology) in different industries, an effective health management system should include four primary functions: sensory input processing, fault identification, failure / life prediction, planning and scheduling. These four functions form the foundation of the method of ICEMS (Intelligent Condition-based Engine / Equipment Management System). To facilitate information processing and decision making, these four functions may be repartitioned and regrouped, such as for network based computer software designed for health management of sophisticated machinery.

Owner:INTEL CORP

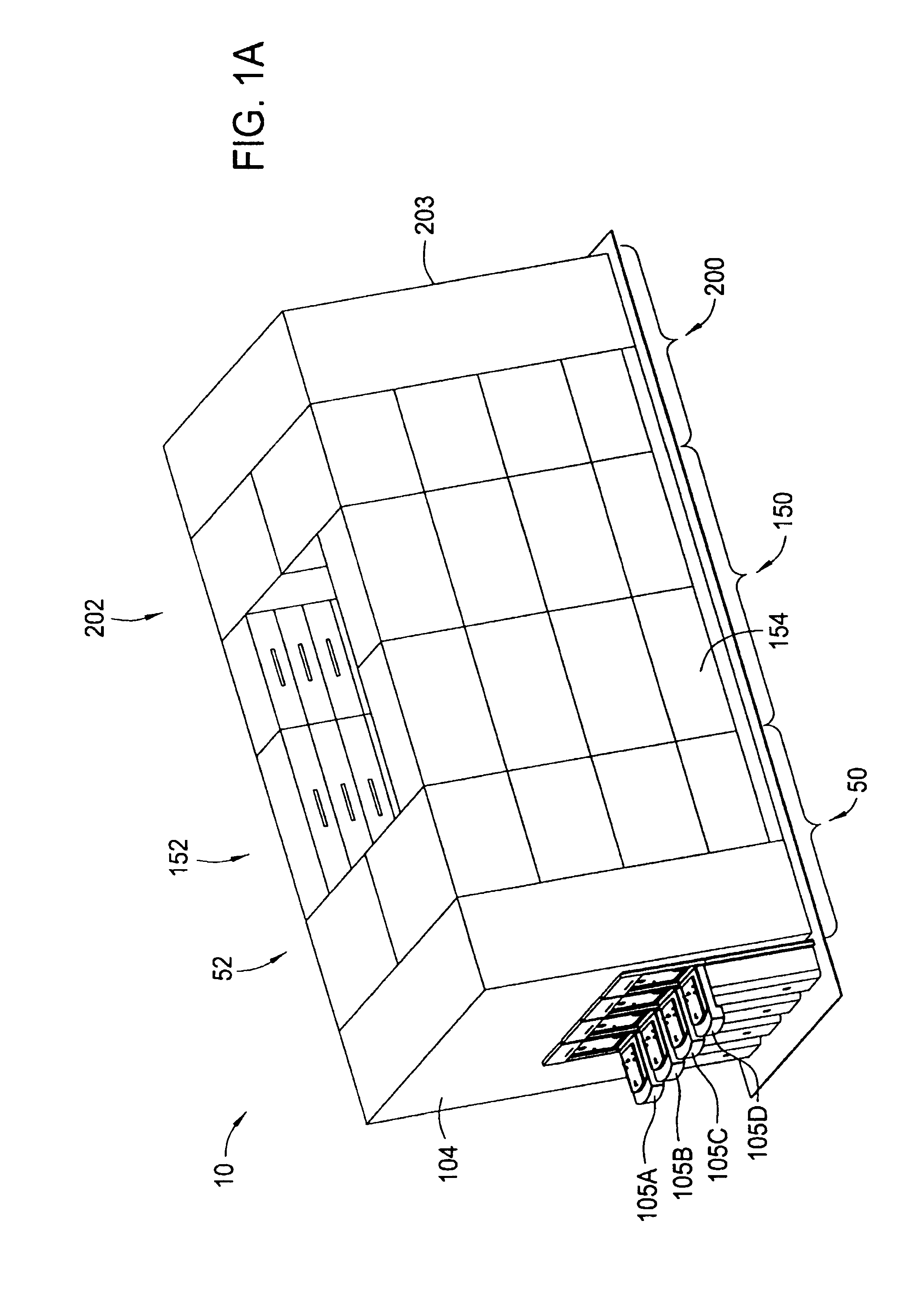

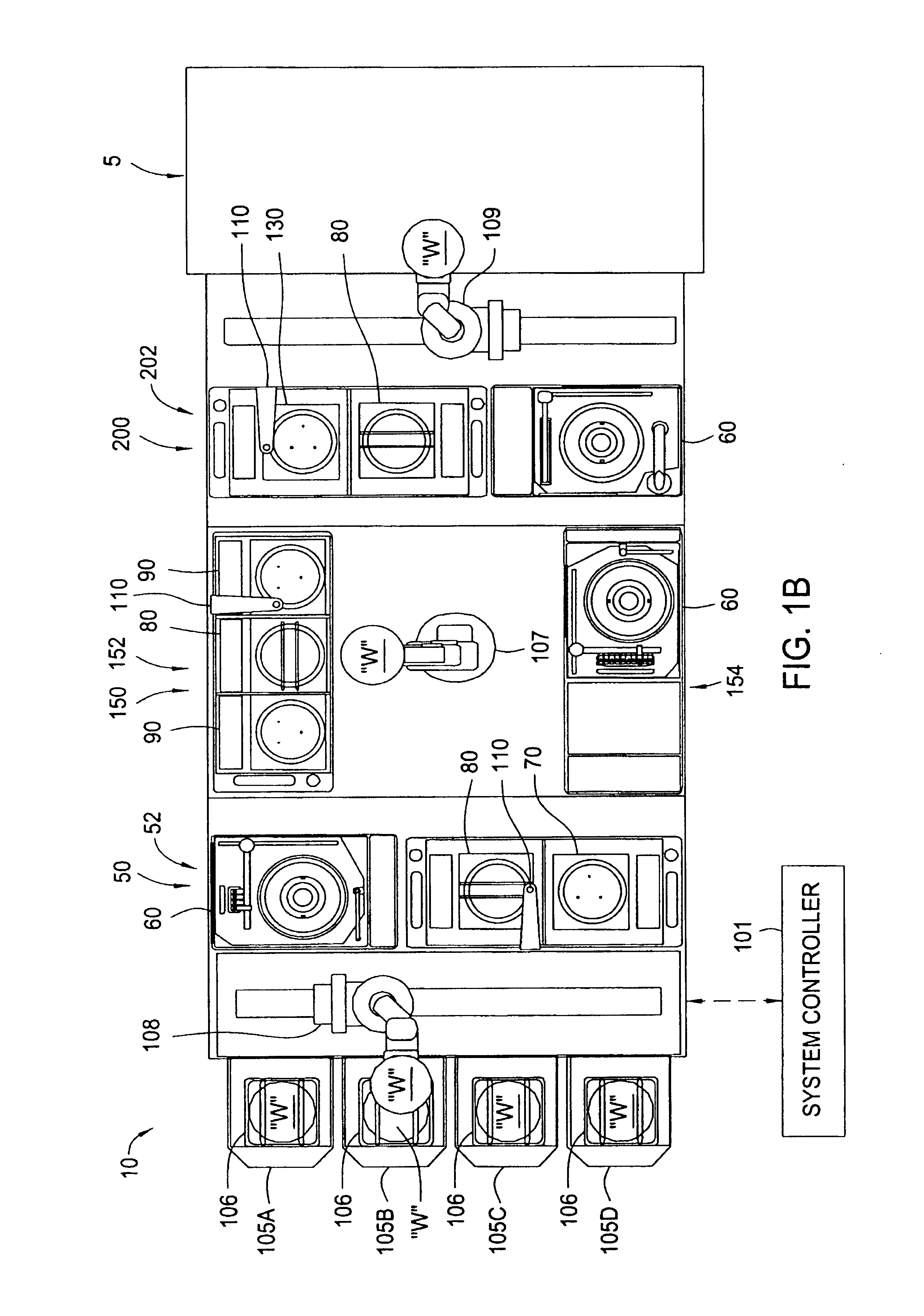

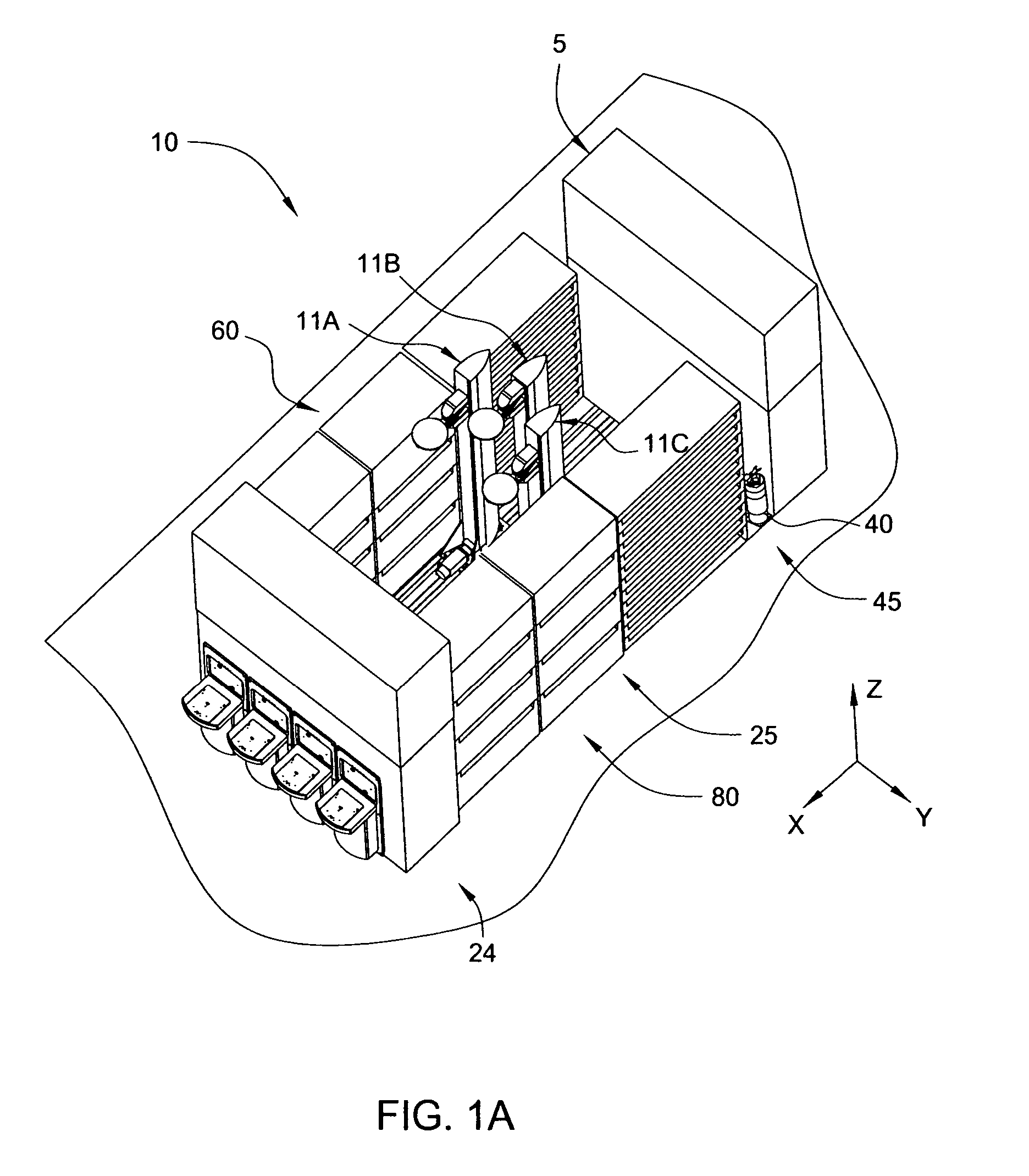

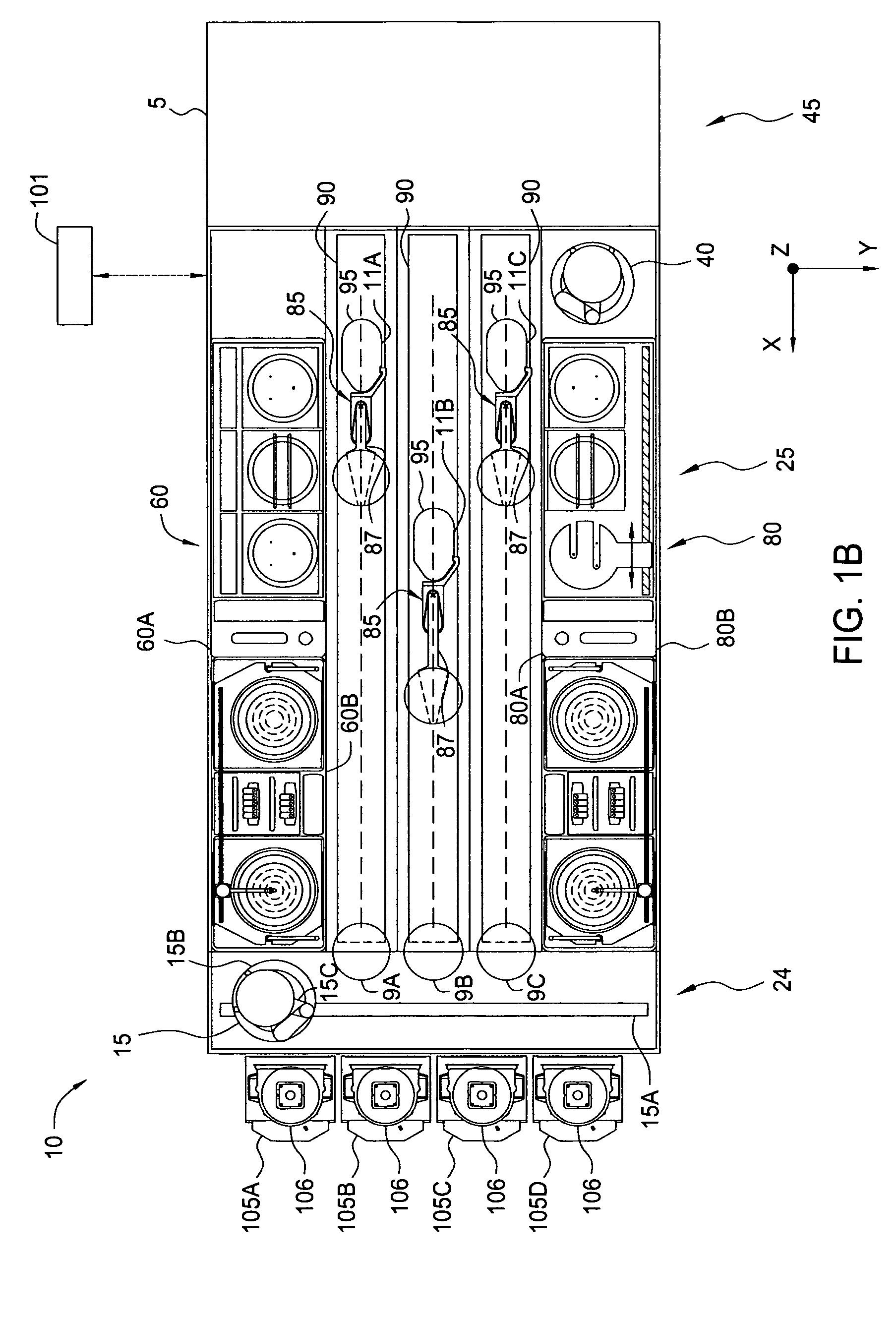

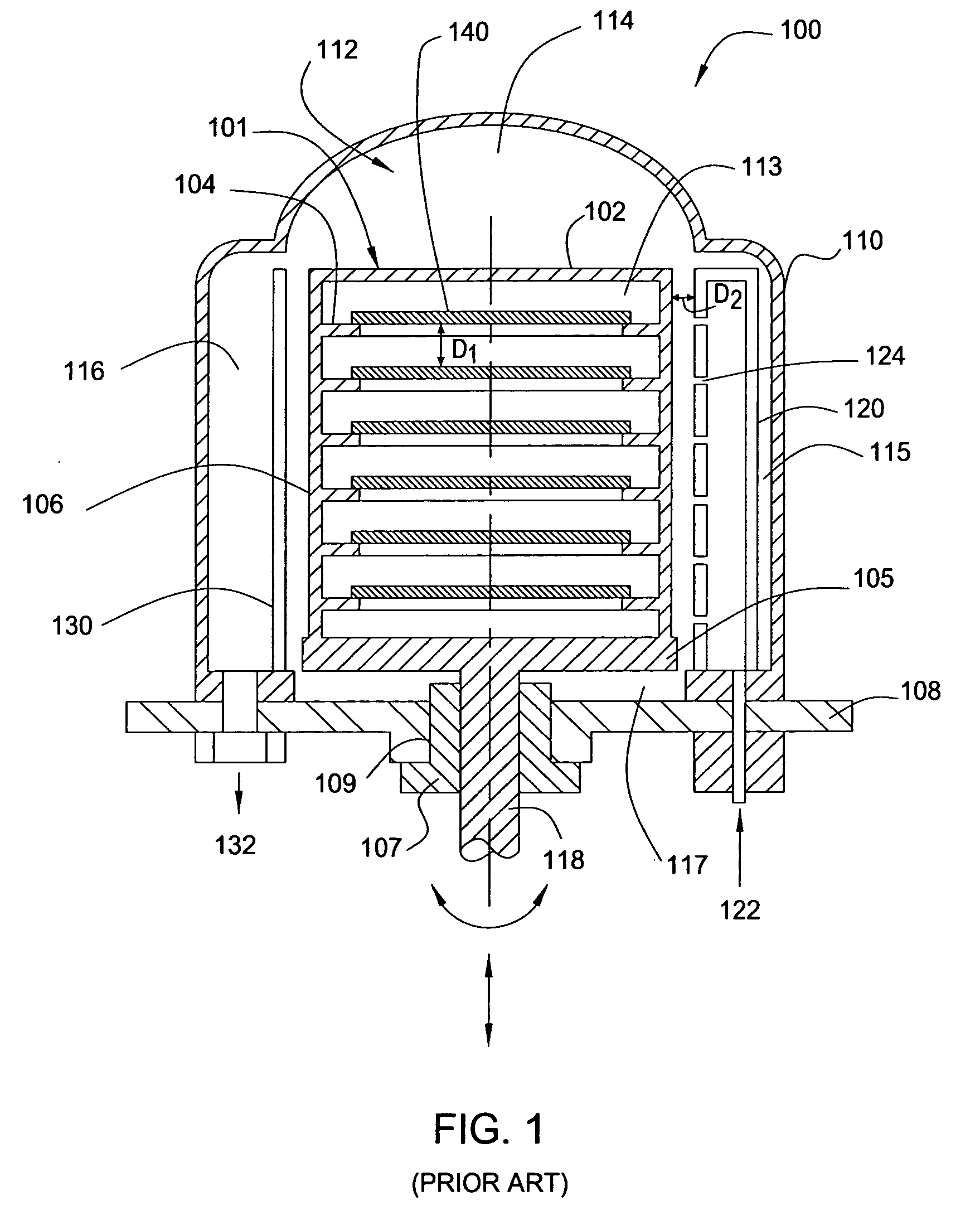

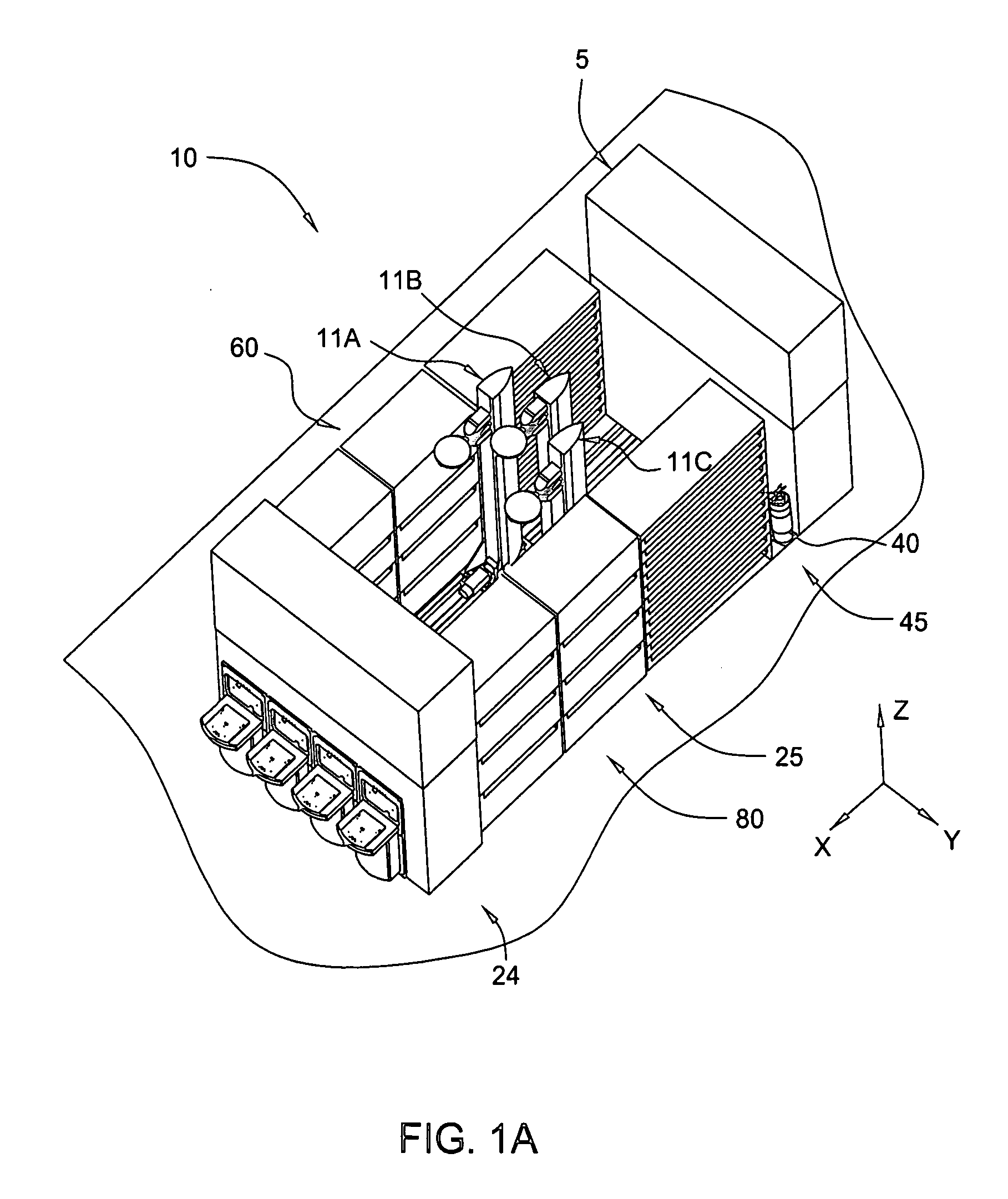

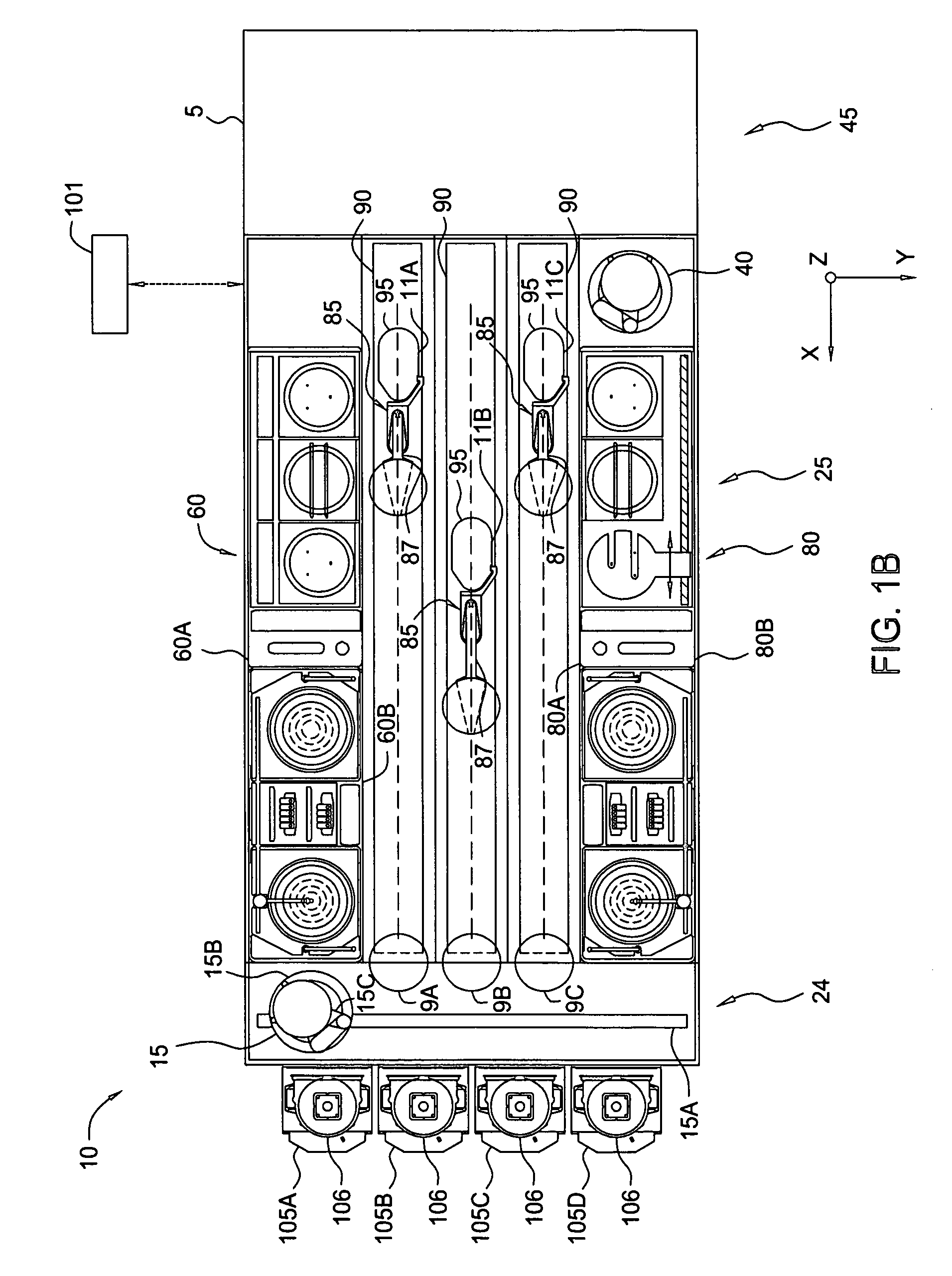

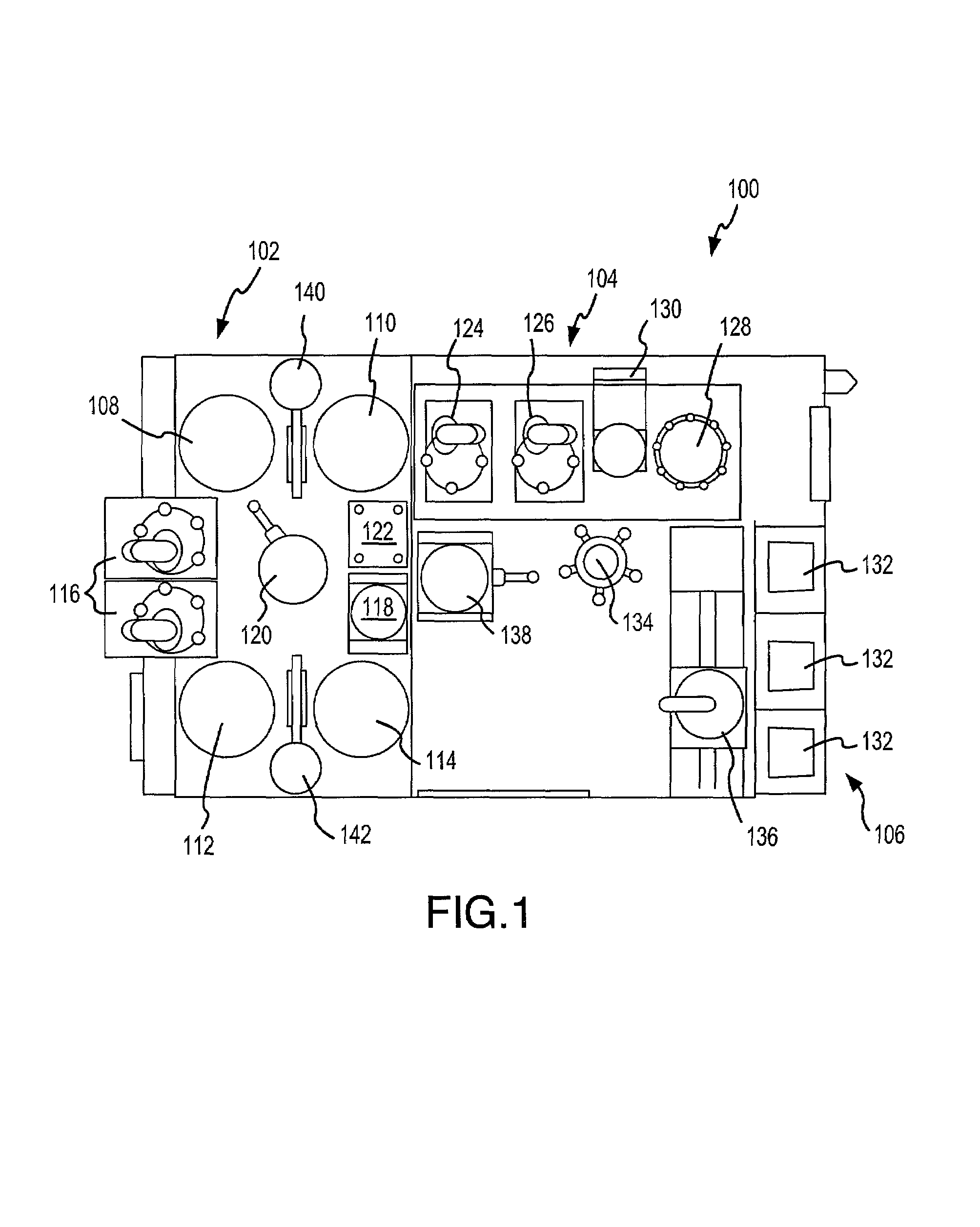

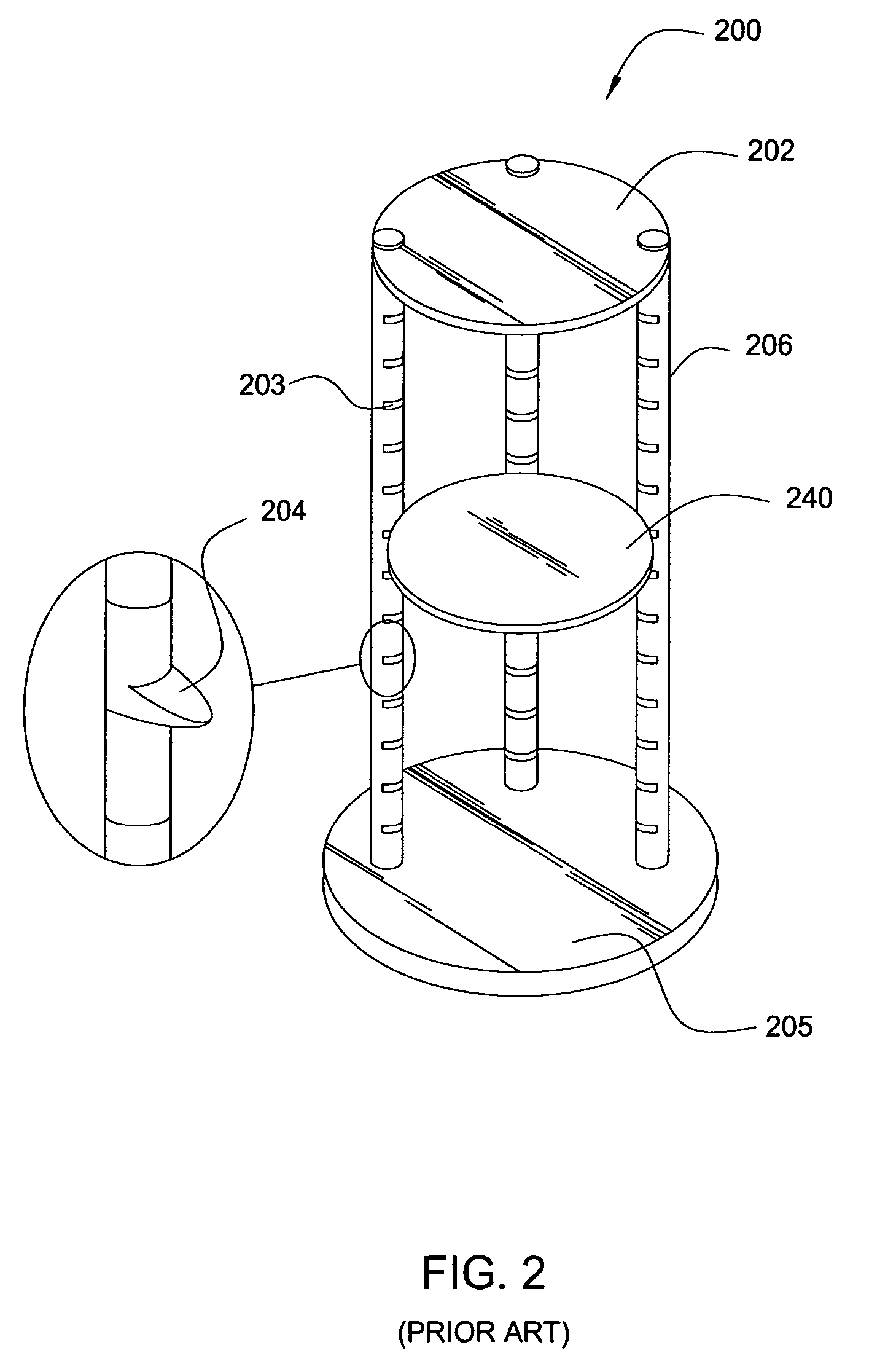

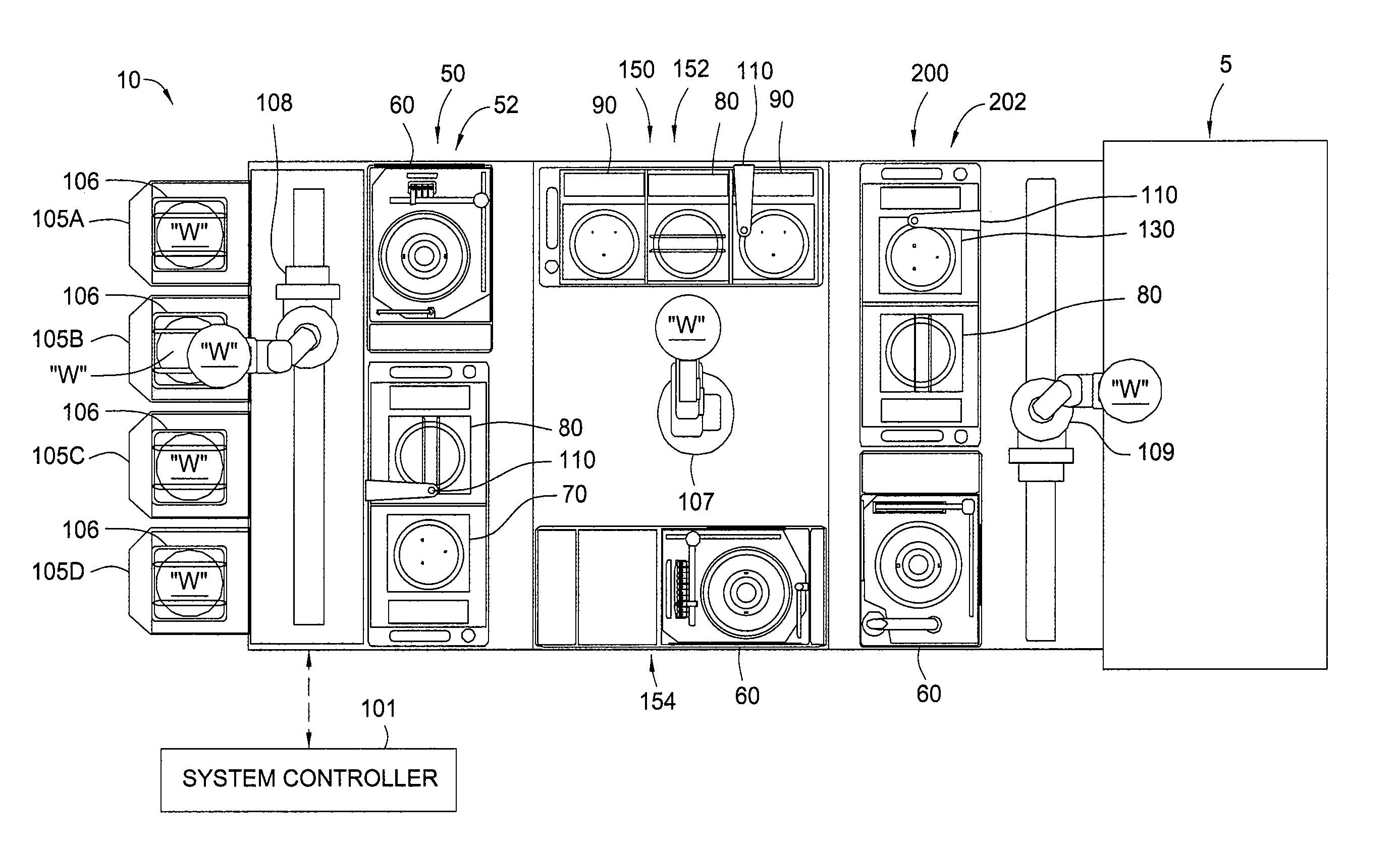

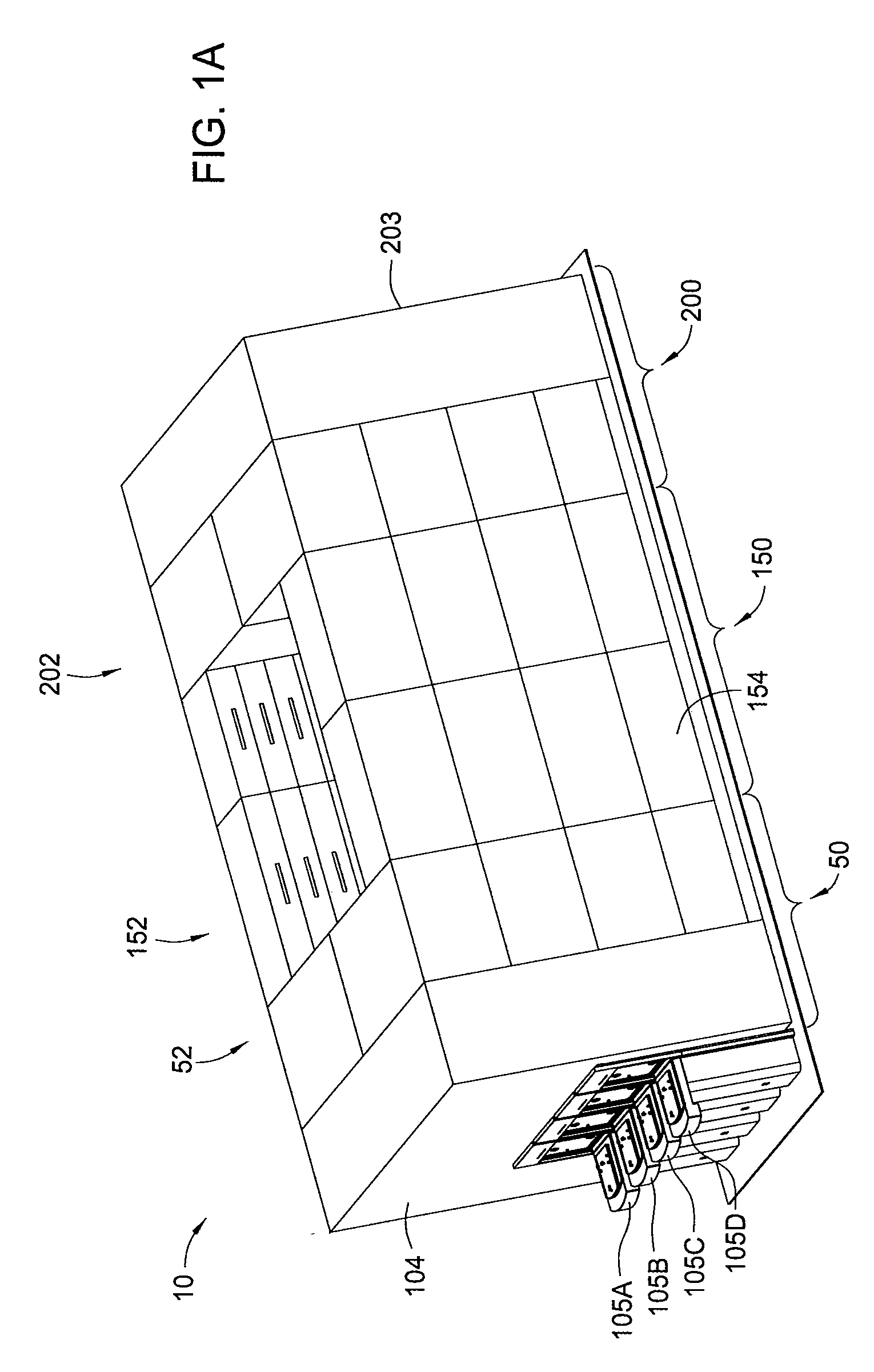

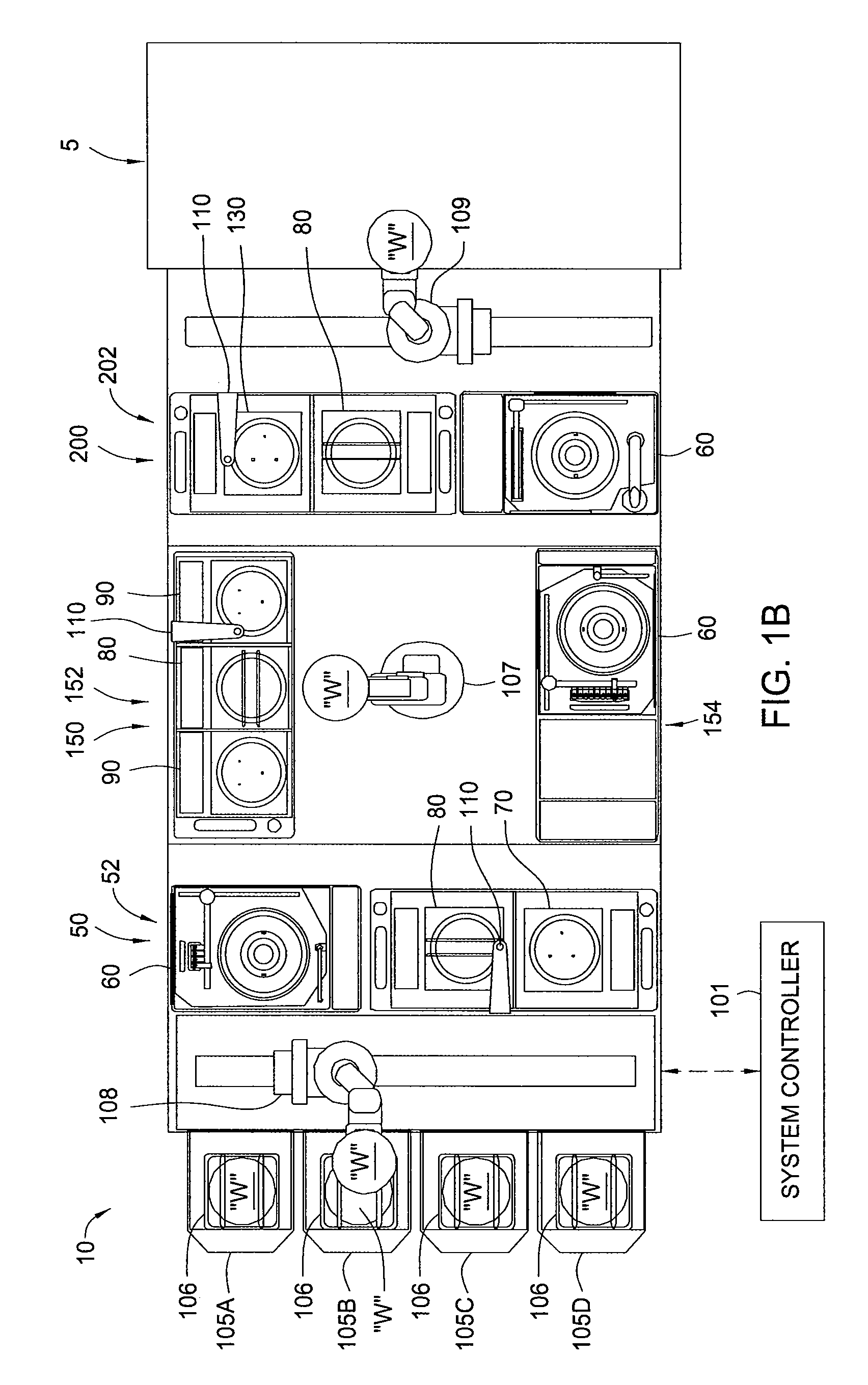

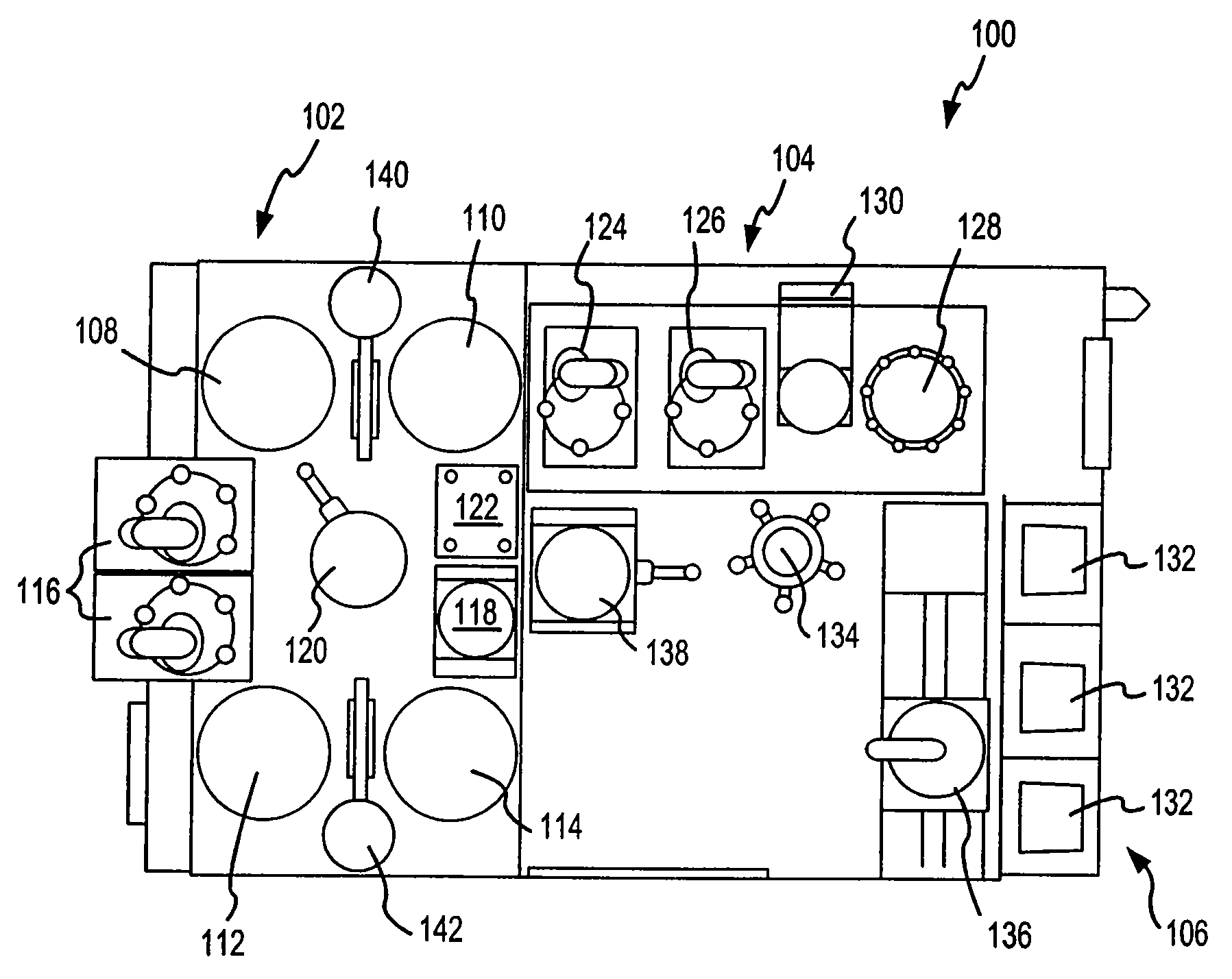

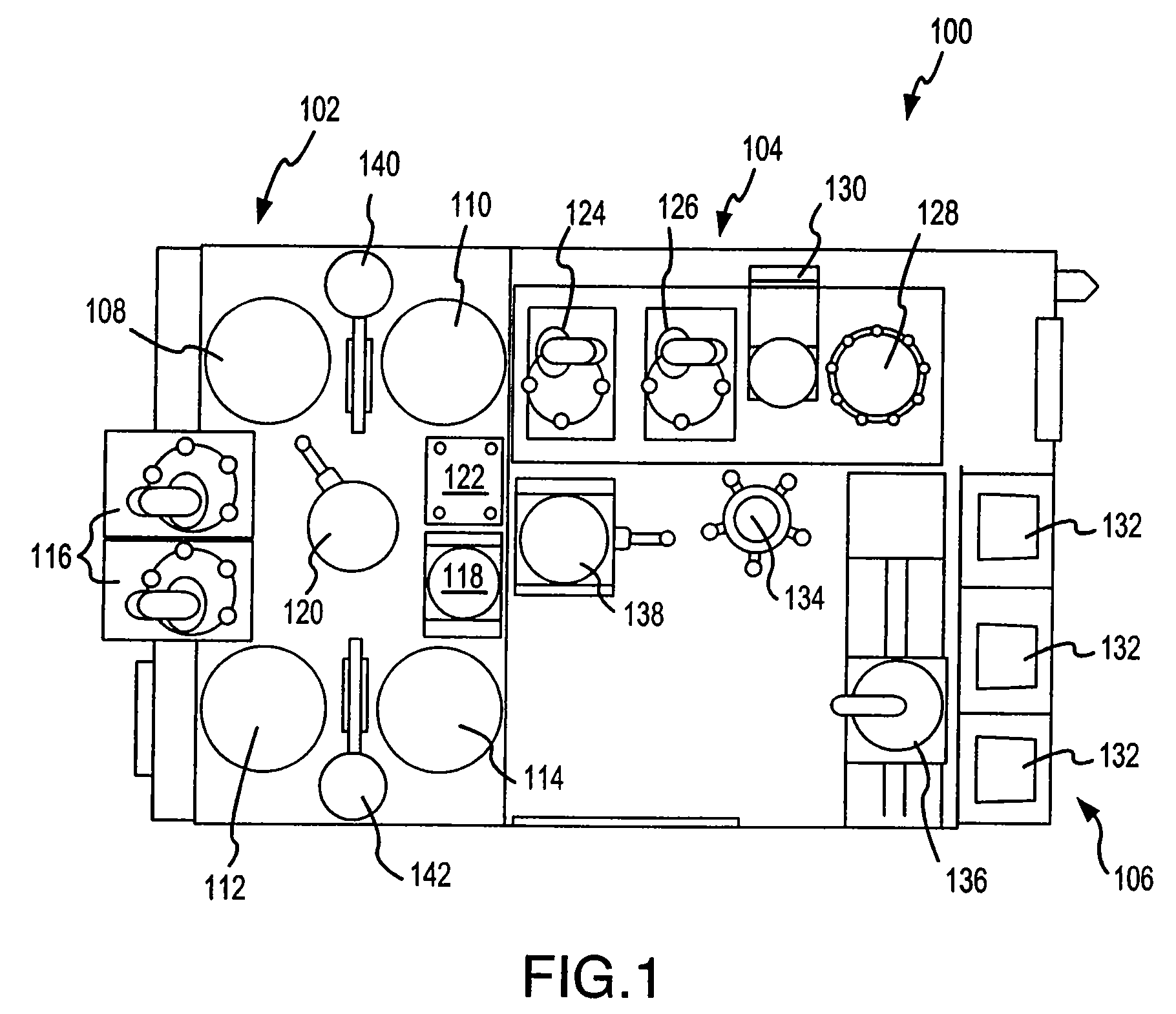

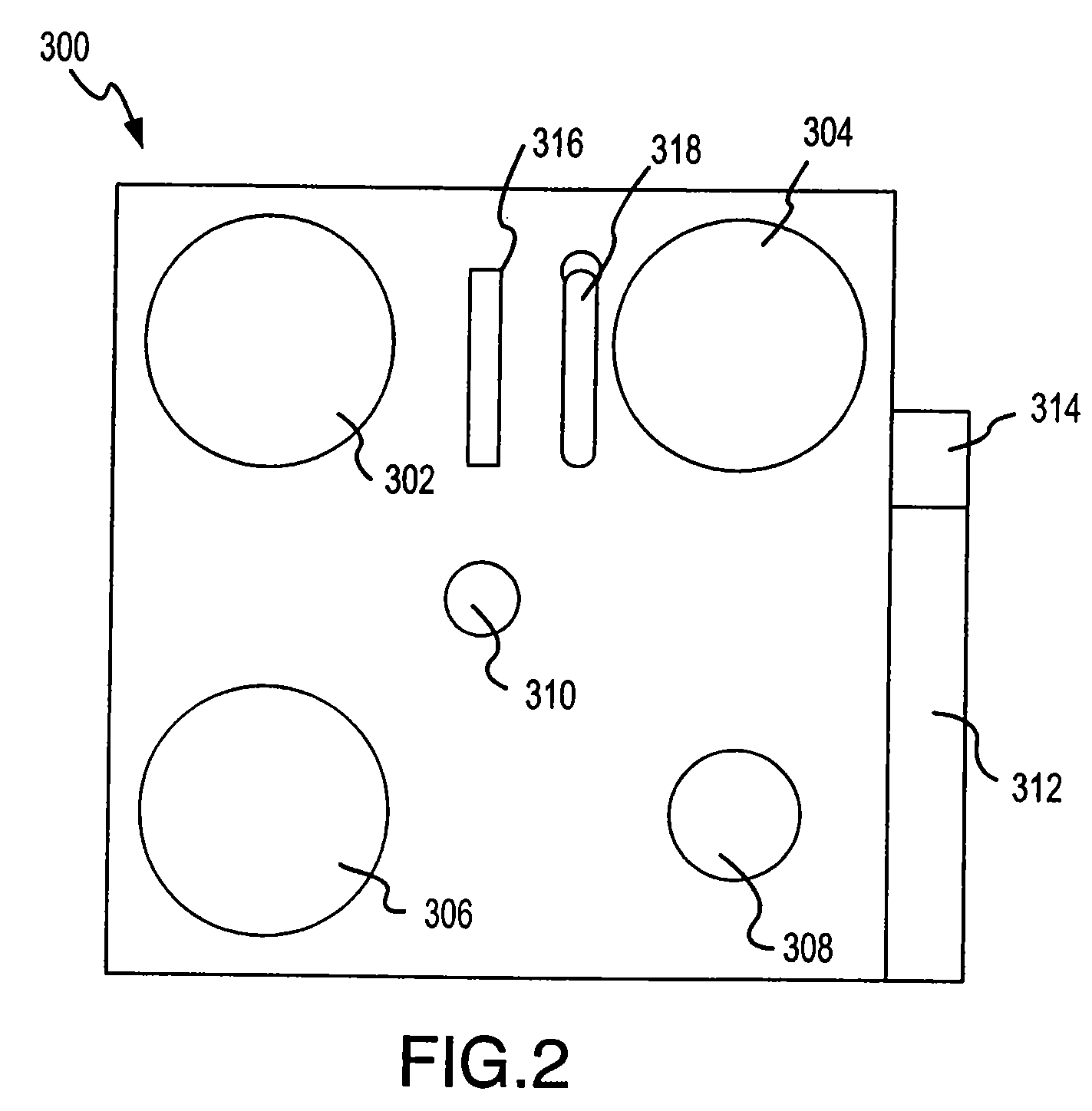

Cluster tool architecture for processing a substrate

ActiveUS20060130750A1Temperature controlMore repeatable wafer processing historyLiquid surface applicatorsSemiconductor/solid-state device testing/measurementLithography processEngineering

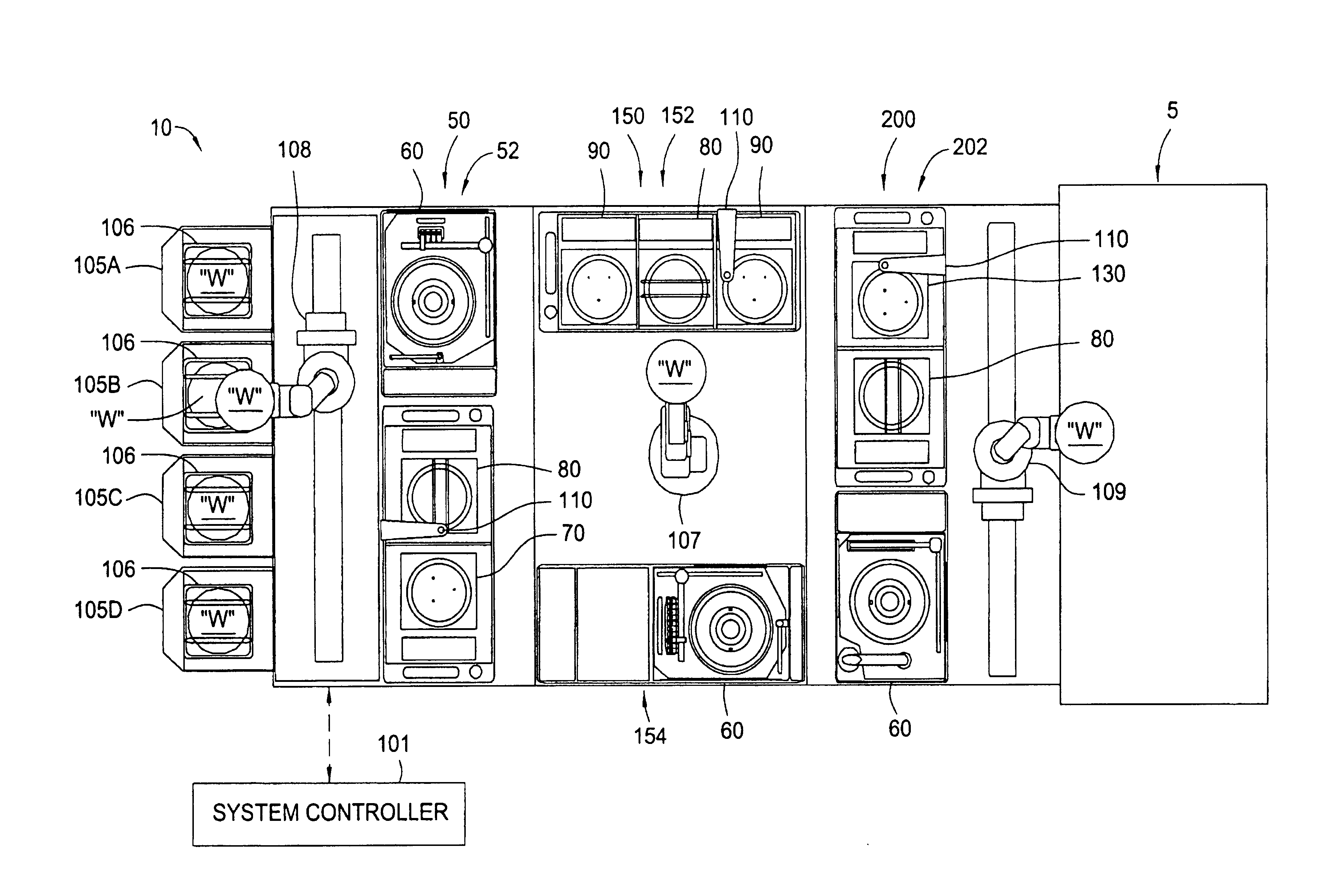

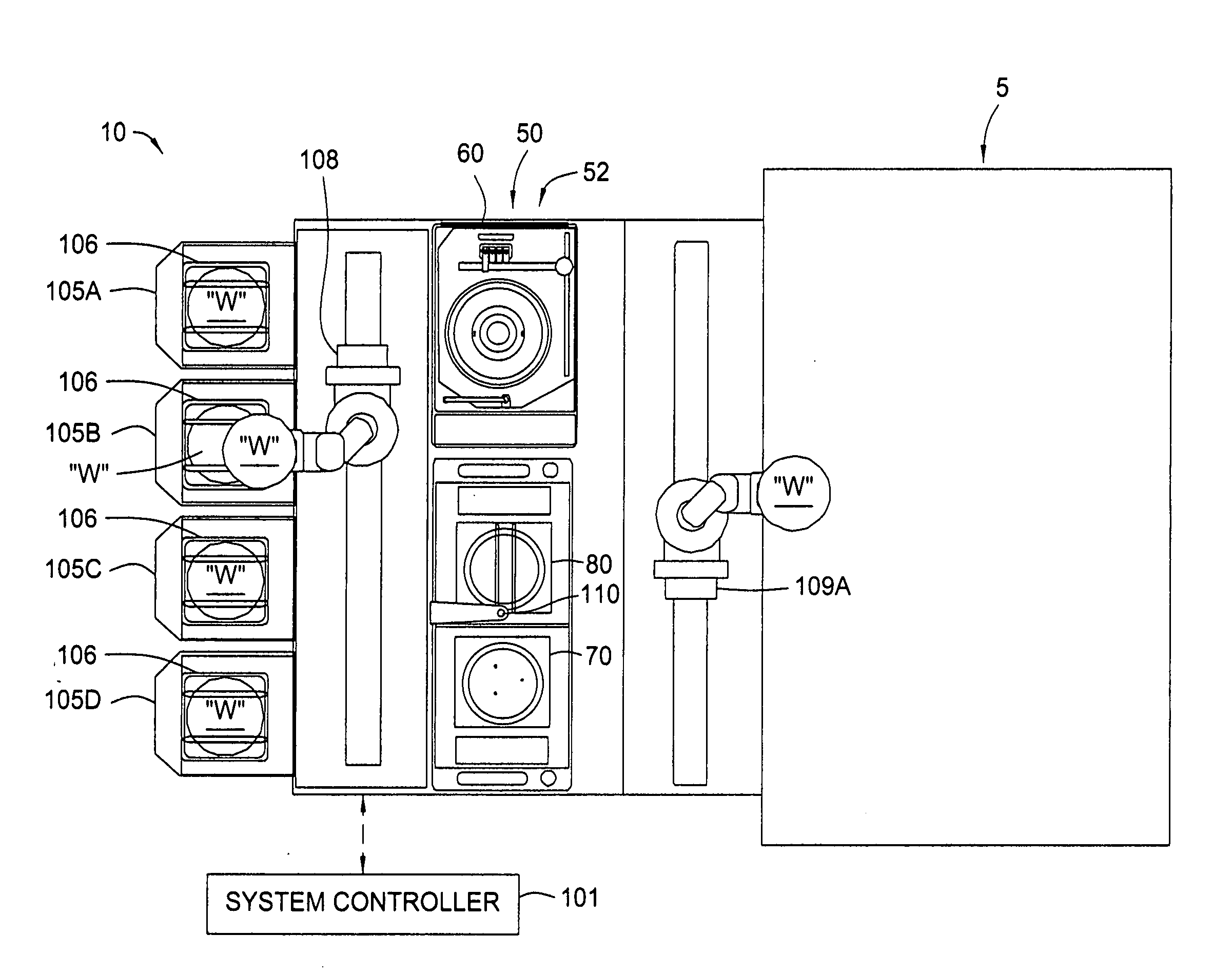

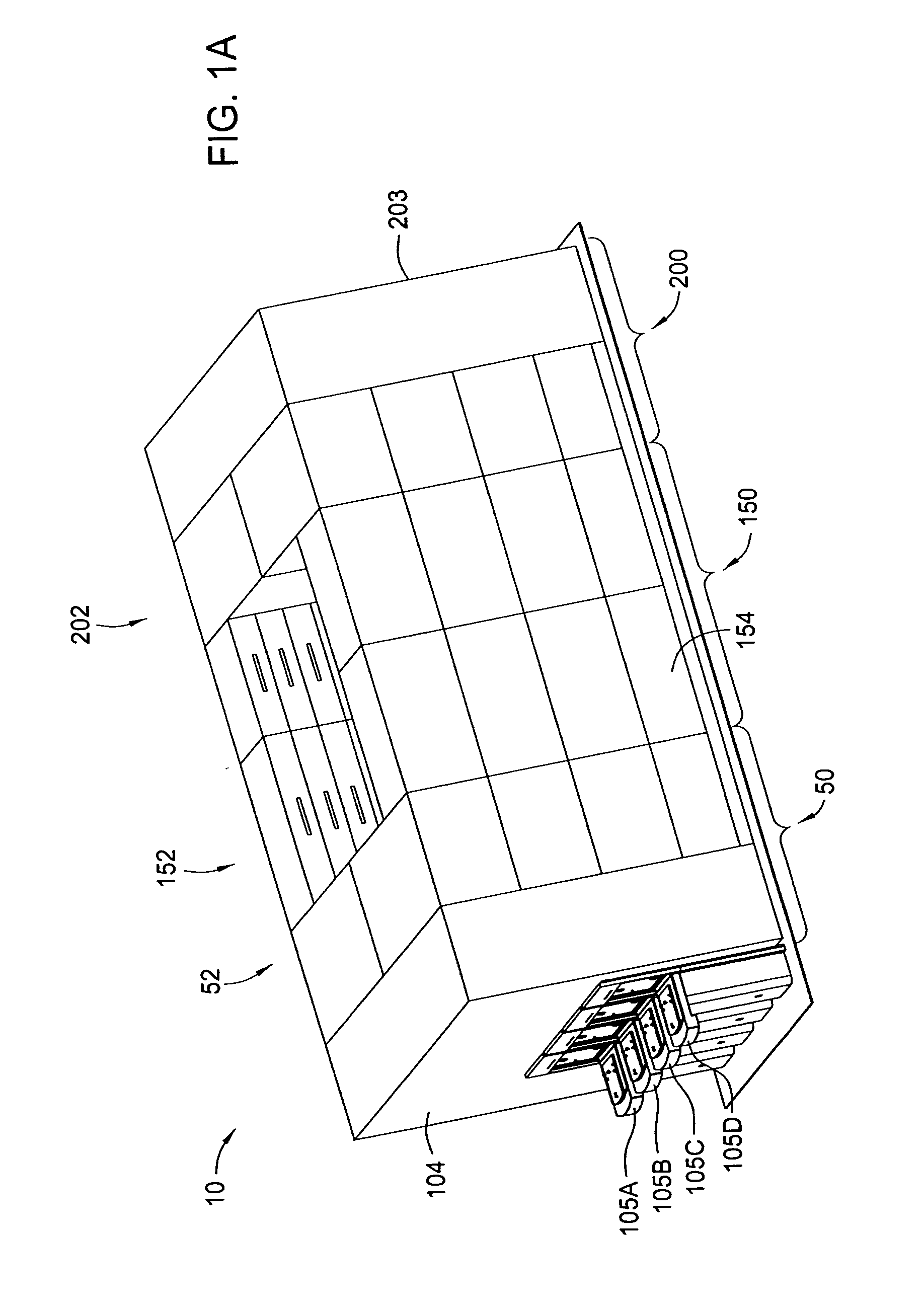

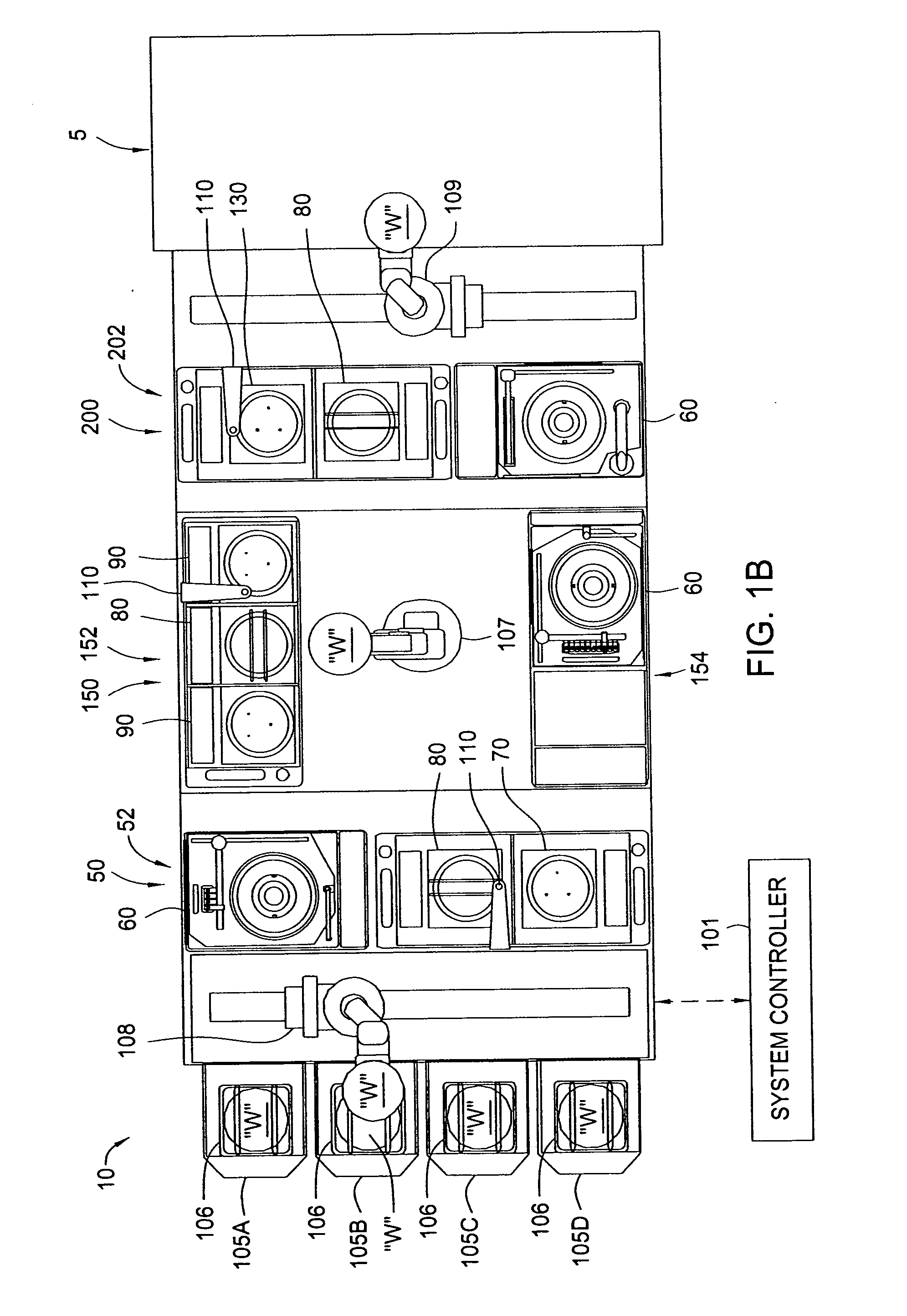

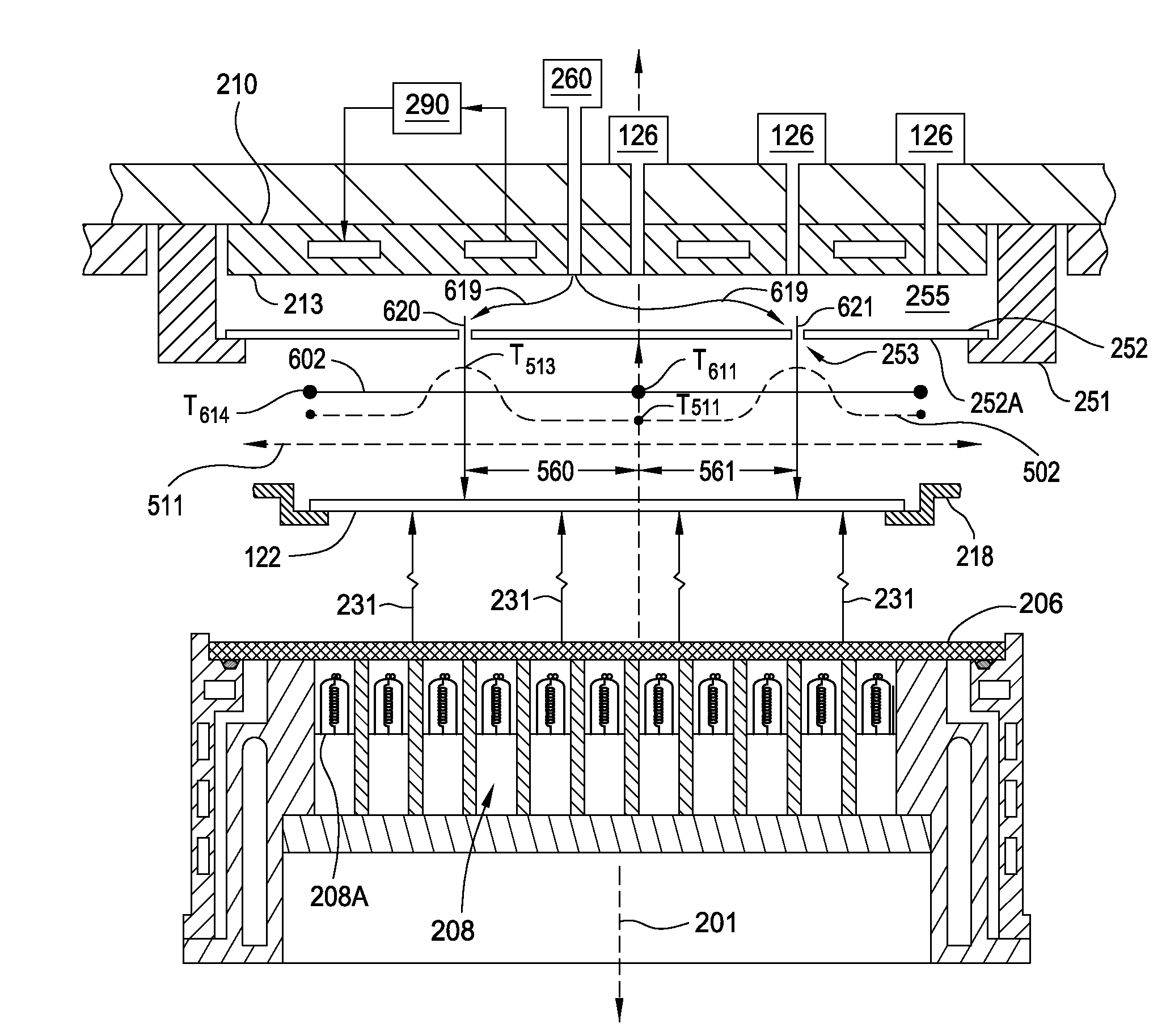

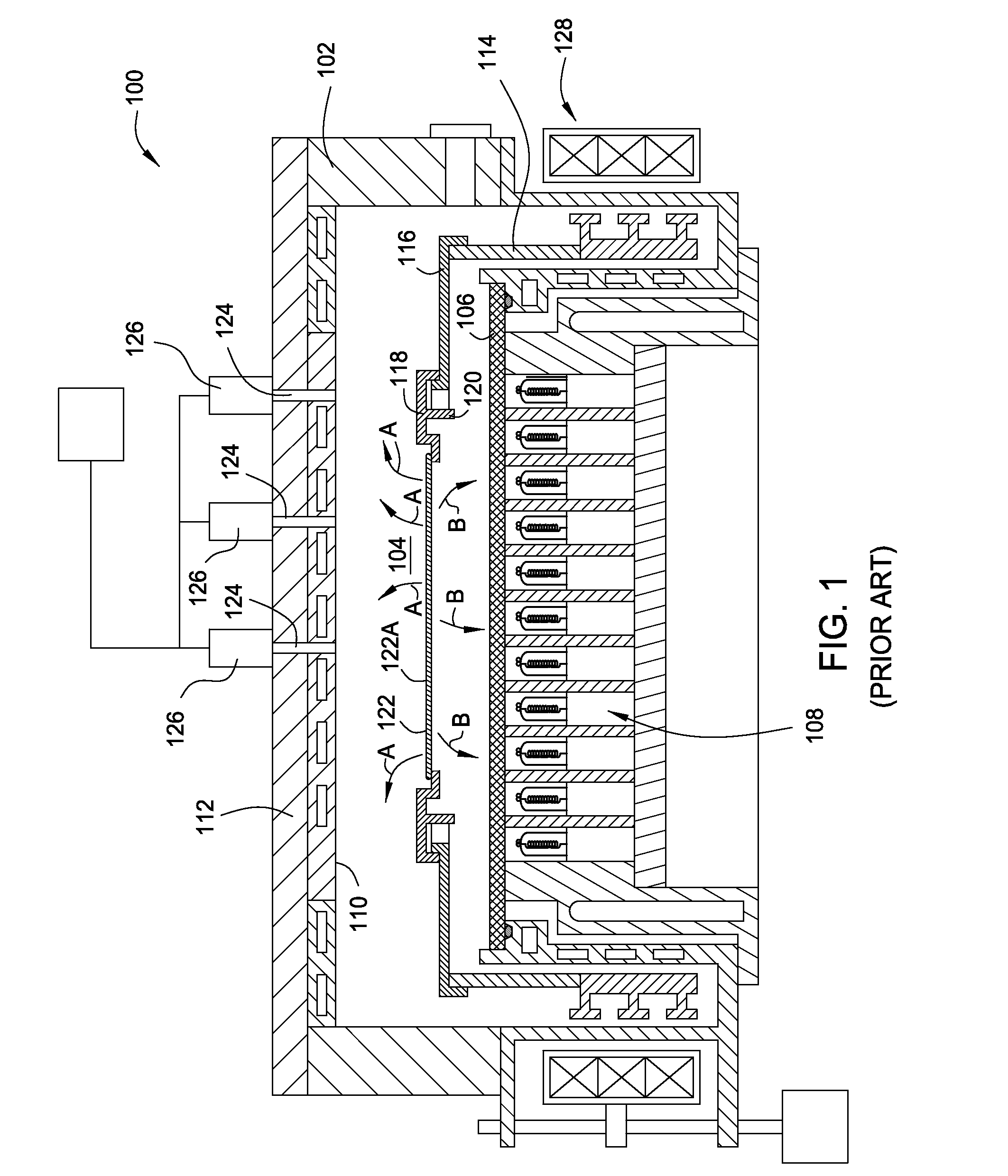

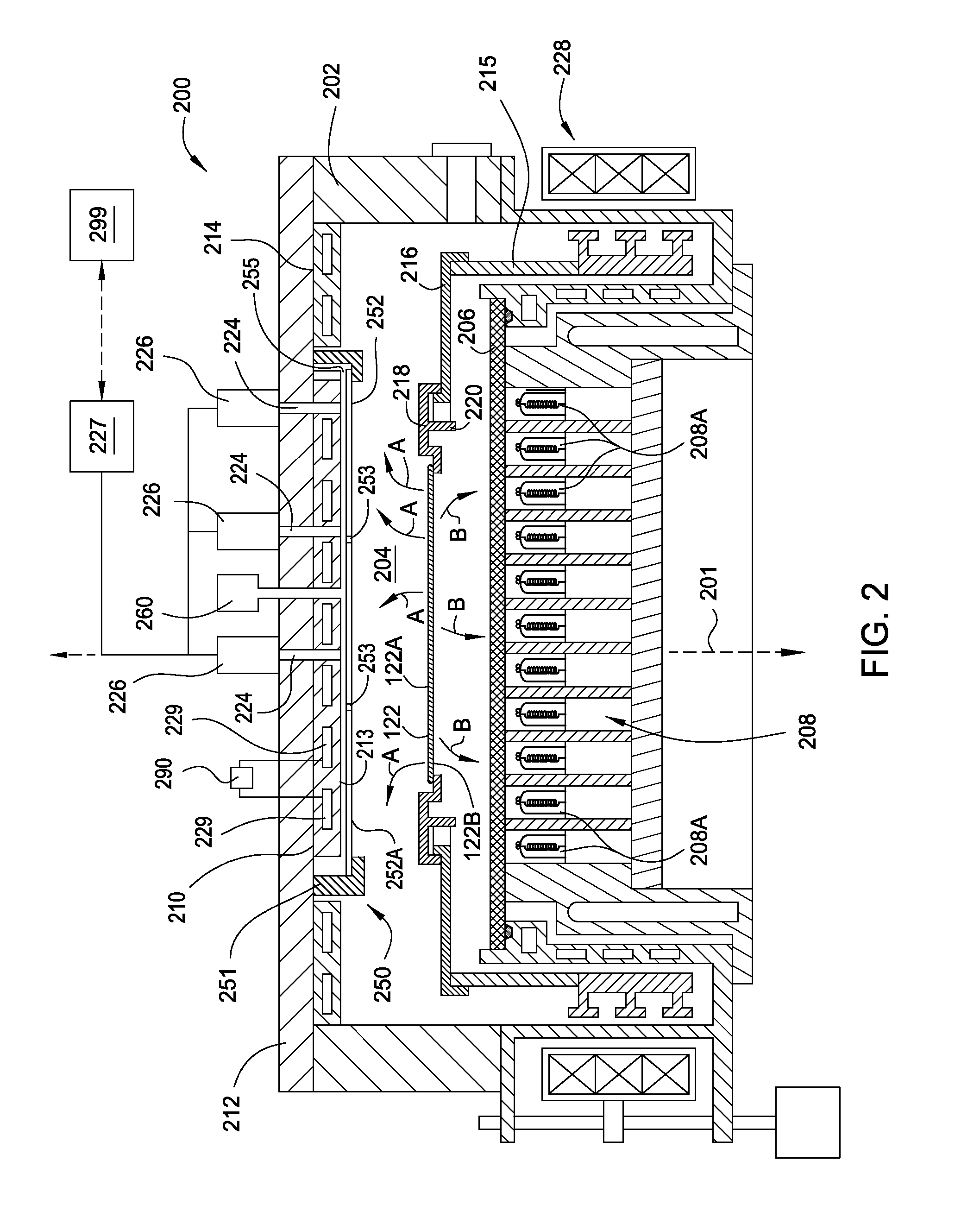

