Steel platform tower crane foundation and construction method thereof

A technology of tower crane foundation and construction method, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of laborious foundation removal, non-reusable, and high requirements for bolt pre-embedding accuracy, so as to save maintenance time, save construction cost, and demolition handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

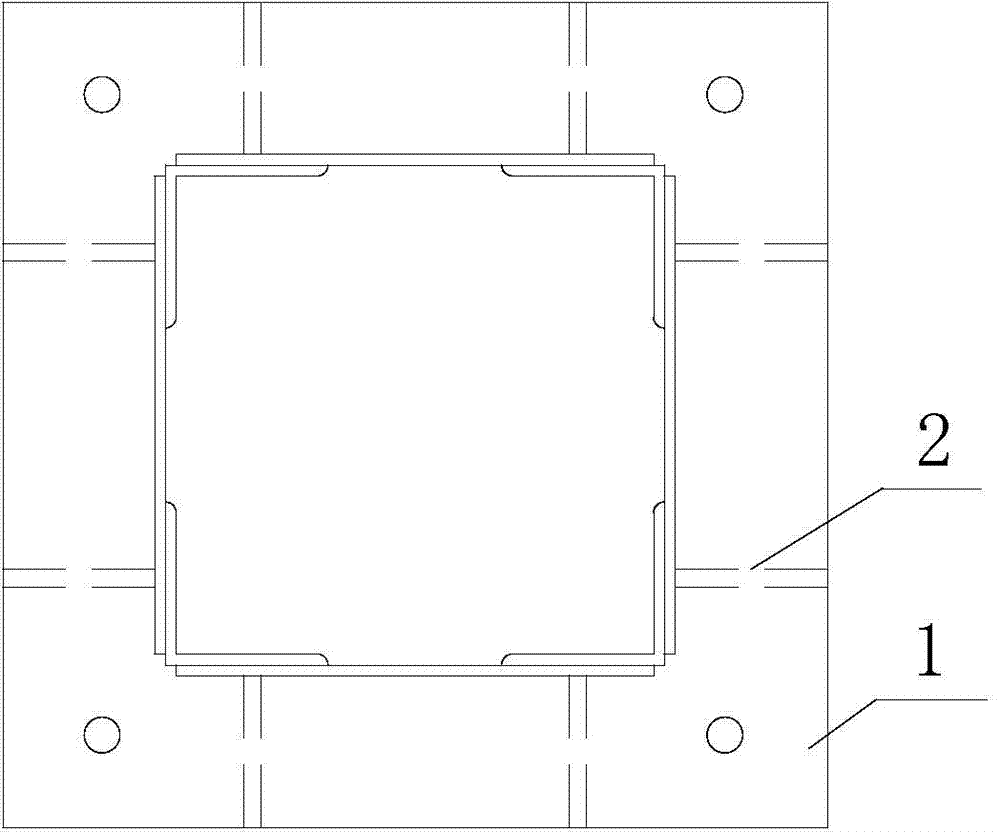

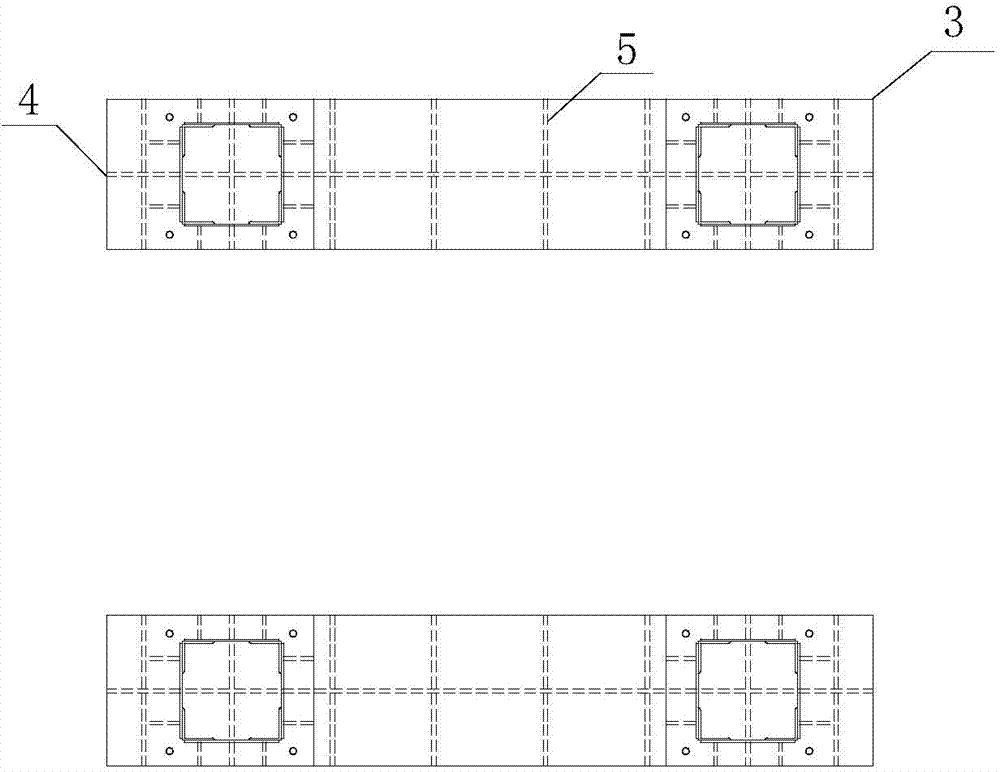

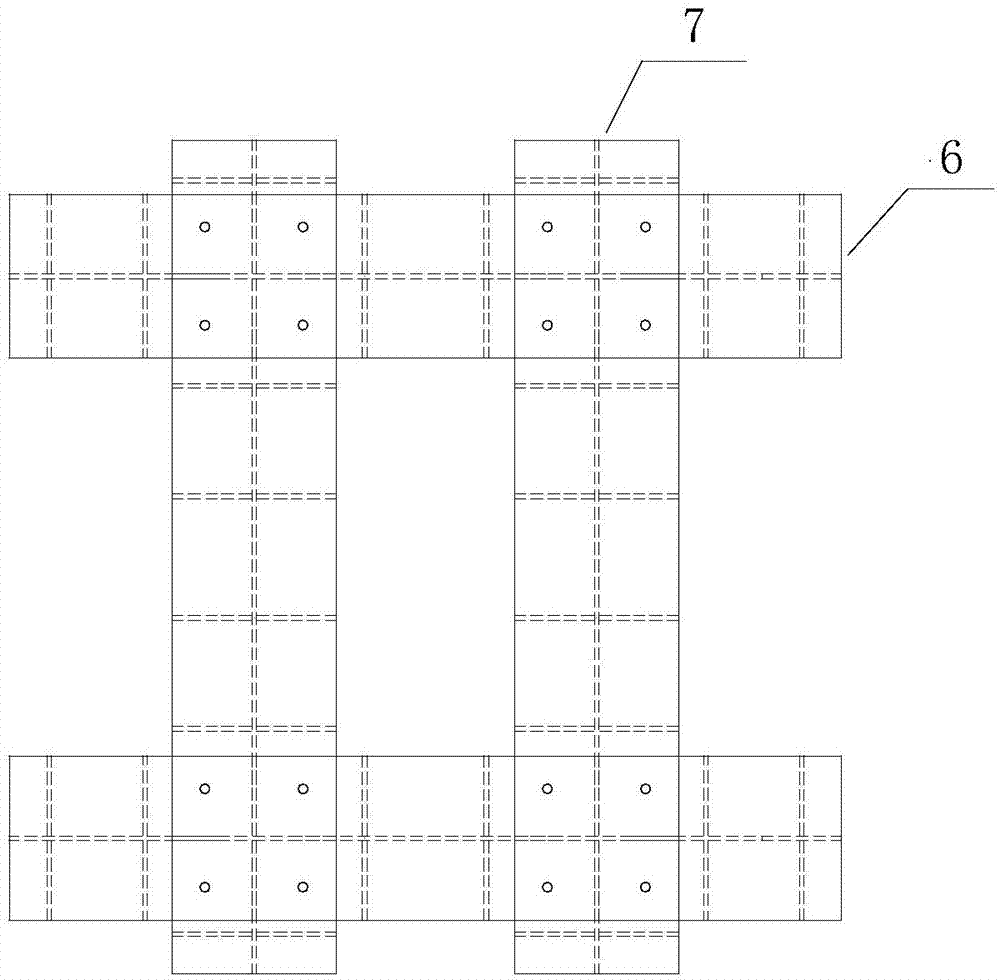

[0029] Example 1: Such as Figures 1 to 4 As shown, a steel platform tower crane foundation includes bored piles, steel lattice columns and steel caps;

[0030] The number of the bored cast-in-situ piles is four, and the connecting line of the pile positions is square, the pile diameter is 0.8m, the distance between adjacent piles is 2.4m, and the effective pile length is 26m.

[0031] The steel lattice columns are welded by four L140×140×14mm angle steels and 440×200×12mm slabs. The cross section is 480mm×480mm square, 11.9m long, and the center distance of slabs is 500mm.

[0032] The top of the steel lattice column is fixed with a steel backing plate, the steel backing plate is Q235 grade steel, the specific size is 760mm×760mm×20mm, the axis of the steel backing plate overlaps with the axis of the steel lattice column, and its The parts protruding from the steel lattice columns around are provided with screw holes for connecting with the lower steel beams; the top four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com