Segmental beam with horizontally distributed reinforcing bars

A technology for distributing steel bars and segmental beams, applied in bridges, buildings, etc., can solve the problem of long construction period of segmental beams, poor bending and shear resistance at joints of segmental beams, unfavorable construction period of segmental beams on site To achieve the effect of protecting the surrounding ecological environment, reducing water and air permeability, facilitating production organization and overall construction quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

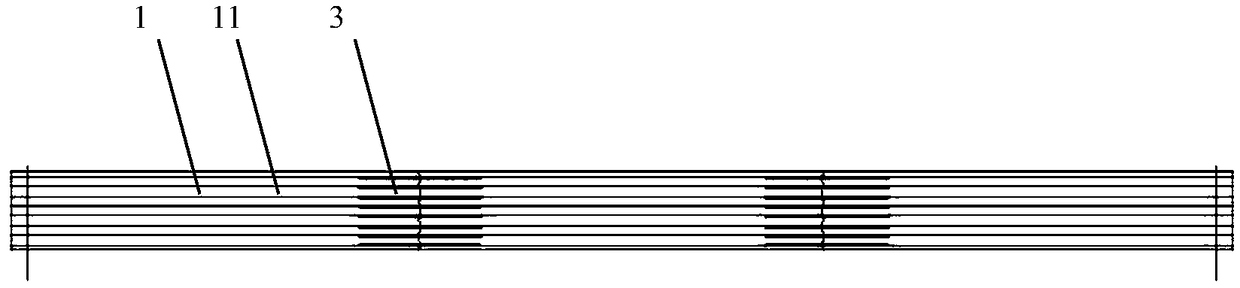

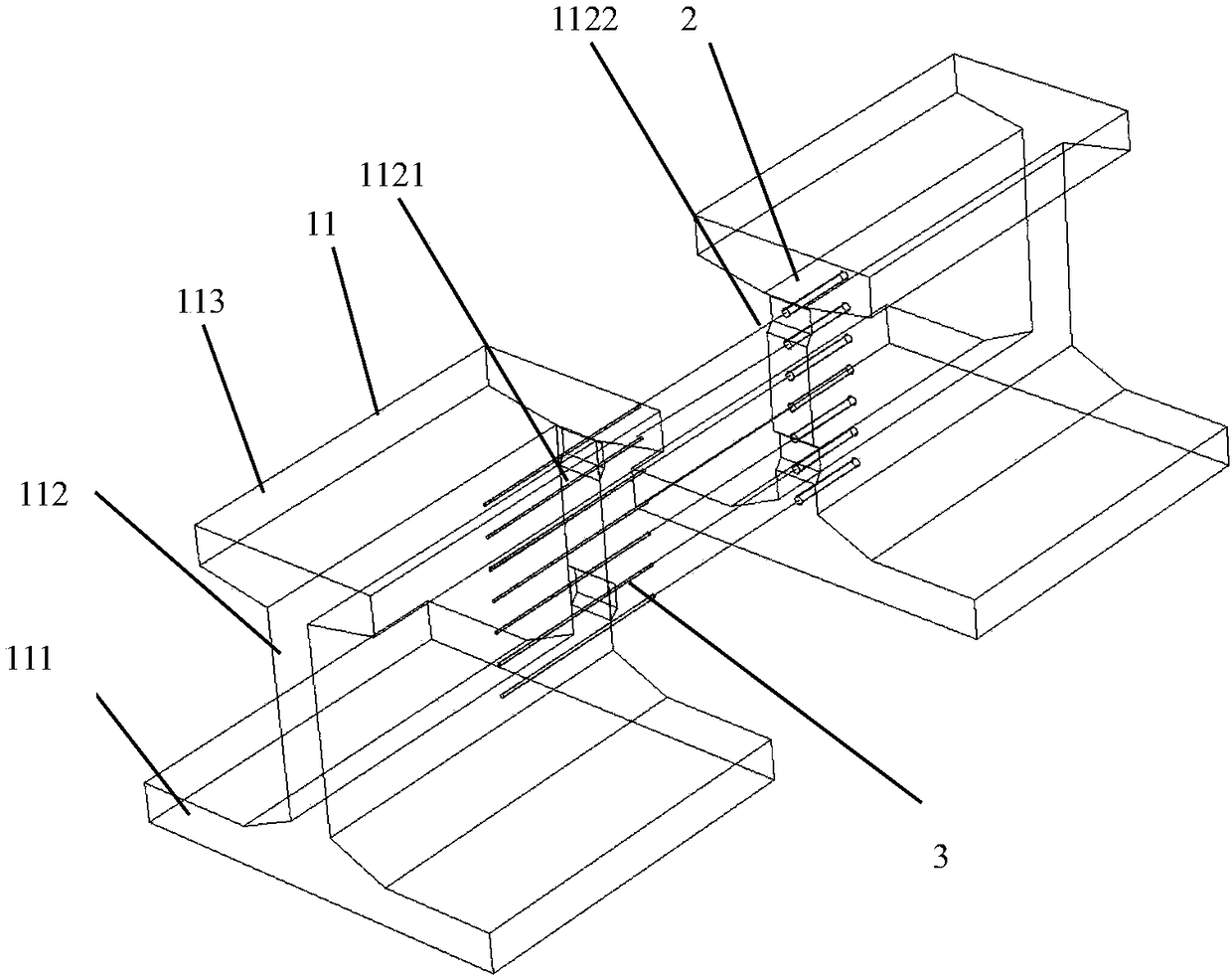

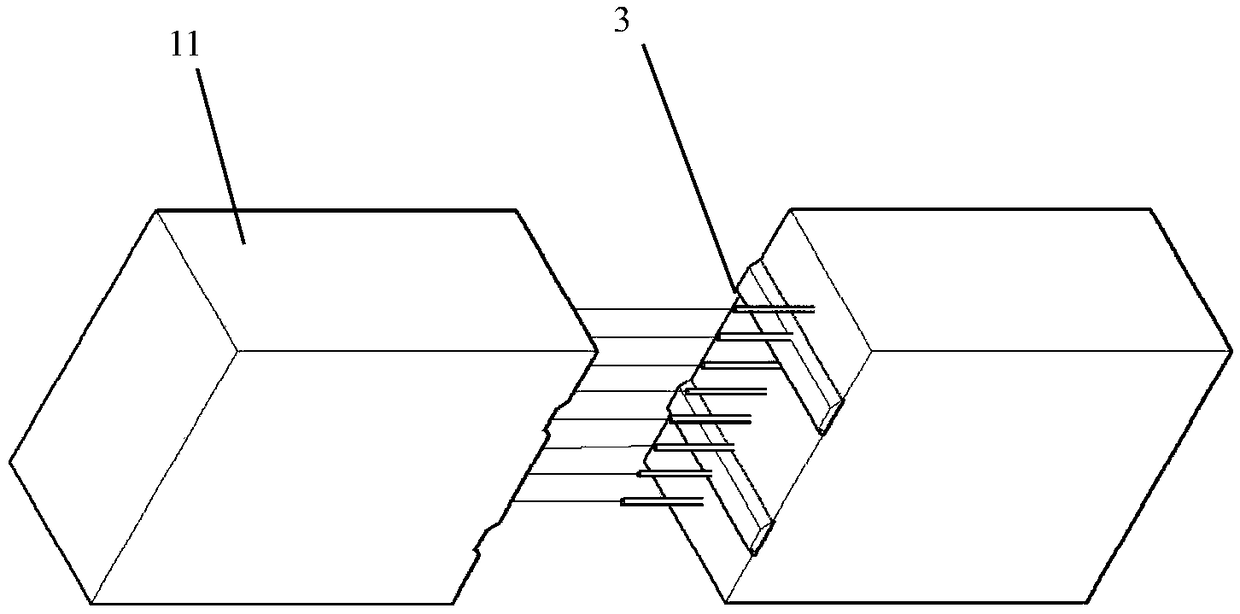

[0036] figure 1 It is a schematic diagram of a segmental beam with additional horizontally distributed steel bars of the present invention; figure 2 It is a three-dimensional view of a segmental beam with horizontally distributed steel bars added in the present invention, please refer to Figure 1 to Figure 2 As shown, it shows the segmental beam of the first preferred embodiment with the addition of horizontally distributed reinforcement, which includes: several beam segments 11, and the longitudinal end faces of several beam segments 11 are connected to each other to form an integral segmental beam 1 .

[0037] In addition, as a preferred embodiment, the segmental beam with horizontally distributed reinforcing bars also includes: several tunnels 2, and each beam segment 11 end has several tunnels 2 formed by removing preset fillers. Arranged along the axial direction of the beam segment 11, the tunnel 2 reserves sufficient anchoring length.

[0038] In addition, as a pre...

Embodiment approach

[0041] In further embodiments of the present invention, please continue to refer to figure 1 , figure 2 As shown, each beam segment 11 includes an upper flange 111 , a web 112 and a lower flange 113 ;