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history, and also the cluster tool has a smaller system footprint. In one embodiment, the cluster tool is adapted to perform a track lithography process in which a substrate is coated with a photosensitive material, is then transferred to a stepper / scanner, which exposes the photosensitive material to some form of radiation to form a pattern in the photosensitive material, which is then removed in a developing process completed in the cluster tool. In track lithography type cluster tools, since the chamber processing times tend to be rather short, and the number of processing steps required to complete a typical track system process is large, a significant portion of the time it takes to process a substrate is taken up by the processes of transferring the substrates in a cluster tool between the various processing chambers. In one embodiment of the cluster tool, the cost of ownership is reduced by grouping substrates together and transferring and processing the substrates in groups of two or more to improve system throughput, and reduces the number of moves a robot has to make to transfer a batch of substrates between the processing chambers, thus reducing wear on the robot and increasing system reliability. In one aspect of the invention, the substrate processing sequence and cluster tool are designed so that the substrate transferring steps performed during the processing sequence are only made to chambers that will perform the next processing step in the processing sequence. Embodiments also provide for a method and apparatus that are used to improve the coater chamber, the developer chamber, the post exposure bake chamber, the chill chamber, and the bake chamber process results. Embodiments also provide for a method and apparatus that are used to increase the reliability of the substrate transfer process to reduce system down time.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

