Low-shrinkage creep wet joint ultrahigh-strength concrete material and preparation method thereof

A technology of ultra-high-strength concrete and low shrinkage and creep, which is applied in the field of building materials, can solve the problems of wet joint concrete shrinkage and creep, and achieve low shrinkage and creep, excellent mechanical properties and durability, and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

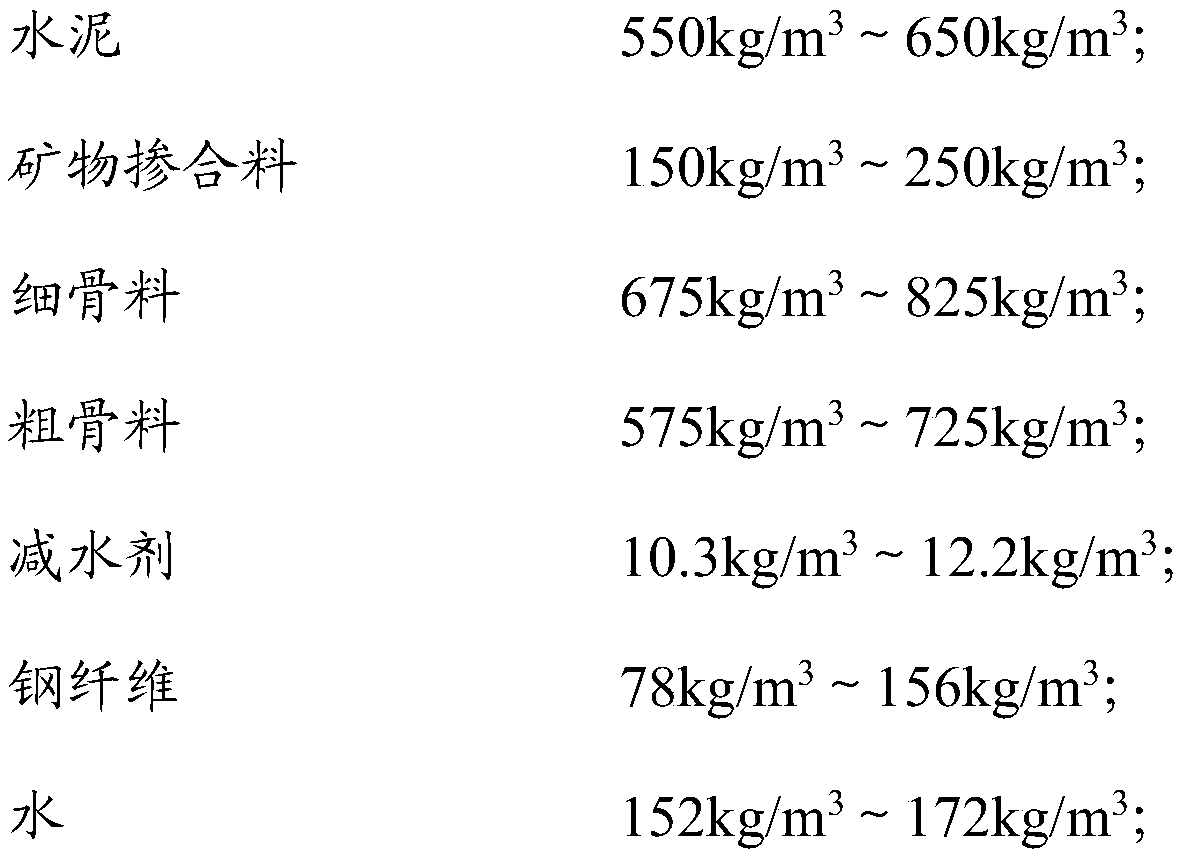

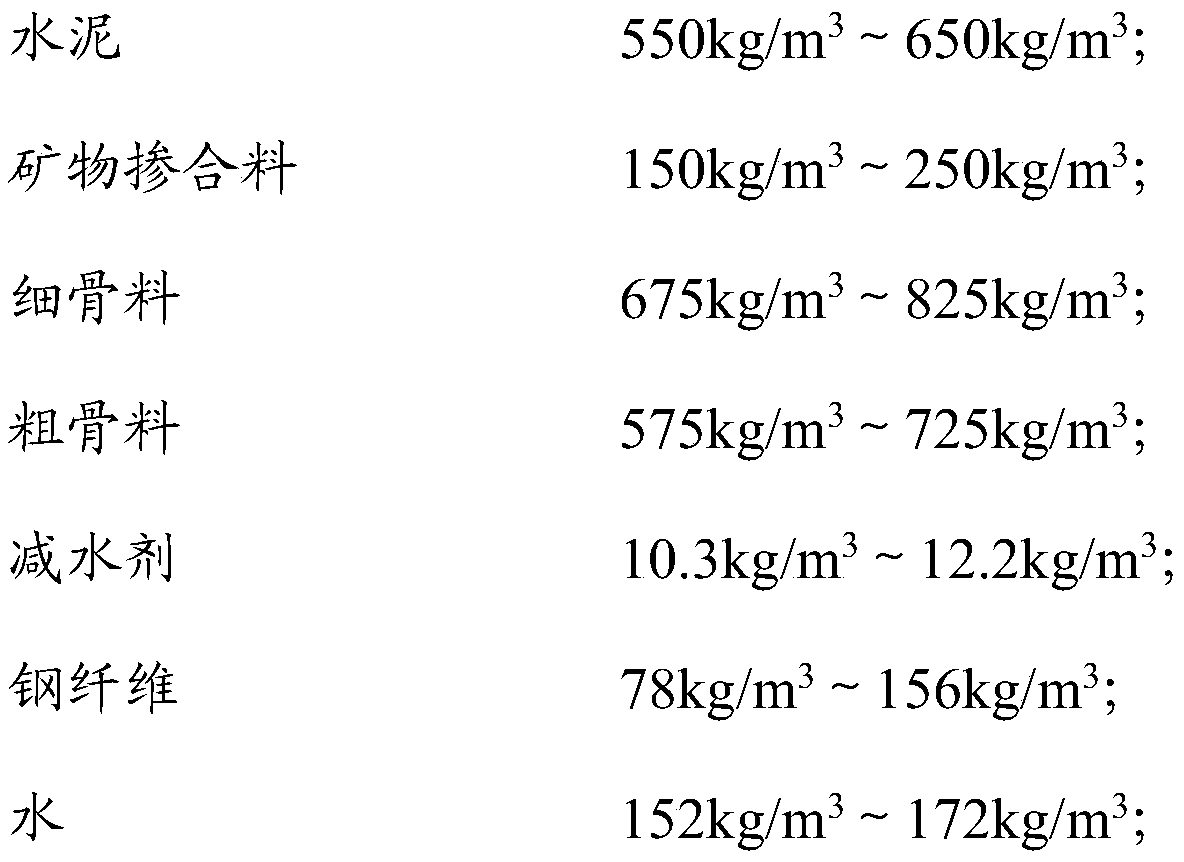

[0034] The low shrinkage and creep wet joint ultra-high strength concrete material prepared in this example has the ratio of raw materials as shown in Table 1:

[0035] Table 1 Low shrinkage creep wet joint ultra-high strength concrete material mix ratio (Kg / m 3 )

[0036] cement mineral admixture fine aggregate Coarse aggregate Superplasticizer steel fiber water 600 200 750 650 10.6 100 160

[0037] Mix 600 parts by weight of cement, 200 parts by weight of mineral admixture, 750 parts by weight of fine aggregate, 650 parts by weight of coarse aggregate, 100 parts by weight of steel fiber and 10.6 parts by weight of water reducing agent in a twin-shaft forced mixer , the stirring time is 2 minutes; 160 parts by weight of water are all added, and stirred for 4 minutes. After the concrete is fully fluidized, continue to stir for 1 minute to obtain a concrete mixture; pour the concrete mixture into a cast iron mold for molding, vibration, and t...

Embodiment 2

[0042] The low shrinkage and creep wet joint ultra-high-strength concrete material prepared in this example has a ratio of raw materials as shown in Table 2:

[0043] Table 2 Low shrinkage creep wet joint ultra-high strength concrete material mix ratio (Kg / m 3 )