[0042] In a further embodiment of the present invention, the longitudinal section of each beam segment 11 is I-shaped.

[0043] In a further embodiment of the present invention, a concave portion 1121 is formed on one longitudinal end surface of the web 112 , and a convex portion 1122 is formed on the other longitudinal end surface of the web 112 , and the convex portion 1122 matches the concave portion 1121 .

[0044] In a further embodiment of the present invention, several holes 2 are opened on the web 112 .

[0045] In a further embodiment of the present invention, glue is injected between the horizontally distributed reinforcing bars 3 and the gap between the channels 2 . The horizontally distributed steel bars are fixed to the beam segment 11 by glue.

[0046] In a f...

no. 2 example

[0048] The present invention has a second preferred embodiment of a segmental beam with additional horizontally distributed reinforcement, which includes: several beam segments, the longitudinal end surfaces of which are connected to each other to form an integral segmental beam.

[0049] In addition, as a preferred embodiment, the segmental beam with horizontally distributed reinforcing bars also includes: several tunnels, one end of each beam segment has several tunnels formed by removing preset fillers, and the tunnels are all along the The axial direction of the beam segment is set, and the hole is reserved for sufficient anchorage length.

[0050] In addition, as a preferred embodiment, the segmental beam with horizontally distributed reinforcing bars also includes: several horizontally distributed reinforcing bars, and several horizontally distributed reinforcing bars are pre-embedded at the other end of each beam segment, and the horizontally distributed reinforcing bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com