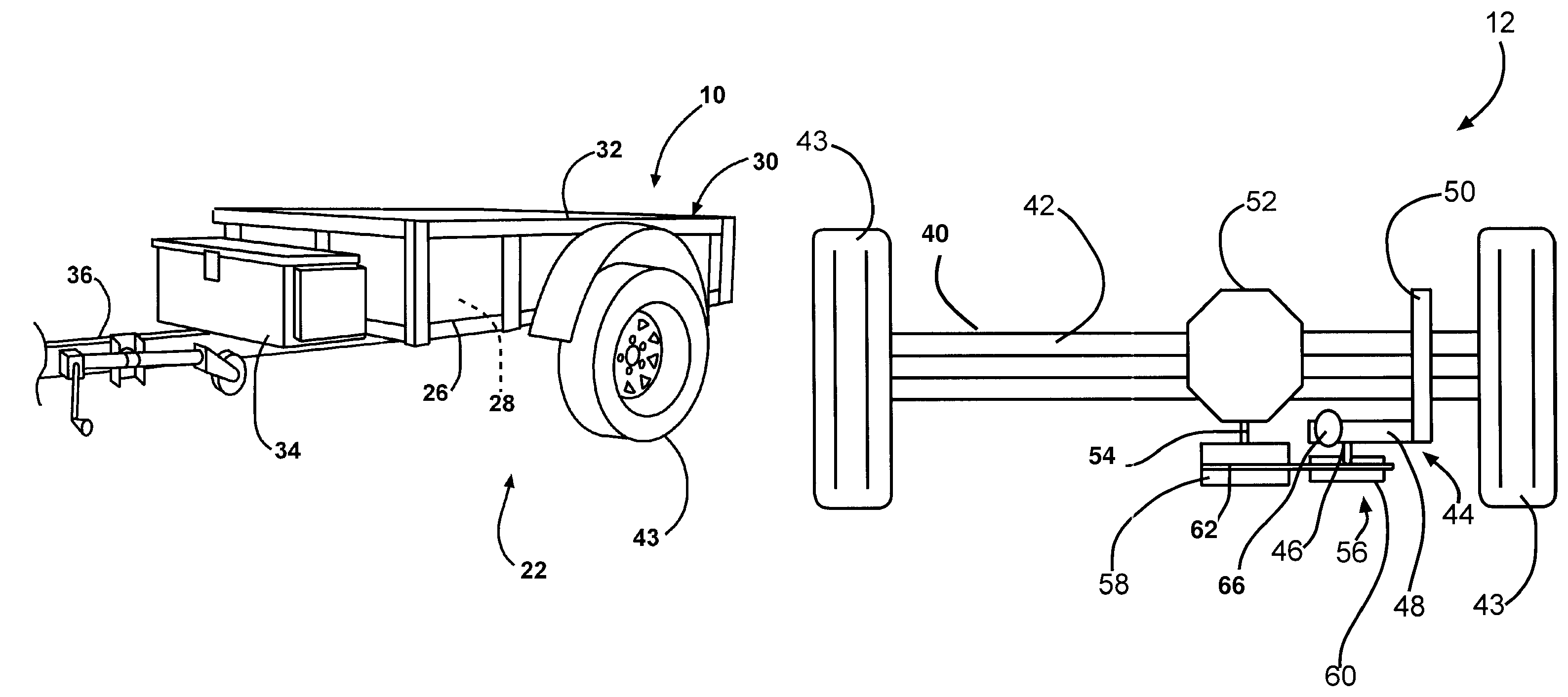

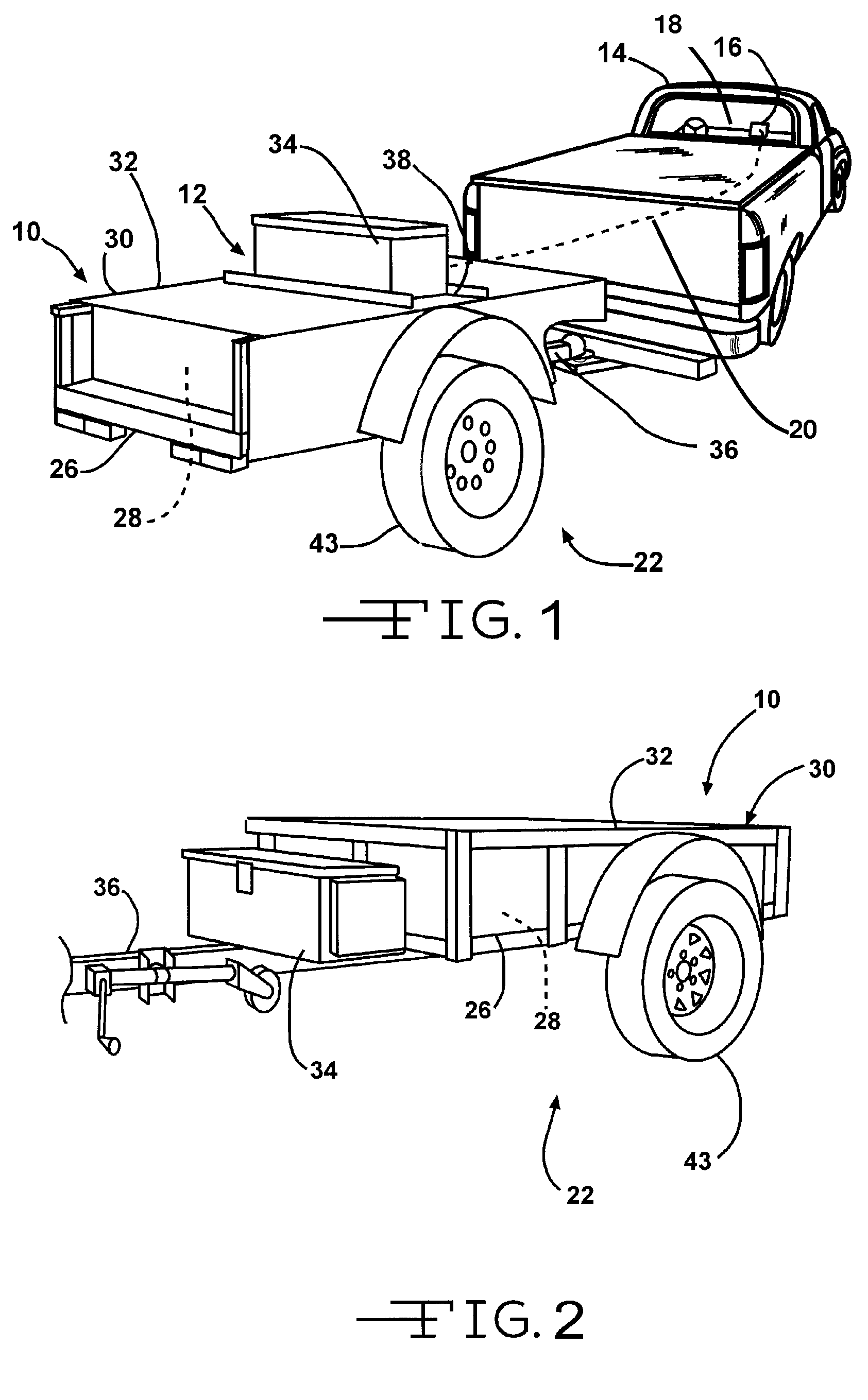

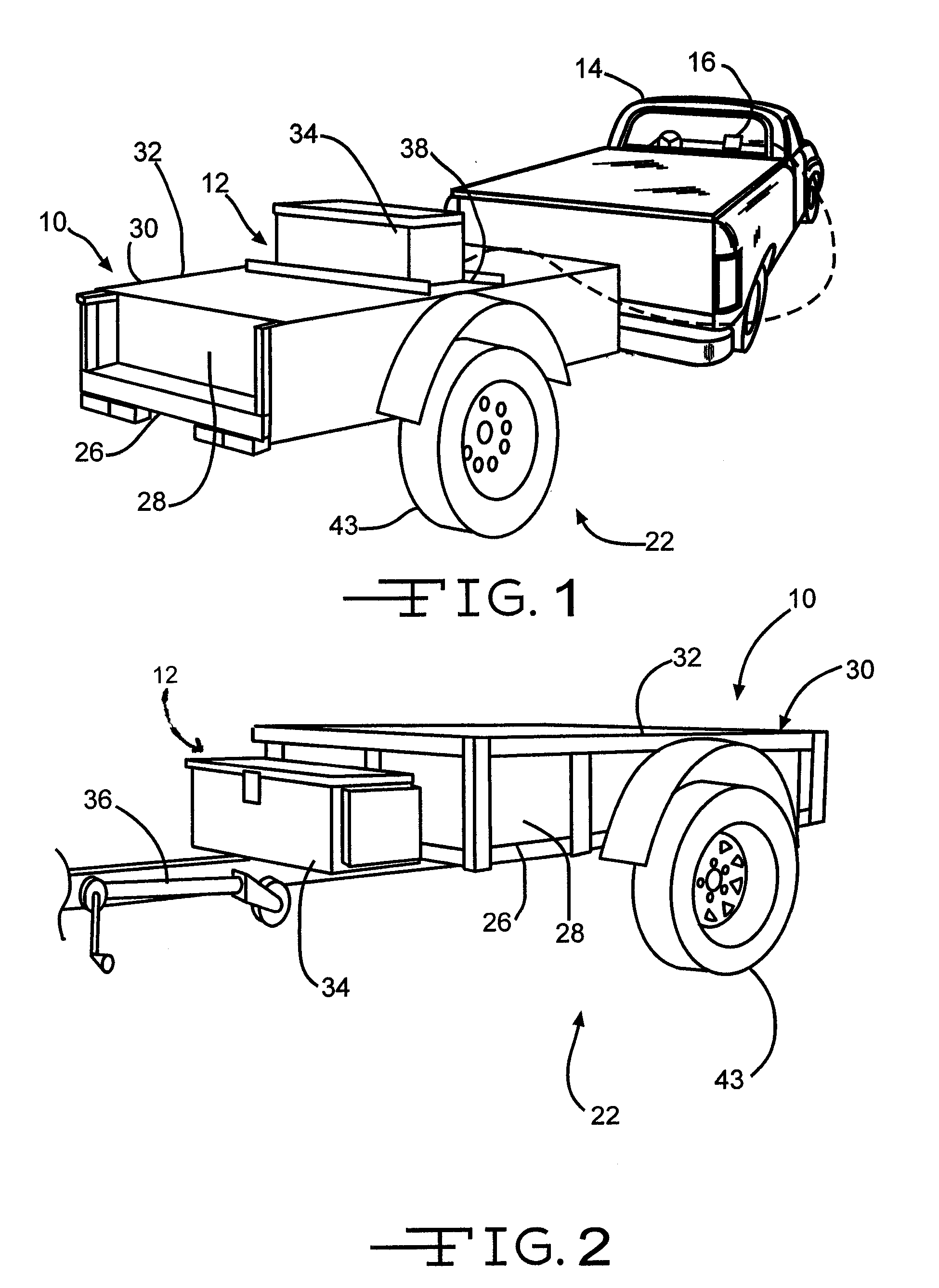

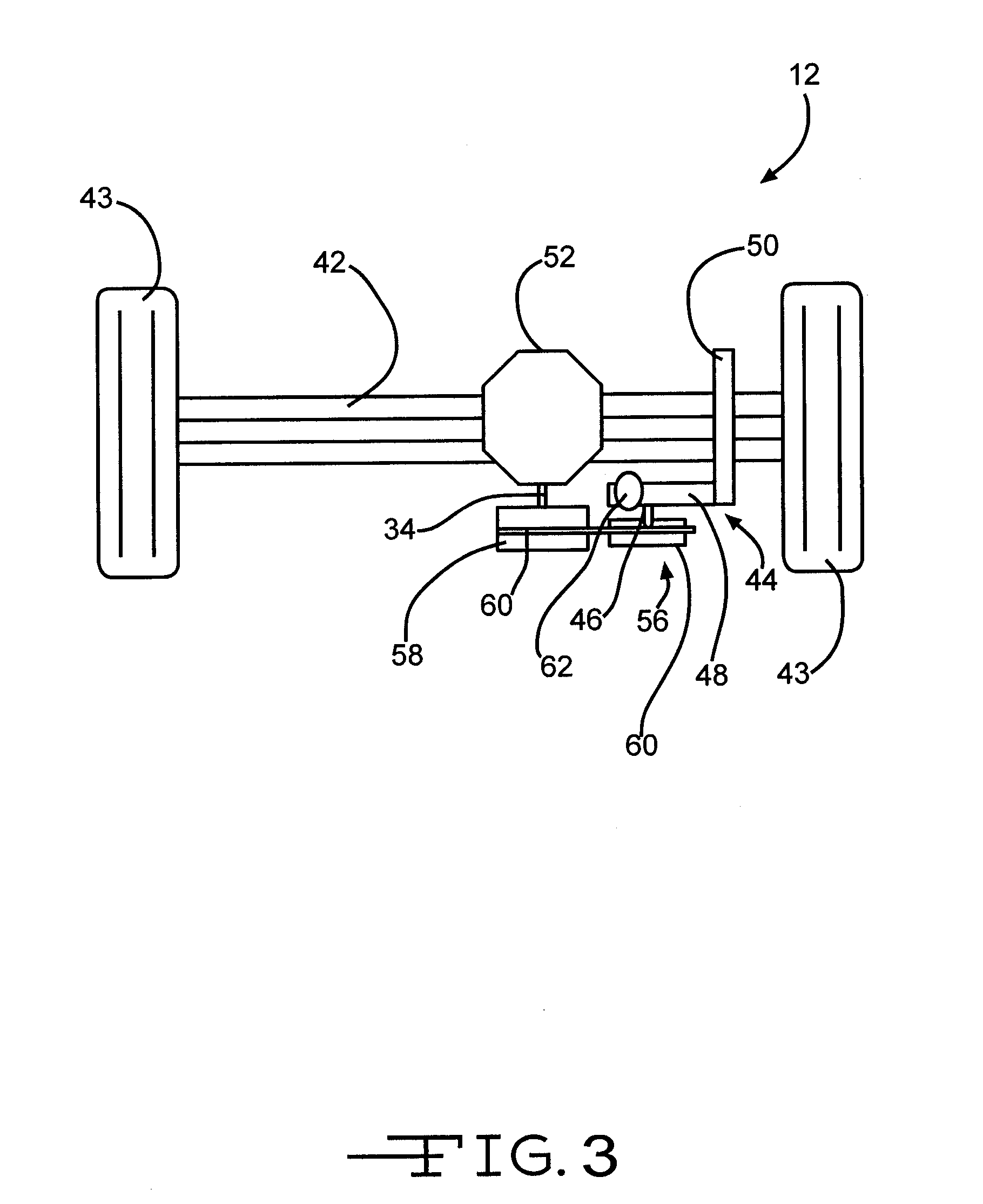

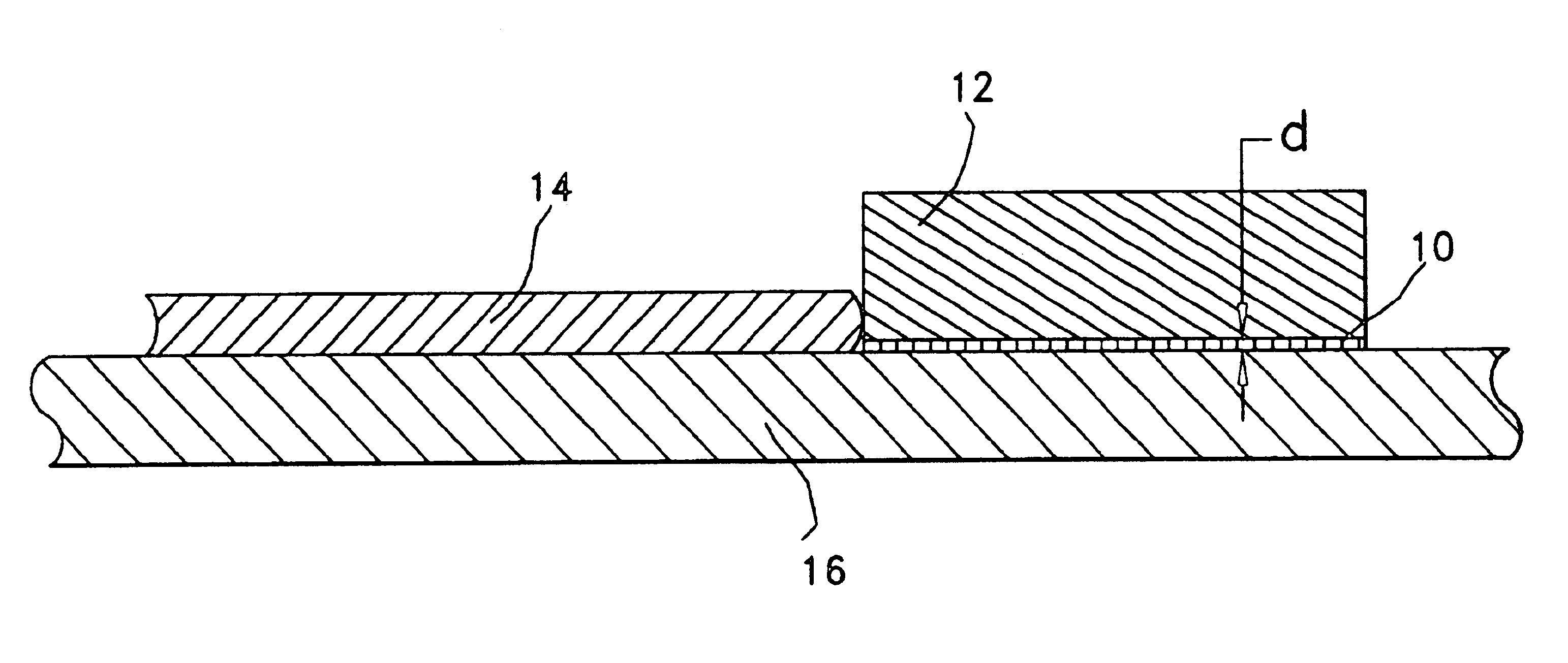

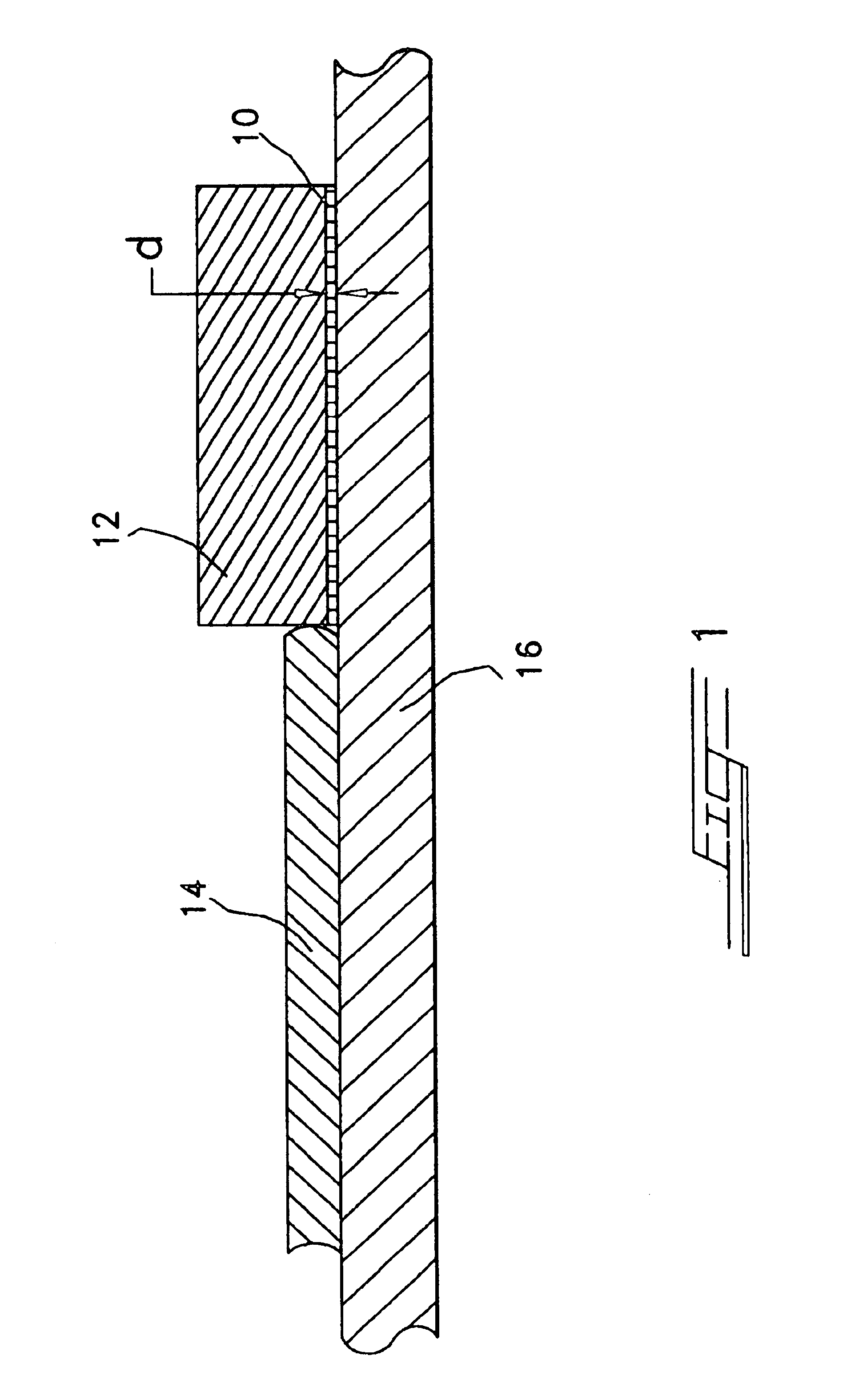

Trailer with integral axle-mounted generator and battery charger

Owner:WILKS PAUL L +1

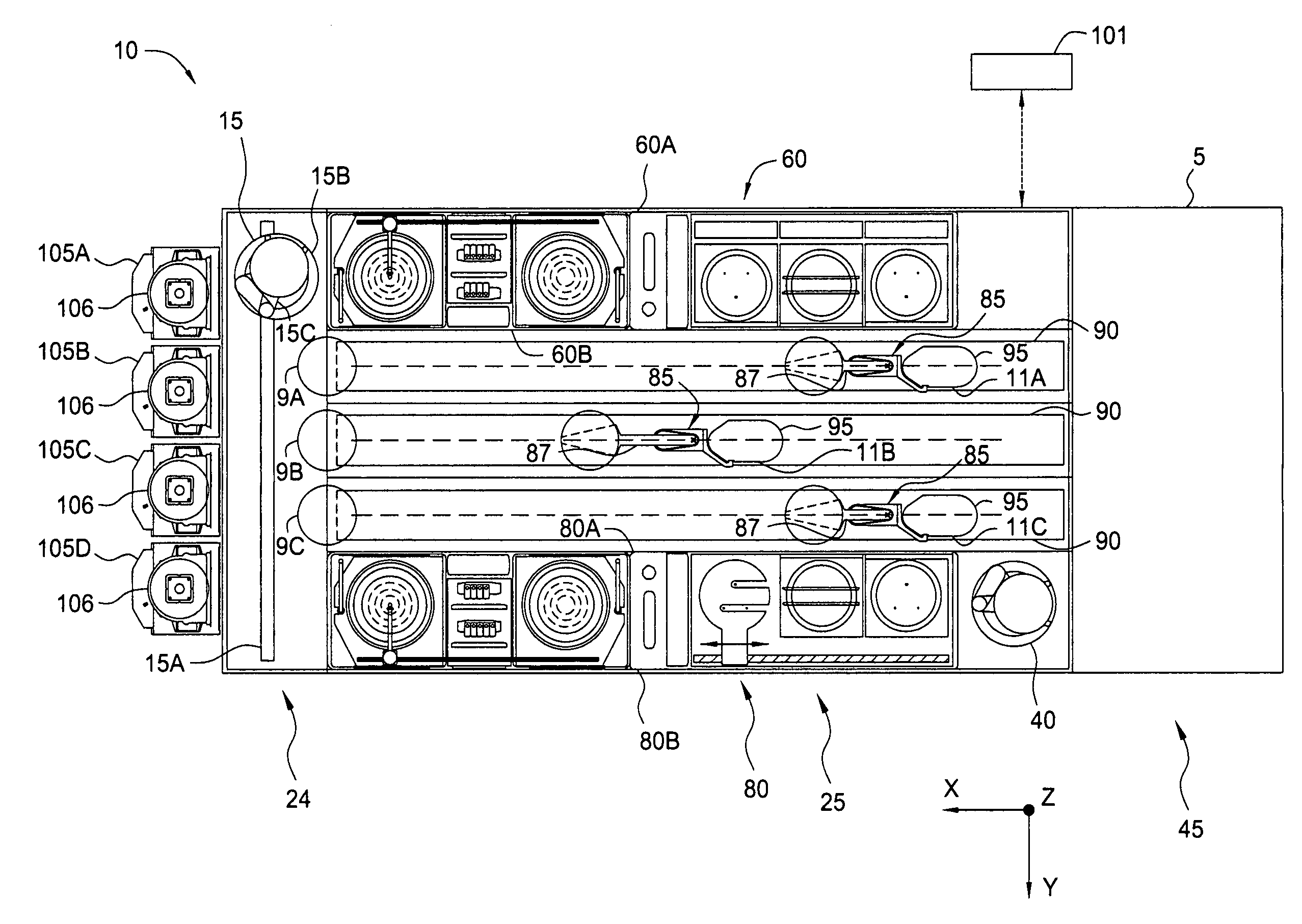

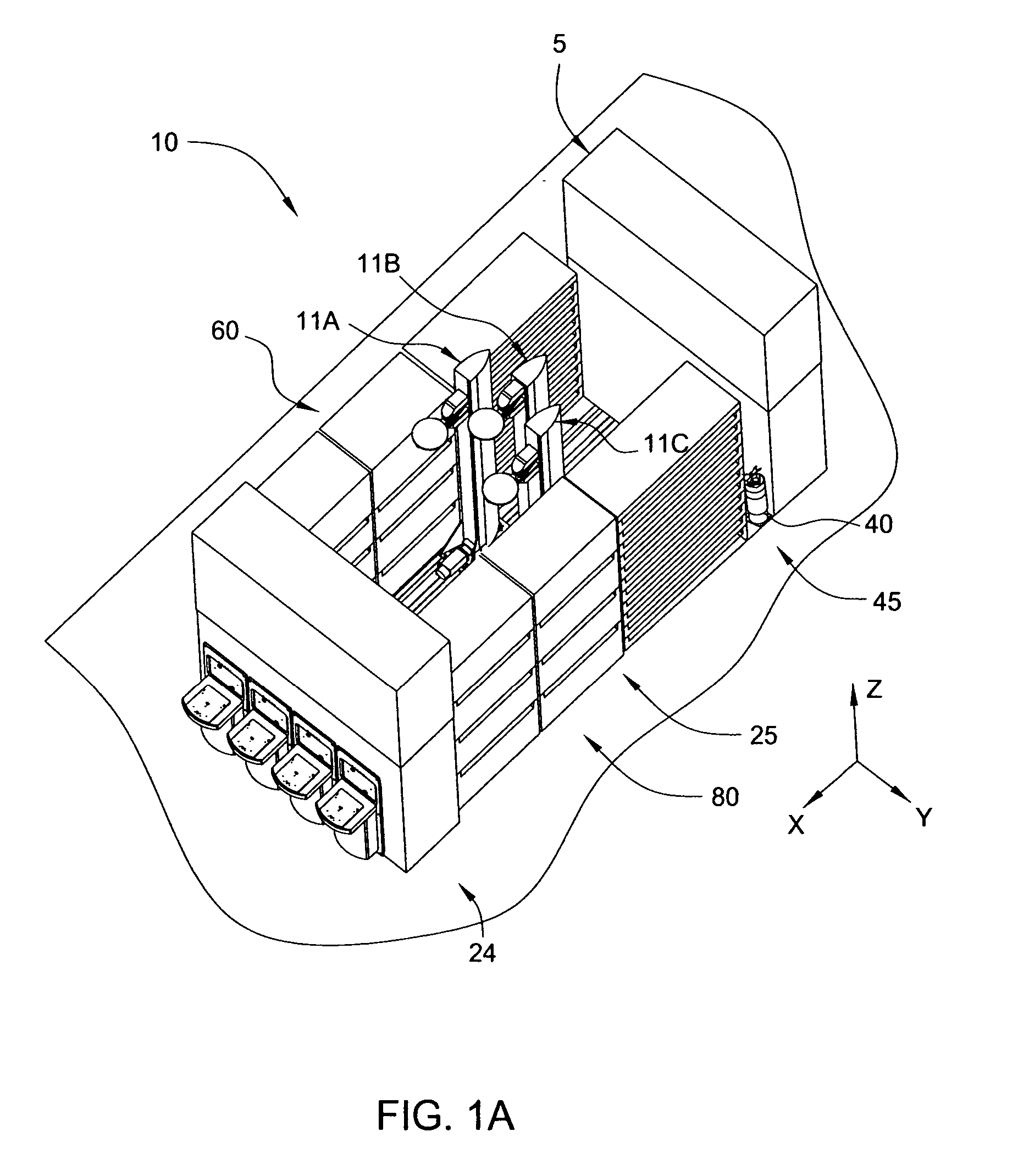

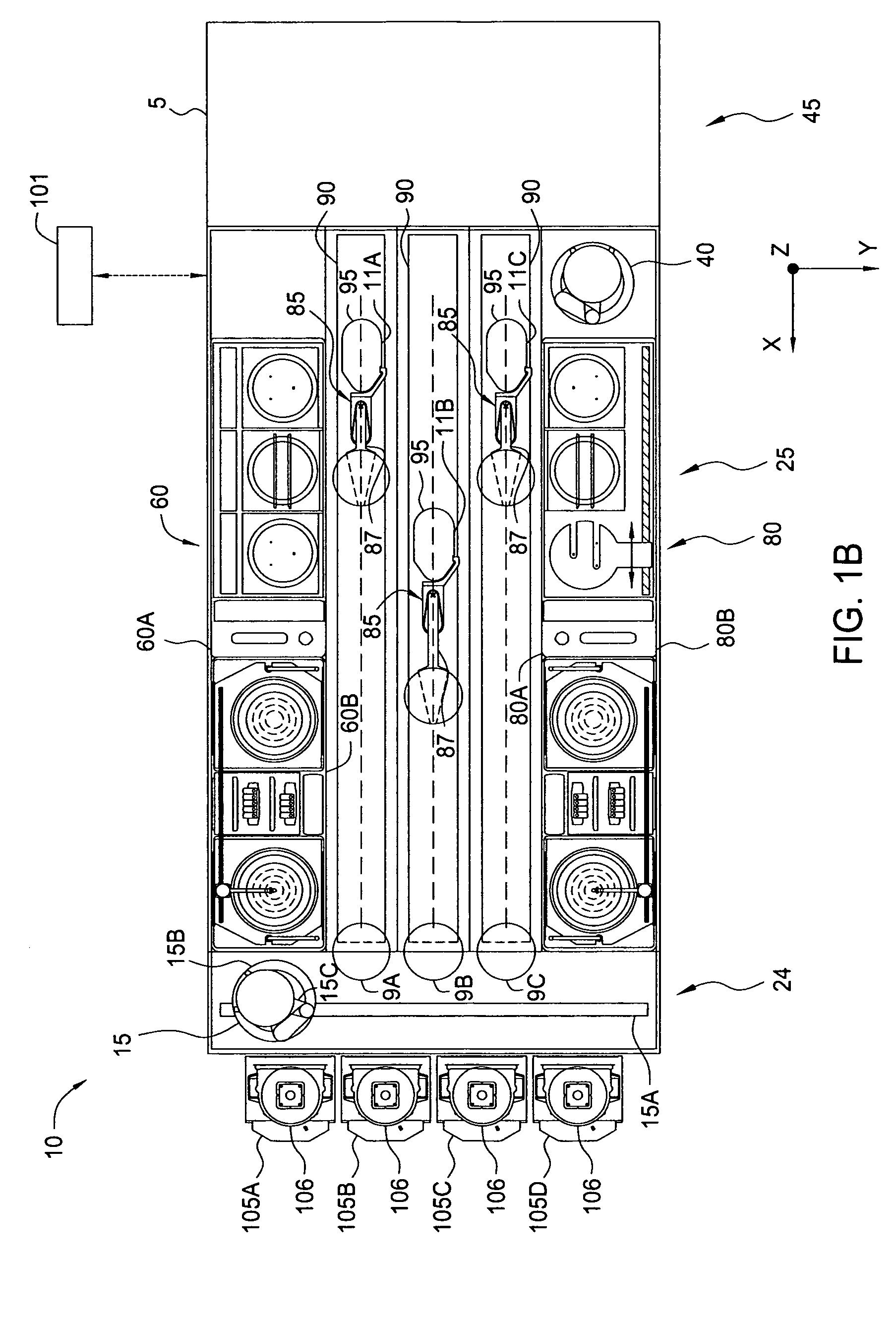

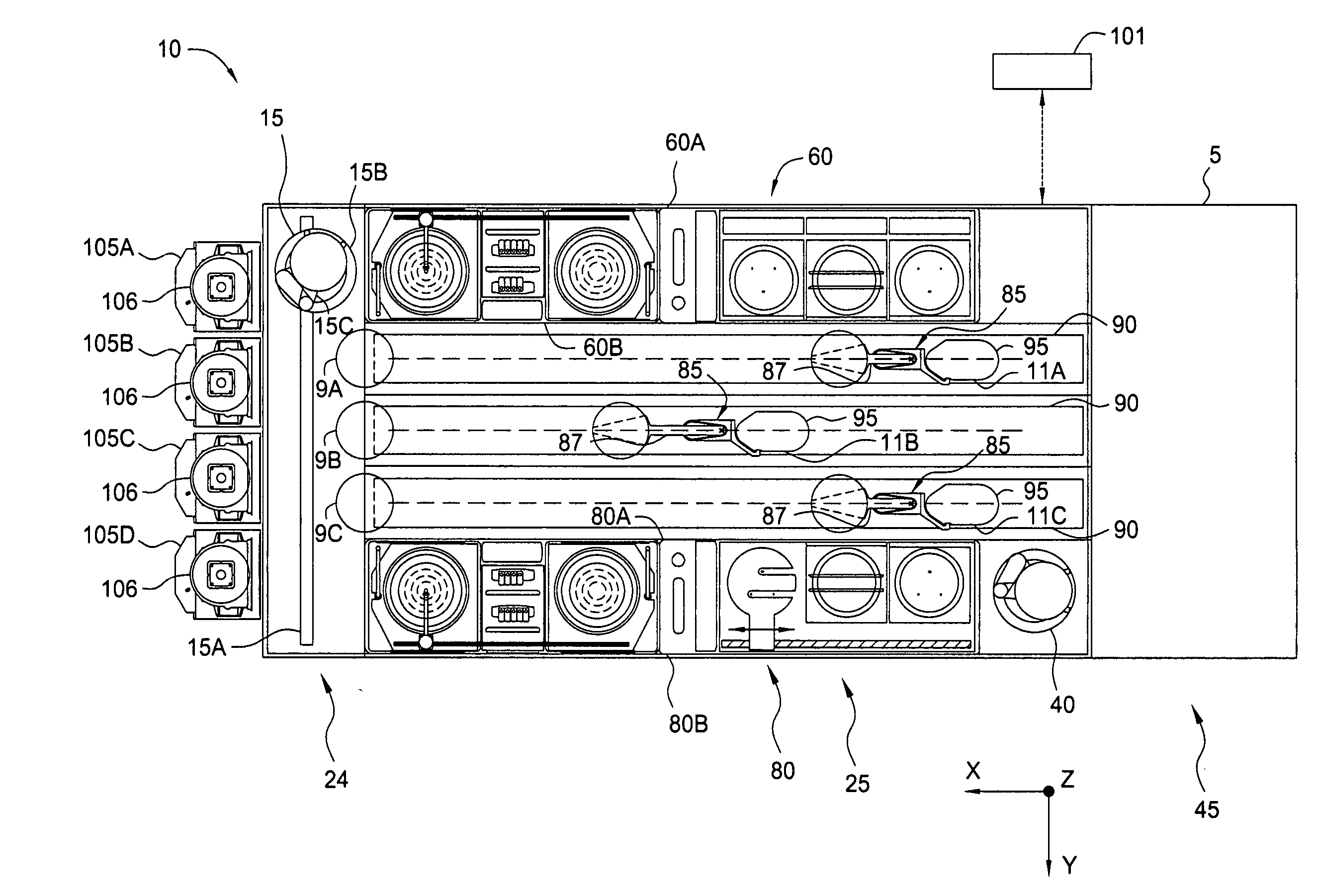

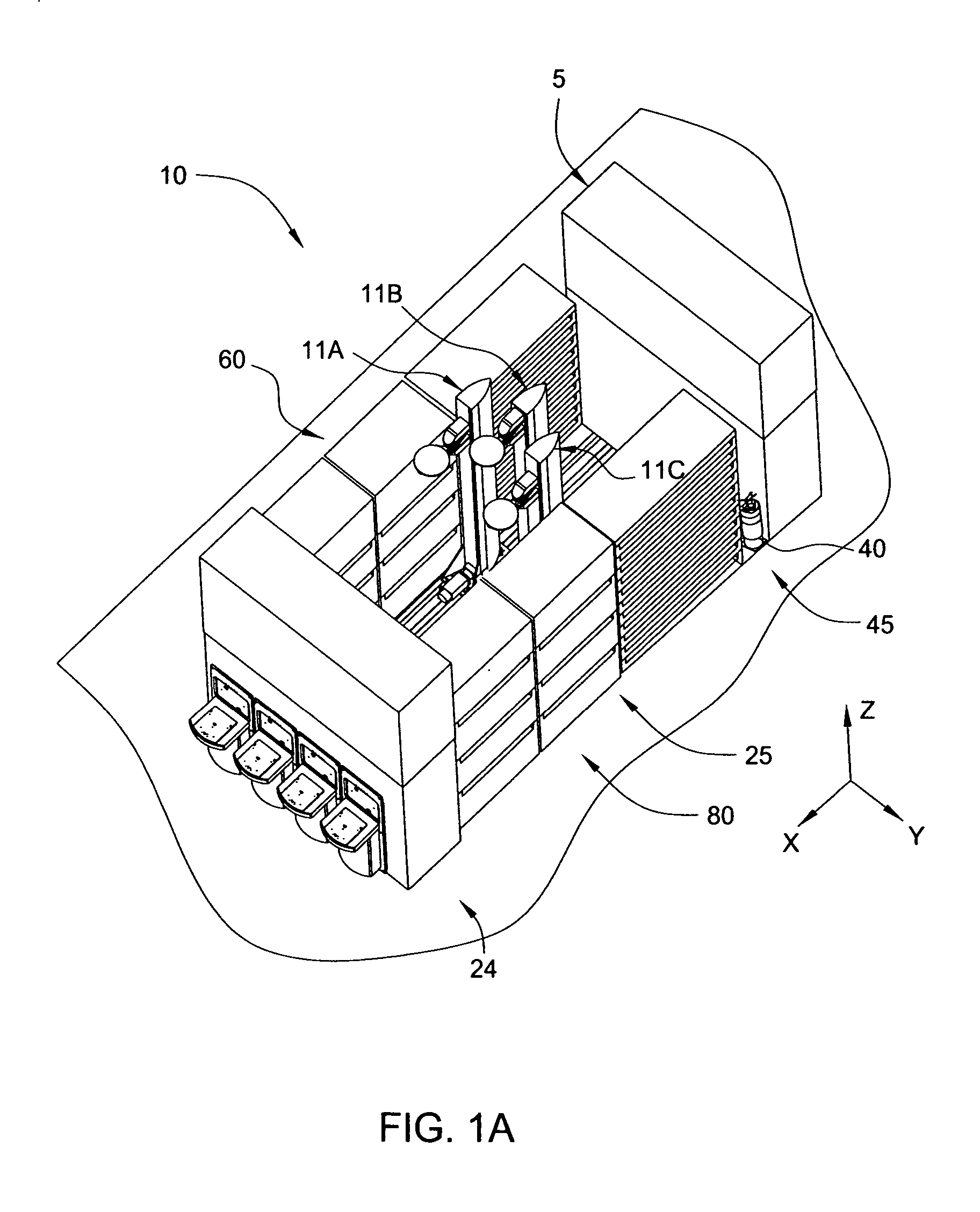

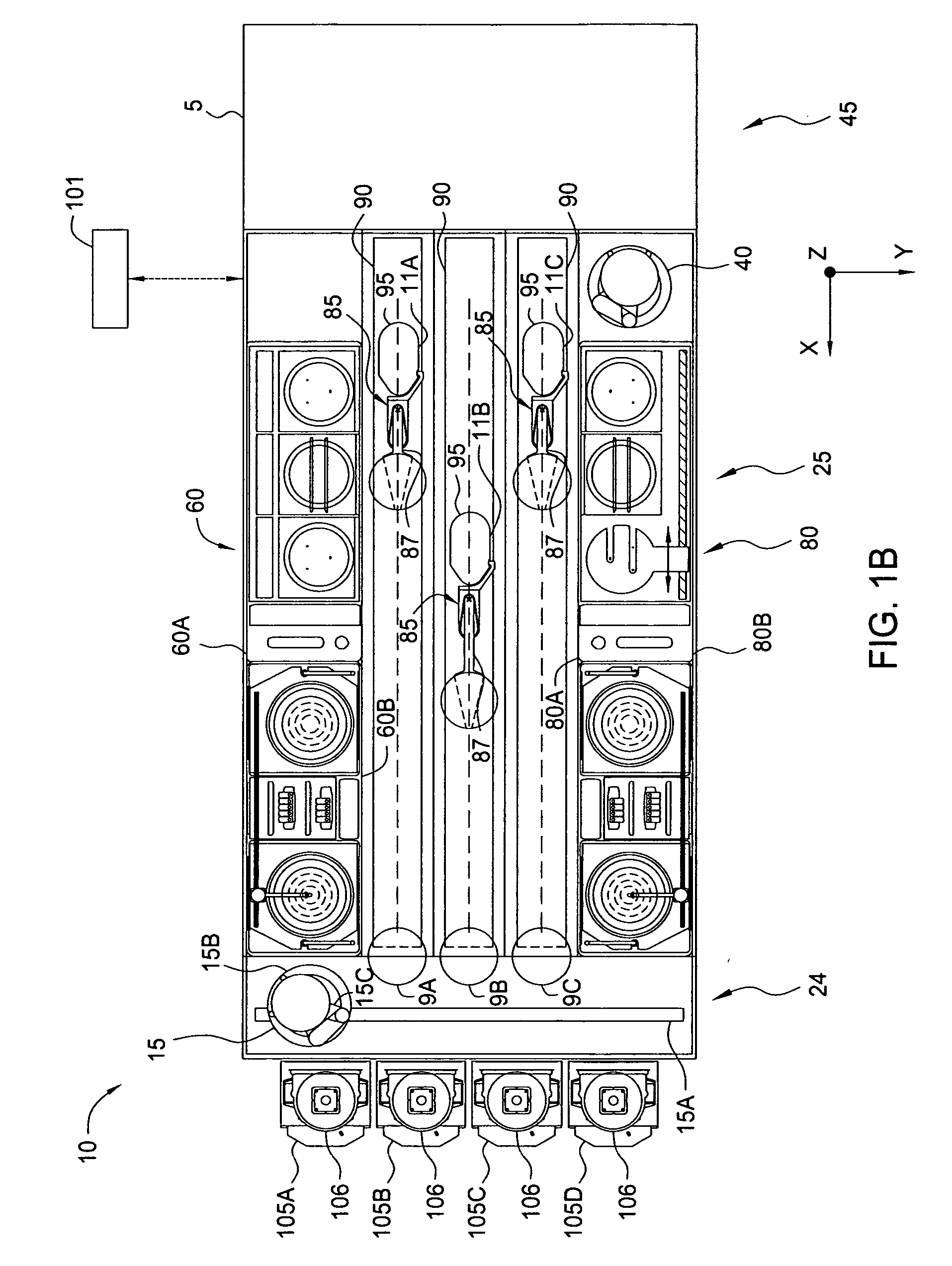

