Low-floor-surface straddle type two-shaft one-rail bogie

A straddle-type bogie technology, which is applied to bogies, railway car body parts, locomotives, etc., can solve the unfavorable problems of simple and streamlined vehicle shape, unfavorable vehicle stability, and low carrying capacity, and achieve considerable application The effect of foreground, improving ornamental value, and strong climbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] bogie embodiment

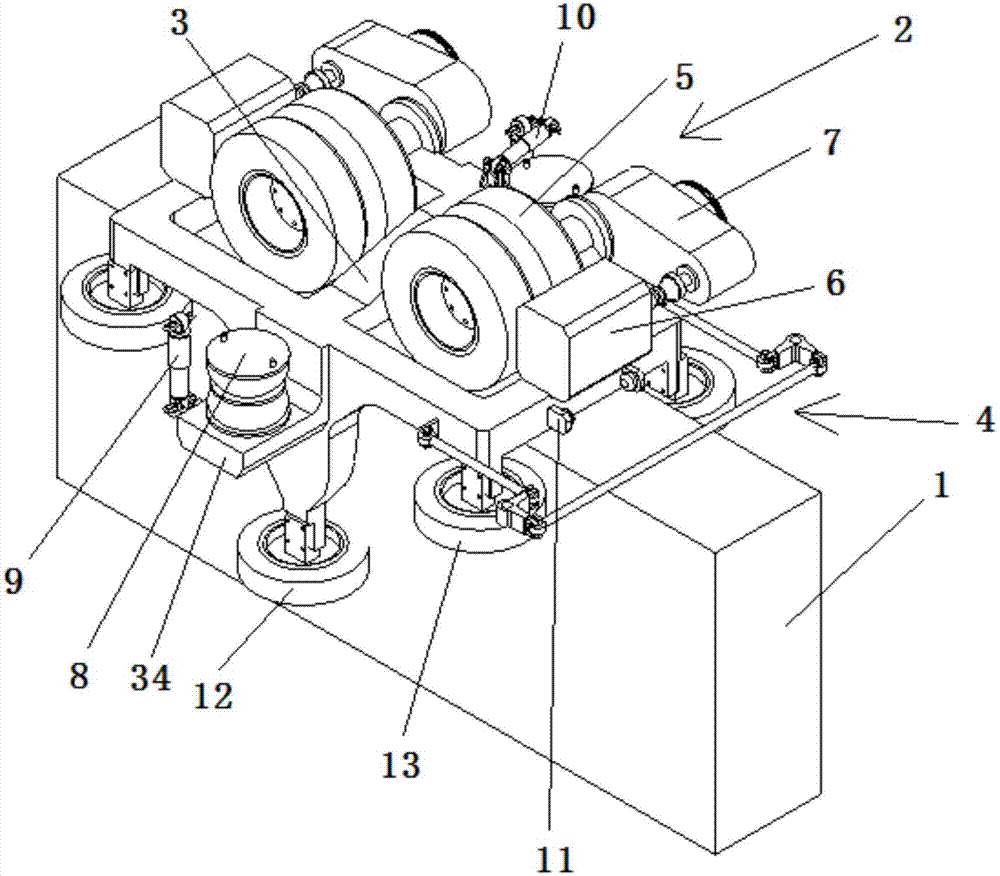

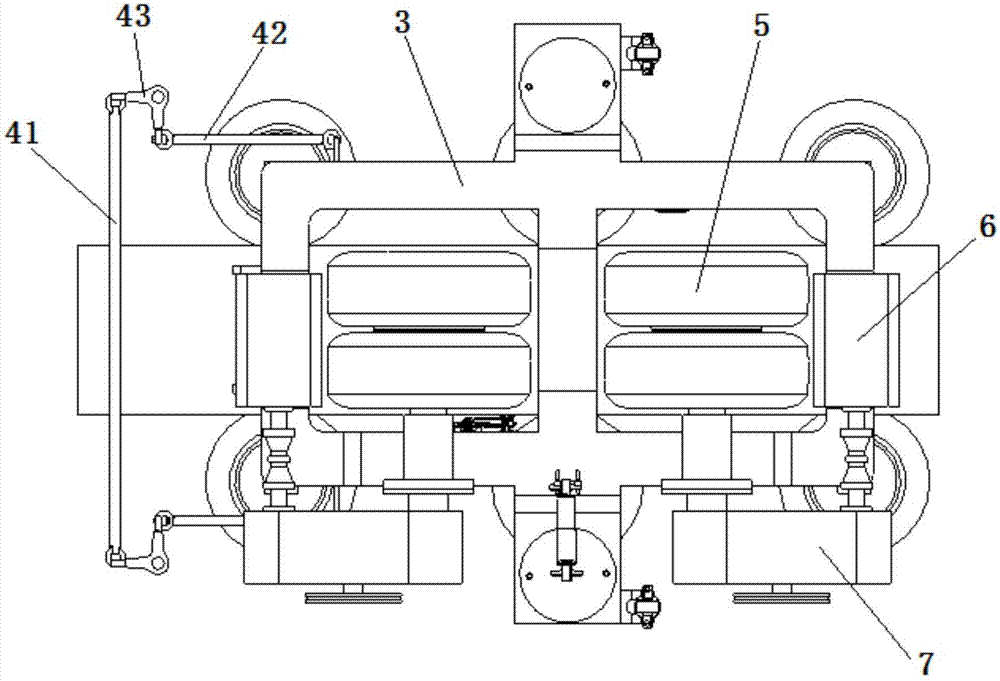

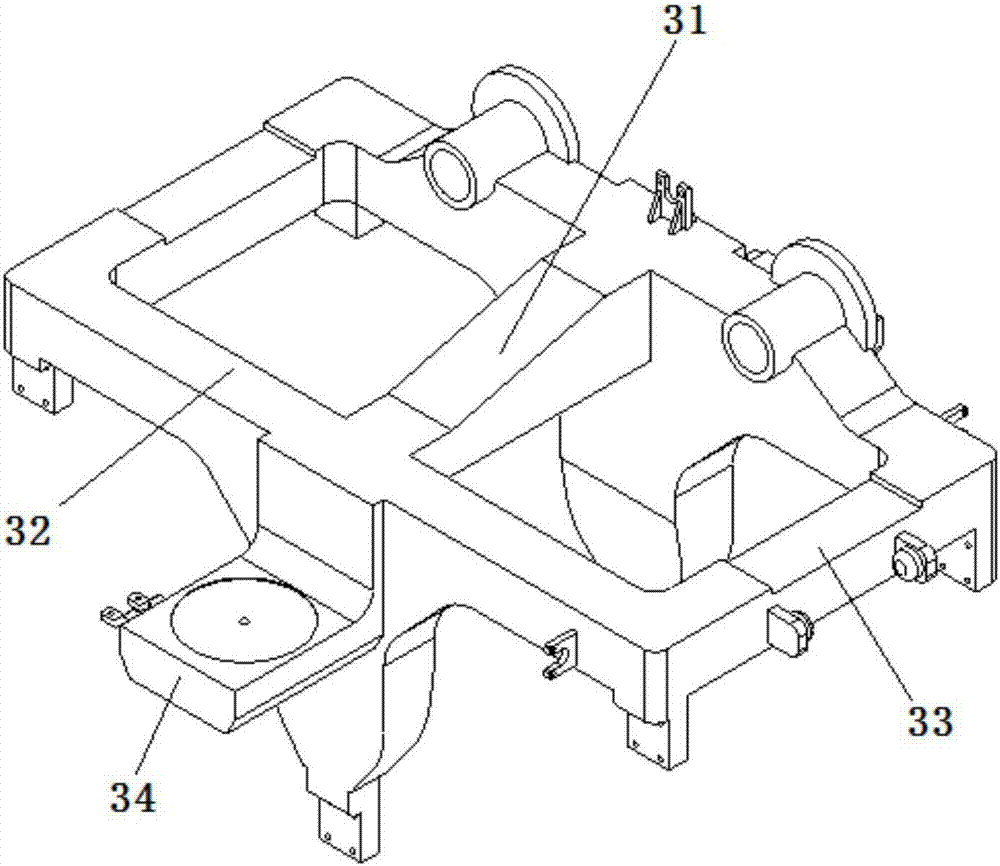

[0030] Such as figure 1 , figure 2 , image 3 As shown, the low-floor straddle-type two-axis monorail bogie 2 of this embodiment includes a frame 3, two traction motors 6 and two sets of road wheels 5, and the frame 3 has a middle beam 31, two side beams 32 and The end beams 33 located at both ends, viewed from the running direction of the vehicle, the frame 3 straddles the track beam 1 in an inverted U shape, and the two sides of the middle part of the frame 3 have L-shaped cantilever 34 extending downward, and the cantilever 34 is installed with a secondary shock absorber Spring 8, two traction motors 6 are respectively arranged on the two end beams 33 of the frame 3, two sets of road wheels 5 are respectively arranged on the front and rear sides of the beam 31 in the middle of the frame, the output shaft of the traction motor 6 is suspended on the steering wheel through the coupling The gear box on one side of the frame is connected, and the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com