Corrugated spiral plate heat exchanger

A spiral plate and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency and small heat transfer area, and achieve good heat exchange effect, The heat transfer area is improved to ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

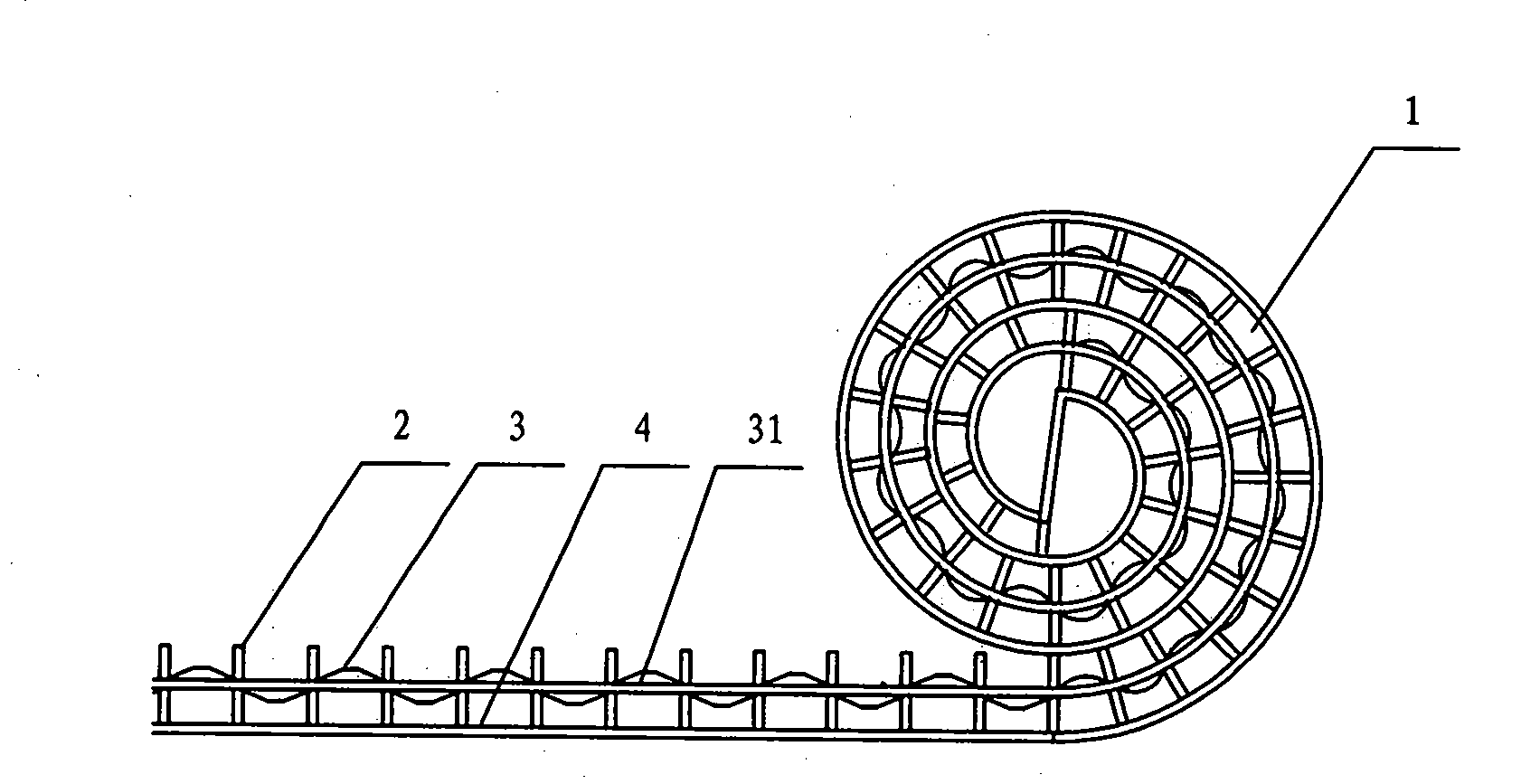

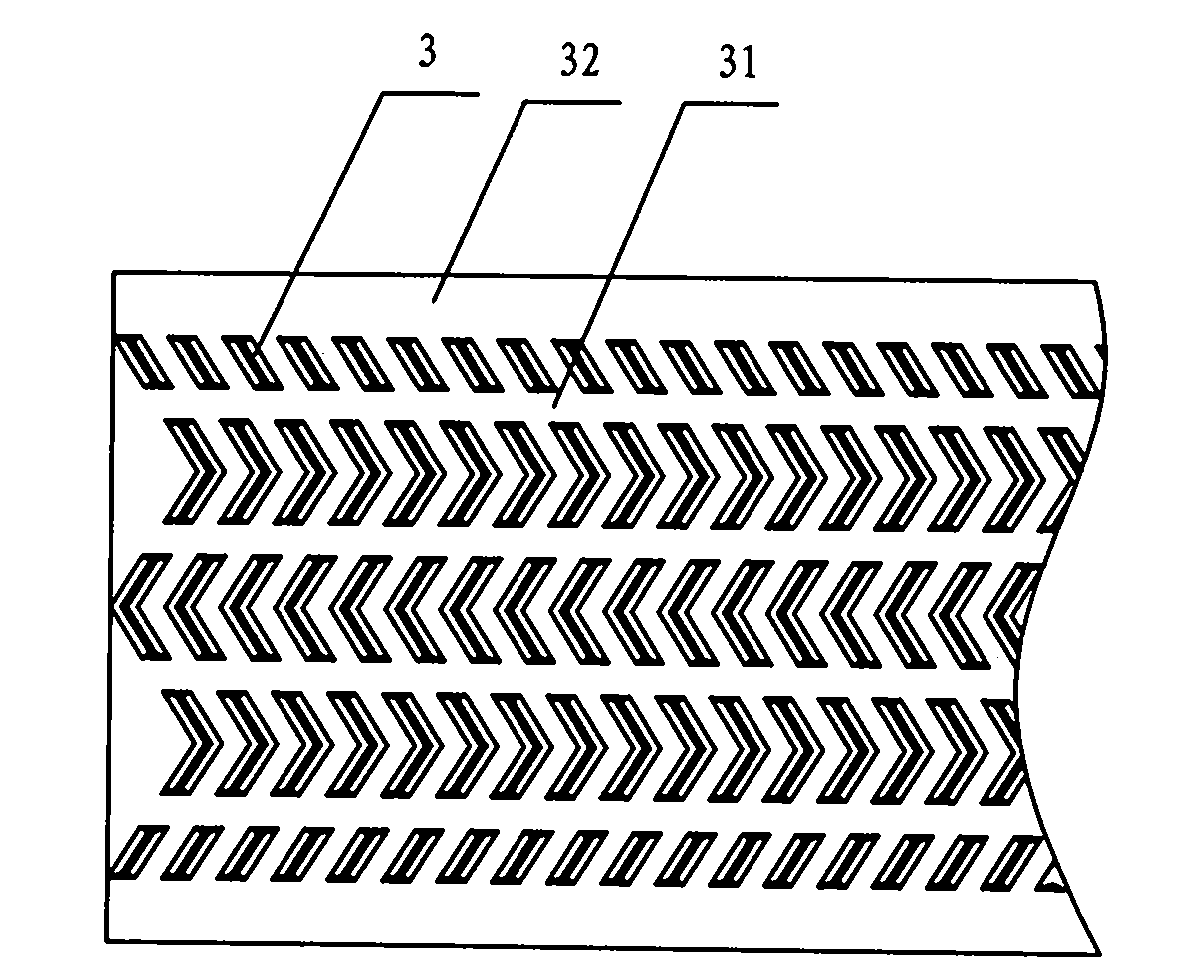

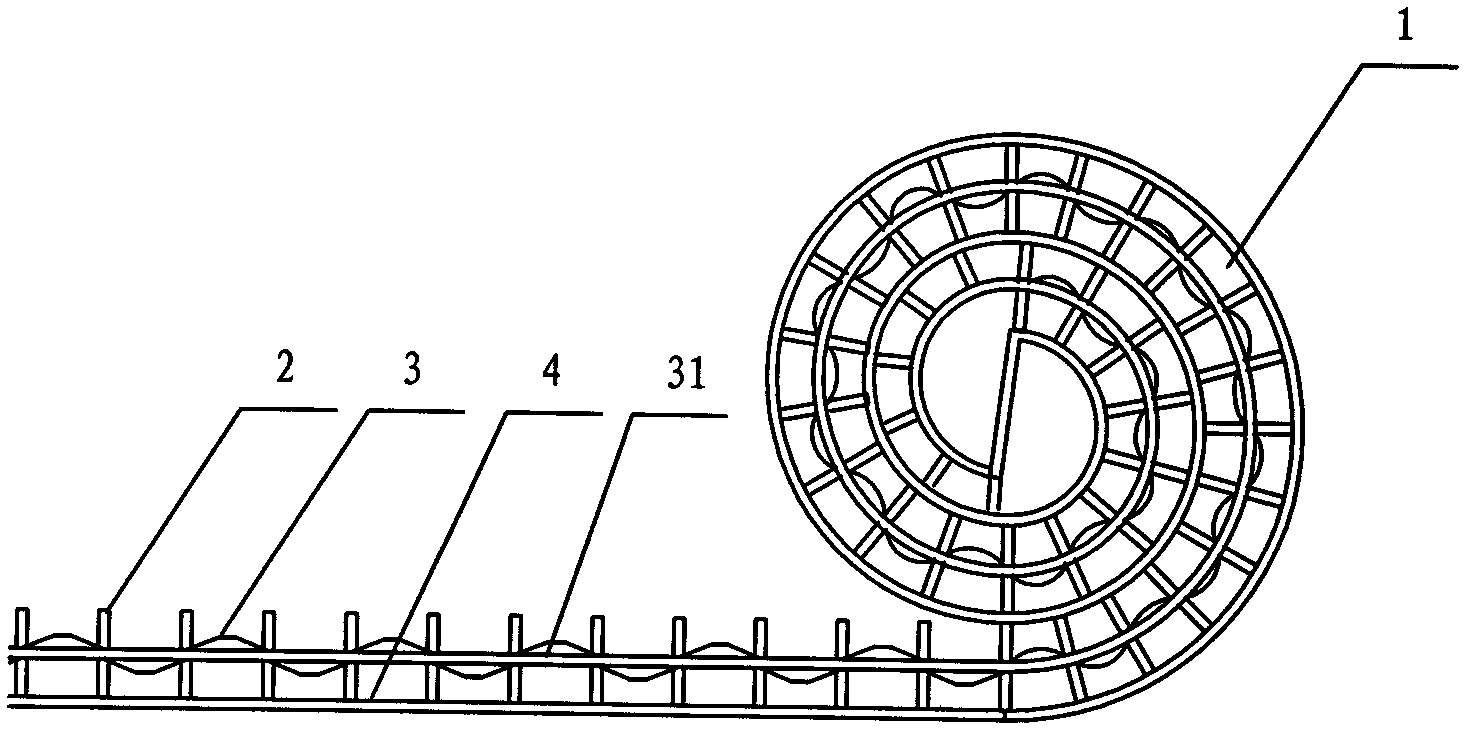

[0012] Such as figure 1 As shown, a corrugated spiral plate heat exchanger includes a double spiral heat exchange plate 1 in a shell. The double spiral heat exchange plate is rolled by a flat steel plate 4 and a corrugated steel plate 3. There are fixed distance posts 2 welded on both sides. Such as figure 2 As shown, the corrugated steel plate is provided with a non-corrugated fixed-distance column welding area, and the fixed-distance column welding area is welded on both sides of the fixed-distance column welding area. The fixed distance column welding area is a non-corrugated strip along the length of the corrugated steel plate. 31. In order to make the plate spacing of the double helix heat exchange plate uniform after rolling, a plurality of non-corrugated belts are arranged on the corrugated steel plate, and each non-corrugated belt is arranged in parallel and equidistant; in order to facilitate the sealing of the ends of the double helix heat exchange plate, There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com