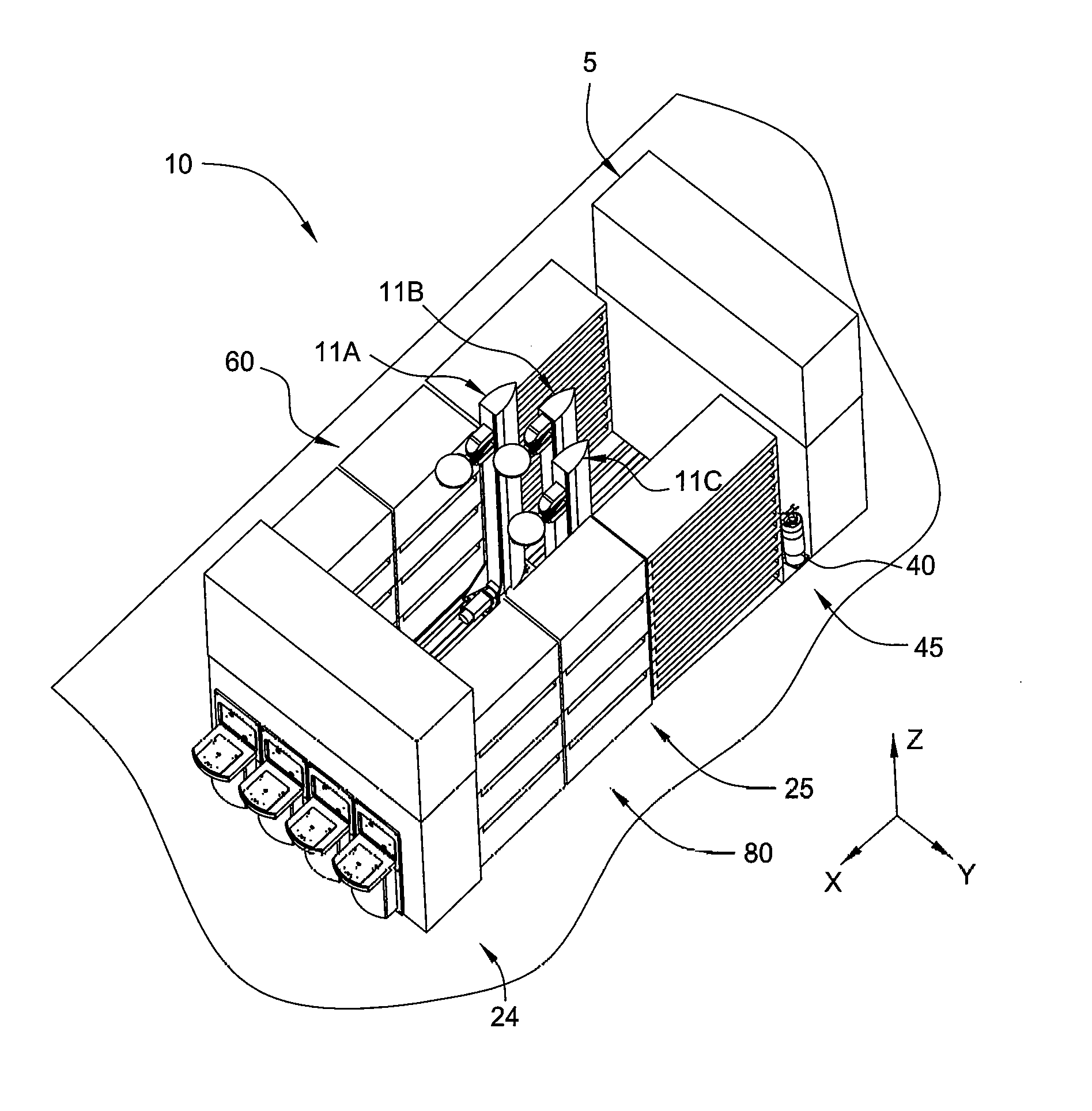

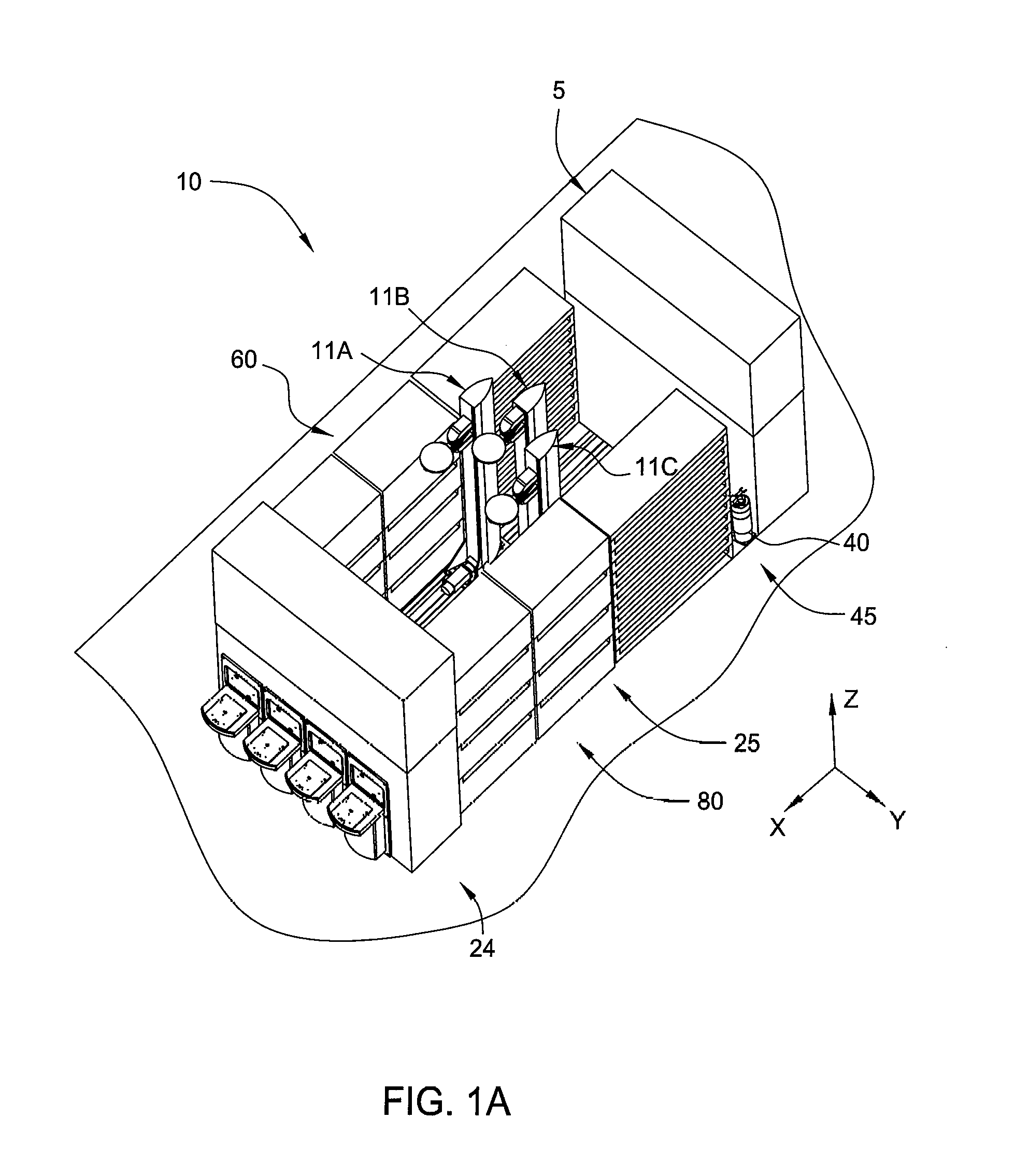

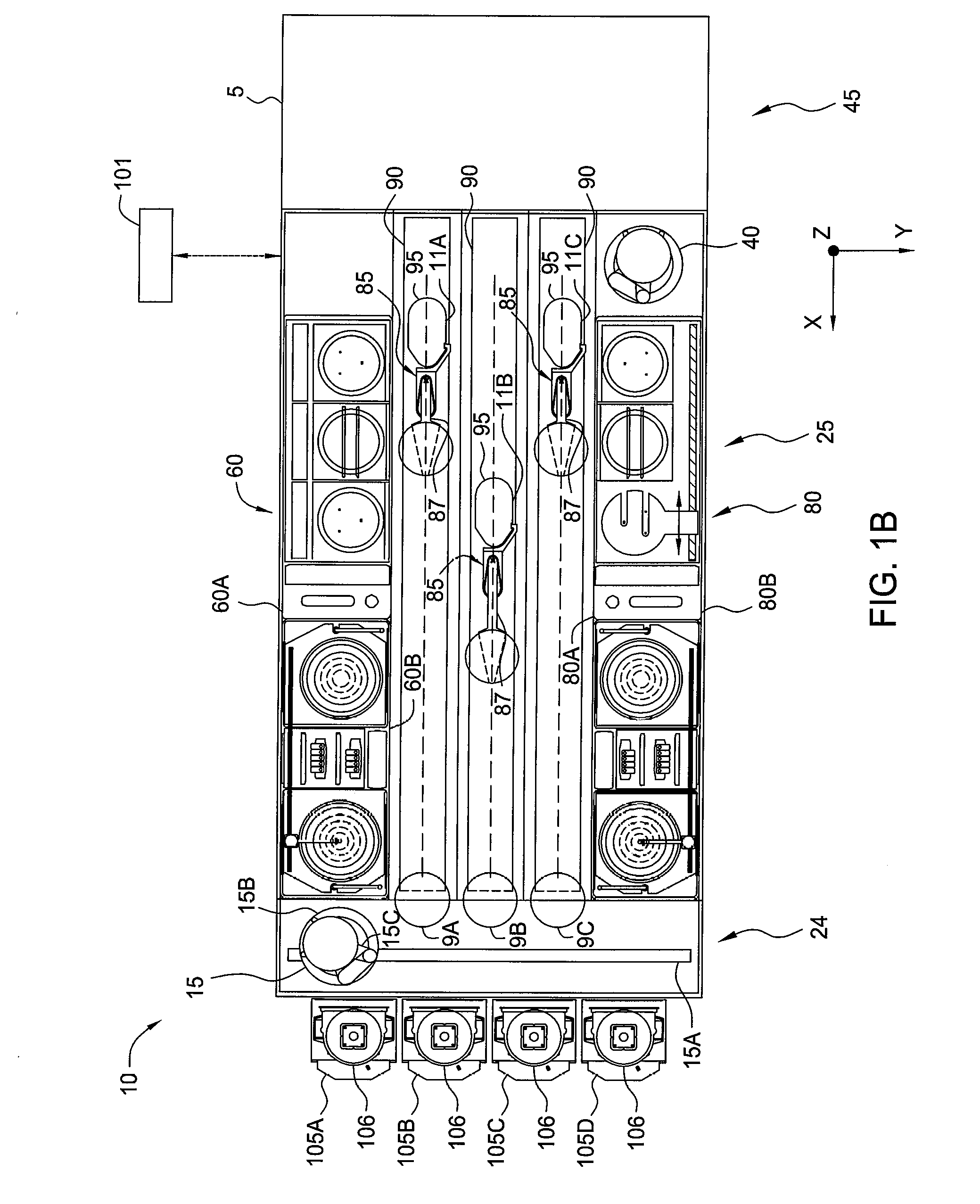

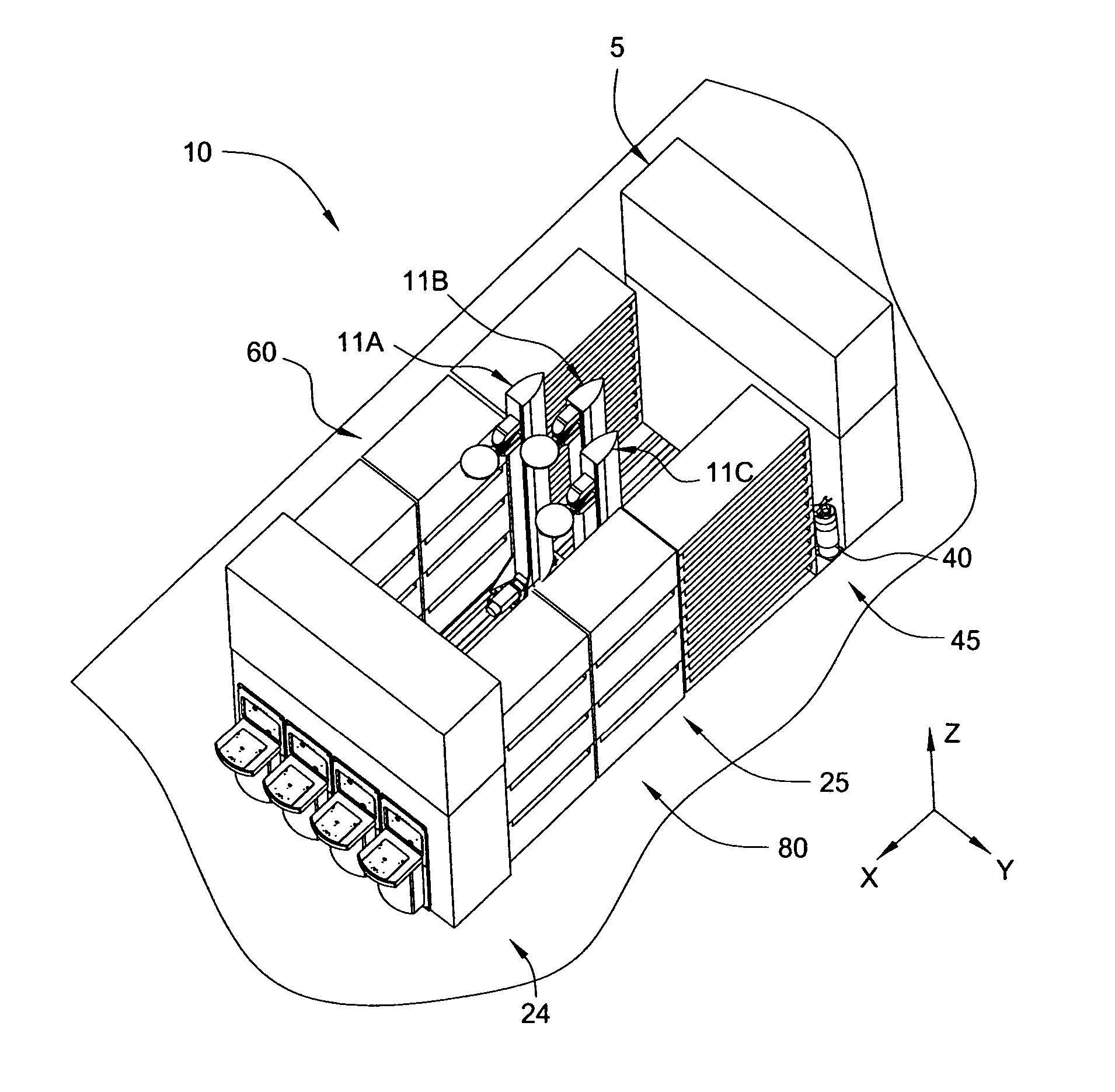

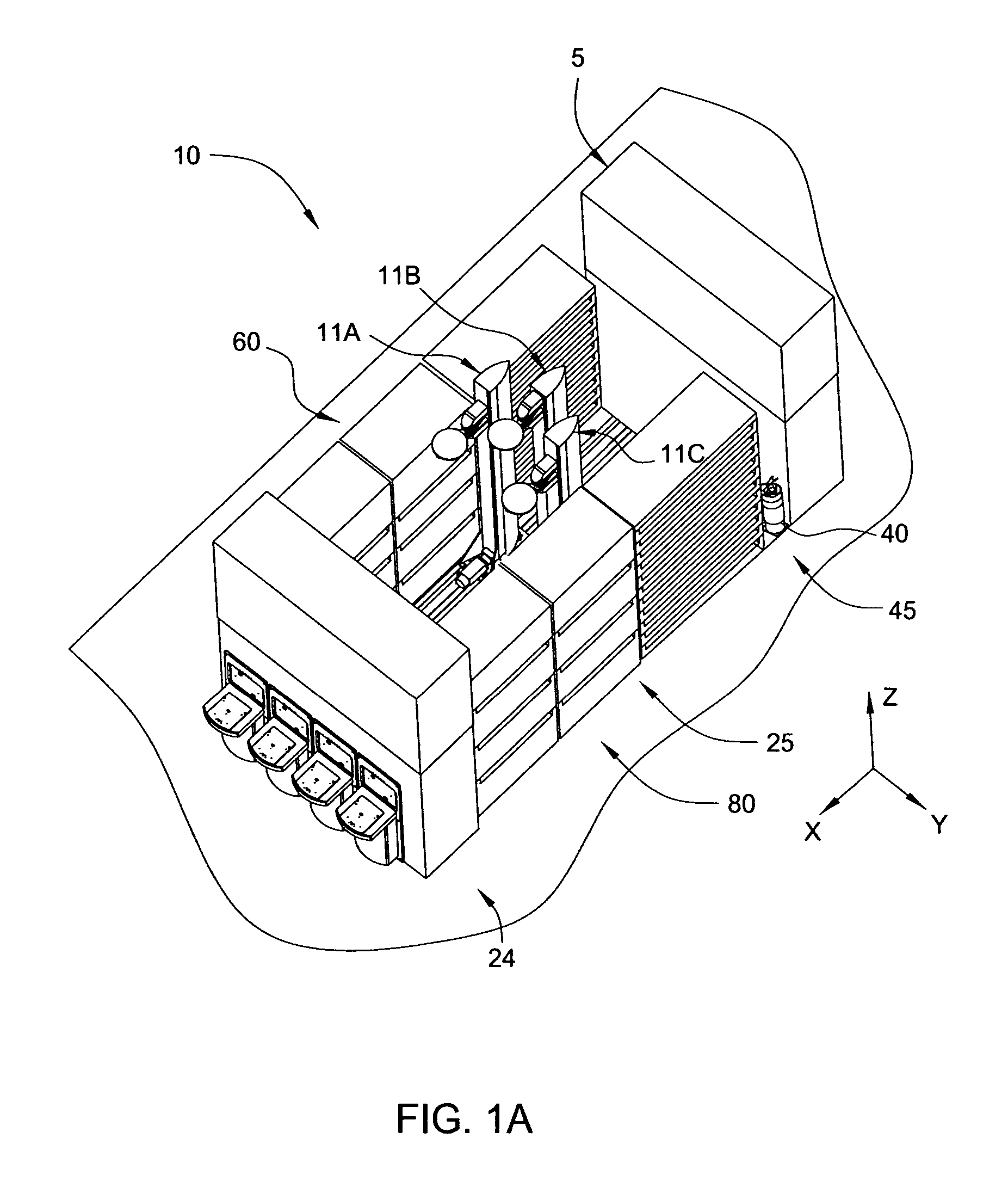

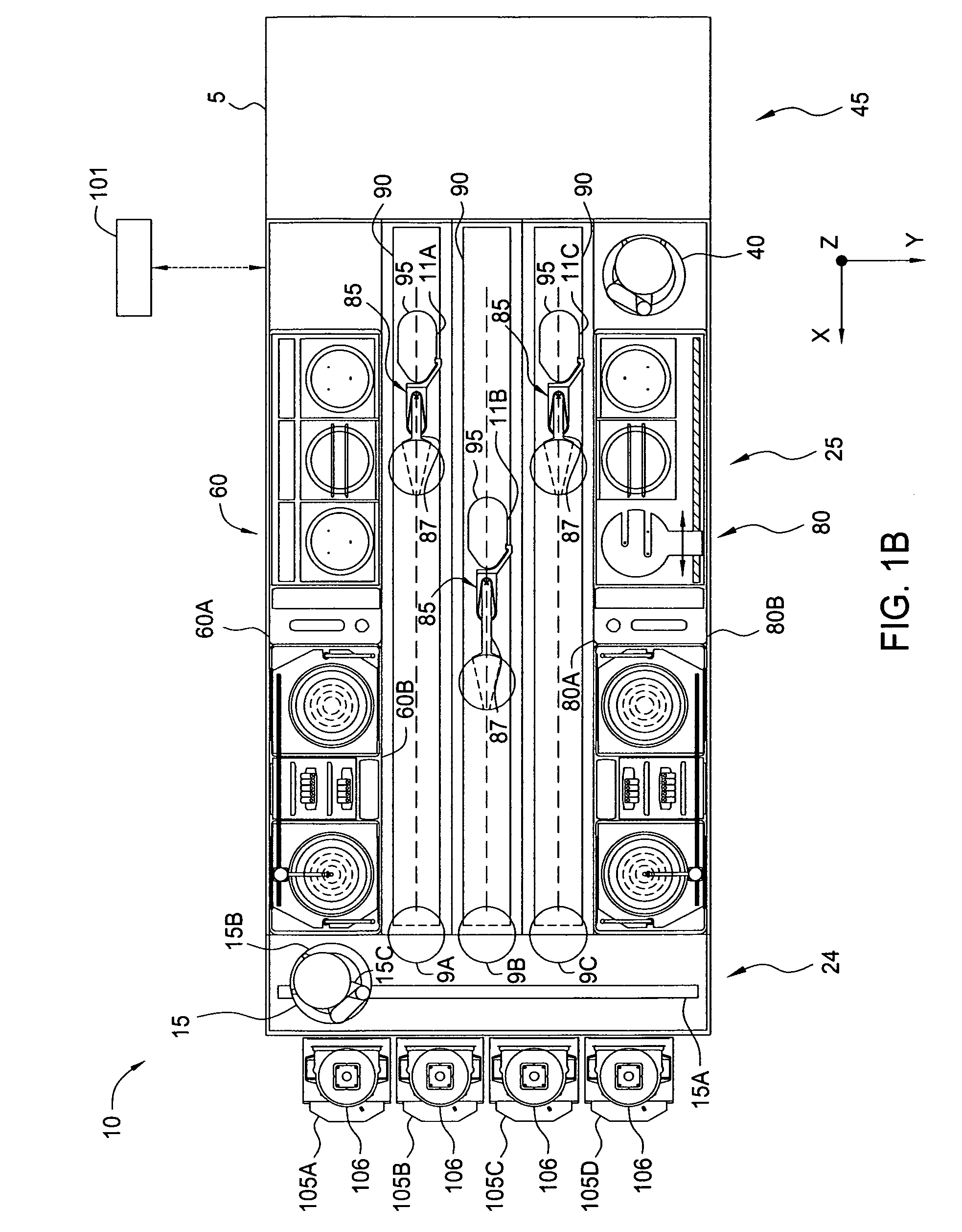

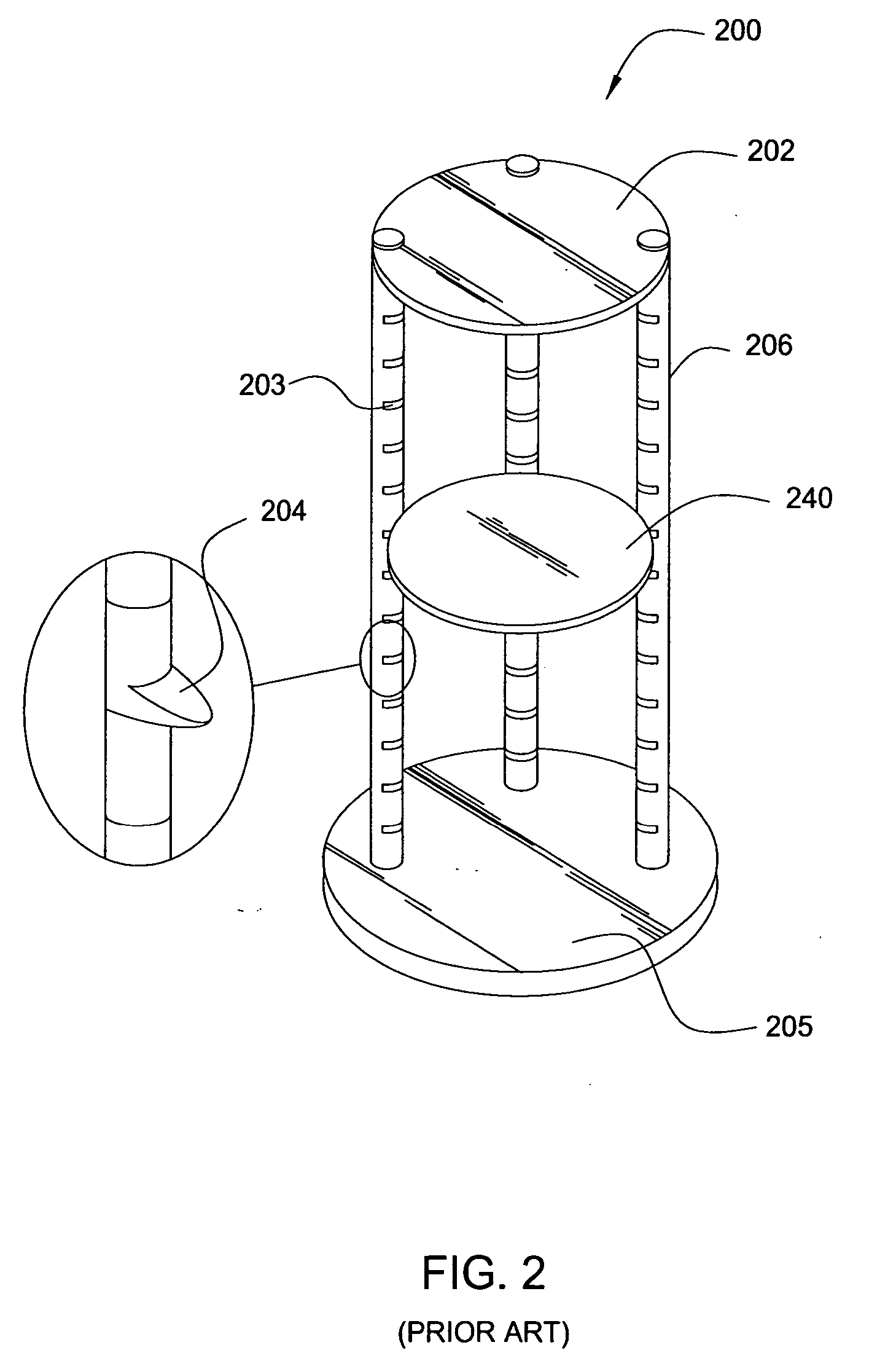

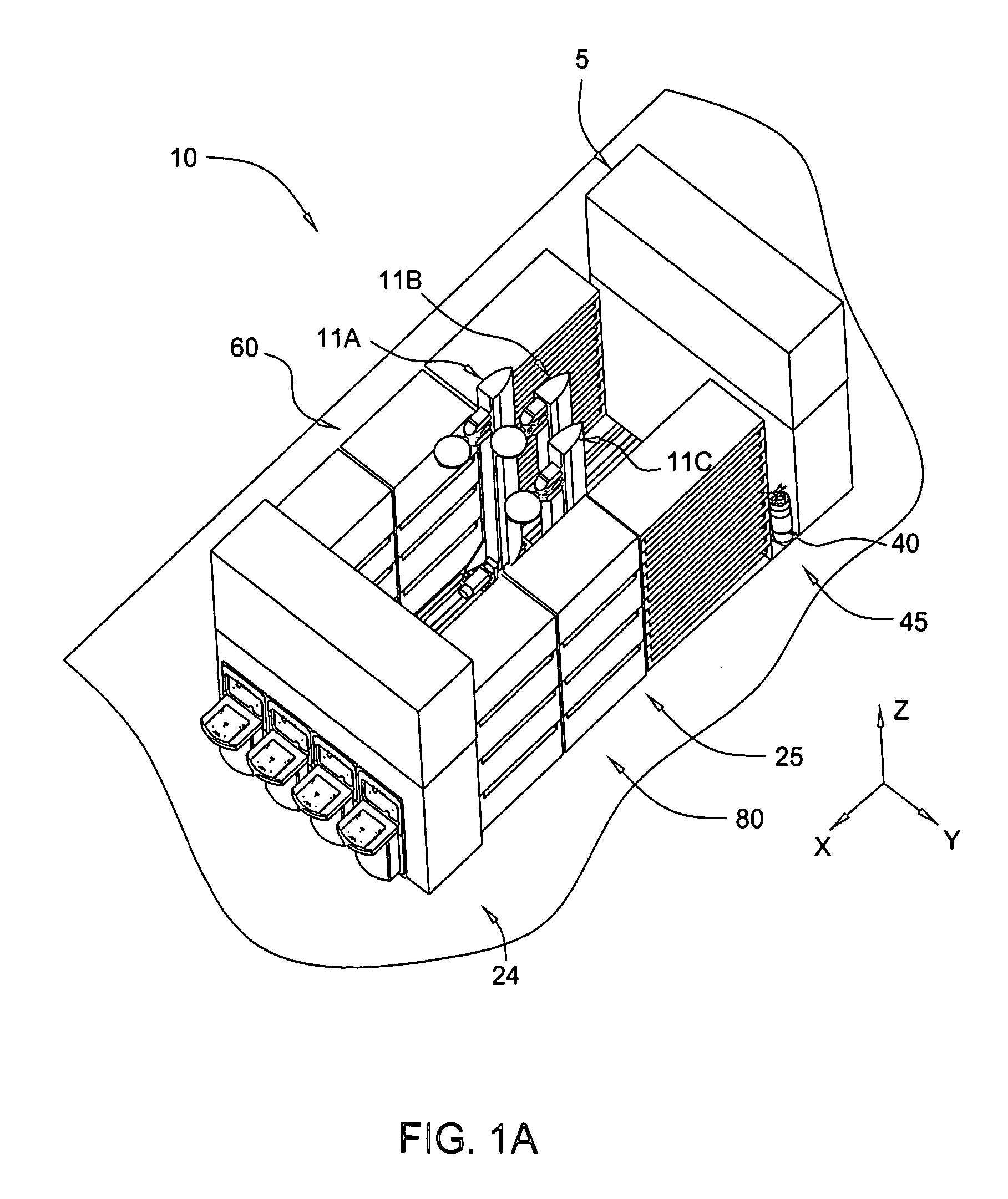

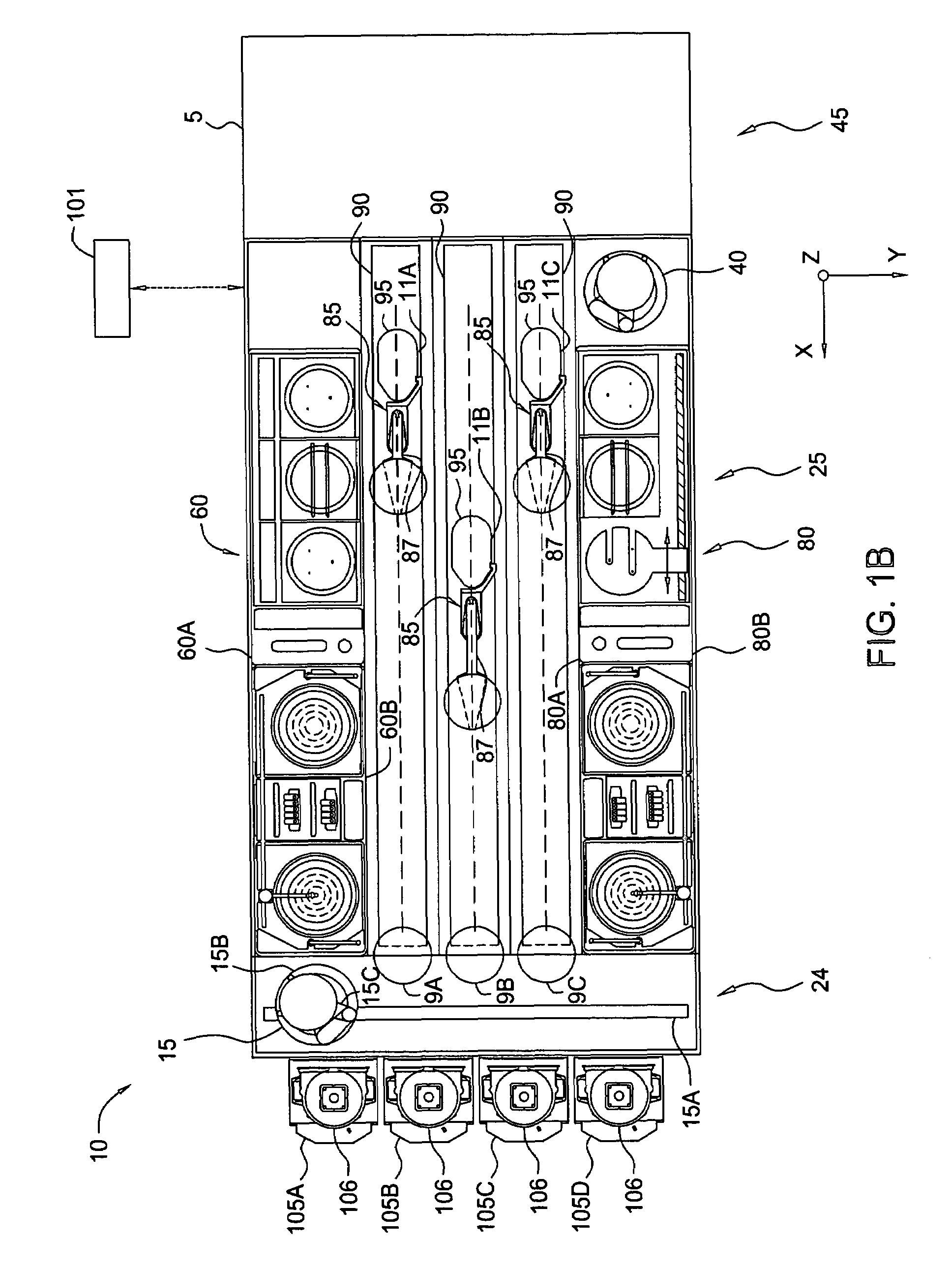

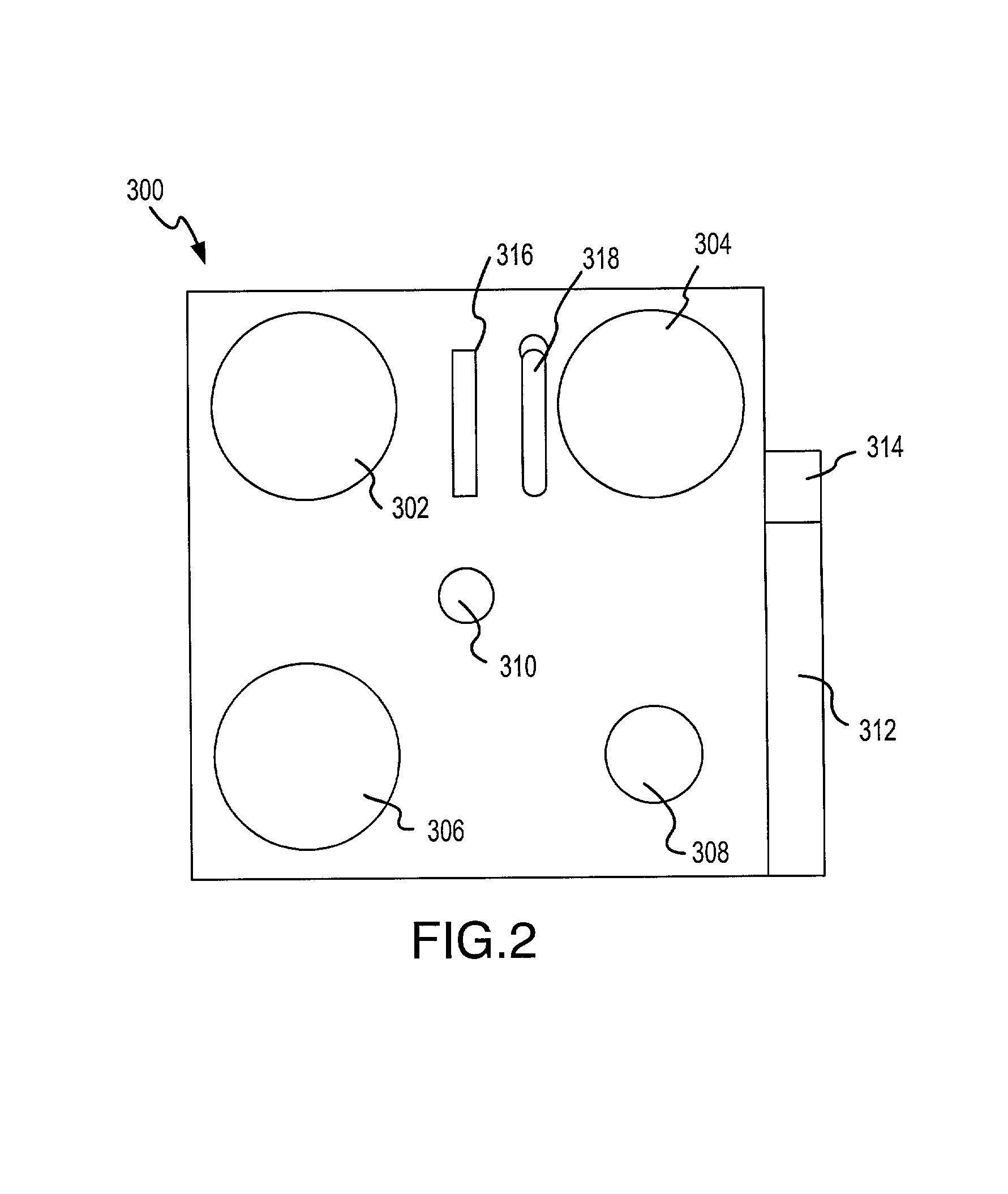

Cartesian robot cluster tool architecture

InactiveUS20060182536A1Semiconductor/solid-state device manufacturingThin material handlingModularityEngineering