[0044] cement mineral admixture fine aggregate Coarse aggregate Superplasticizer steel fiber water 550 225 825 600 12 150 155

[0045] Mix 550 parts by weight of cement, 225 parts by weight of mineral admixtures, 825 parts by weight of fine aggregate, 600 parts by weight of coarse aggregate, 150 parts by weight of steel fiber and 12 parts by weight of water reducing agent in a vertical shaft planetary forced mixer, The stirring time is 3 minutes; 155 parts by weight of water are all added, and stirred for 3 minutes. After the concrete is fully fluidized, continue stirring for 2 minutes to obtain a concrete mixture; The environment of 20±5°C and relative humidity ≥50% should be lef...

Embodiment 3

[0050] The low shrinkage and creep wet joint ultra-high strength concrete material prepared in this example has the ratio of raw materials as shown in Table 3:

[0051] Table 3 Low shrinkage and creep wet joint ultra-high strength concrete material mix ratio (Kg / m 3 )

[0052] cement mineral admixture fine aggregate Coarse aggregate Superplasticizer steel fiber water 650 175 800 550 11.4 78 178

[0053] Mix 650 parts by weight of cement, 175 parts by weight of mineral admixture, 800 parts by weight of fine aggregate, 550 parts by weight of coarse aggregate, 78 parts by weight of steel fiber and 11.4 parts by weight of water reducing agent in a twin-shaft forced mixer , the stirring time is 2min; 178 parts by weight of water are all added and stirred for 3min, after the concrete is fully fluidized, continue to stir for 2min to obtain a concrete mixture; Stand for 1 day in an environment of 20±5°C and relative humidity ≥50%, remove the formwo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com