A kind of wood-uhpc composite box girder and preparation method thereof

A combination box and beam technology, applied in bridges, manufacturing tools, bridge parts, etc., can solve the problems that limit the application and development of wood-concrete composite beam bridges, and achieve shrinkage and creep reduction, light weight, and high overall rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

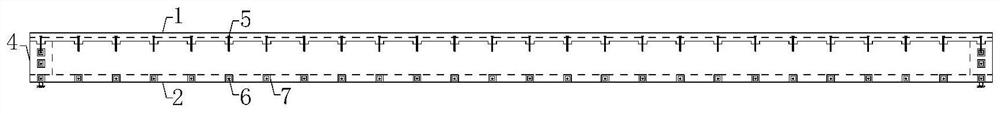

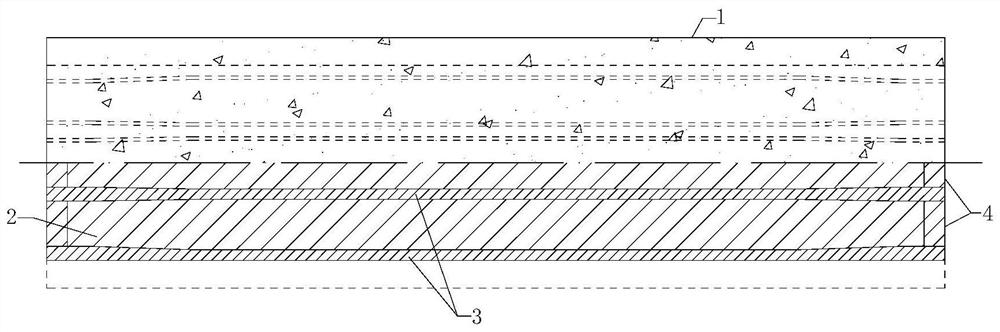

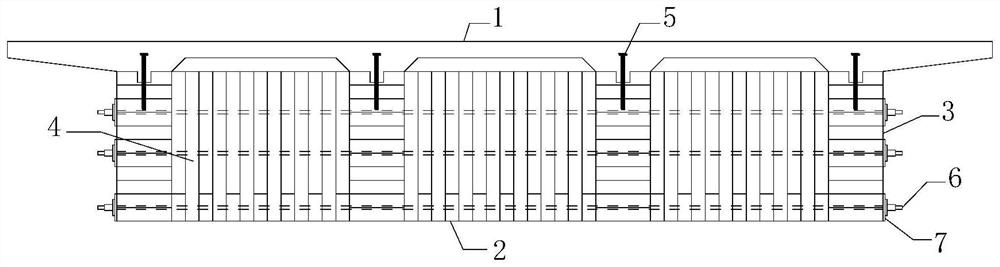

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] see Figure 1-5 , wood-UHPC composite box girder bridge structure, which is a single-box three-chamber box girder, including a UHPC top plate 1, four glulam webs 3, three glulam bottom plates 2, and glulam beams set at the fulcrums at both ends of the beam body 4. The glulam web 3 , the glulam beam 4 and the glulam bottom plate 2 all include a number of wood boards superimposed on each other.

[0032] The upper surface of the glued wood web 3 is connected to the lower surface of the UHPC top plate 1, and the glued wood bottom plate 2 is arranged between the lower ends of two adjacent glued wood webs 3; the UHPC top plate 1 is parallel to the glued wood bottom plate 2.

[0033]The glulam beam 4 is located at the fulcrum of the wood-UHPC composite box girder, and the glulam beam 4 is filled between two adjacent glulam webs 3 .

[0034] The glulam botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com