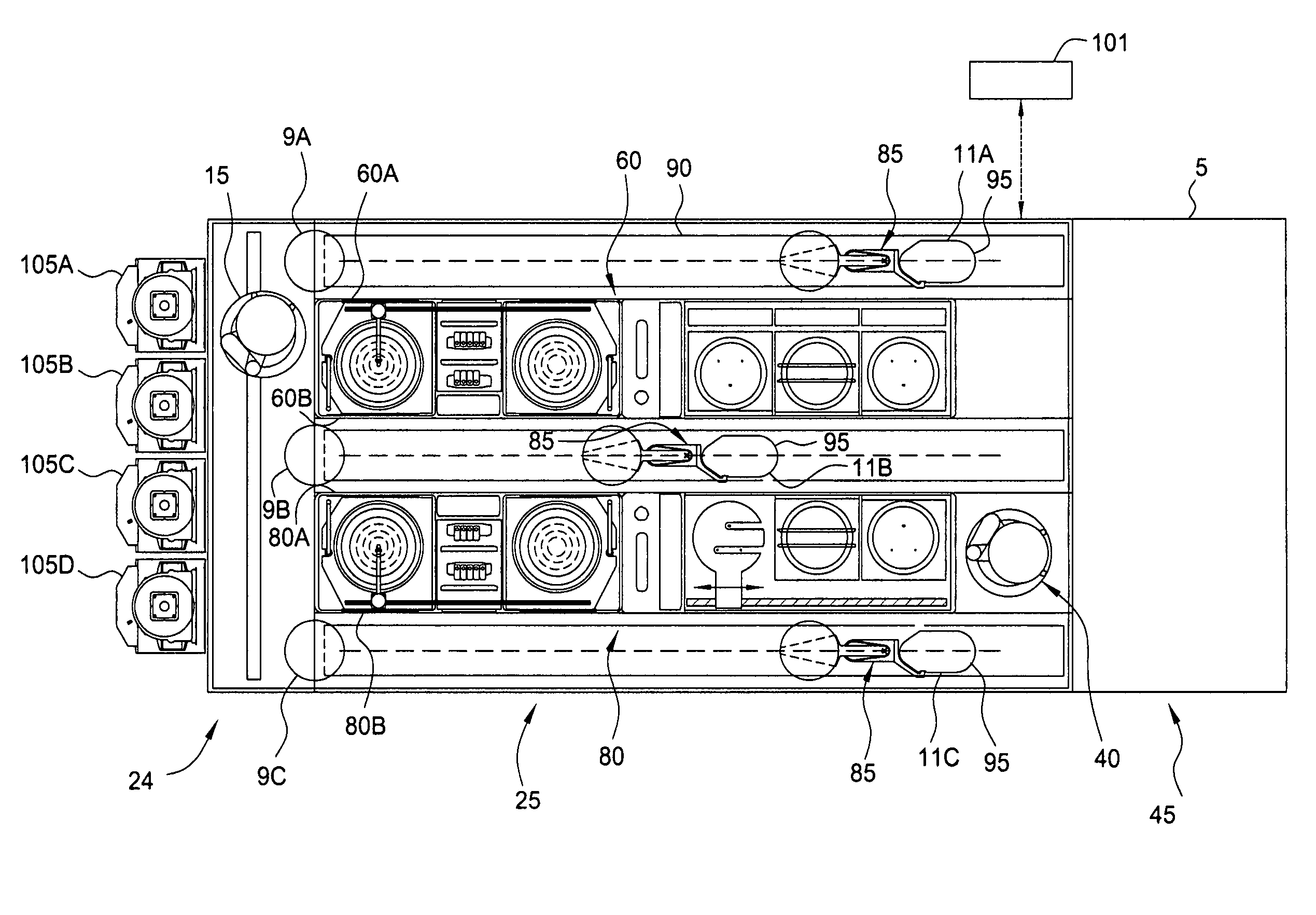

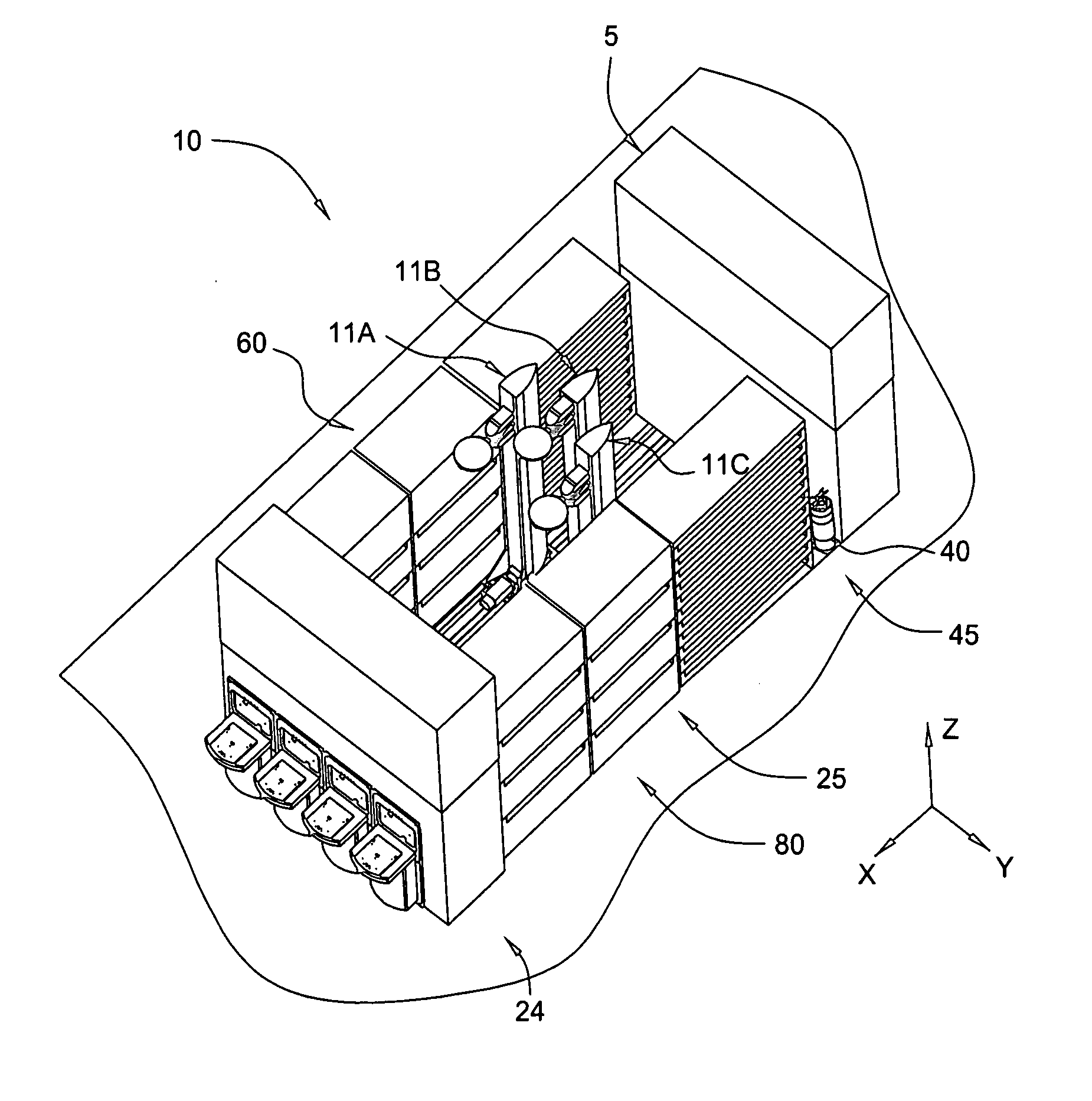

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

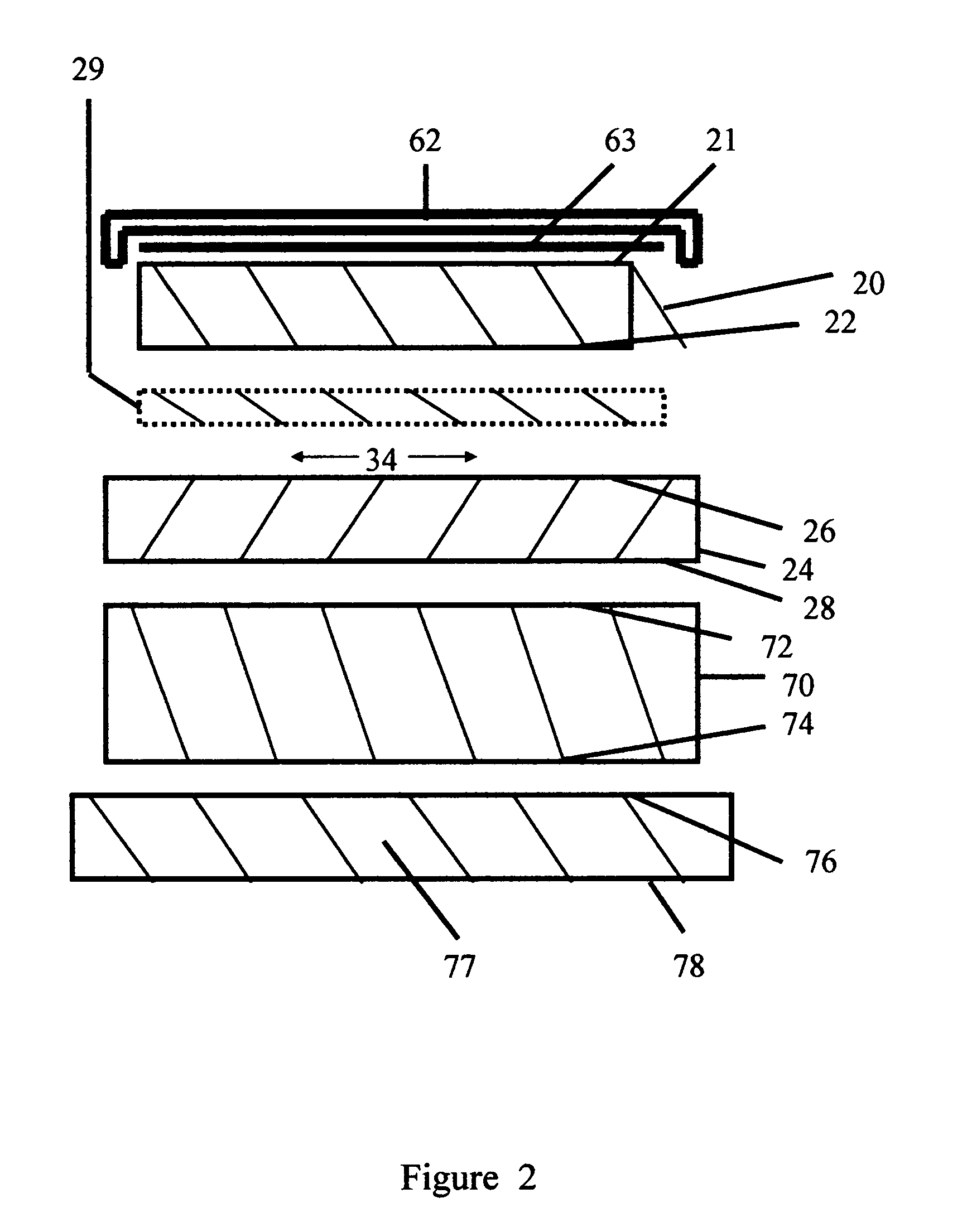

Cluster tool architecture for processing a substrate

InactiveUS20060134330A1More repeatable wafer processing historyReduced footprintProgramme controlSemiconductor/solid-state device testing/measurementLithography processEngineering

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history, and also the cluster tool has a smaller system footprint. In one embodiment, the cluster tool is adapted to perform a track lithography process in which a substrate is coated with a photosensitive material, is then transferred to a stepper / scanner, which exposes the photosensitive material to some form of radiation to form a pattern in the photosensitive material, which is then removed in a developing process completed in the cluster tool. In track lithography type cluster tools, since the chamber processing times tend to be rather short, and the number of processing steps required to complete a typical track system process is large, a significant portion of the time it takes to process a substrate is taken up by the processes of transferring the substrates in a cluster tool between the various processing chambers. In one embodiment of the cluster tool, the cost of ownership is reduced by grouping substrates together and transferring and processing the substrates in groups of two or more to improve system throughput, and reduces the number of moves a robot has to make to transfer a batch of substrates between the processing chambers, thus reducing wear on the robot and increasing system reliability. In one aspect of the invention, the substrate processing sequence and cluster tool are designed so that the substrate transferring steps performed during the processing sequence are only made to chambers that will perform the next processing step in the processing sequence. Embodiments also provide for a method and apparatus that are used to improve the coater chamber, the developer chamber, the post exposure bake chamber, the chill chamber, and the bake chamber process results. Embodiments also provide for a method and apparatus that are used to increase the reliability of the substrate transfer process to reduce system down time.

Owner:SOKUDO CO LTD

Cartesian robot cluster tool architecture

InactiveUS7651306B2Semiconductor/solid-state device manufacturingThin material handlingParallel processingTreatment system

Embodiments of the invention provide a method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool.

Owner:APPLIED MATERIALS INC

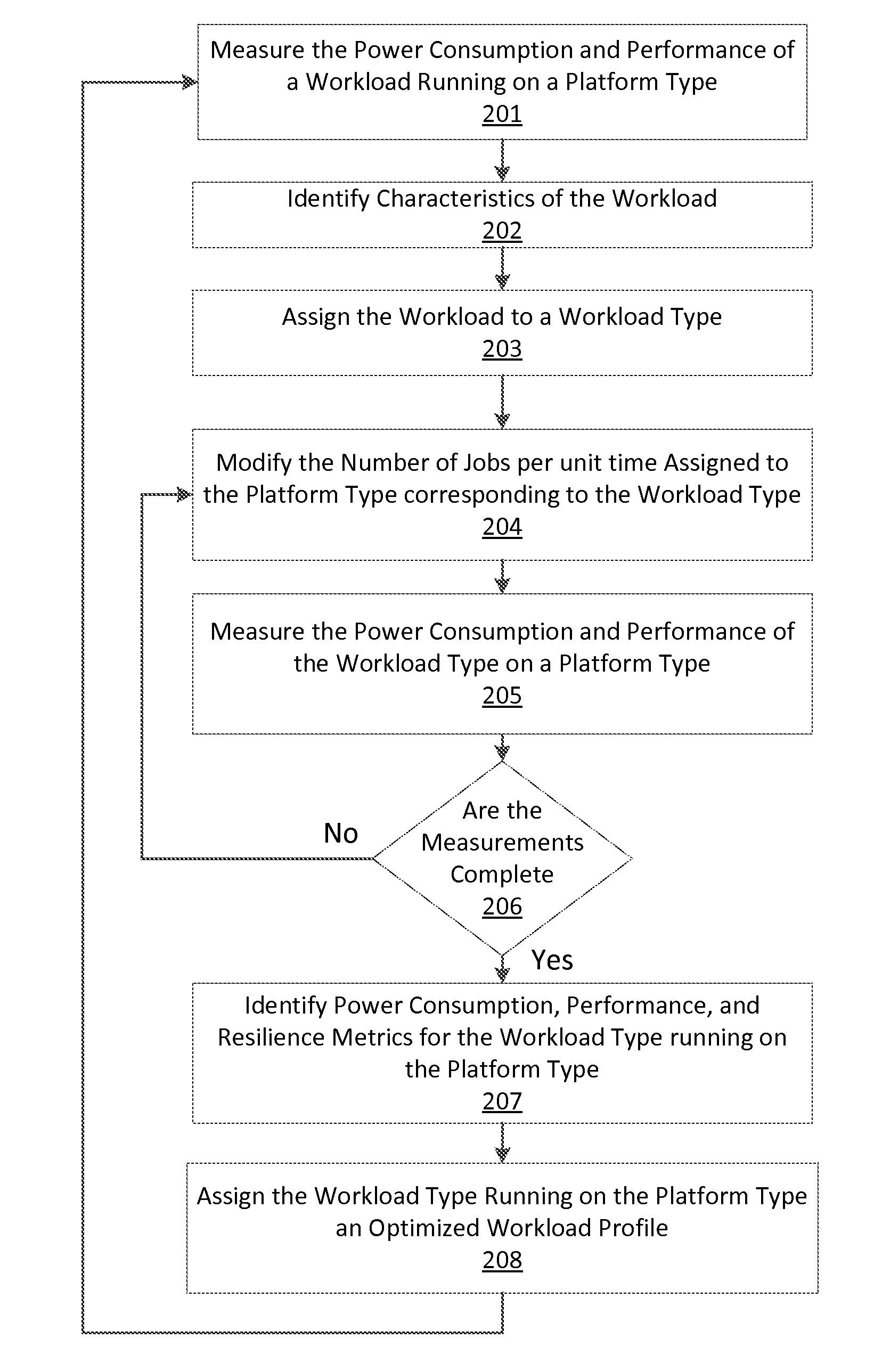

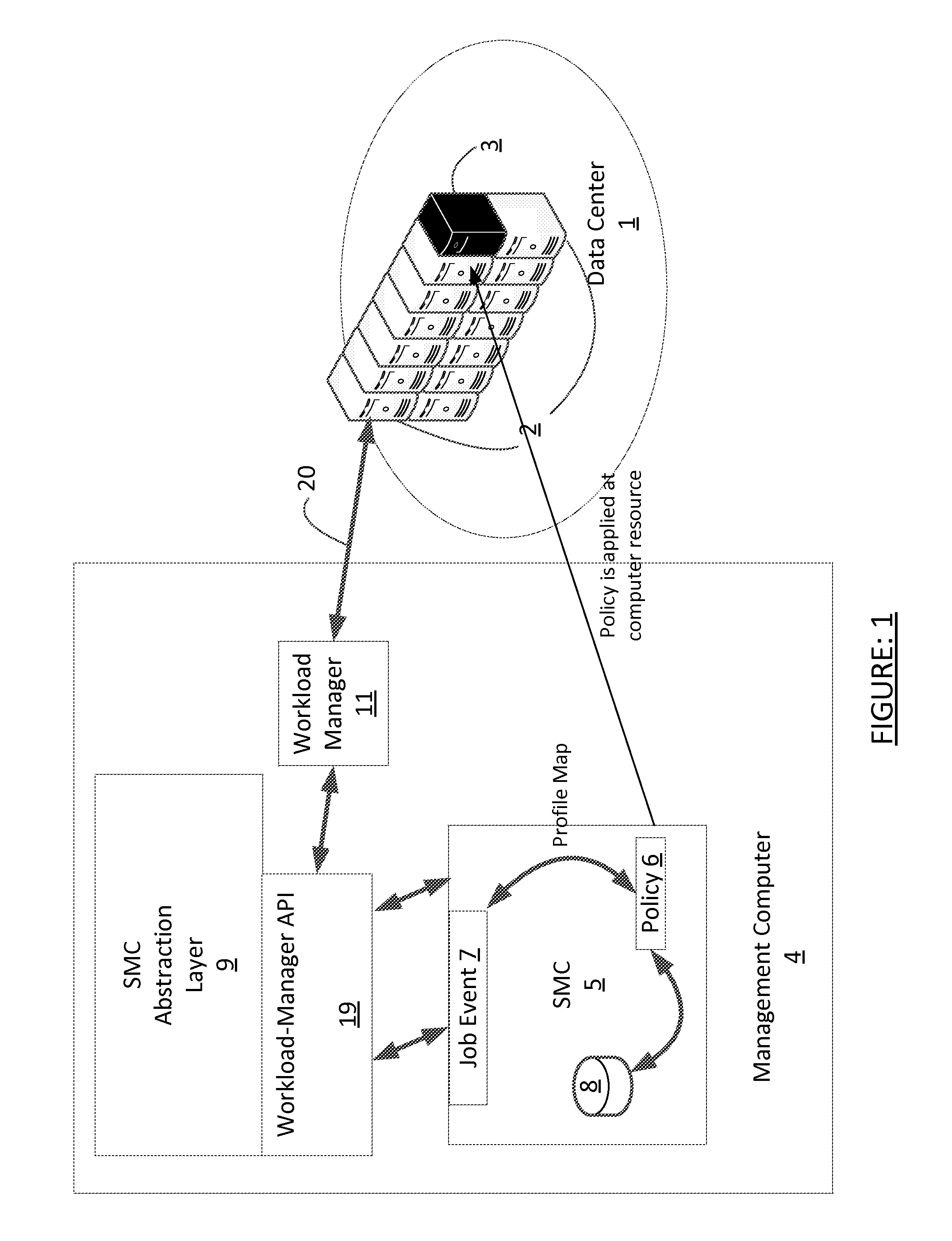

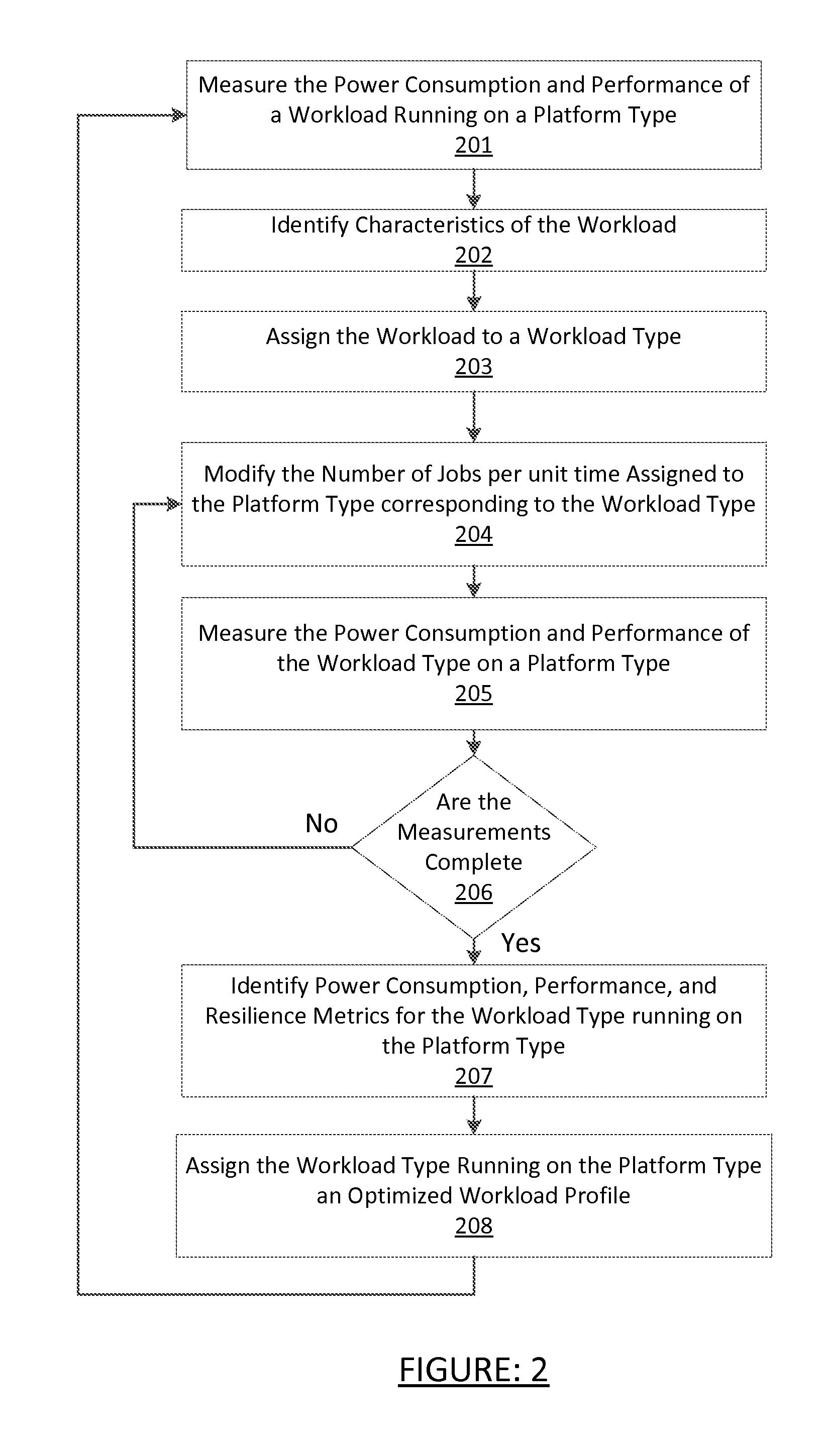

Dynamic resource scheduling

ActiveUS20140068627A1Low costMaximize efficiencyResource allocationError detection/correctionData centerDynamic resource

Embodiments of the invention relate to a system and method for dynamically scheduling resources using policies to self-optimize resource workloads in a data center. The object of the invention is to allocate resources in the data center dynamically corresponding to a set of policies that are configured by an administrator. Operational parametrics that correlate to the cost of ownership of the data center are monitored and compared to the set of policies configured by the administrator. When the operational parametrics approach or exceed levels that correspond to the set of policies, workloads in the data center are adjusted with the goal of minimizing the cost of ownership of the data center. Such parametrics include yet are not limited to those that relate to resiliency, power balancing, power consumption, power management, error rate, maintenance, and performance.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

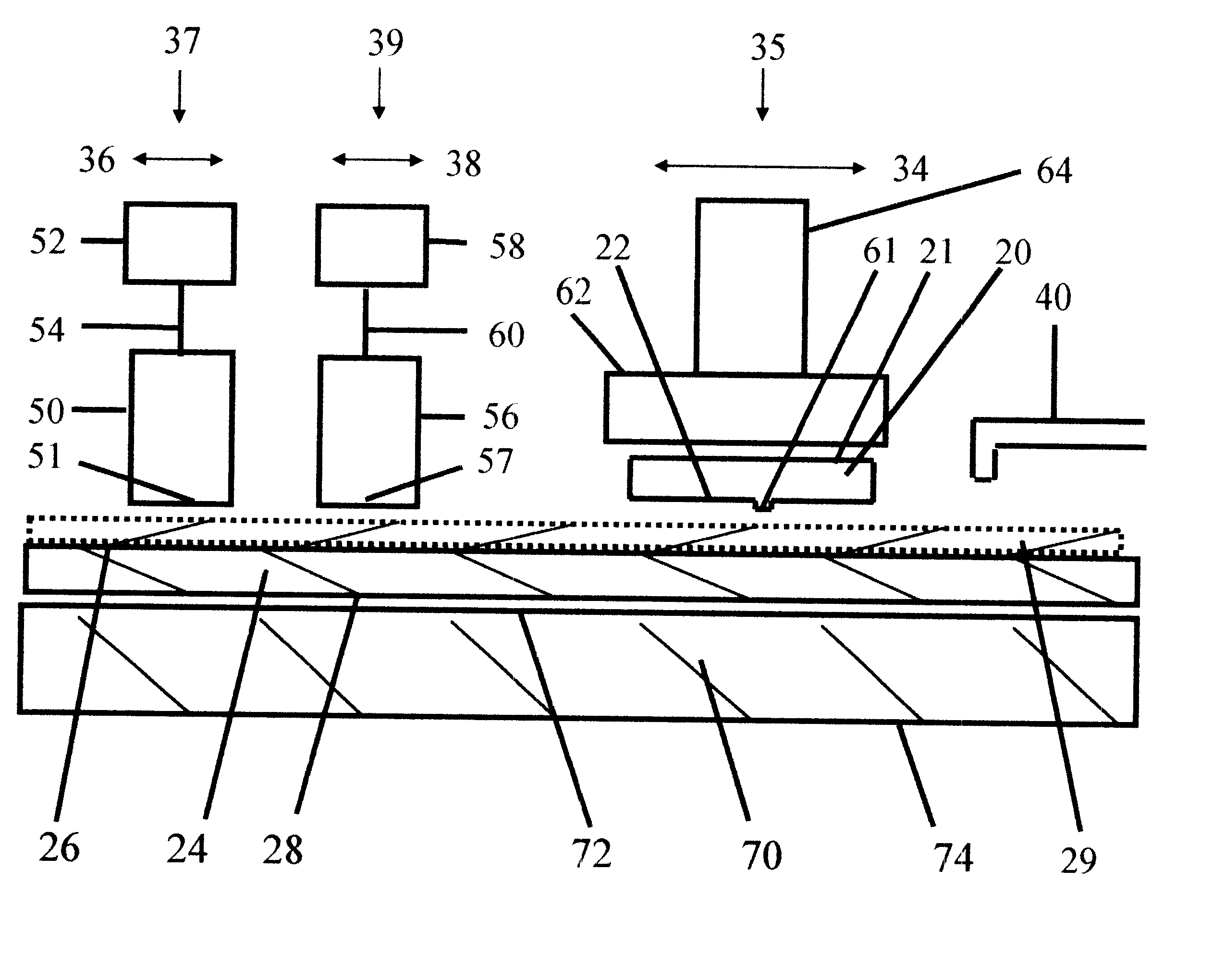

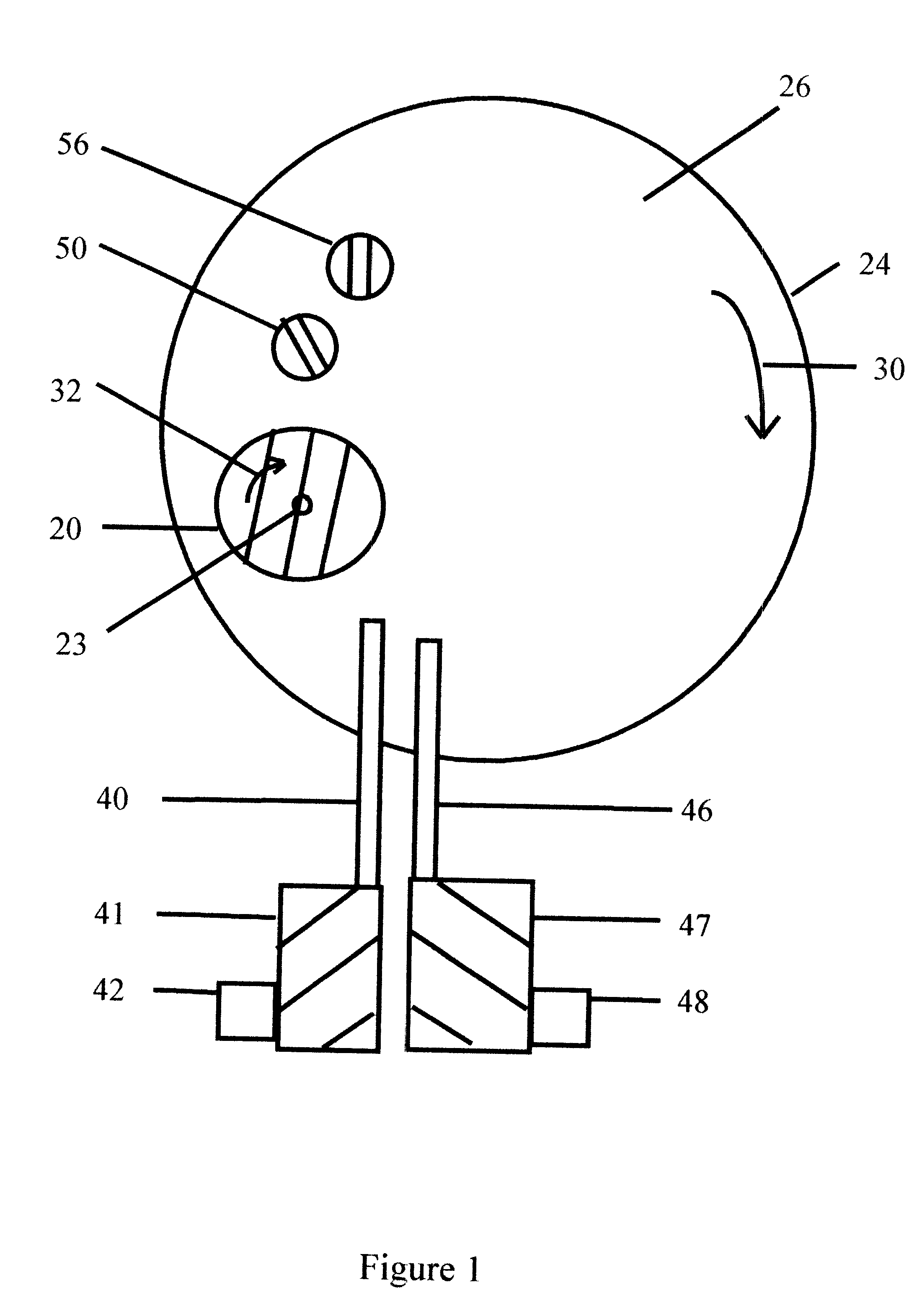

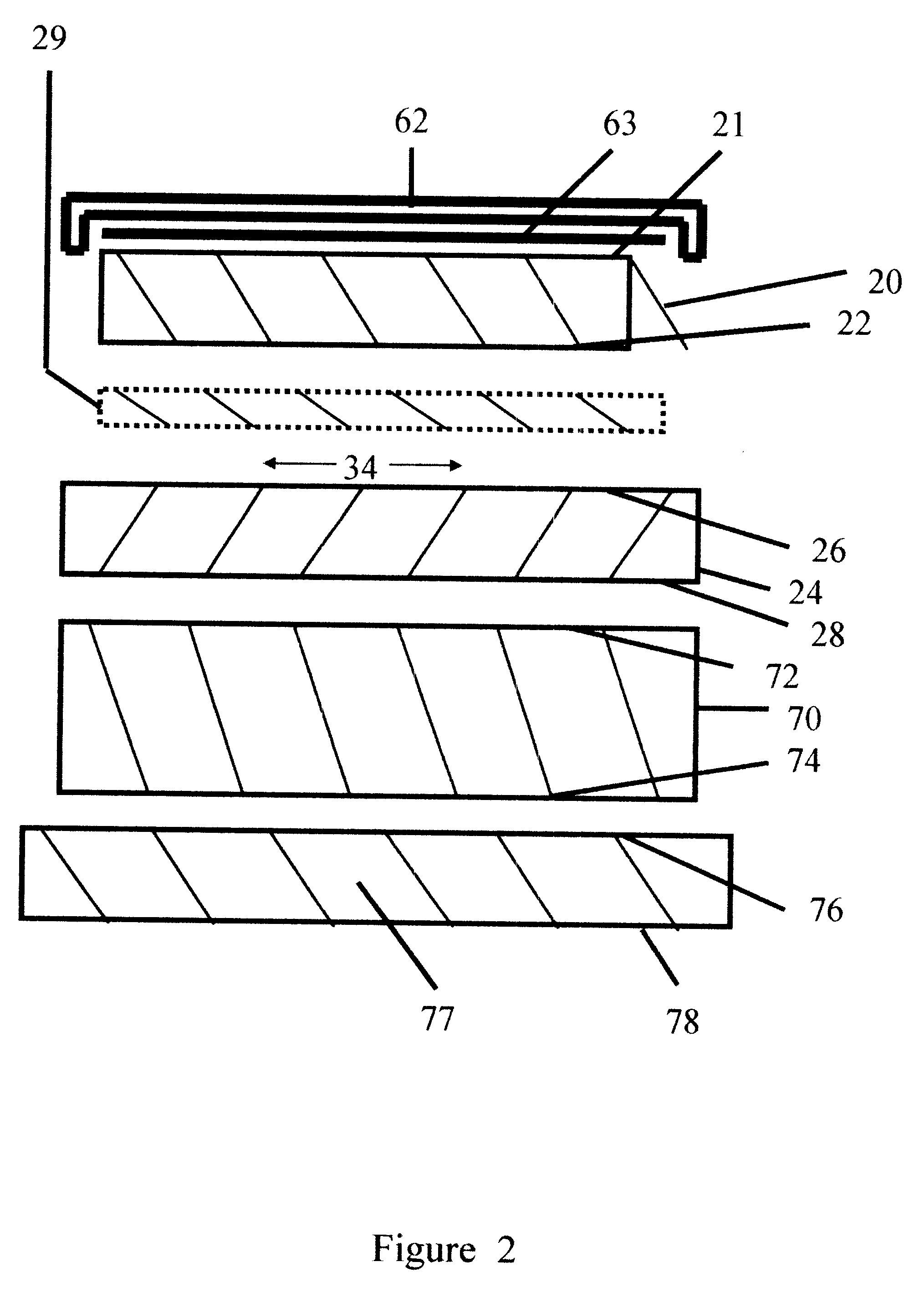

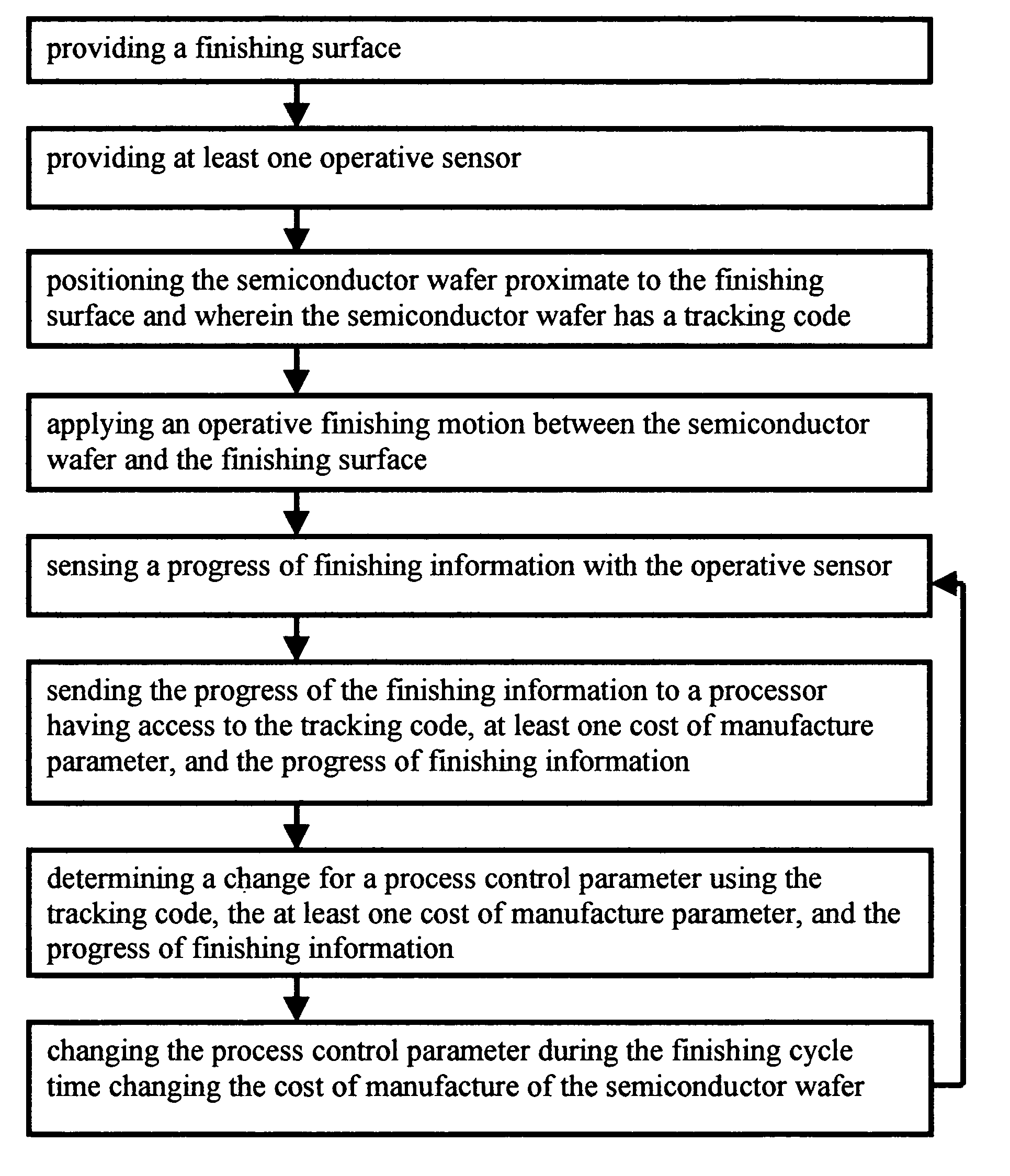

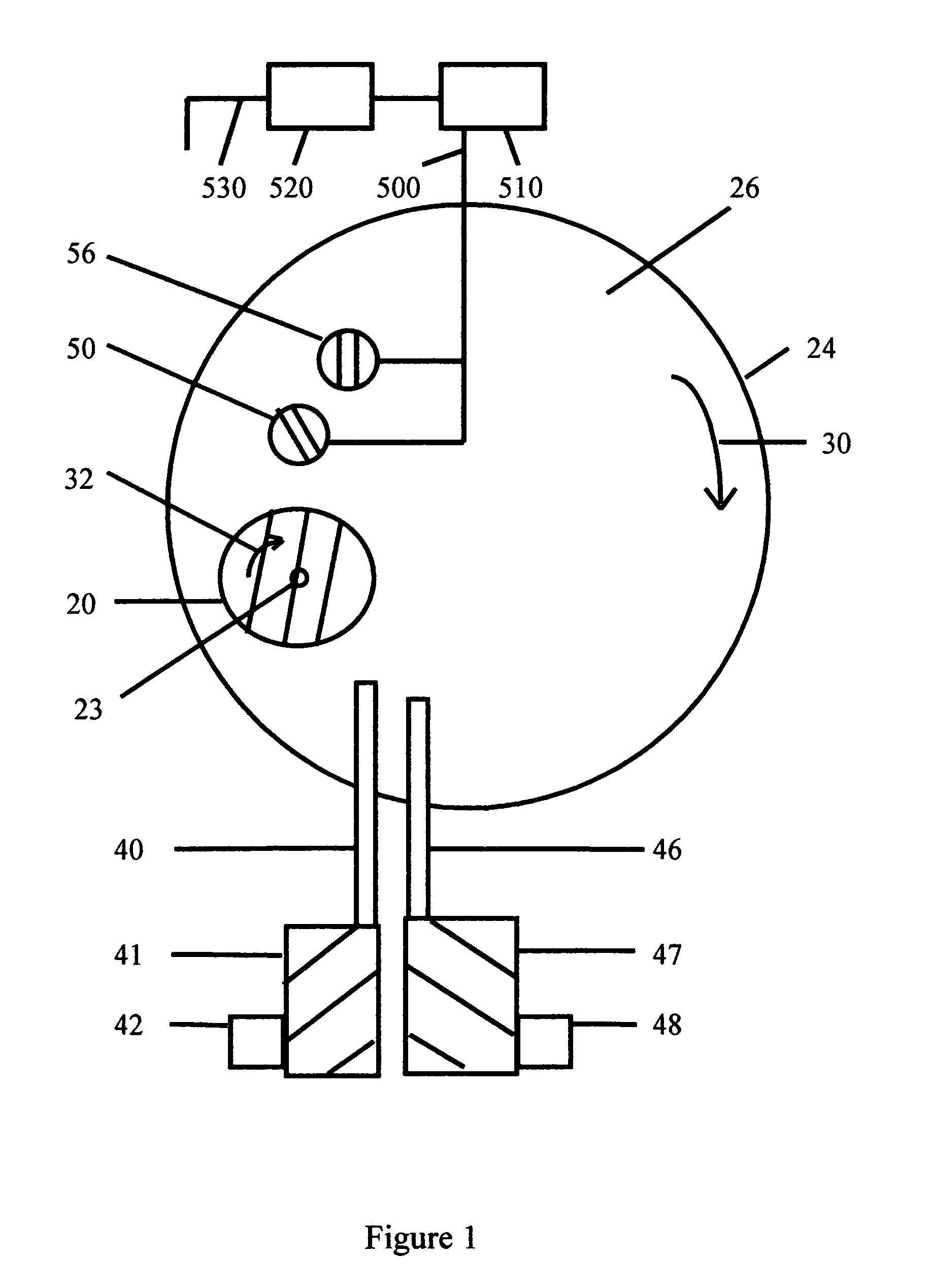

Semiconductor wafer finishing control

InactiveUS6568989B1Manufacturing cost is increasedOne costLapping machinesGrinding feed controlEngineeringSemiconductor

A method of in situ control for finishing semiconductor wafers to improve cost of ownership is discussed. A method to use business calculations combined with physical measurements to improve control. The use of boundary lubricating layer control in the operative finishing interface and business calculations to improve the cost of finishing semiconductor wafers is discussed. The method aids control of differential lubricating boundary layers and improved differential finishing of semiconductor wafers. Planarization and localized finishing can be improved using differential lubricating boundary layer methods of finishing.

