PCB plate mount-connect positioning device and method

A PCB board and bottom board technology, which is applied in the field of PCB board assembly and positioning devices, can solve the problems that fixture resources cannot be shared, resource sharing cannot be realized, and the production cycle of fixtures is long, etc., so as to achieve convenient and flexible positioning, assembly and connection, and effective and flexible positioning welding , The effect of meeting the requirements of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

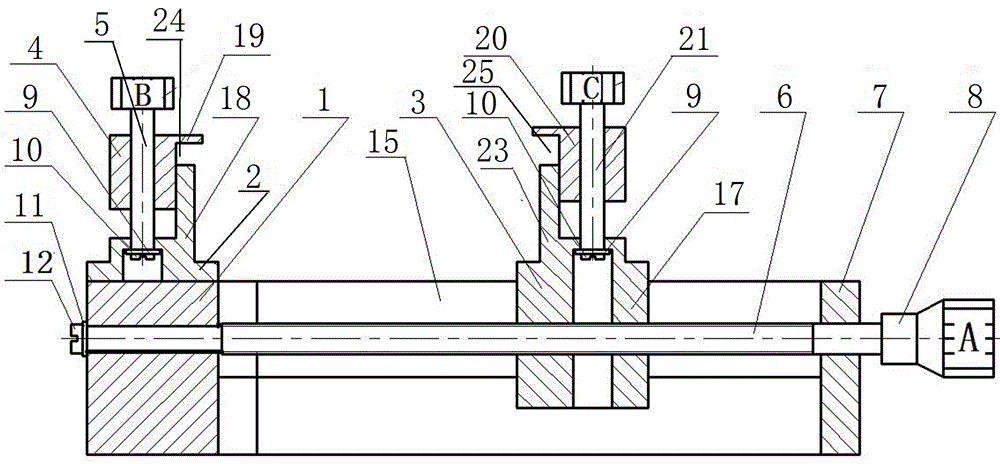

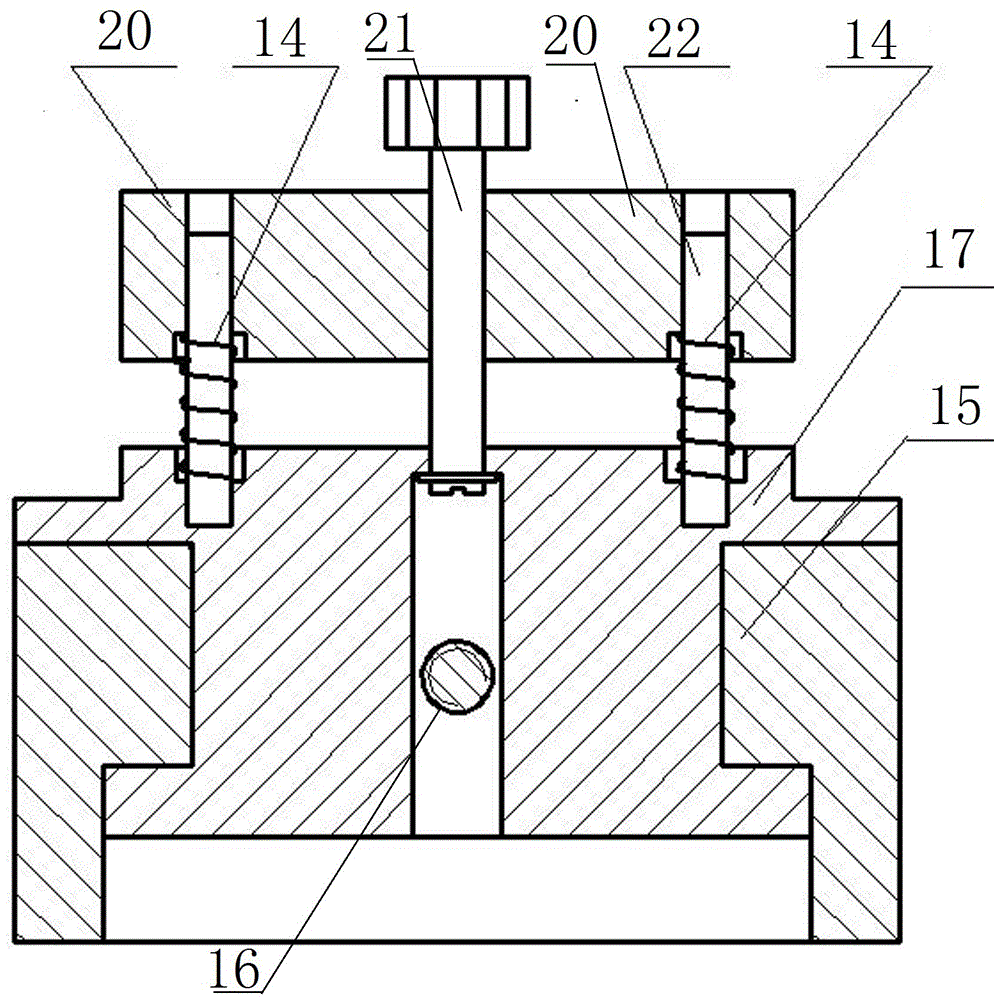

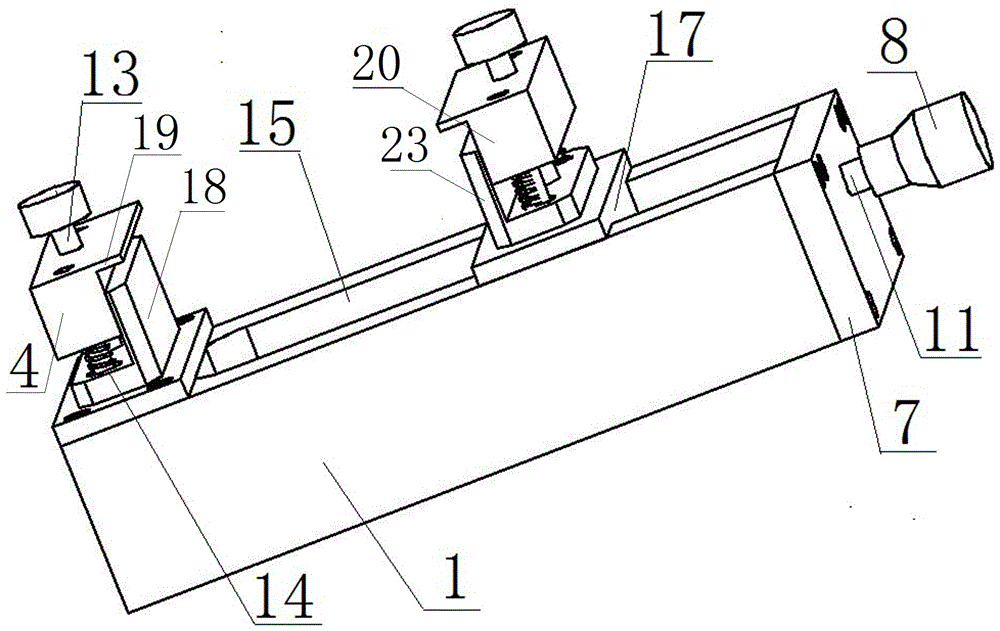

[0035] Such as Figure 4 As shown, a method of positioning using the above-mentioned device, when the upper and lower boards are connected, rotate the horizontal screw shaft 6 through the rotating handle A to move the right bracket horizontally to the left, when the distance between the two clamping blocks is slightly smaller than the width of the lower board of the module At the same time, the two ends of the lower plate of the module should be horizontally placed on the top surfaces of the first pillar and the second pillar, and the upper plate of the module to be fixed should be raised and placed flat on the extension platform of the two clamping blocks. The lower plate of the module is fixed, and the horizontal screw shaft 6 is turned by the handle A to move the right bracket horizontally to the left, and the PCB board product is clamped horizontally; The block lowers with the upper board of the module. Refer to the scales on the scales of the two clamping blocks. After fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com