Manufacturing method of copper-copper bonding salient points

A technology of copper-copper bonding and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. Surface flatness requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A method for manufacturing a copper-copper bonding bump, comprising the following steps:

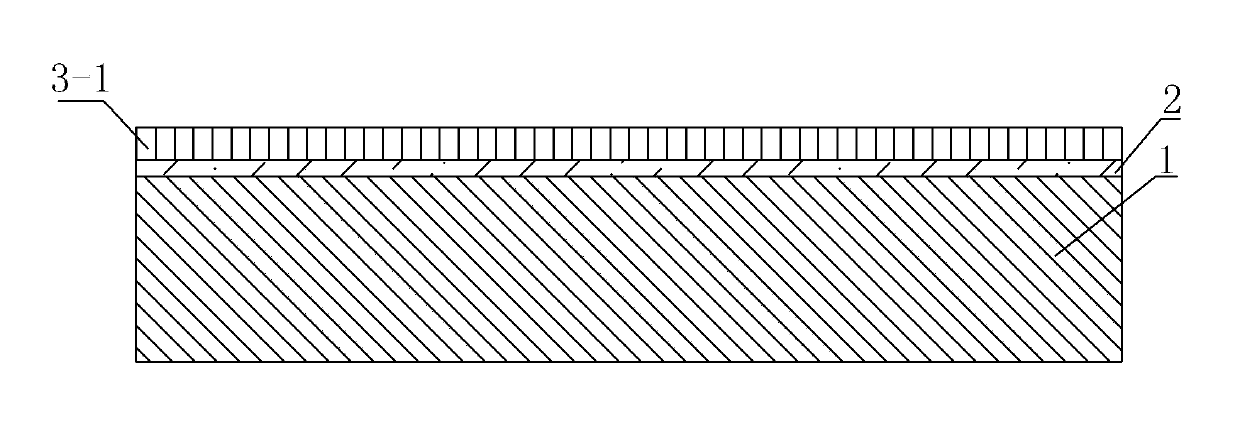

[0032] See figure 1 , (1) Make an adhesion layer 2 and a seed layer 3-1 on the surface of the wafer 1. The material of the adhesion layer can be one or more materials such as titanium, titanium nitride, tantalum, and tantalum nitride. The seed layer The material is copper;

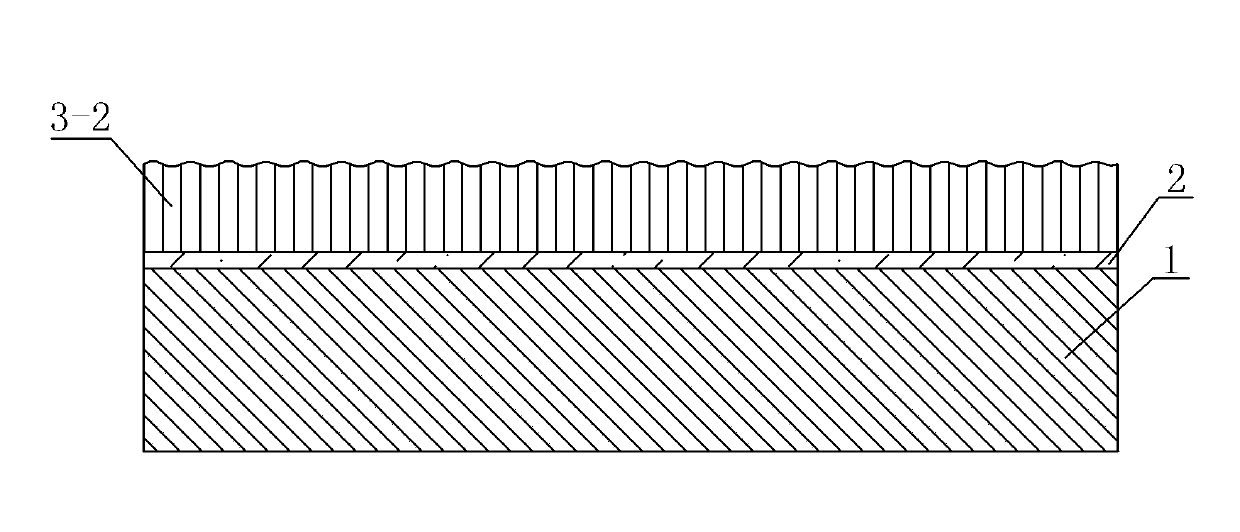

[0033] See figure 2 , (2) Deposit a copper layer 3-2 on the surface of the wafer by electroplating process, the thickness of the copper layer is 1-15 μm. Limited by the capability of the electroplating process itself, the roughness and flatness of the copper layer surface after electroplating are relatively poor;

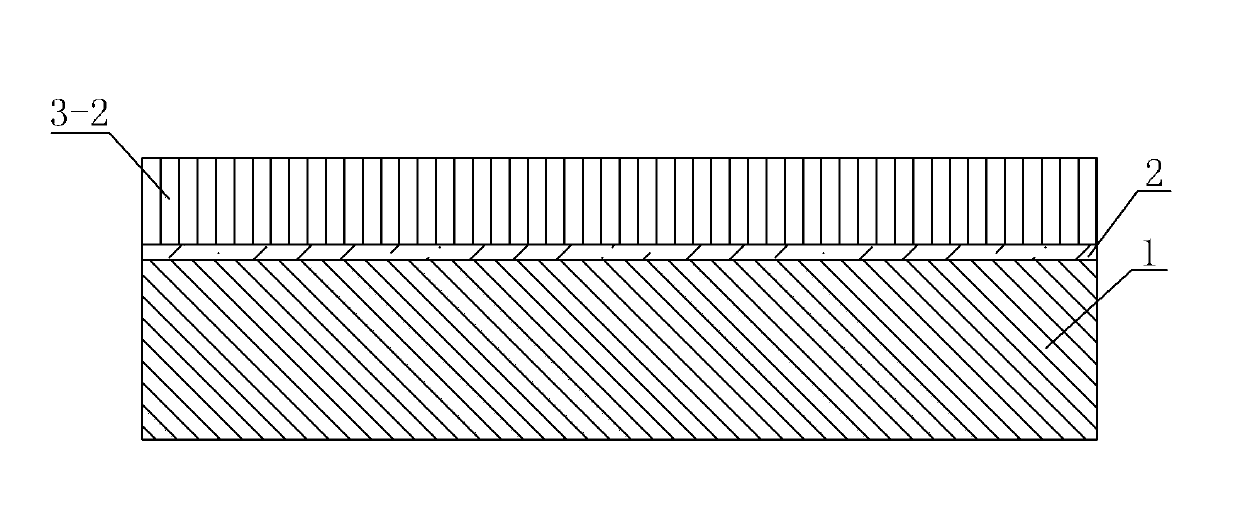

[0034] See image 3 , (3) Use chemical mechanical polishing technology to process the copper layer 3-2 on the wafer surface to improve the roughness and flatness of the copper surface, making it suitable for copper-copper bonding process;

[0035] See Figure 4 , (4) Patterning the copper lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com