Owner:SEMCON TECH

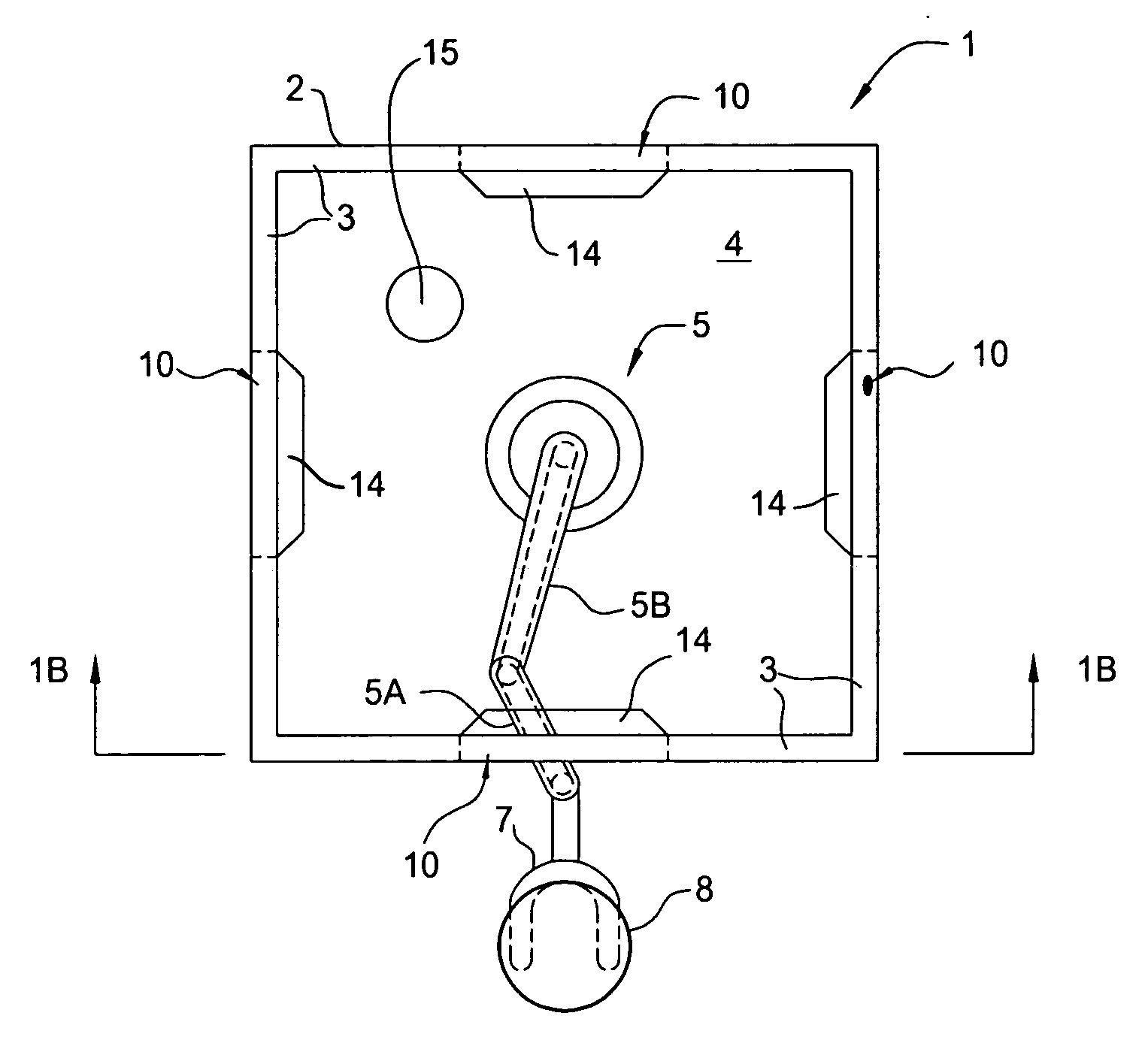

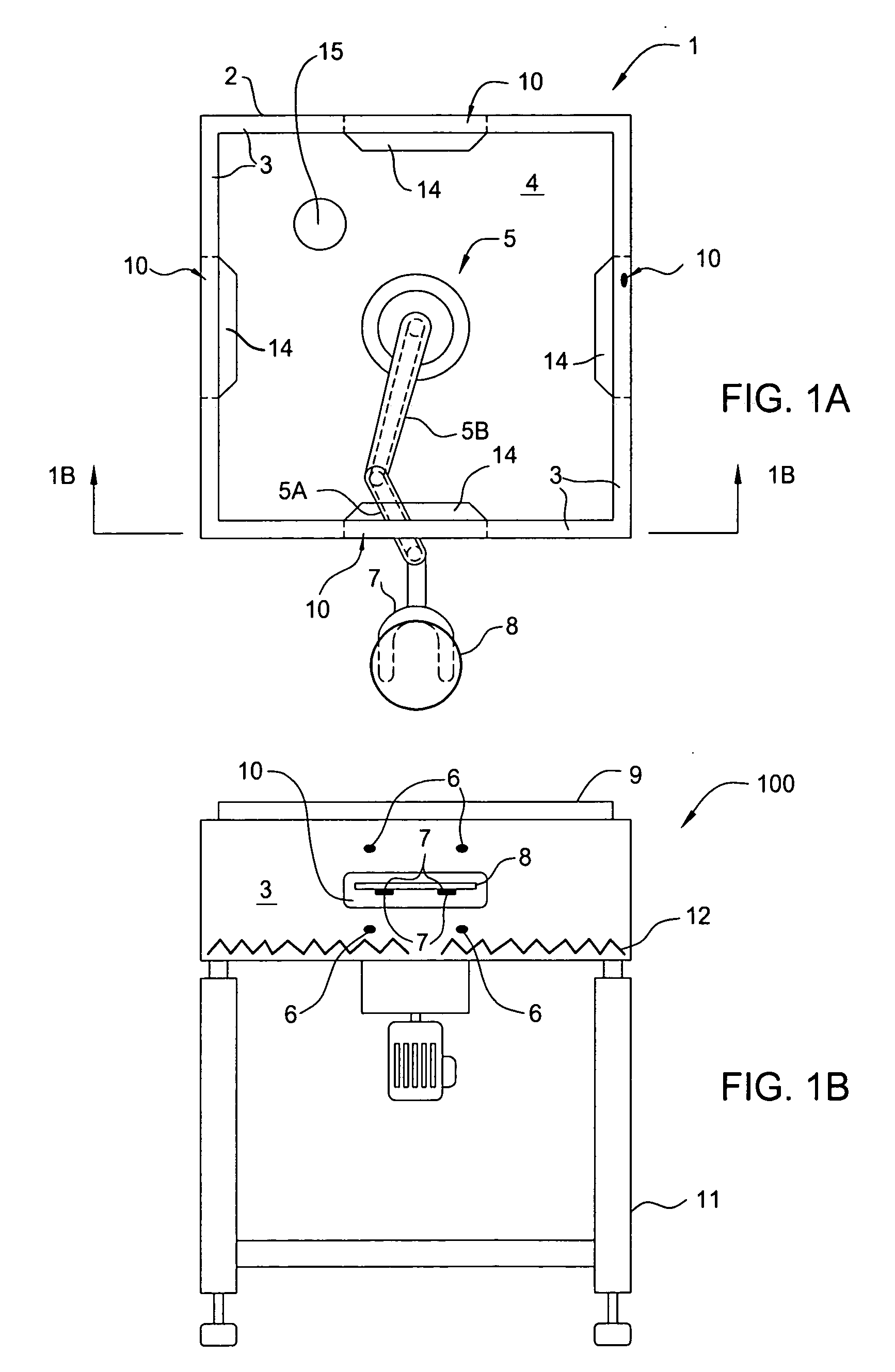

Cartesian robot design

InactiveUS20060182535A1Semiconductor/solid-state device manufacturingConveyor partsModularityEngineering

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

Wafer refining

InactiveUS6986698B1Improve controlEasy to controlNuclear monitoringDigital computer detailsProcess engineeringBusiness forecasting

A method of in situ control for finishing semiconductor wafers to improve cost of ownership is discussed. A method to use business calculations combined with physical measurements to improve control is discussed. The use of lubricating layer control in the operative finishing interface is discussed. Use of business calculations to change the cost of finishing semiconductor wafers is discussed. The method aids control of differential lubricating films and improved differential finishing of semiconductor wafers. The method aids cost of manufacture forecasting. The method can help manage and / or reduce cost of manufacture for pre-ramp-up, ramp-up, and commercial manufacture of the workpieces. The method can aid cost of manufacture forecasting for pre-ramp-up, ramp-up, and commercial manufacture of the workpieces. The method can aid process control for pre-ramp-up, ramp-up, and commercial manufacture of workpieces. Activity based accounting can be preferred for some applications. Planarization and localized finishing can be improved using differential lubricating films for finishing. New methods and new apparatus for finishing control are disclosed.

Owner:SEMCON TECH

Substrate processing sequence in a cartesian robot cluster tool

InactiveUS20070147976A1Photomechanical apparatusSemiconductor/solid-state device manufacturingModularityEngineering

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

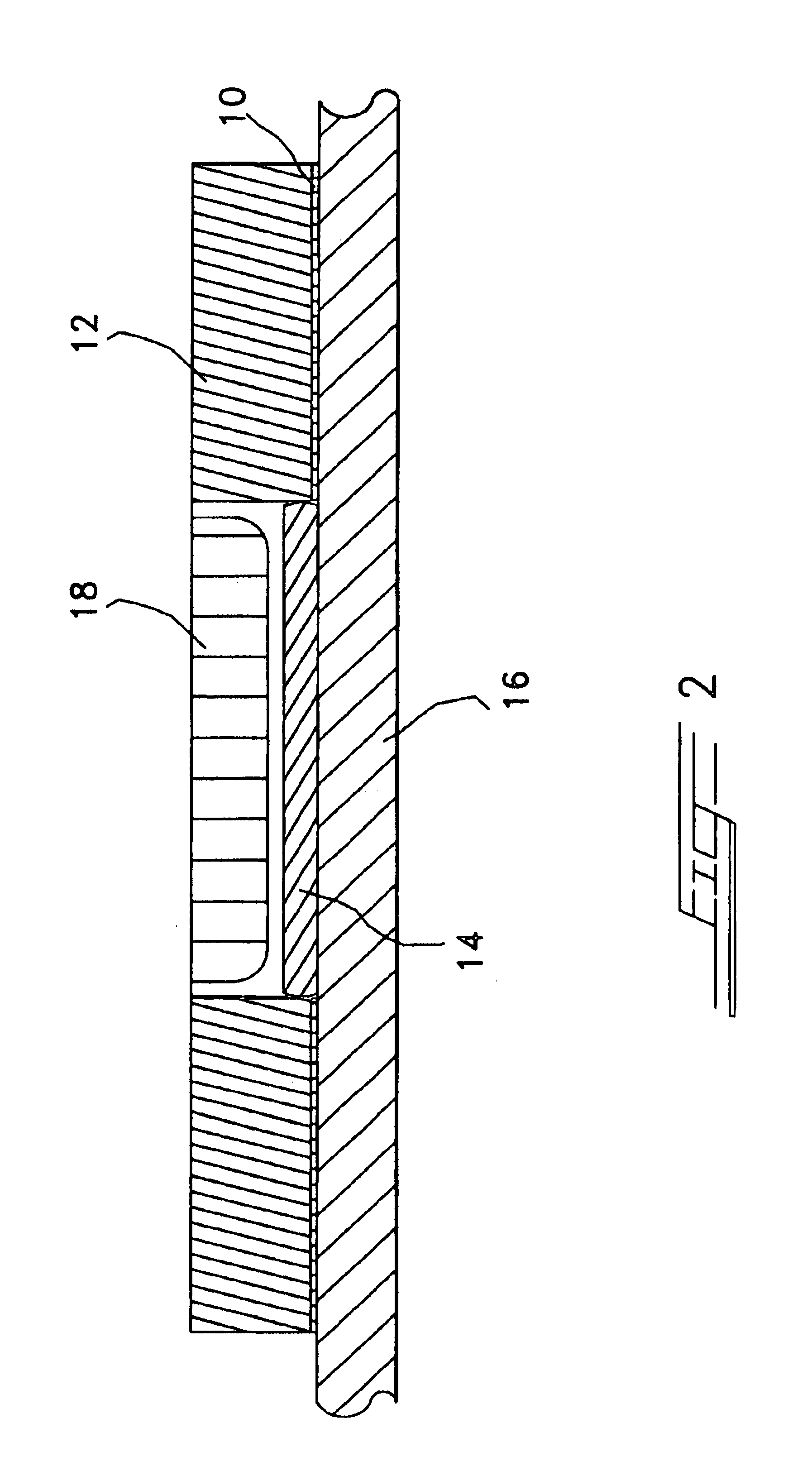

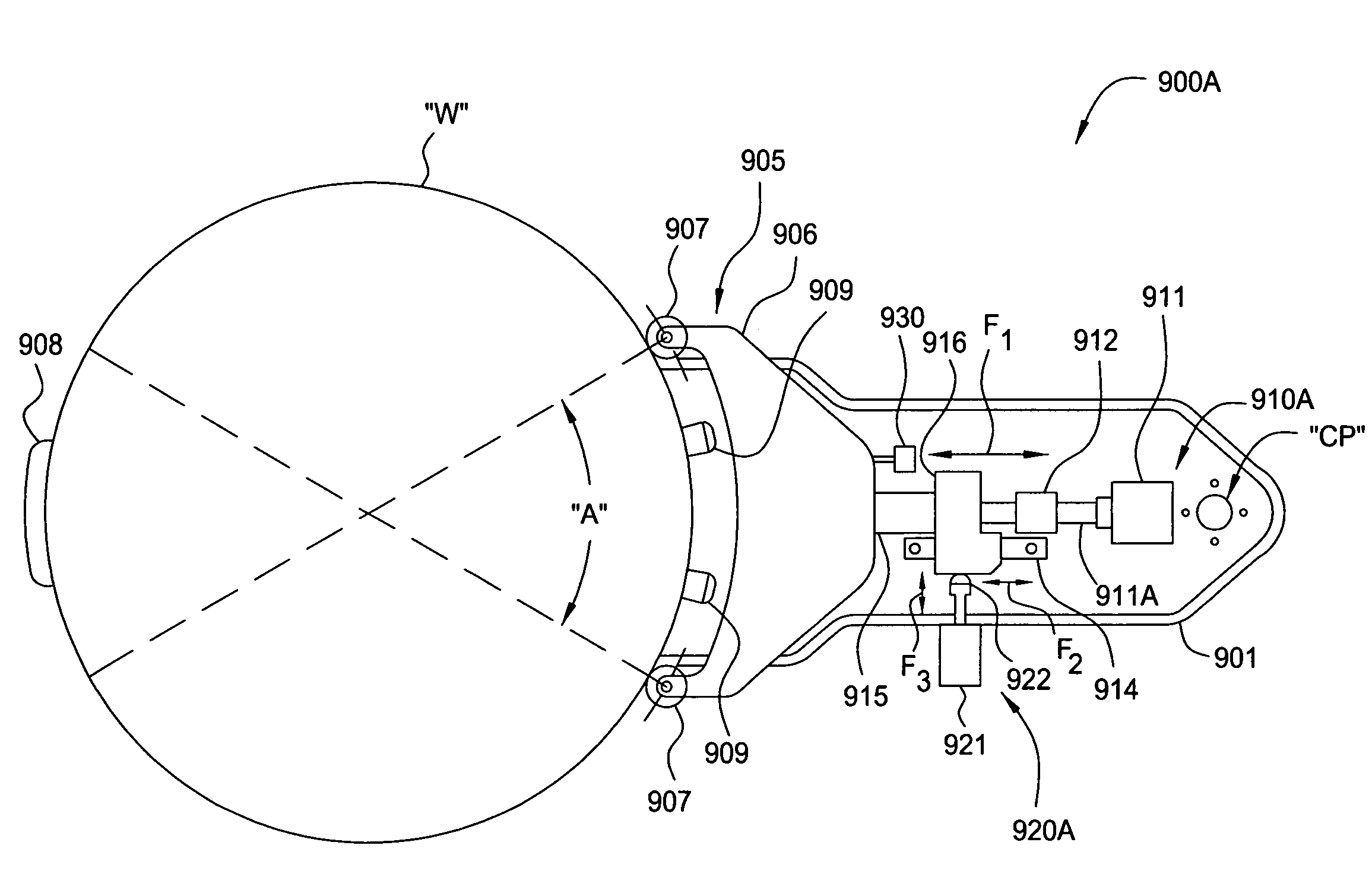

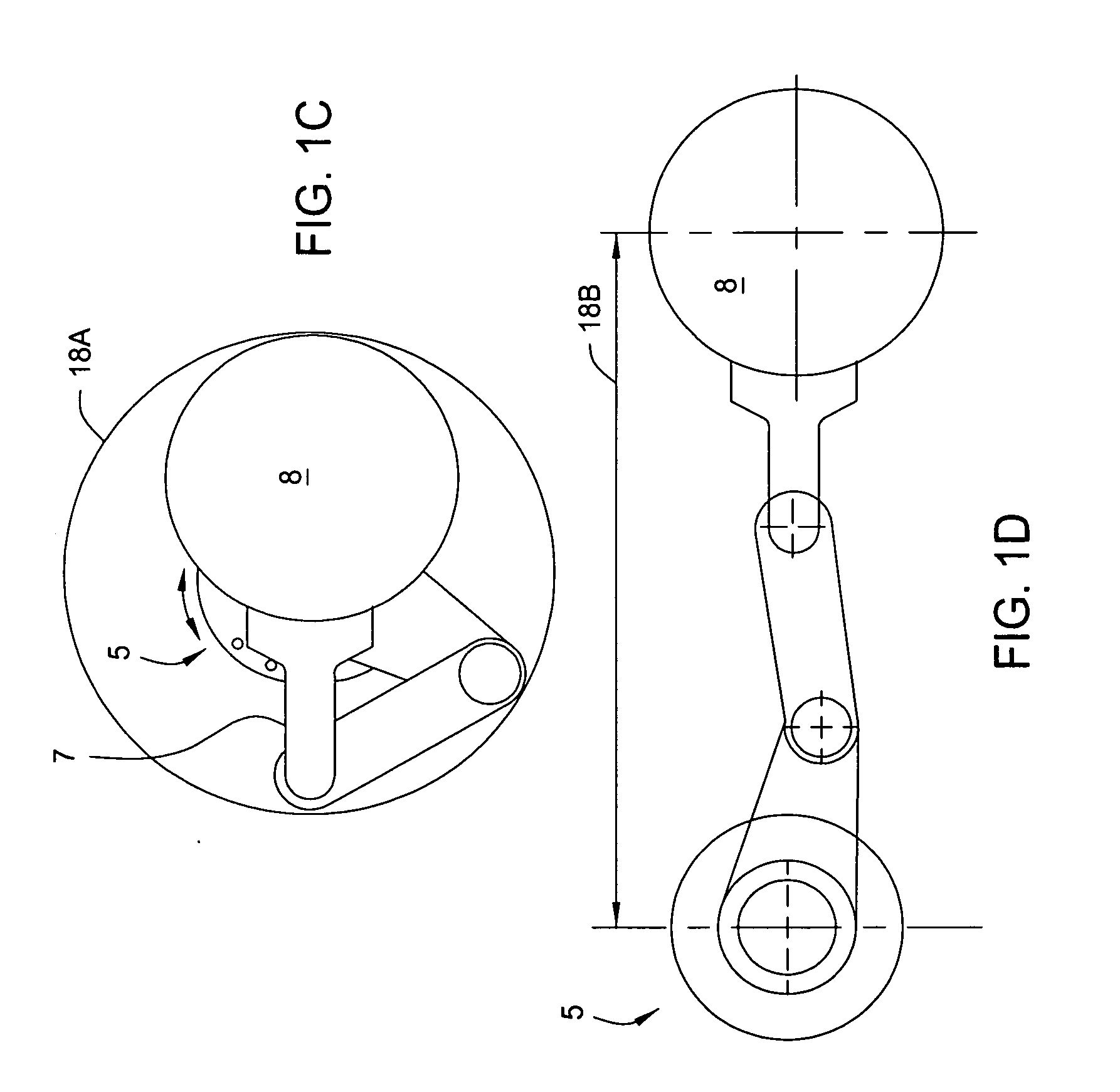

Substrate gripper for a substrate handling robot

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

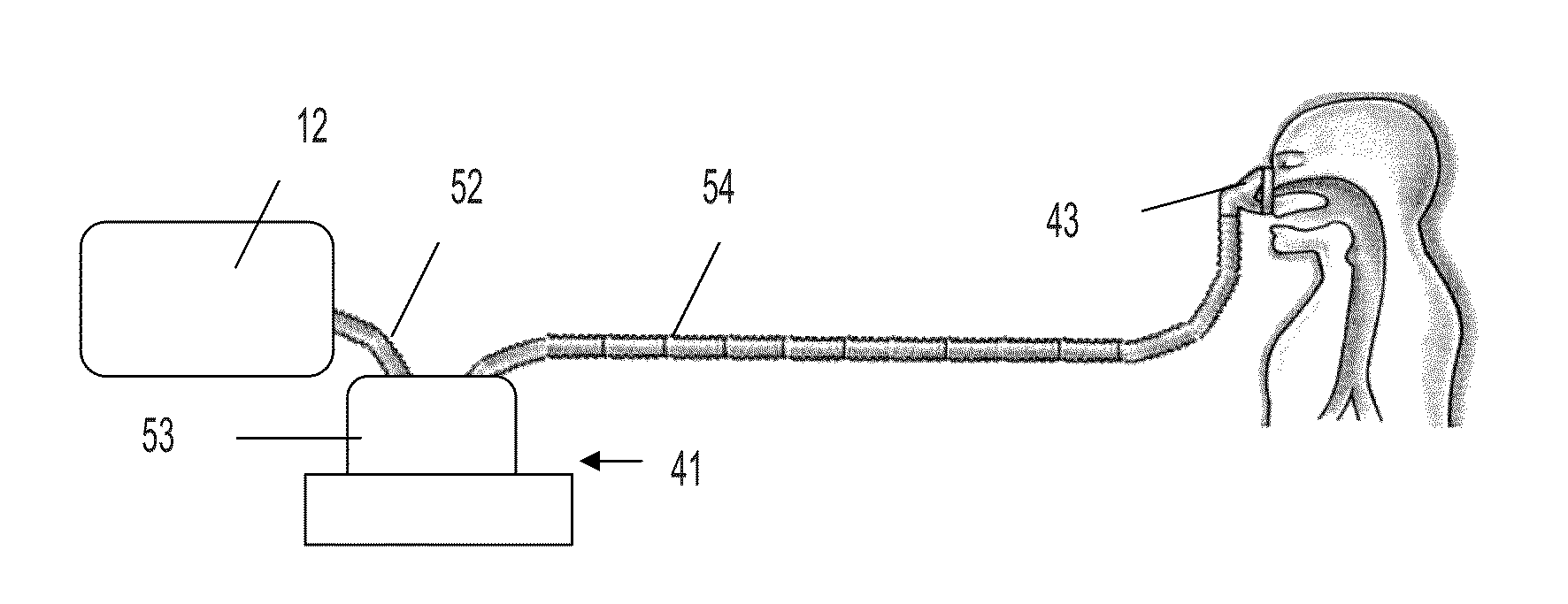

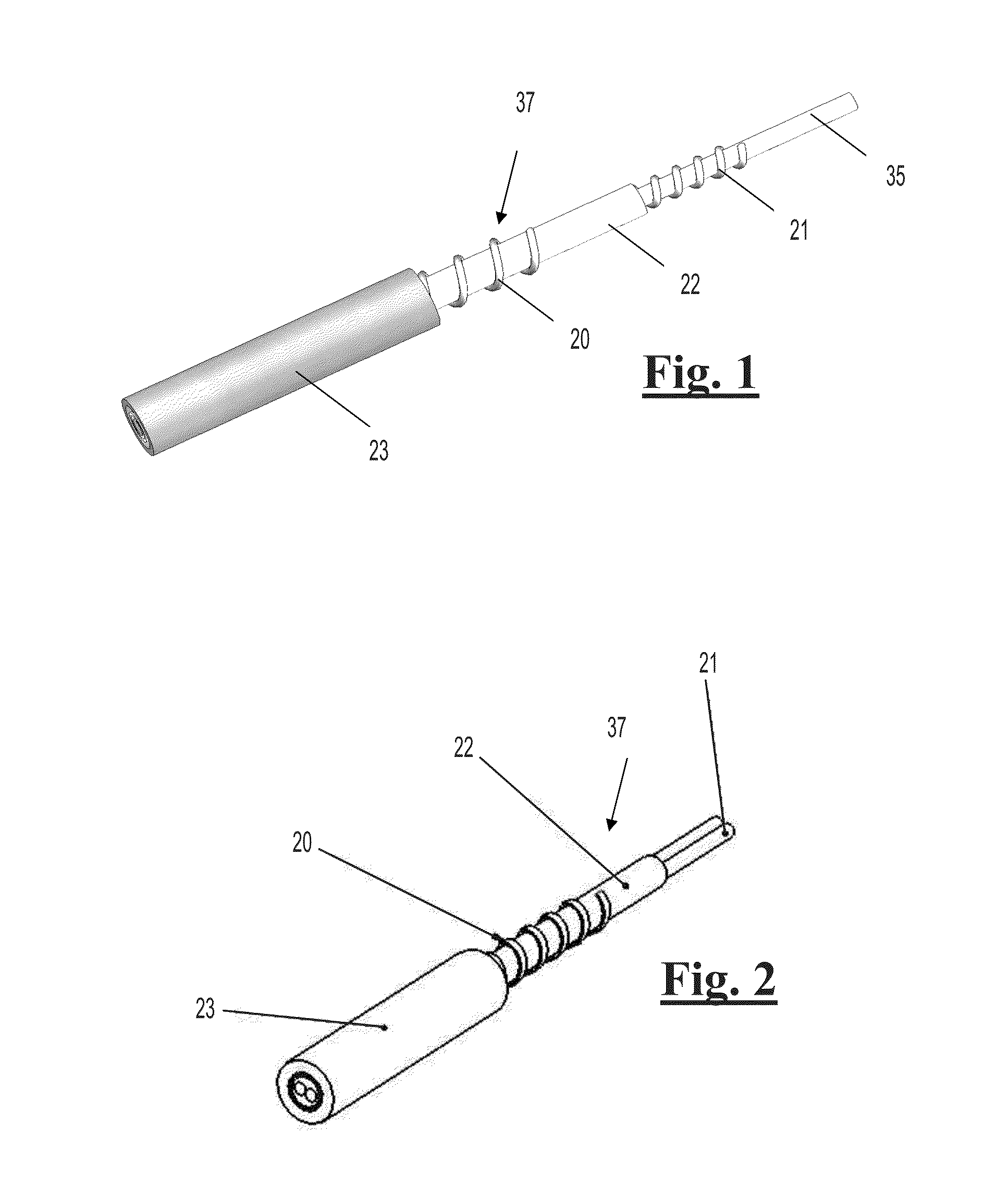

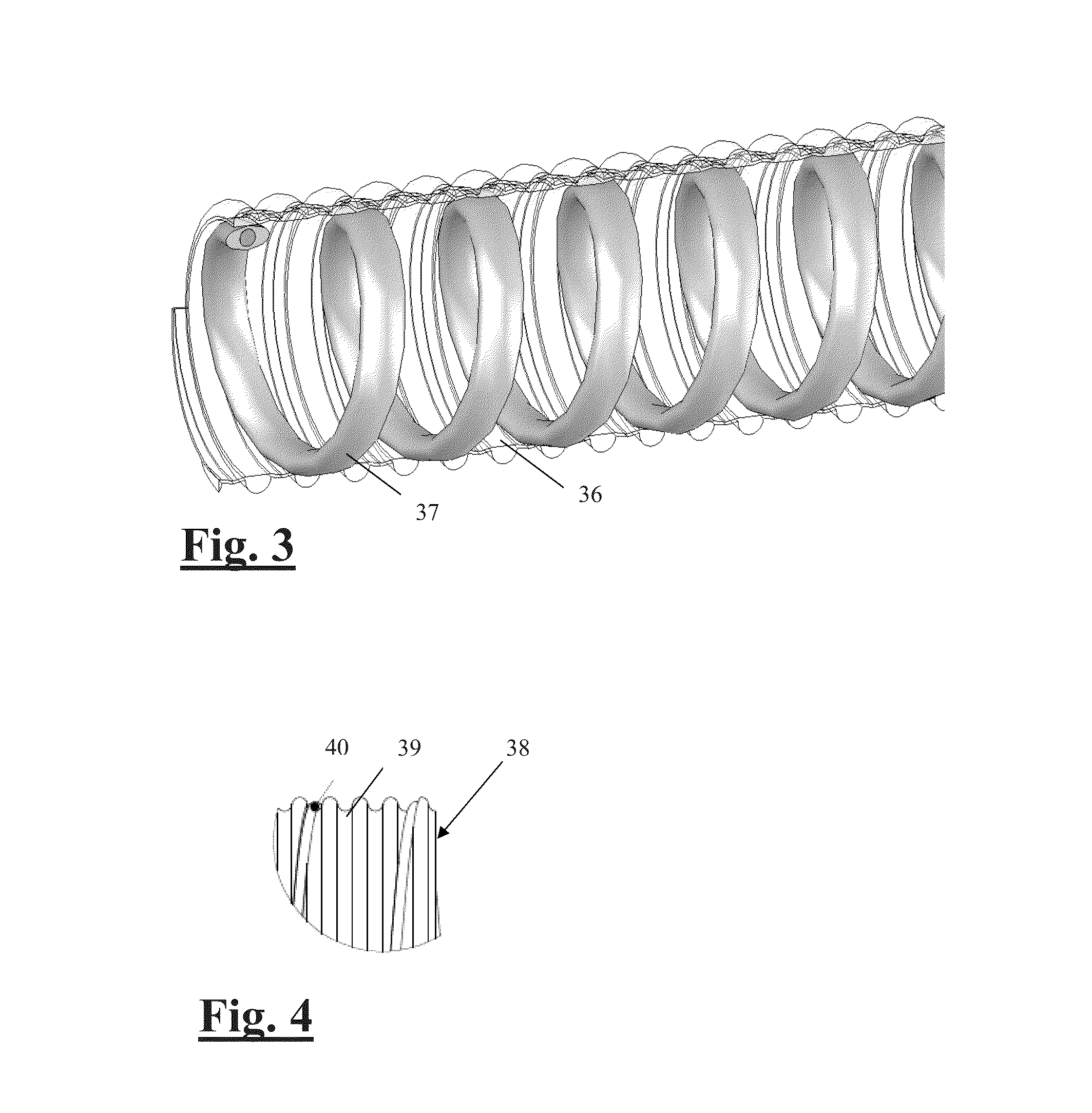

Respiratory system

ActiveUS9119933B2Reduction of overheatingReduce detectionRespiratory masksPipe heating/coolingIntensive care medicineRespiratory system

A modular respiratory system to which different parts can be added in a convenient way enabling such upgraded respiratory system to deliver the most comfortable respiratory conditions at an acceptable cost of ownership.

Owner:PLASTIFLEX GRP NV

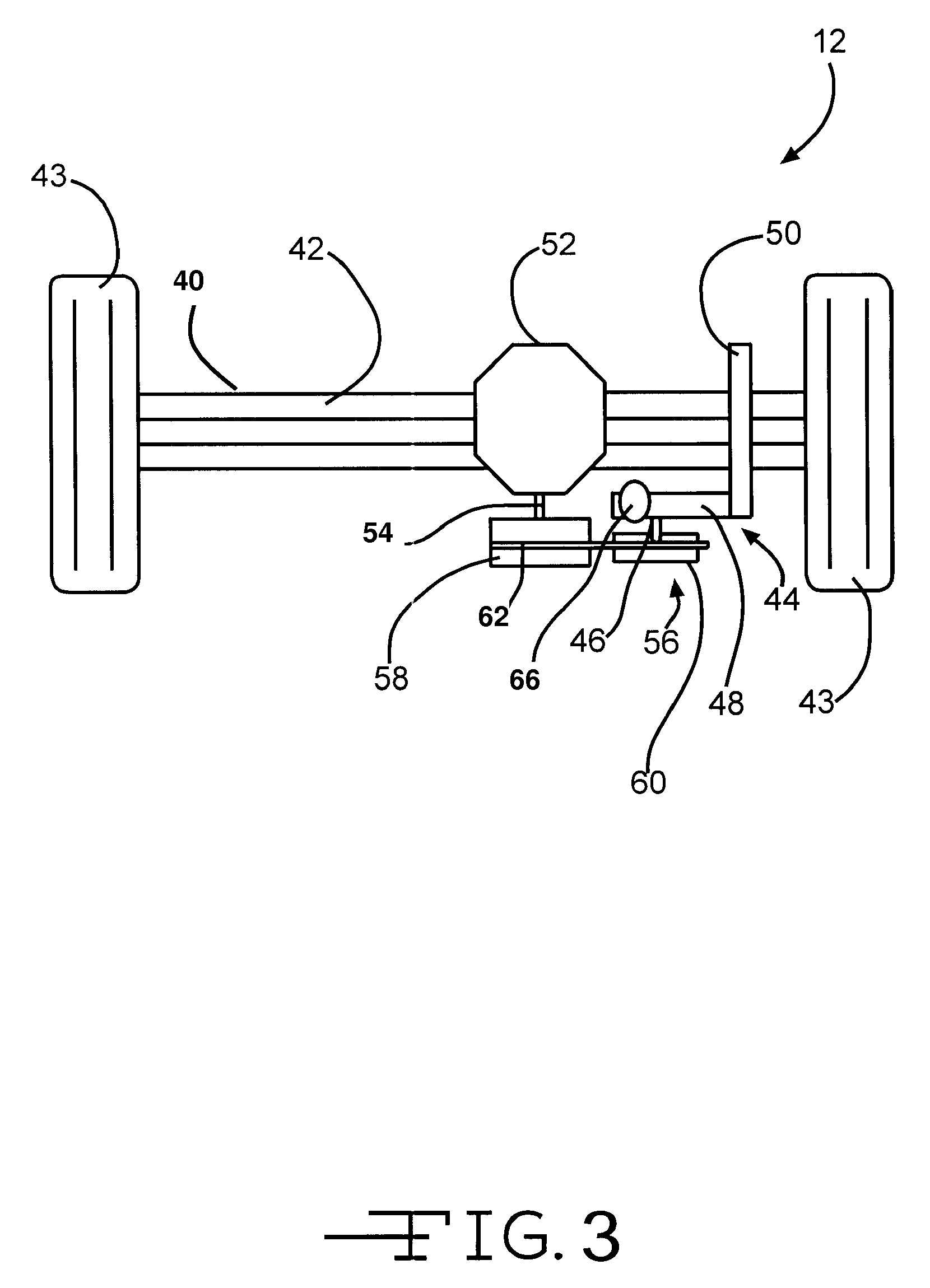

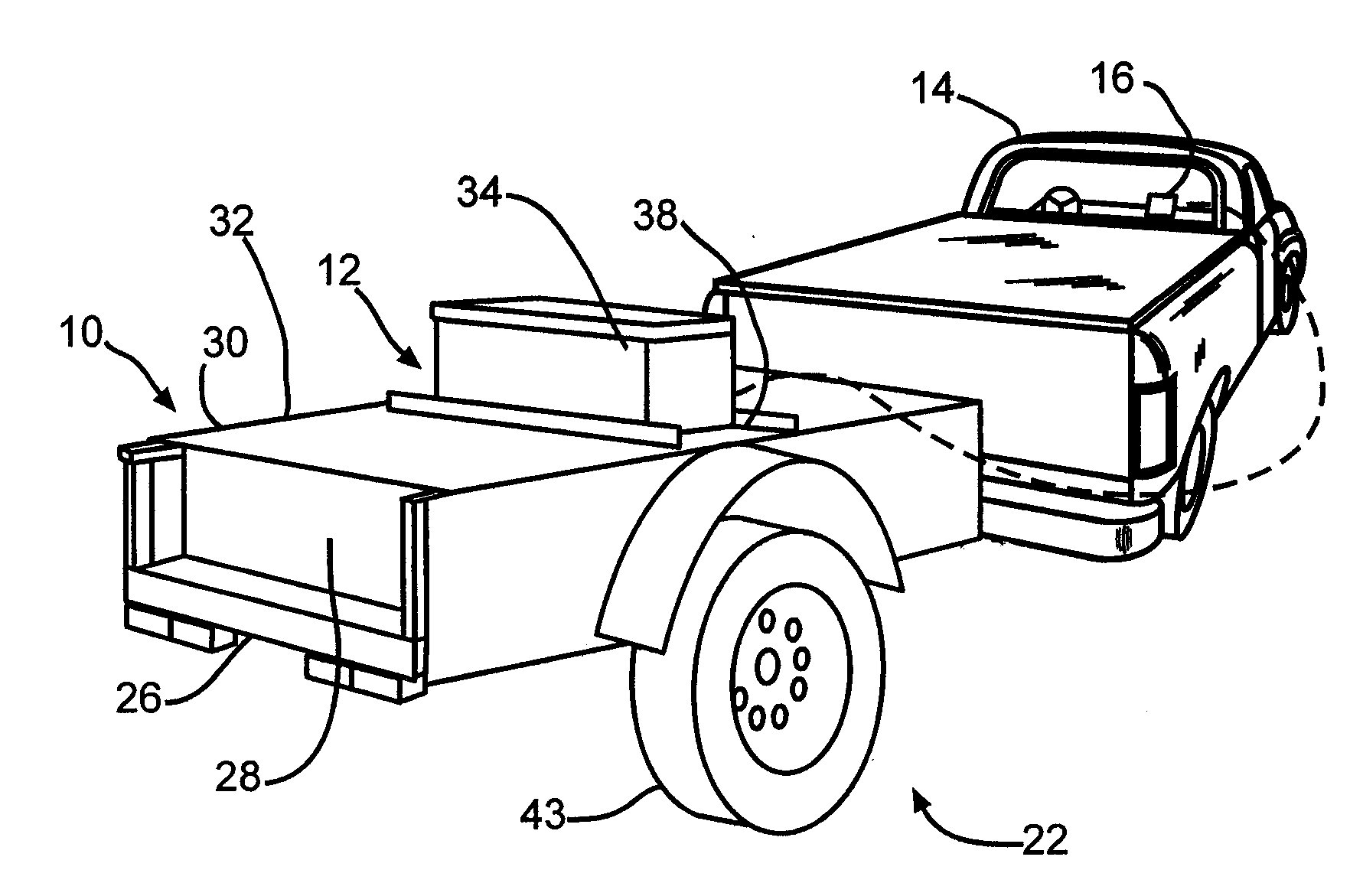

Trailer with Integral Axle-Mounted Generator and Battery Charger

A working surface incorporates a means for transferring mechanical energy produced by a rotating member of the working surface so that the energy rotates a shaft attached to an alternator that charges a bank of 12 V batteries. The alternator is responsible for converting the mechanical energy being input by the rotating shaft to electrical energy that is fed to the batteries. The batteries transfer the energy into an inverter for use depending upon the required amount. Thereby, backup electrical power may be generated and stored, taking advantage of excess horsepower at cruise provided by a vehicle as well as better utilizing travel time. Additionally, the added cost of ownership and noise of a portable power generator is avoided.

