Design method for glass Fresnel lens mould

A technology of Fresnel lens and design method, which is applied in the field of manufacturing, and can solve the problems of affecting the rolling effect and different temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

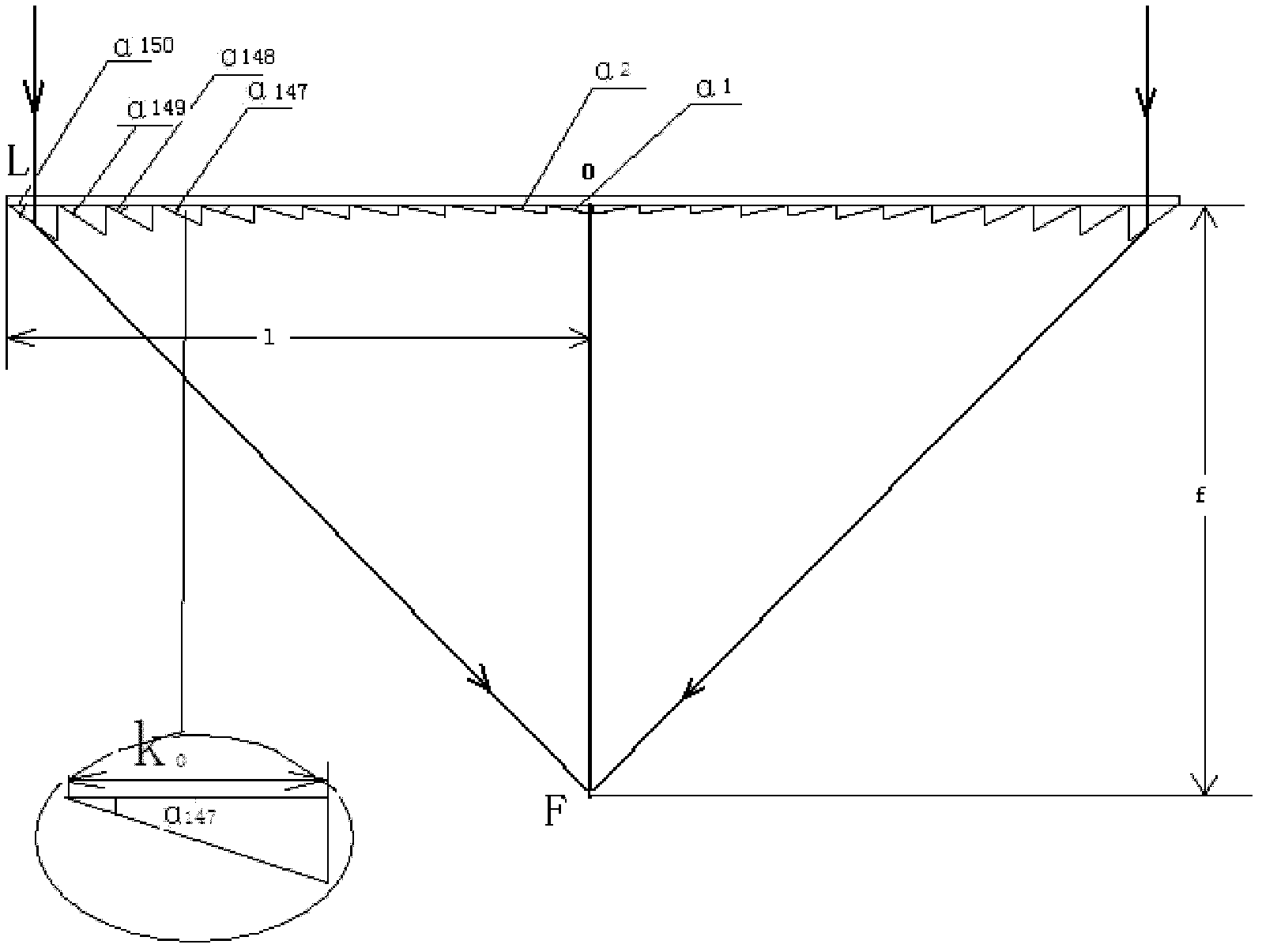

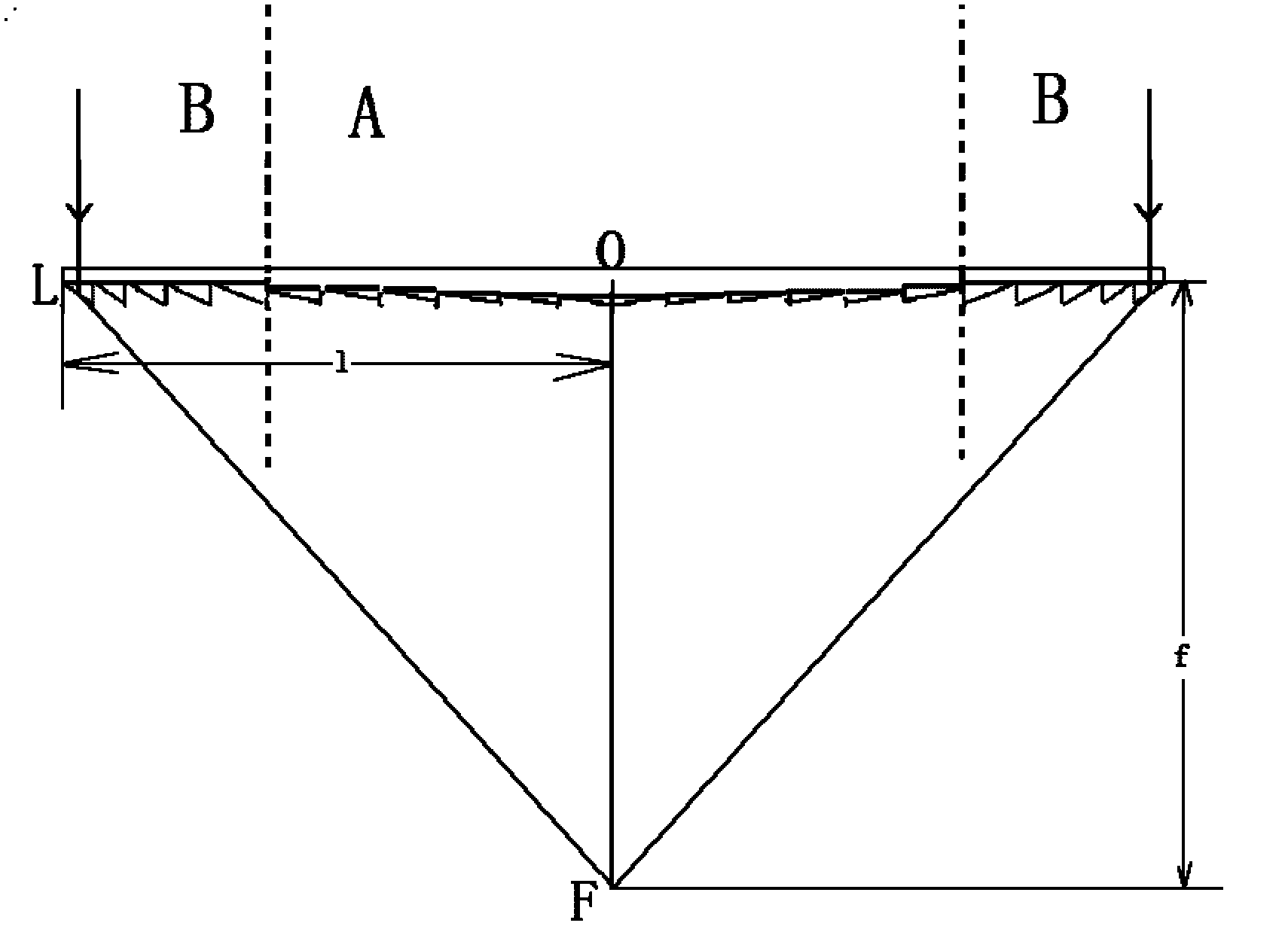

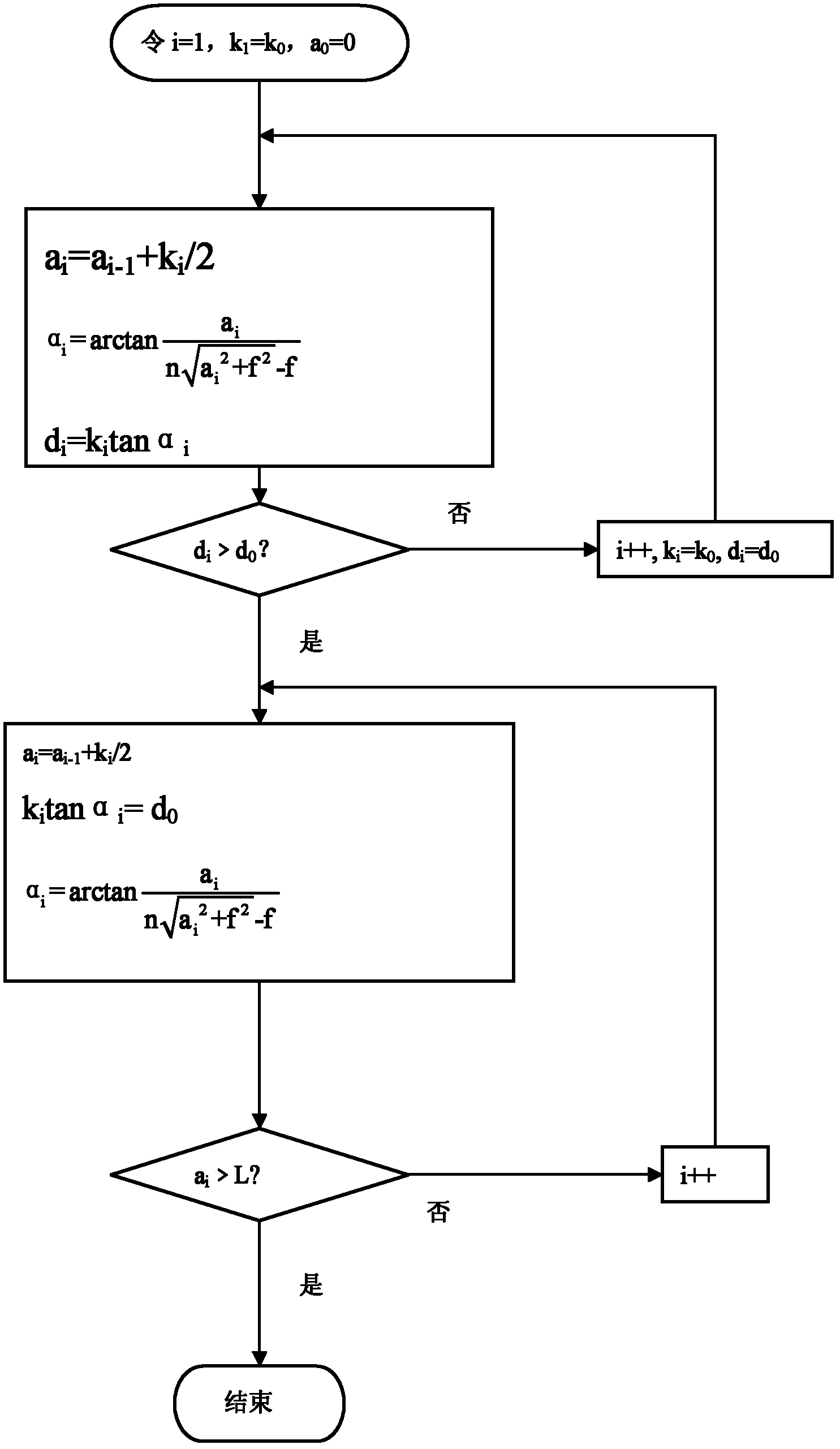

[0041] see figure 2 , the present invention divides the Fresnel lens mold into two parts A and B according to the distance from the optical axis, wherein the A part is the part close to the center of the Fresnel lens mold, the B part is the edge part of the Fresnel lens mold, and the A part On the basis of adopting the ordinary Fresnel lens mold design method, the tooth width and tooth angle are kept constant, and the height of the tooth is raised in turn to make the height of the tooth consistent, so that the thickness of the tooth profile is uniform, The rib teeth of part B adopt the design method of equal tooth height, that is, the height of the rib teeth is constant, and the width of the rib teeth is different; the specific design process is as follows (see image 3 ):

[0042] Suppose the width of the Fresnel lens mold is 2l, the focal length is f, and the spot width of the spotlight is k0 , the expected height allowed by the tooth is d 0 , starting from the main optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com