Owner:WILKS PAUL L +1

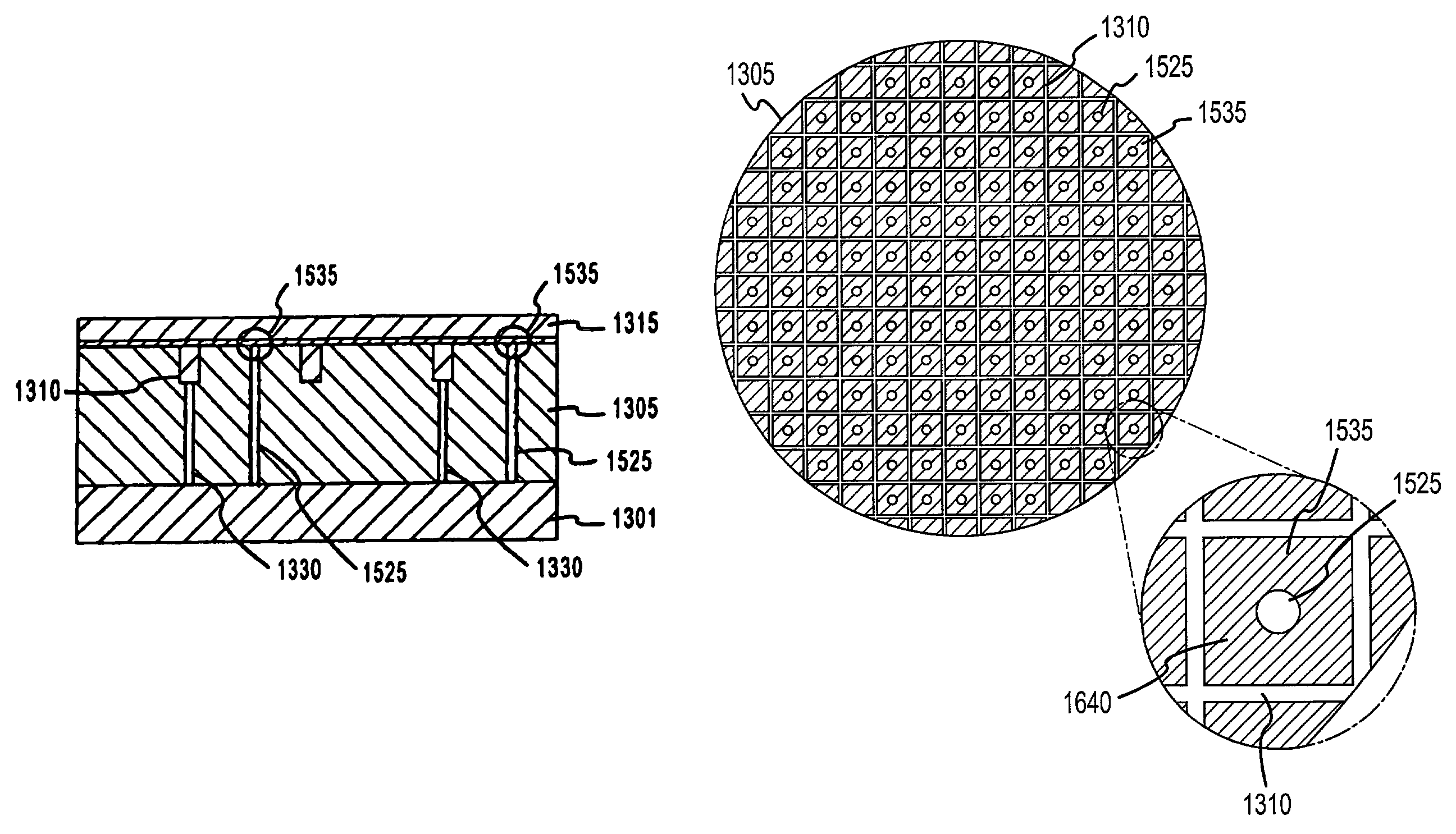

Retaining ring with wear pad for use in chemical mechanical planarization

InactiveUS6899610B2Improve the immunityIncrease pressurePolishing machinesRevolution surface grinding machinesEngineeringWear resistance

A novel retaining ring having a wear pad of such construction, design and material such that it provides improved resistance to wear and / or degradation as compared to currently available products for use in the chemical mechanical planarization (CMP) of semiconductor wafers and similar materials. The retaining ring with wear pad of the invention is able to withstand increased operating temperatures and pressures at the polishing surface of the wafer with less wear than would normally be encountered with currently used materials and designs. The ability to operate at increased temperature and pressure can accelerate the rate of removal of material from a semiconductor wafer in some processes. The flexibility of a manufacturer to use an expanded range of temperature and pressure in CMP processes, combined with a significant reduction in the cost of consumables, provides a significant advantage in the final cost of ownership in the production of multilayer, integrated circuit devices and other products where CMP is utilized in manufacture. Moreover, the retaining with wear pad of the present invention may also retrofitted to previously used and worn retaining rings of the prior-art design, thus salvaging the major structural component of the CMP processing apparatus, thereby reducing costs. It is also an integral part of this invention to make the consumable component of the new design replaceable, so as to make replacement of this part less costly when such replacement finally does become necessary.

Owner:RAYBESTOS POWERTRAIN

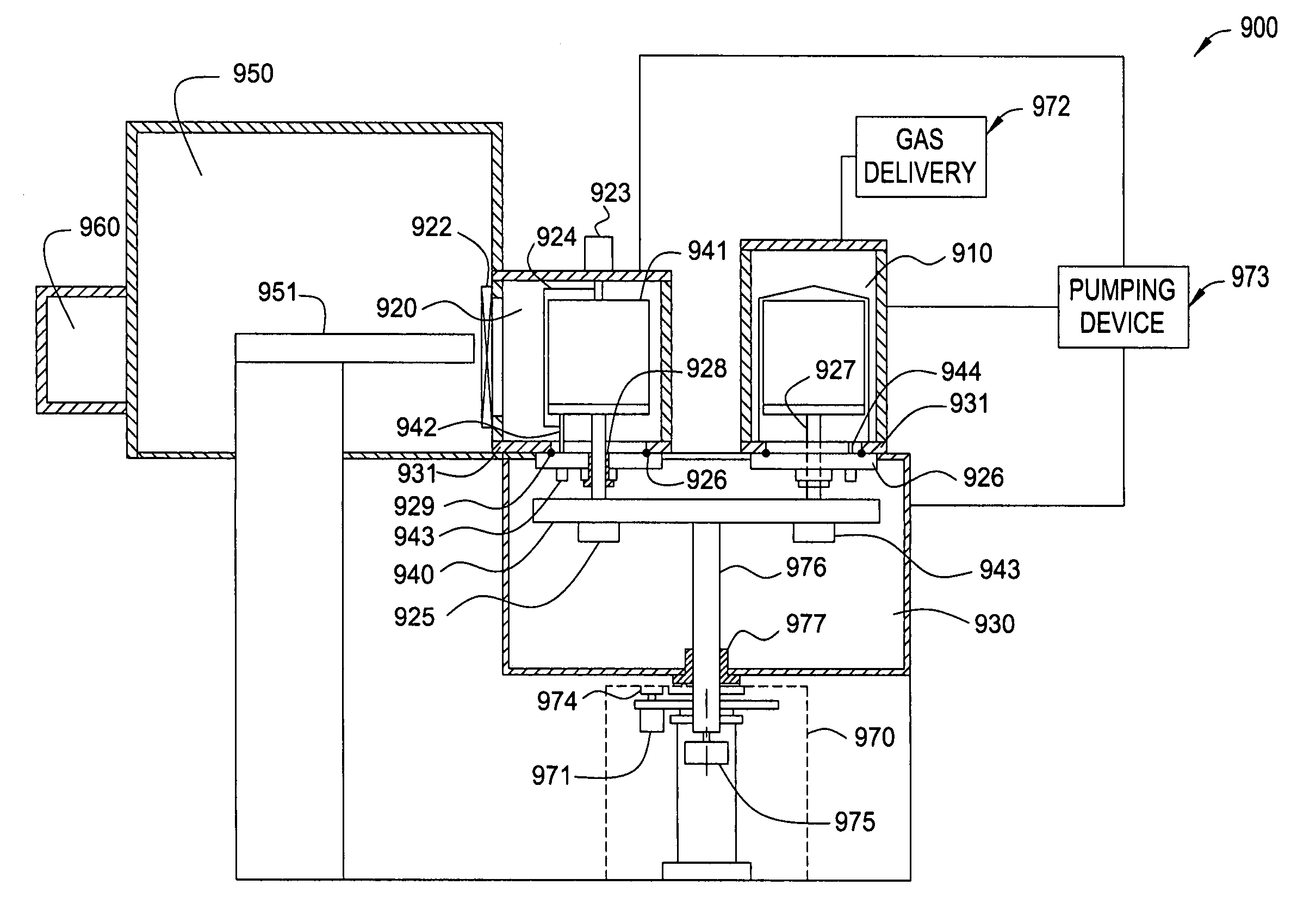

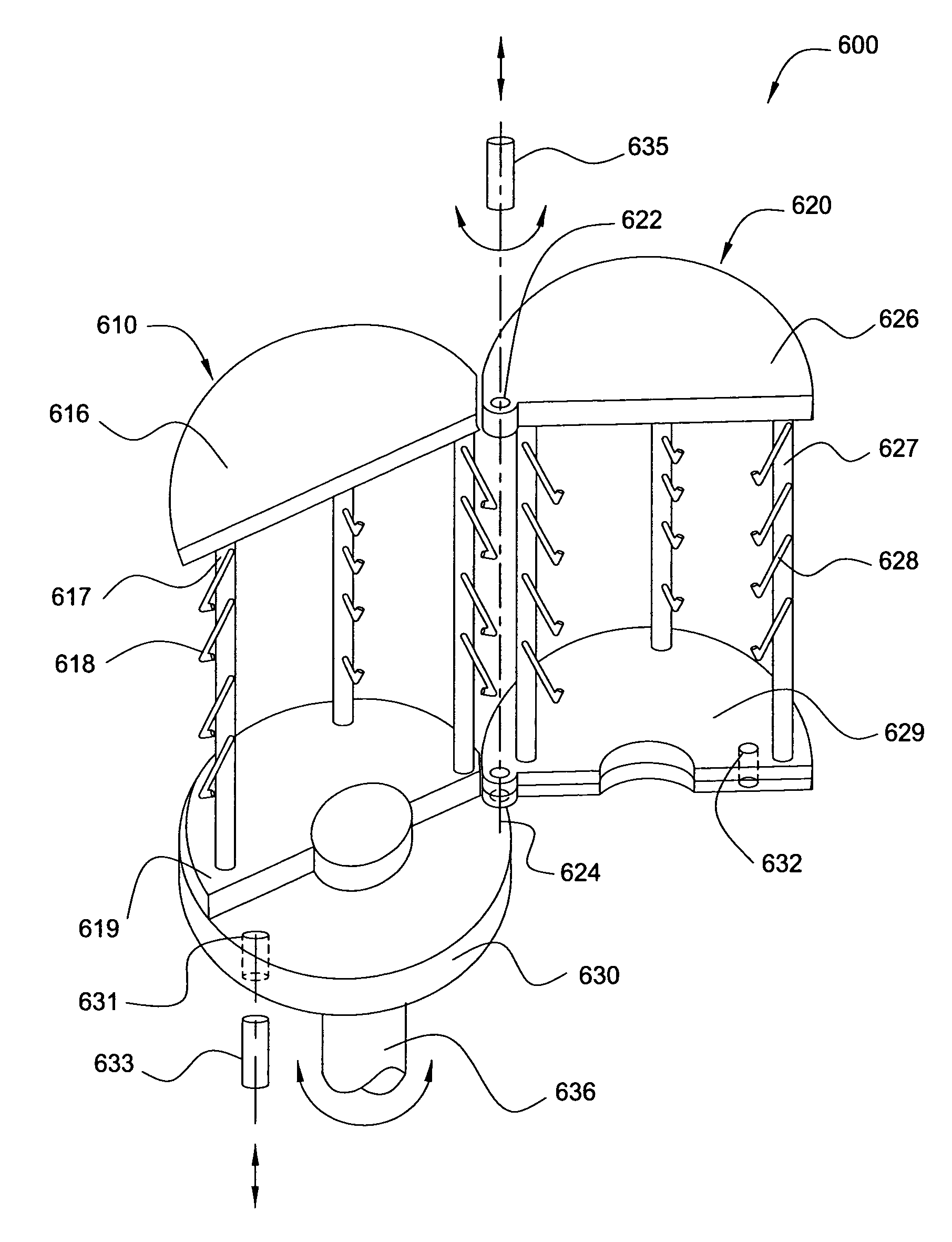

Batch deposition tool and compressed boat

InactiveUS20070059128A1Compresses boat sizeLess spaceSemiconductor/solid-state device manufacturingThin material handlingBatch processingSusceptor

Aspects of the invention include methods and apparatus for processing a batch of substrates. In one embodiment, a compressed substrate boat is configured to reduce pumping volume in a batch processing chamber. The compressed substrate boat comprises a stationary substrate boat and a movable substrate boat, each may be loaded / unloaded independently. The movable substrate boat and the stationary substrate boat may be interleaving with one another such that the distance between the substrates is reduced. In another embodiment, a substrate boat having removable substrate holder is configured to provide susceptors without dramatically increasing pumping volume. The removable substrate holder may be loaded / unloaded away from the substrate boat with susceptors. The removable substrate holder is engaged with the substrate boat such that substrates thereon are interleaving with the susceptors. Embodiments of the present invention reduces pumping volume and increases throughput, hence reduces cost of ownership during batch processing.

Owner:APPLIED MATERIALS INC

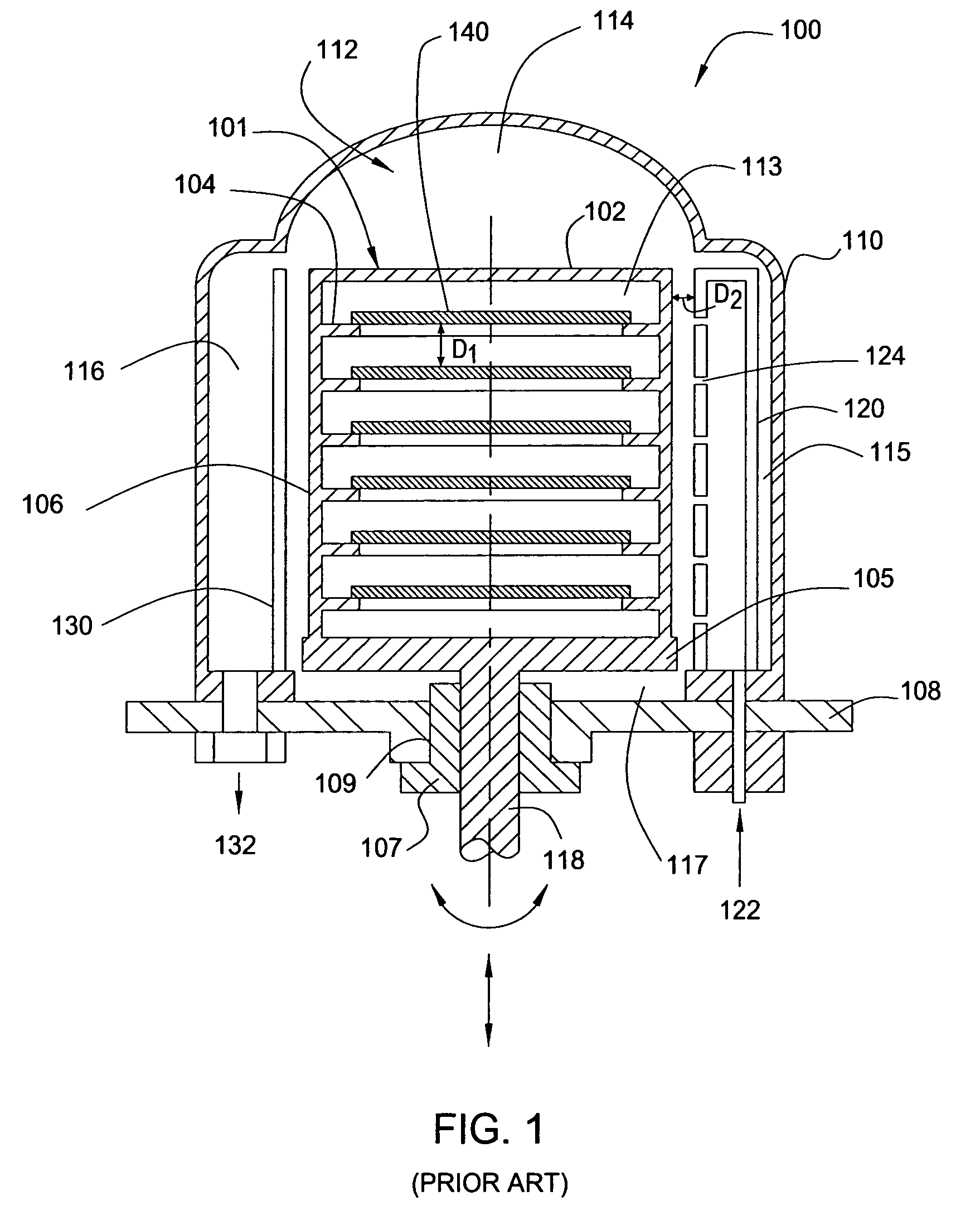

Apparatus for reducing the effect of contamination on a rapid thermal process

ActiveUS20150155190A1Improve temperature uniformityReduced chamber down timeSemiconductor/solid-state device testing/measurementBaking ovenEngineeringContamination

Embodiments of the present disclosure provide a cover assembly that includes a cover disposed between a device side surface of a substrate and a reflector plate, which are disposed within a thermal processing chamber. The presence of the cover between the device side surface of a substrate and a reflector plate has many advantages over conventional thermal processing chamber designs, which include an improved temperature uniformity during processing, a reduced chamber down time and an improved cost-of-ownership of the processes performed in the thermal processing chamber. In some configurations, the cover includes two or more ports that are formed therein and are positioned to deliver a gas, from a space formed between the reflector plate and the cover, to desired regions of the substrate during processing to reduce the temperature variation across the substrate.

Owner:APPLIED MATERIALS INC

Method of retaining a substrate during a substrate transferring process

ActiveUS20070147982A1Minimize variation amountSemiconductor/solid-state device manufacturingCranesModularityEngineering

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

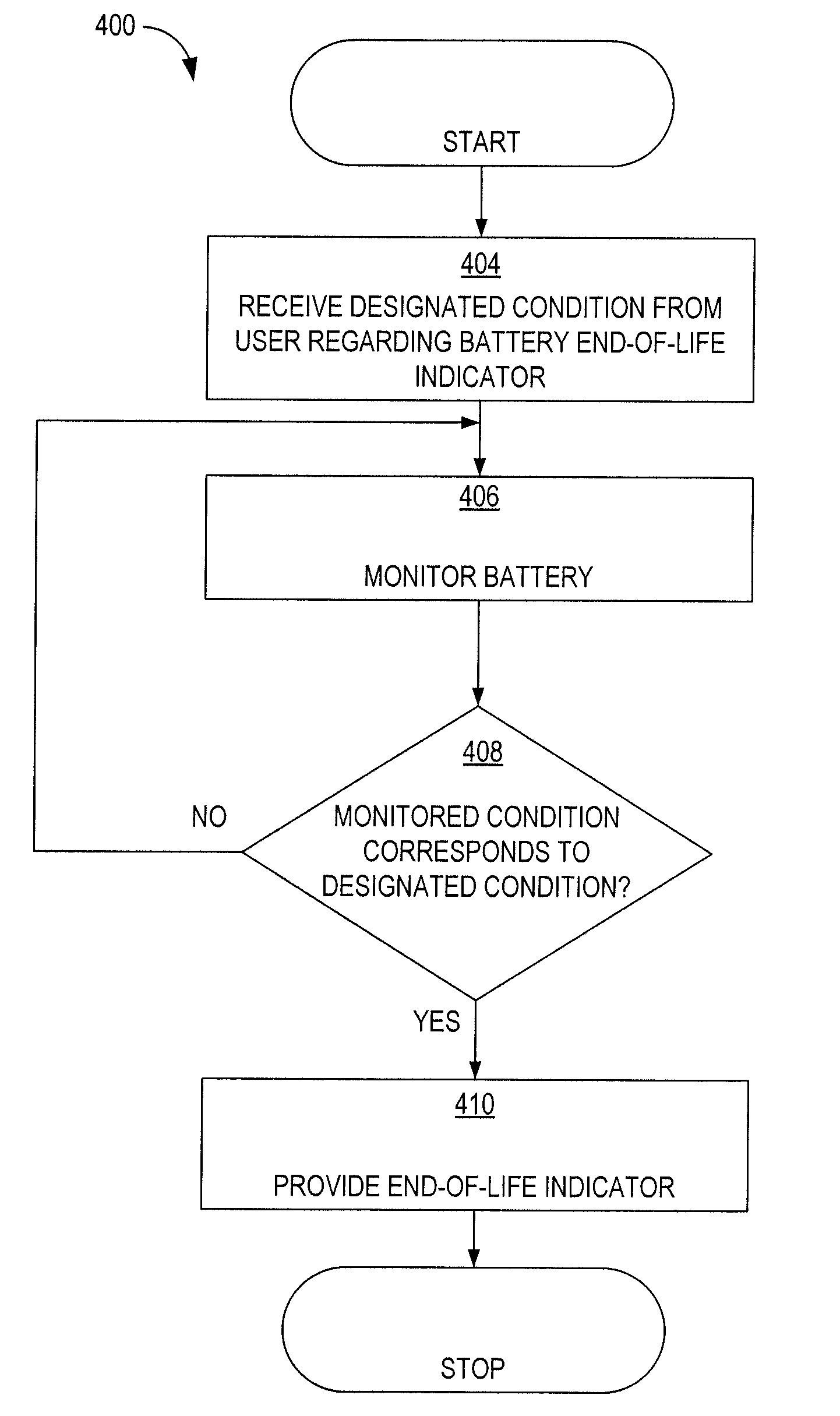

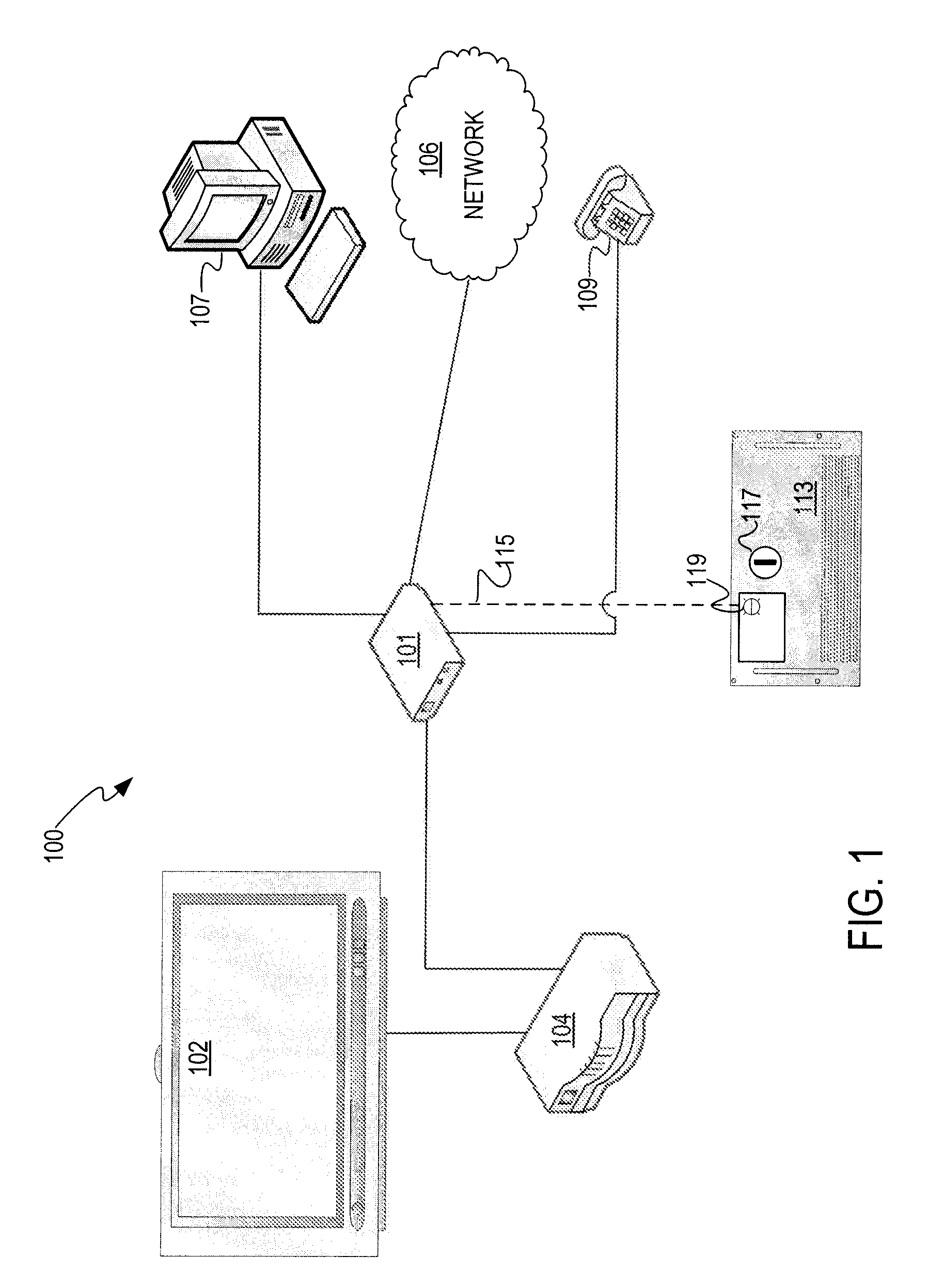

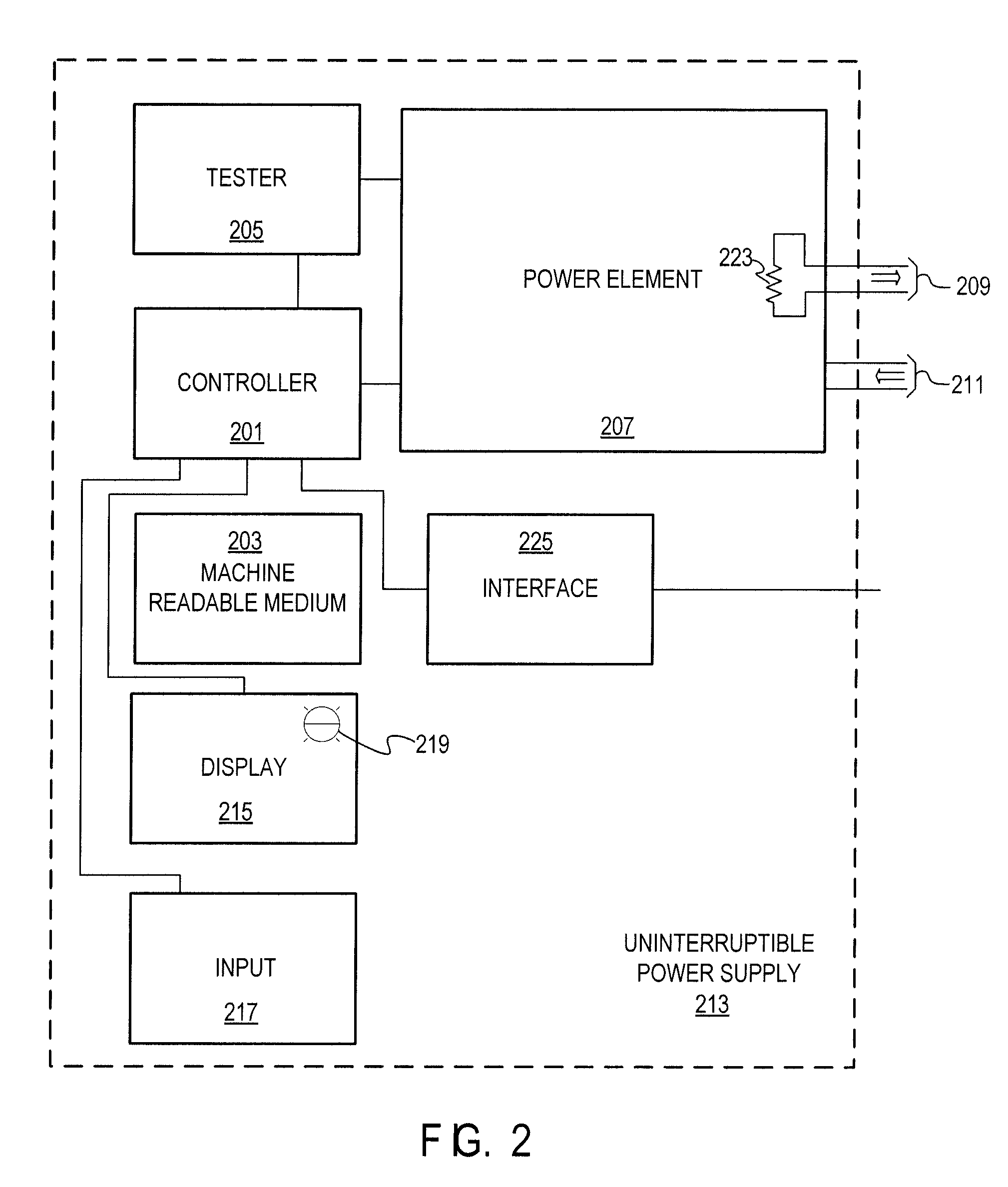

Configurable Battery End-of-Life Indicator

ActiveUS20090167543A1Circuit monitoring/indicationDifferent batteries chargingUser inputCritical system

A method, system, and computer program product are disclosed for providing end-of-life indicators for uninterruptible power supply (UPS) systems. User input is received regarding designated conditions for activating the end-of-life indicator. The UPS system monitors itself to determine whether monitored conditions correspond to the designating conditions. Upon the monitored conditions corresponding to the designating conditions, an audible or visible end-of-life indicator is activated. For critical systems, a user may specify conservative settings for the designated conditions. For other systems, a user may provide a designated condition (i.e., user input) that results in maximizing service life for the UPS system or associated batteries and reducing costs of ownership and operation.

Owner:AT&T INTPROP I L P

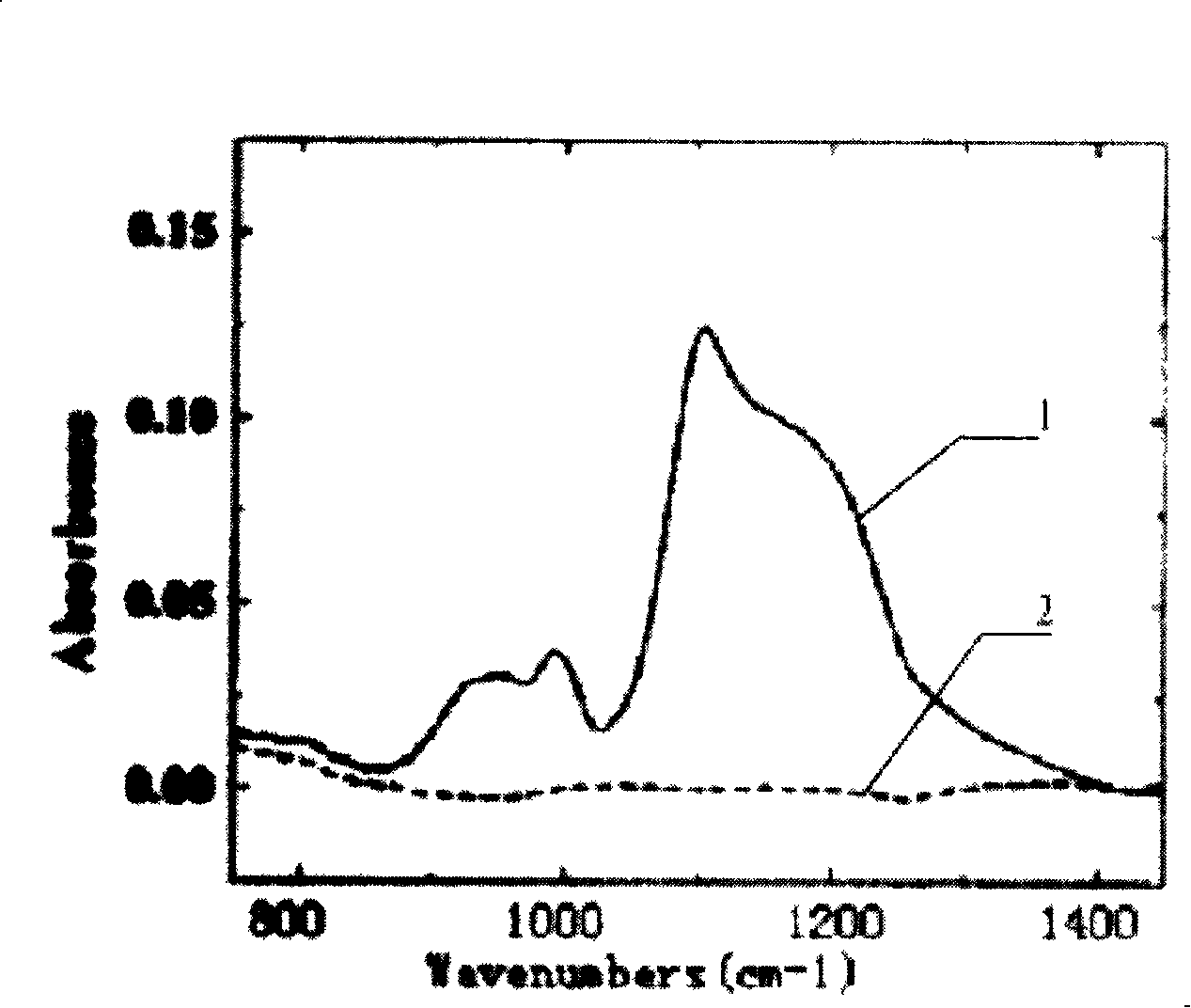

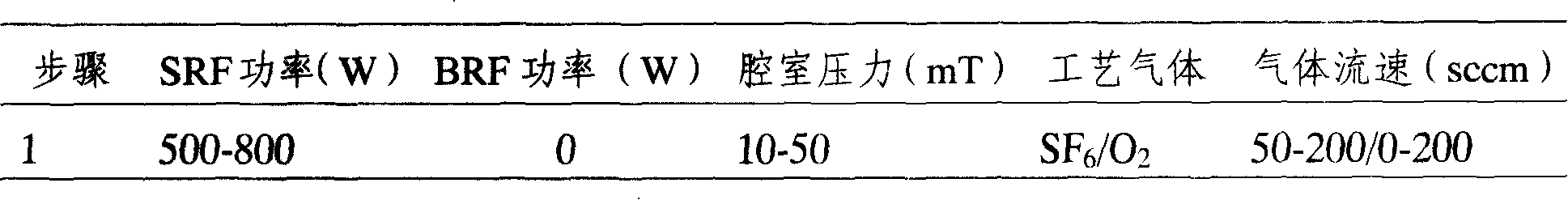

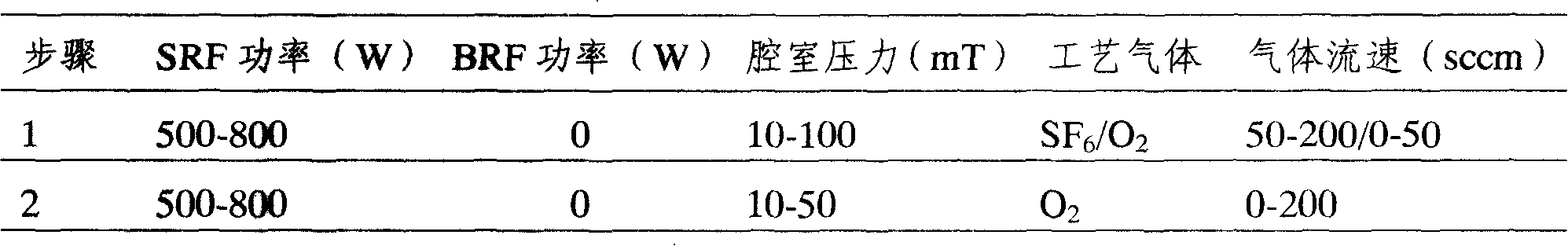

Method for cleaning cavity of semiconductor etching equipment

ActiveCN101214487AExtend your lifeReduce the numberSemiconductor/solid-state device manufacturingCleaning processes and apparatusEtchingProduct gas

The invention relates to a method for cleaning the chamber of a semiconductor etching equipment. The procedures of the method are as follows: mixed gas composed of CIF3 and inert gas is used for cleaning the chamber of a semiconductor etching equipment. The inert gas or O2 or the mixed gas composed of the inert gas and O2 is used for cleaning the chamber of a semiconductor etching equipment. The method of the invention can attain the aim of cleaning the chamber of the semiconductor etching equipment on condition of non-plasma starting. The method can effectively prolong the service life of the part, reduce the number of metal particle and improve the yield rate of product. In addition, the method does not require plasma starting during the cleaning process, with the result that the cost of ownership can be further reduced during the processing of wafer.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Method of retaining a substrate during a substrate transferring process

ActiveUS7374393B2Minimize variation amountSemiconductor/solid-state device manufacturingStacking articlesModularityEngineering

A method and apparatus for processing substrates using a multi-chamber processing system, or cluster tool, that has an increased system throughput, increased system reliability, improved device yield performance, a more repeatable wafer processing history (or wafer history), and a reduced footprint. The various embodiments of the cluster tool may utilize two or more robots that are configured in a parallel processing configuration to transfer substrates between the various processing chambers retained in the processing racks so that a desired processing sequence can be performed on the substrates. In one aspect, the parallel processing configuration contains two or more robot assemblies that are adapted to move in a vertical and horizontal directions, to access the various processing chambers retained in generally adjacently positioned processing racks. Generally, the various embodiments described herein are advantageous since each row or group of substrate processing chambers are serviced by two or more robots to allow for increased throughput and increased system reliability. Also, the various embodiments described herein are generally configured to minimize and control the particles generated by the substrate transferring mechanisms, to prevent device yield and substrate scrap problems that can affect the cost of ownership of the cluster tool. The flexible and modular architecture allows the user to configure the number of processing chambers, processing racks, and processing robots required to meet the throughput needs of the user.

Owner:APPLIED MATERIALS INC

Method and apparatus for controlling slurry distribution

InactiveUS7314402B2Easy to controlLoss of chemical reactivityPolishing machinesRevolution surface grinding machinesChemical compositionChemical reaction

Owner:SPEEDFAM IPEC

Batch deposition tool and compressed boat

InactiveUS7748542B2Compresses the boat sizeLess spaceSemiconductor/solid-state device manufacturingPlatesBatch processingEngineering

Aspects of the invention include methods and apparatus for processing a batch of substrates. In one embodiment, a compressed substrate boat is configured to reduce pumping volume in a batch processing chamber. The compressed substrate boat comprises a stationary substrate boat and a movable substrate boat, each may be loaded / unloaded independently. The movable substrate boat and the stationary substrate boat may be interleaving with one another such that the distance between the substrates is reduced. In another embodiment, a substrate boat having removable substrate holder is configured to provide susceptors without dramatically increasing pumping volume. The removable substrate holder may be loaded / unloaded away from the substrate boat with susceptors. The removable substrate holder is engaged with the substrate boat such that substrates thereon are interleaving with the susceptors. Embodiments of the present invention reduces pumping volume and increases throughput, hence reduces cost of ownership during batch processing.

Owner:APPLIED MATERIALS INC

Small footprint modular processing system

InactiveUS20080019806A1Programme-controlled manipulatorSemiconductor/solid-state device manufacturingModularitySmall footprint

A method and apparatus for a modular processing system is described. The apparatus includes a transfer chamber as the foundation for the system and includes sidewalls adapted to receive at least three 200 mm and / or 300 mm process chambers. The transfer chamber includes a robot capable of withstanding high temperatures and is configured to transfer 200 mm and 300 mm substrates. The modularity of the transfer chamber is highly transportable and provides a research and development platform at a low cost of ownership and may be modularly built into a production system as additional chambers and peripheral hardware is added.

Owner:APPLIED MATERIALS INC

Cluster tool architecture for processing a substrate

ActiveUS20060278165A1Liquid surface applicatorsSemiconductor/solid-state device testing/measurementLithography processEngineering

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history, and also the cluster tool has a smaller system footprint. In one embodiment, the cluster tool is adapted to perform a track lithography process in which a substrate is coated with a photosensitive material, is then transferred to a stepper / scanner, which exposes the photosensitive material to some form of radiation to form a pattern in the photosensitive material, which is then removed in a developing process completed in the cluster tool. In track lithography type cluster tools, since the chamber processing times tend to be rather short, and the number of processing steps required to complete a typical track system process is large, a significant portion of the time it takes to process a substrate is taken up by the processes of transferring the substrates in a cluster tool between the various processing chambers. In one embodiment of the cluster tool, the cost of ownership is reduced by grouping substrates together and transferring and processing the substrates in groups of two or more to improve system throughput, and reduces the number of moves a robot has to make to transfer a batch of substrates between the processing chambers, thus reducing wear on the robot and increasing system reliability. In one aspect of the invention, the substrate processing sequence and cluster tool are designed so that the substrate transferring steps performed during the processing sequence are only made to chambers that will perform the next processing step in the processing sequence. Embodiments also provide for a method and apparatus that are used to improve the coater chamber, the developer chamber, the post exposure bake chamber, the chill chamber, and the bake chamber process results. Embodiments also provide for a method and apparatus that are used to increase the reliability of the substrate transfer process to reduce system down time.

Owner:APPLIED MATERIALS INC

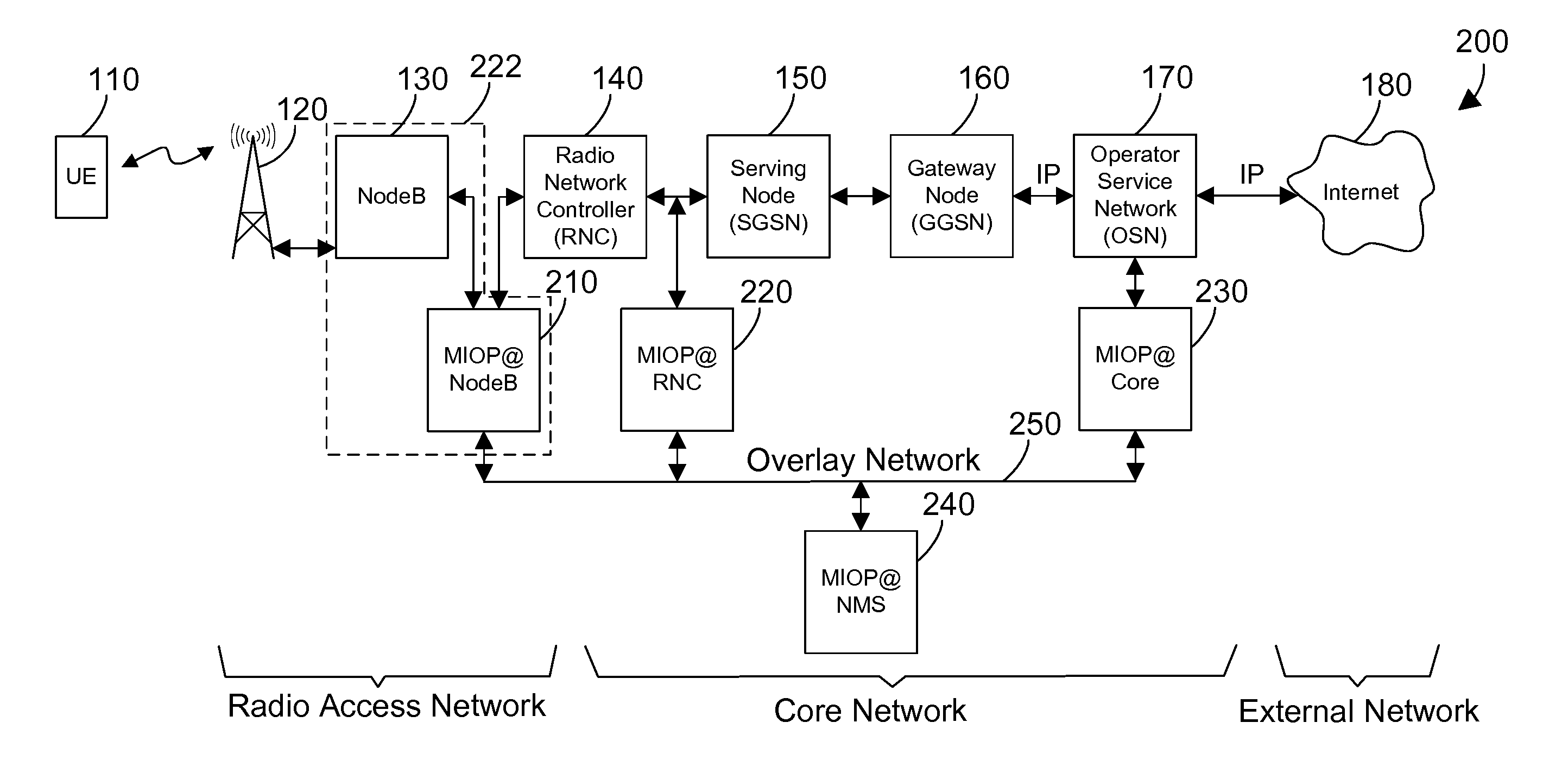

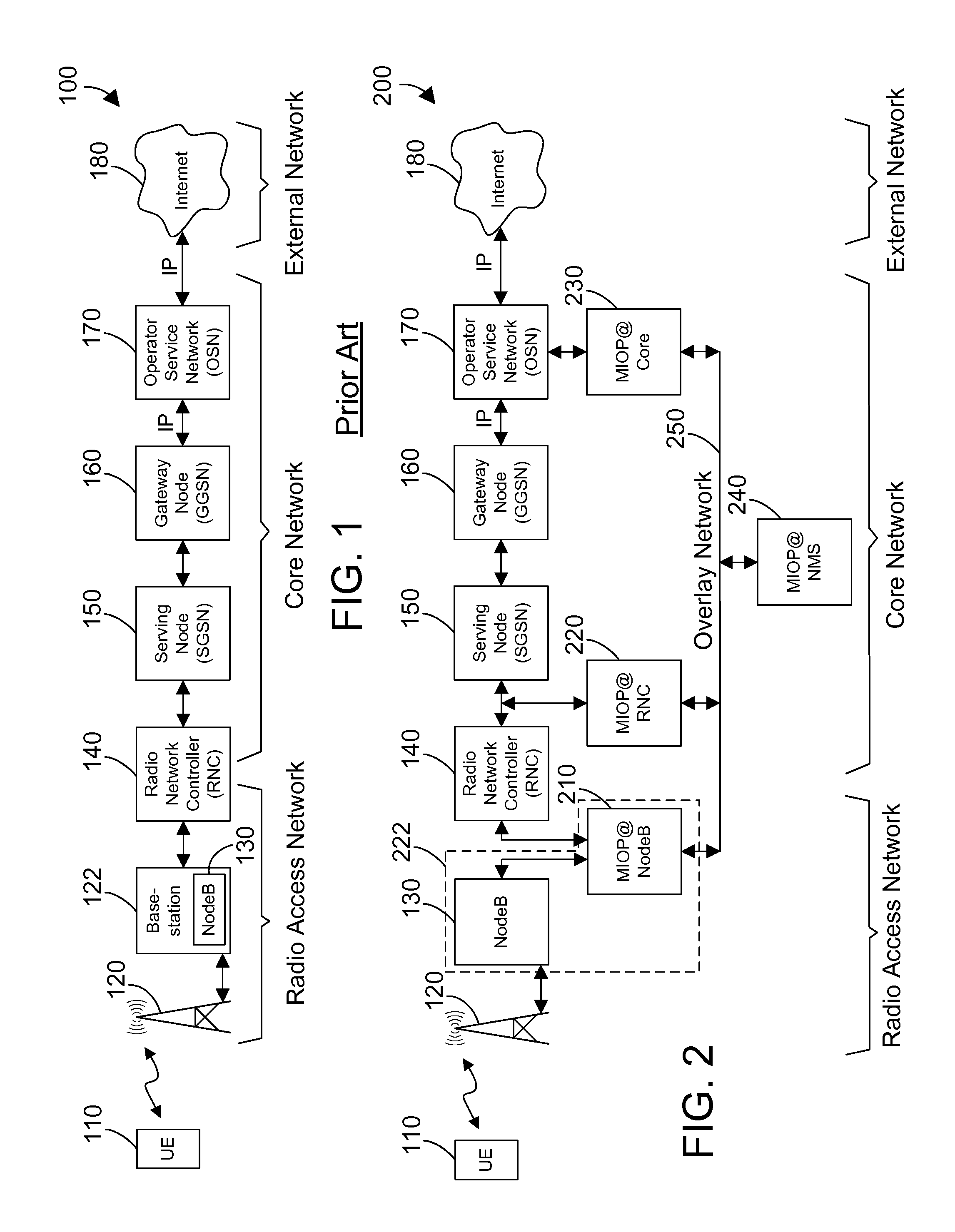

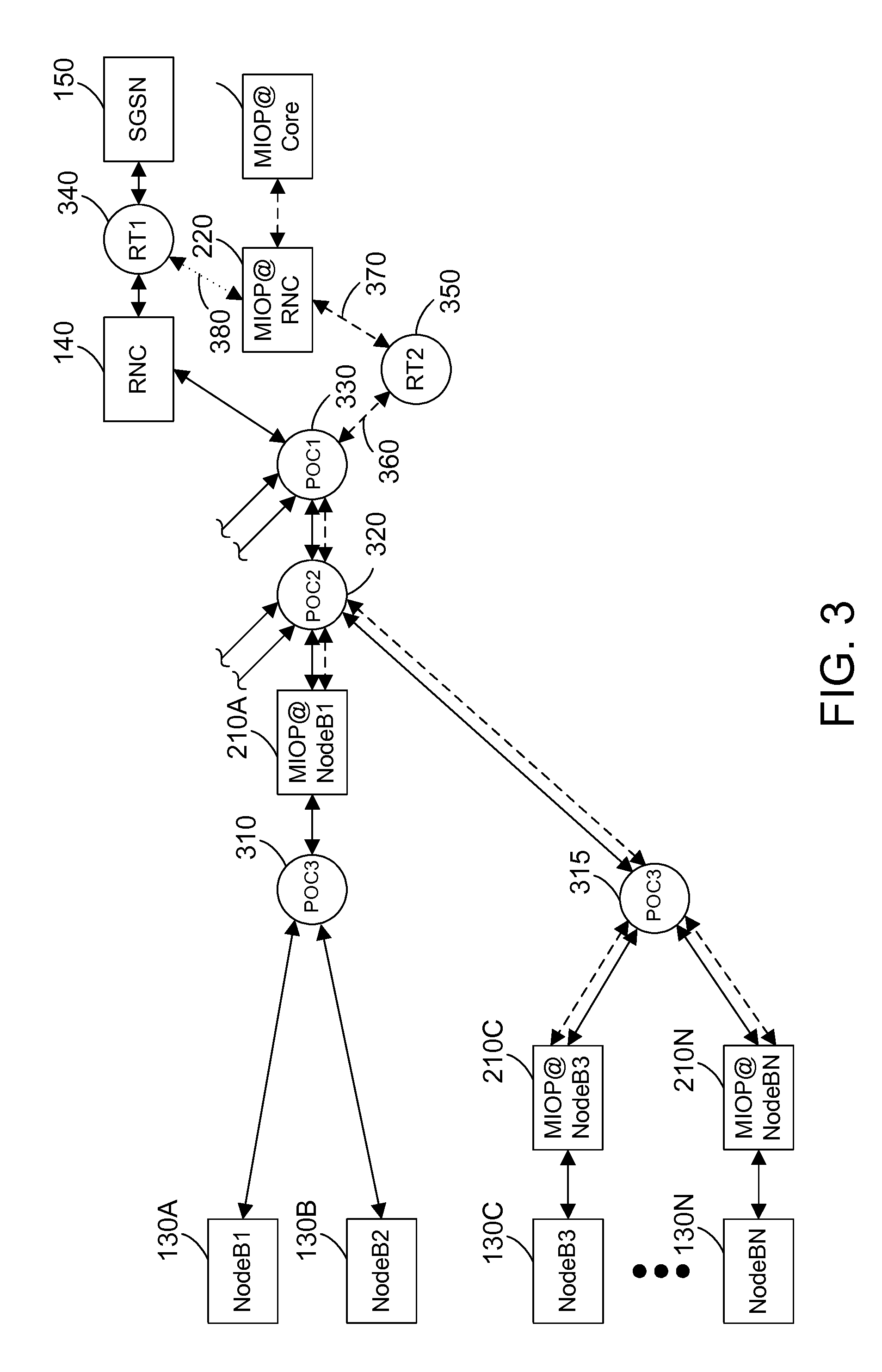

Autonomic error recovery for a data breakout appliance at the edge of a mobile data network

InactiveUS20130157644A1Error preventionFrequency-division multiplex detailsTraffic flowRecovery function

A mechanism provides autonomic recovery for a breakout appliance at the edge of a mobile data network from a variety of errors using a combination of hardware, software and network recovery actions. The recovery actions proceed upon a sliding scale depending on the severity of the problem to achieve the goals of minimizing disruption to traffic flowing through the NodeB while also maintaining an acceptable cost of ownership / maintenance of the system by automatically recovering from as many problems as possible. The error recovery functions within the breakout system hide the error recovery complexities from the management system upstream in the mobile data network. For critical, non-recoverable errors, the autonomic recovery mechanism works in conjunction with a fail-to-wire module to remove the breakout system in the event of a failure in such a way that the mobile data network functions as if the breakout system is no longer present.

Owner:IBM CORP

Method and apparatus for controlled slurry distribution

InactiveUS20060151110A1Easy to controlLoss of chemical reactivityRevolution surface grinding machinesSemiconductor/solid-state device manufacturingChemical compositionChemical reaction

A method and apparatus for ‘through-the-pad’ delivery of slurry polishing agents directly to the land areas of a polishing pad is disclosed. The present invention further provides for improved control of the chemical composition of the slurry to address loss of chemical reactivity of the slurry during the polishing cycle. Additionally, various groove modifications to the polishing surface of the pad are also disclosed for improved slurry retention over substantially the entire surface of the polishing pad and reduction of the slow band effect. The present invention thus provides for a higher degree of planarization and uniformity of material removed from the surface of a processed workpiece in order to eliminate, or otherwise reduce, small-scale roughness and large-scale topographic differentials as well as to reduce the Cost-of-Ownership associated with slurry costs.

Owner:NOVELLUS SYSTEMS

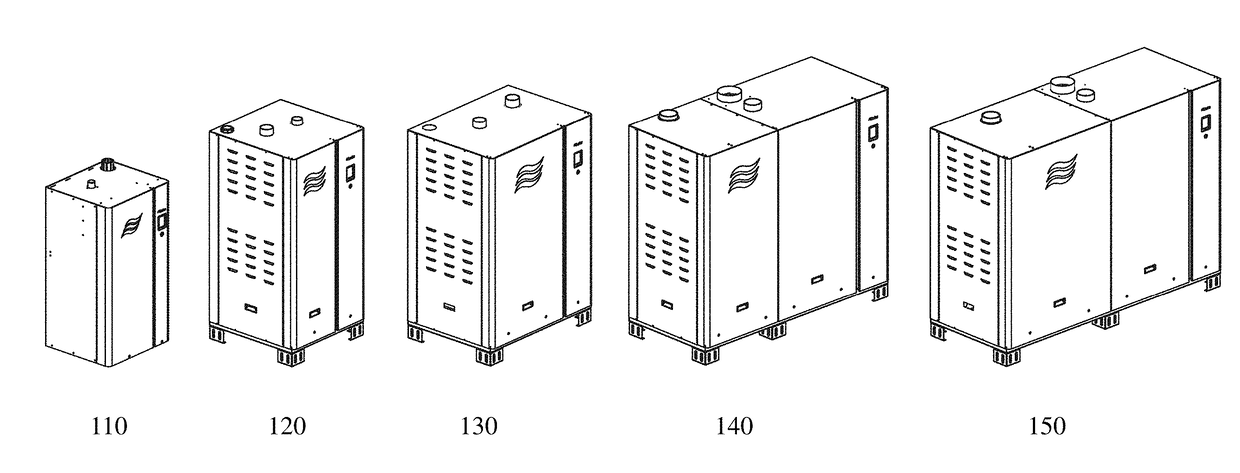

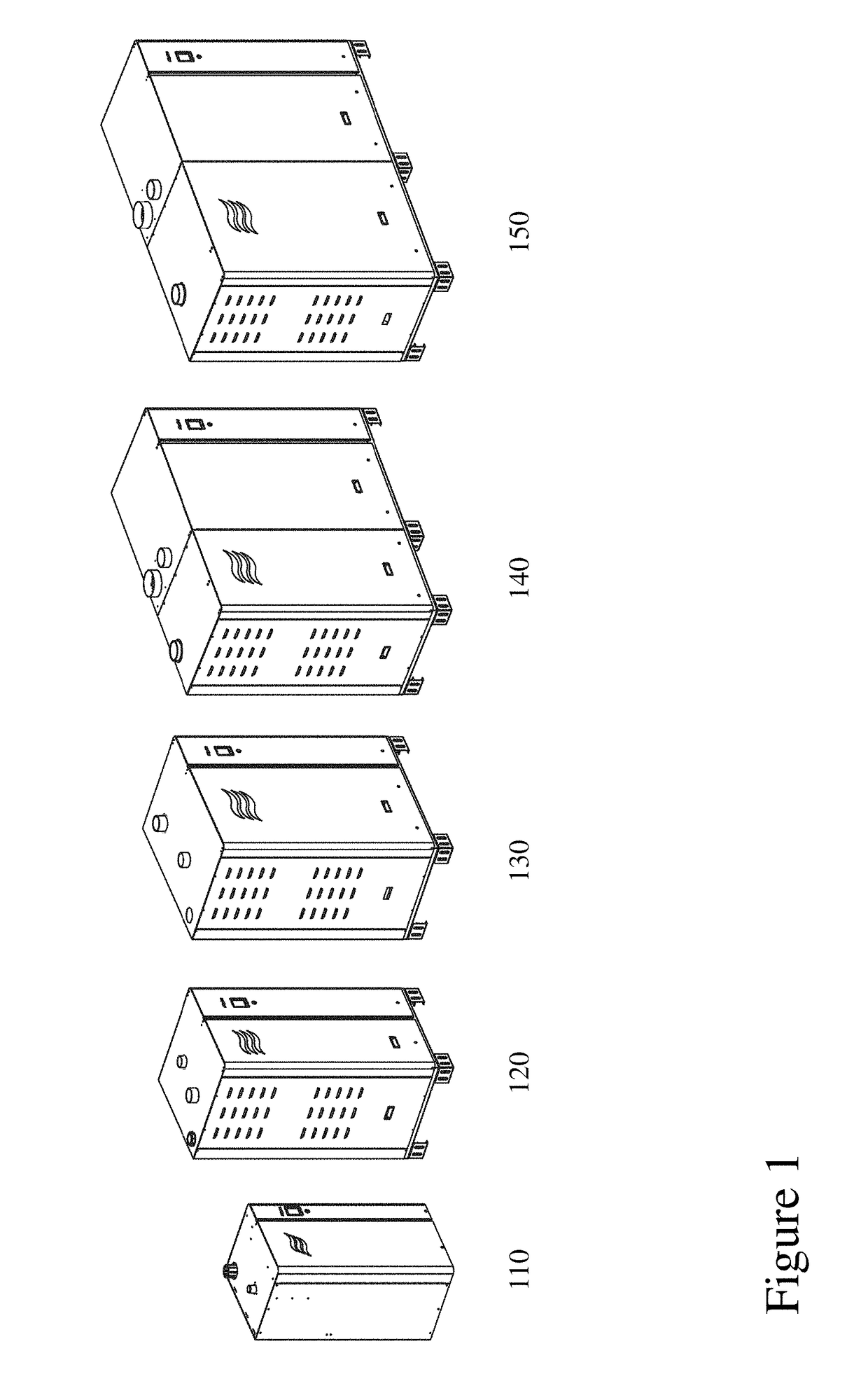

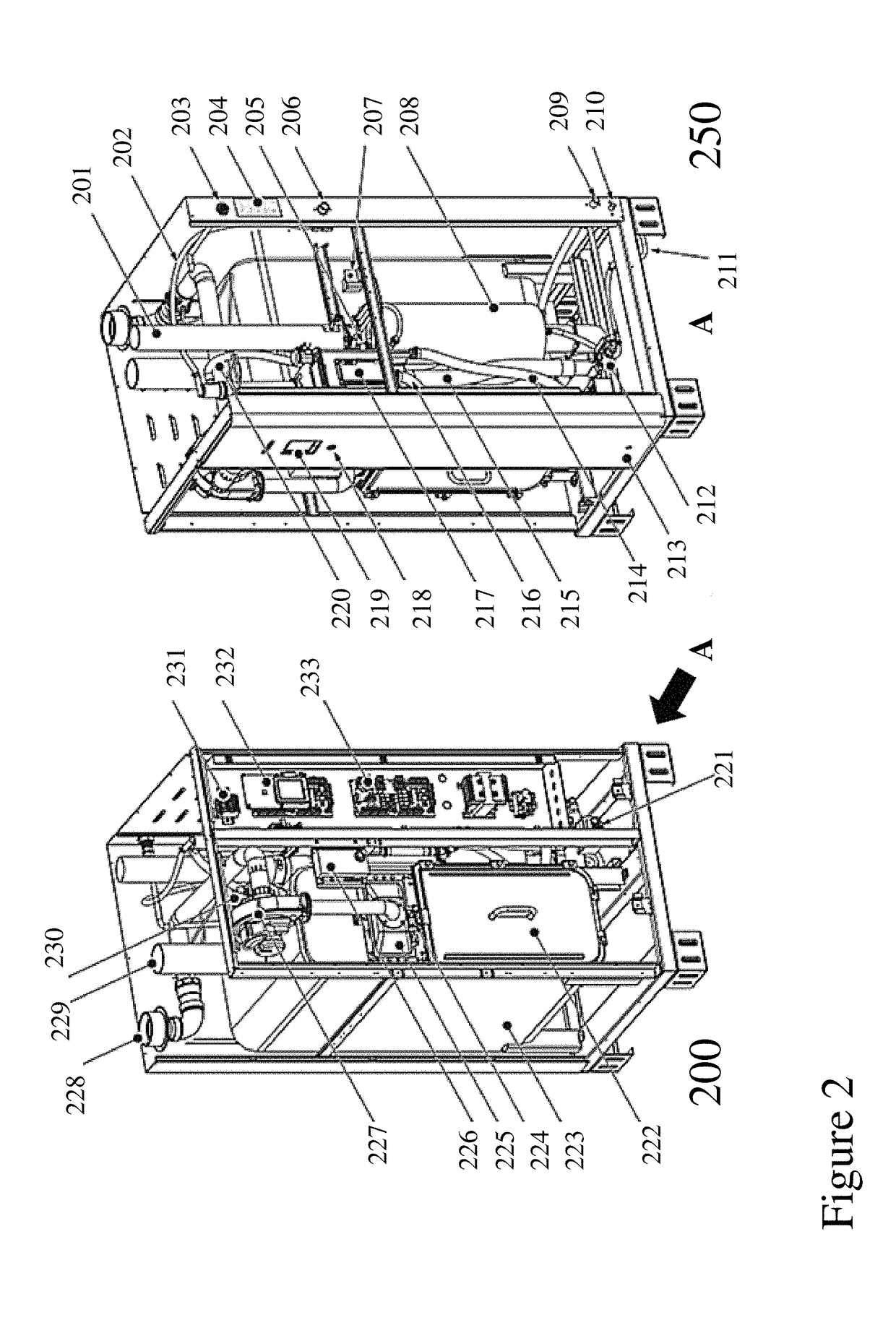

Dual-stage humidifier methods and systems

Today vaporizing humidifier must achieve their desired function and operate with conflicting requirements such as cost of ownership (CoO) and regulatory guidelines. Low CoO requires high injection efficiency, low water consumption, and high energy efficiency to reduce energy consumption and running costs. All of this is sought with variable humidification and low exhaust gas temperatures from safety / regulatory viewpoints as well as ducting material selection and venting of the exhaust gases and high efficiency. To date vaporizing humidifiers have been partially successful utilizing a single stage heat exchanger that could not extract latent energy from exhaust gases because the secondary fluid is boiling water. High exhaust temperature requires high temperature stainless steel exhaust venting. Embodiments of the invention provide dual-stage humidification systems with an effective design for achieving the conflicting objectives under variable humidification operation as well as addressing the control loop design of such dual-stage humidification systems.

Owner:CONDAIR GRP

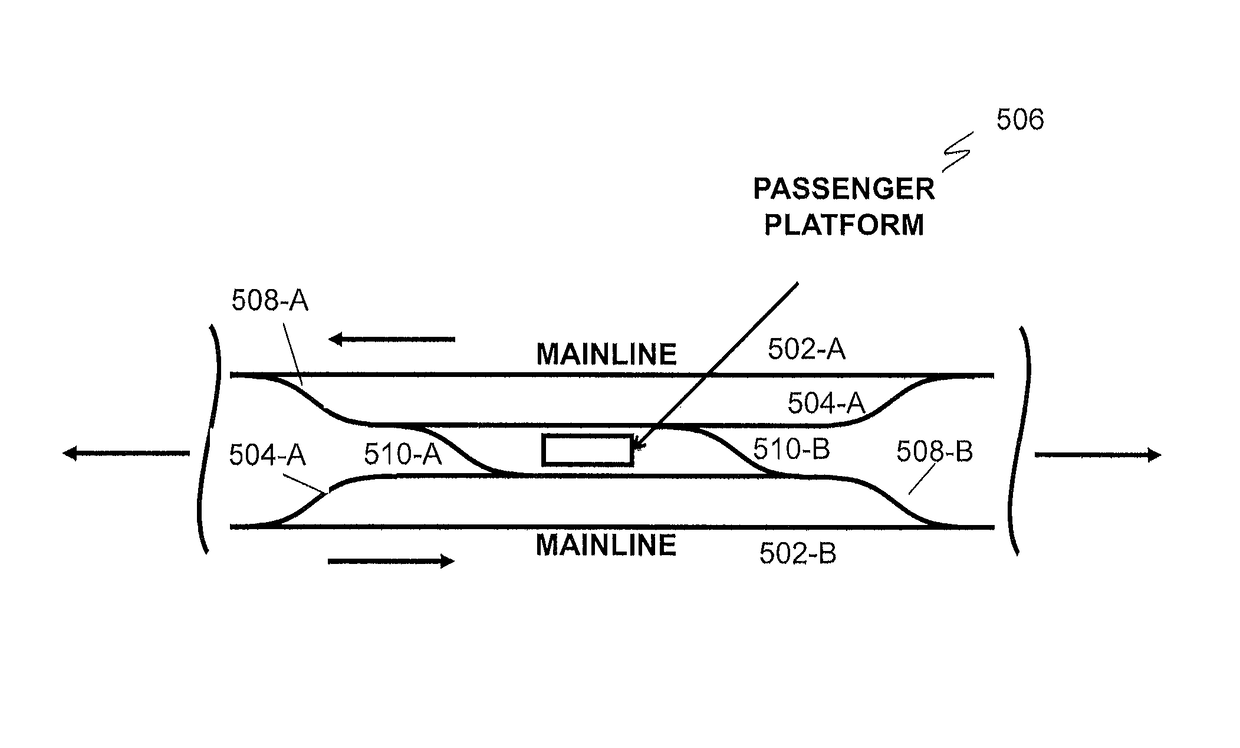

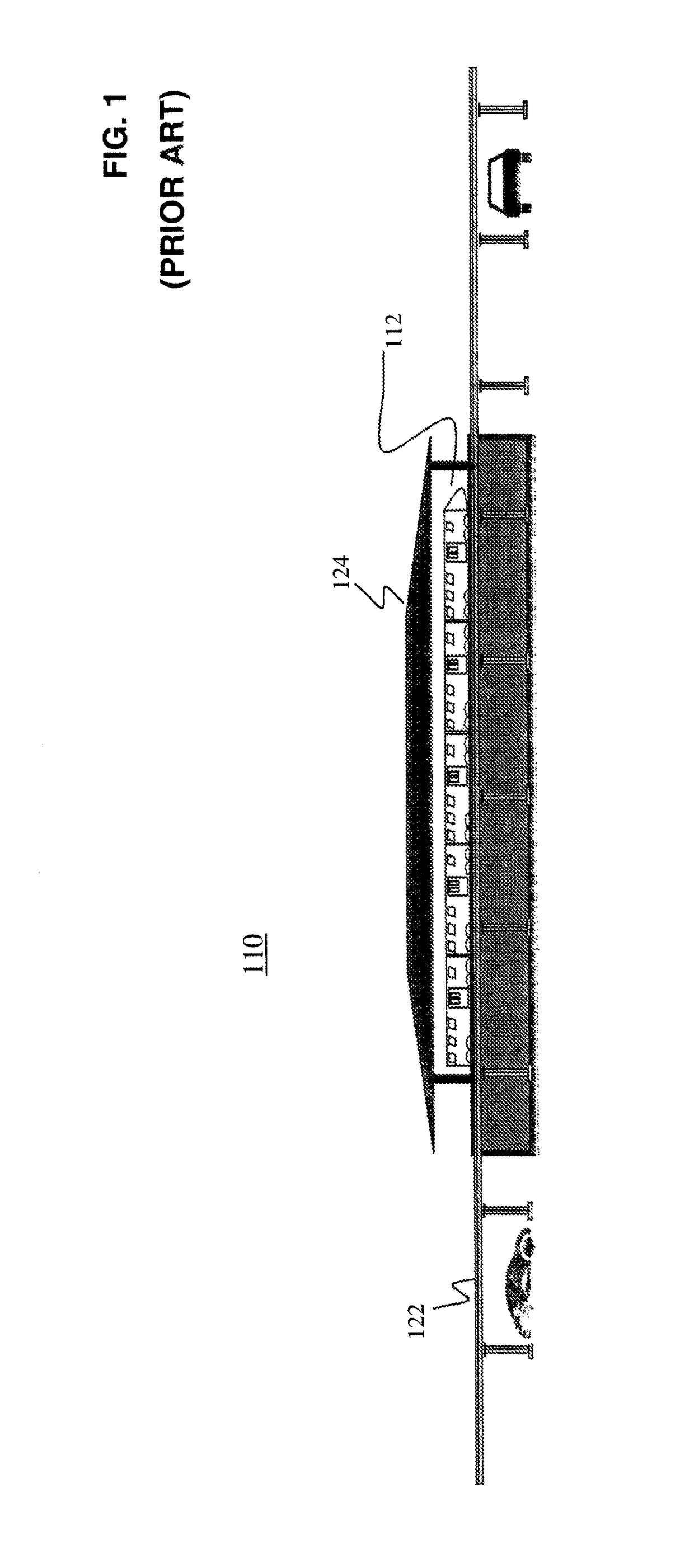

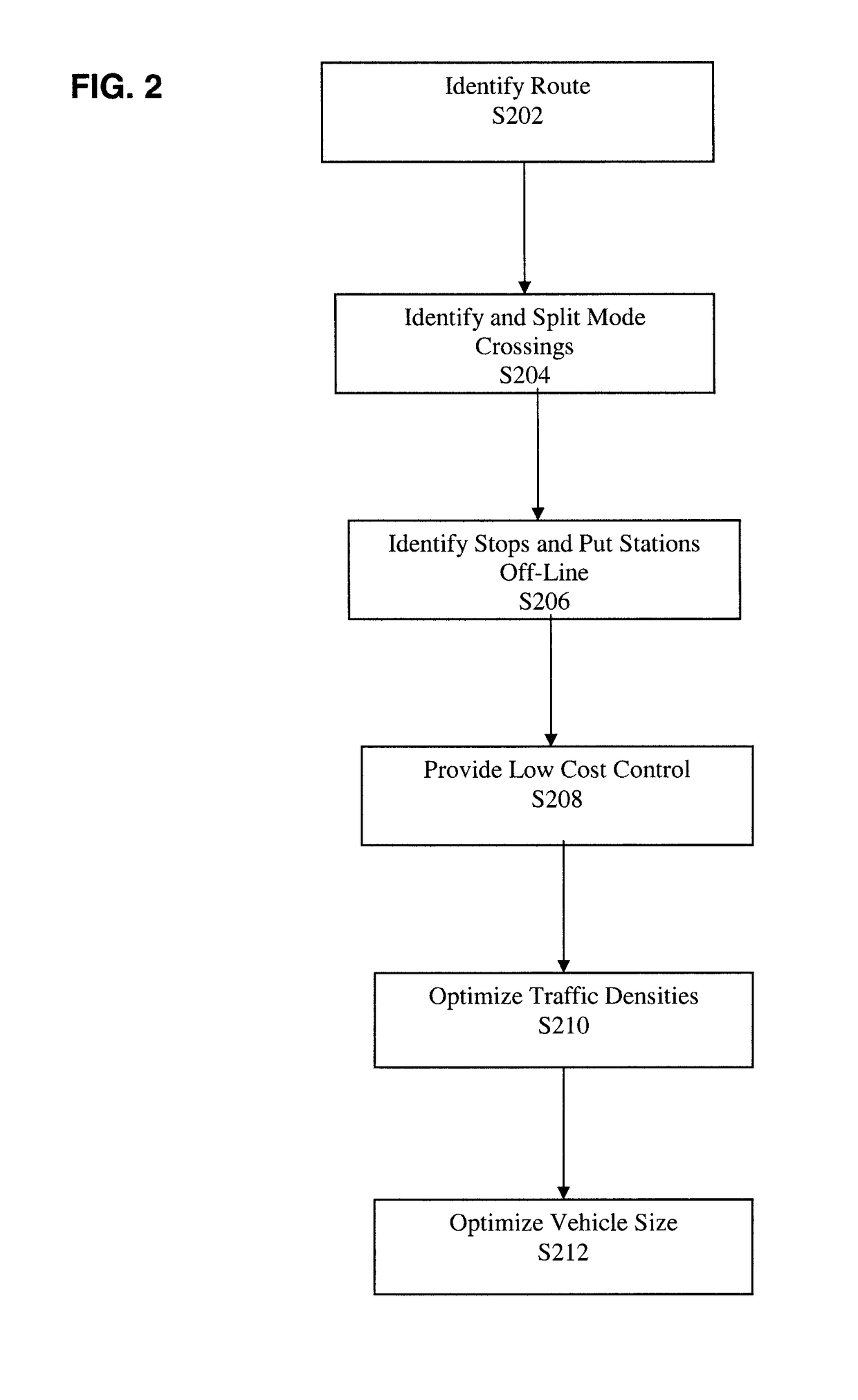

Fixed guideway transportation systems having lower cost of ownership and optimized benefits

ActiveUS9802633B1Superior amount of benefits per costNet present costAutomatic systemsRoad vehicles traffic controlCarrying capacityHigh density

The present invention relates generally to ground transportation systems, and more particularly to a fixed guideway transportation system that achieves a superior ratio of benefits per cost, is lower in net present cost and thus more easily justified for lower density corridors, and can provide passenger carrying capacities appropriate for higher density corridors serviced by mass rapid transit systems today.

Owner:CYBERTRAN INT

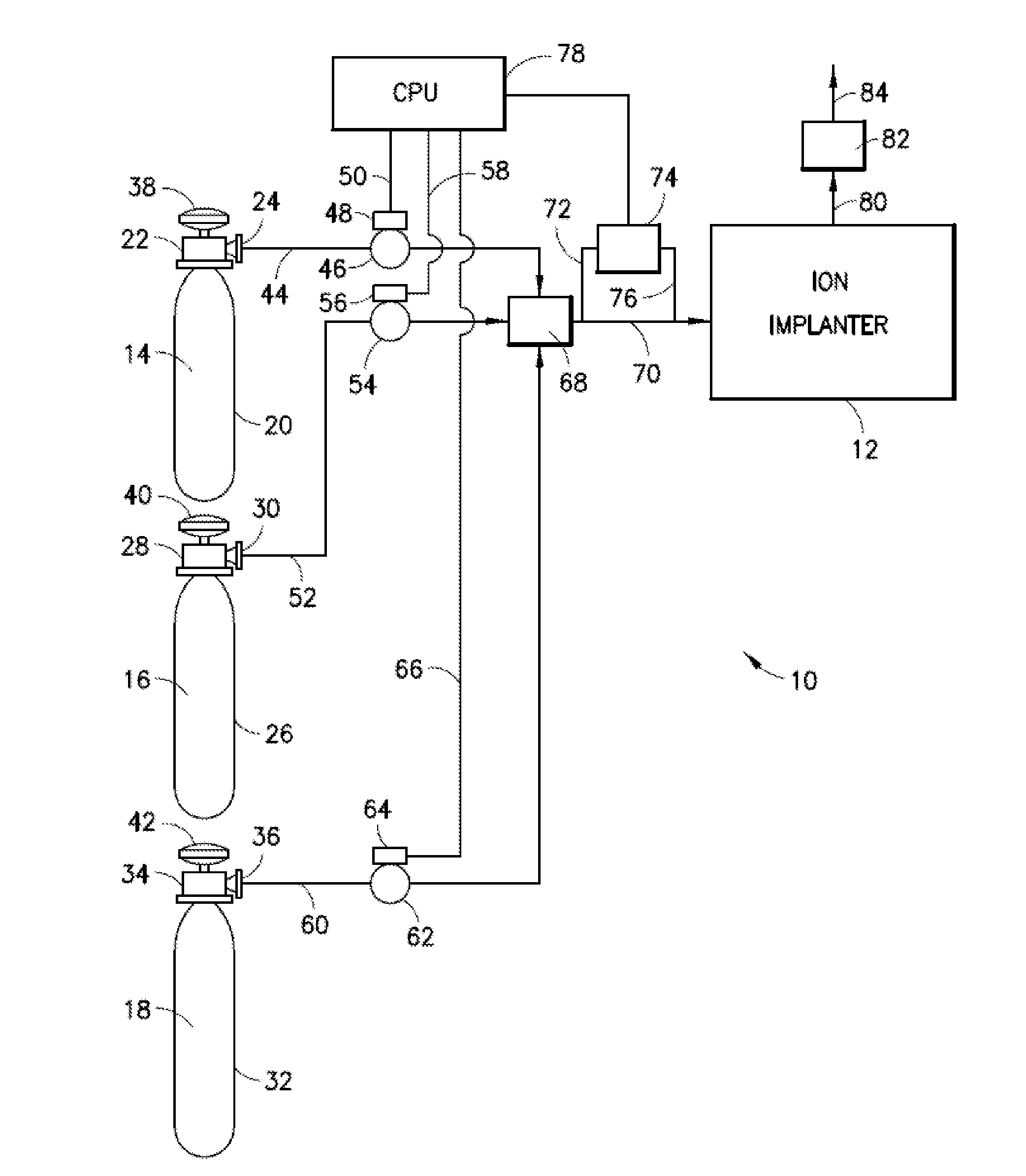

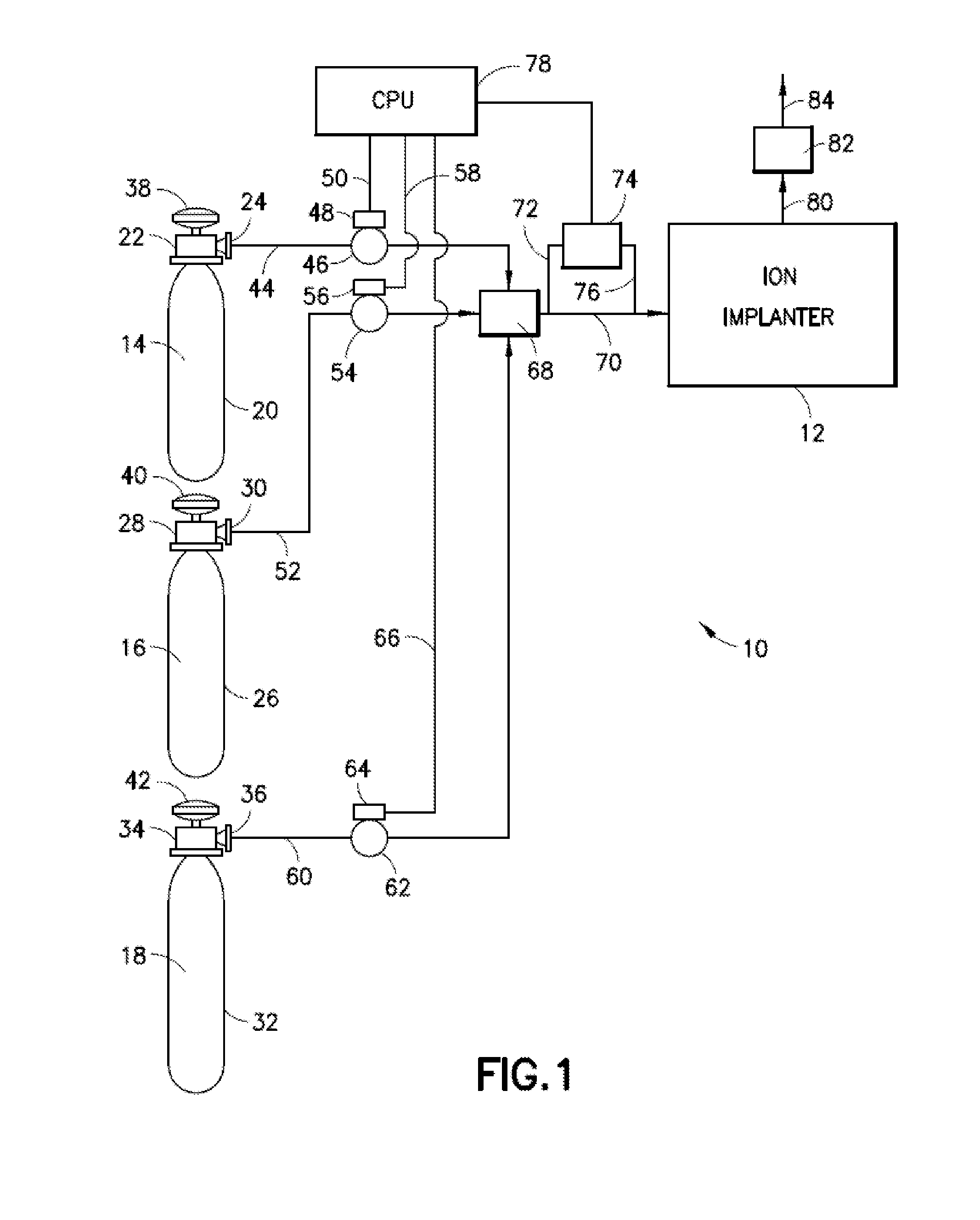

Ion implantation compositions, systems, and methods

Ion implantation compositions, systems and methods are described, for implantation of dopant species. Specific selenium dopant source compositions are described, as well as the use of co-flow gases to achieve advantages in implant system characteristics such as recipe transition, beam stability, source life, beam uniformity, beam current, and cost of ownership.

Owner:ENTEGRIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com