Clamping and turning device

A flipping device and clamping technology, which is applied to the lifting device, transmission device, hoisting device, etc., can solve the problems of unsynchronized displacement, inconvenience of clamping and flipping unit 10, etc., and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

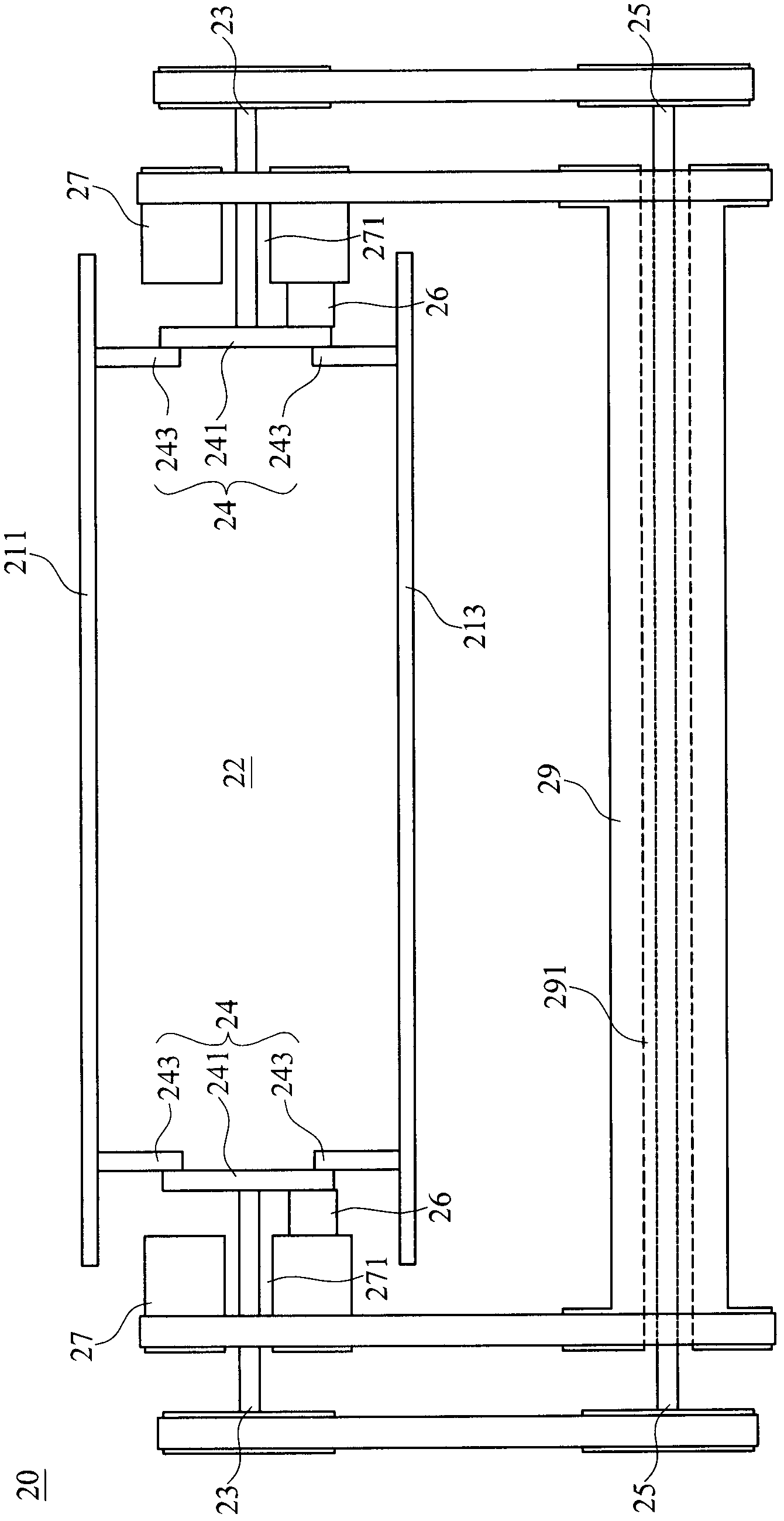

[0042] see figure 2 , is a schematic structural view of an embodiment of the clamping and turning device of the present invention. As shown in the figure, the clamping and turning device 20 includes a first plate body 211, a second plate body 213, two first rod bodies 23, two linkage units 24, two second rod bodies 27, and a third rod body 25 and a fourth rod body 29. The first plate body 211 is disposed opposite to the second plate body 213 , and there is a clamping space 22 between them. When in use, the clamped object (such as stacked fiber products) can be placed in the clamping space 22 , and the clamped object can be clamped and turned over by the first plate body 211 and the second plate body 213 .

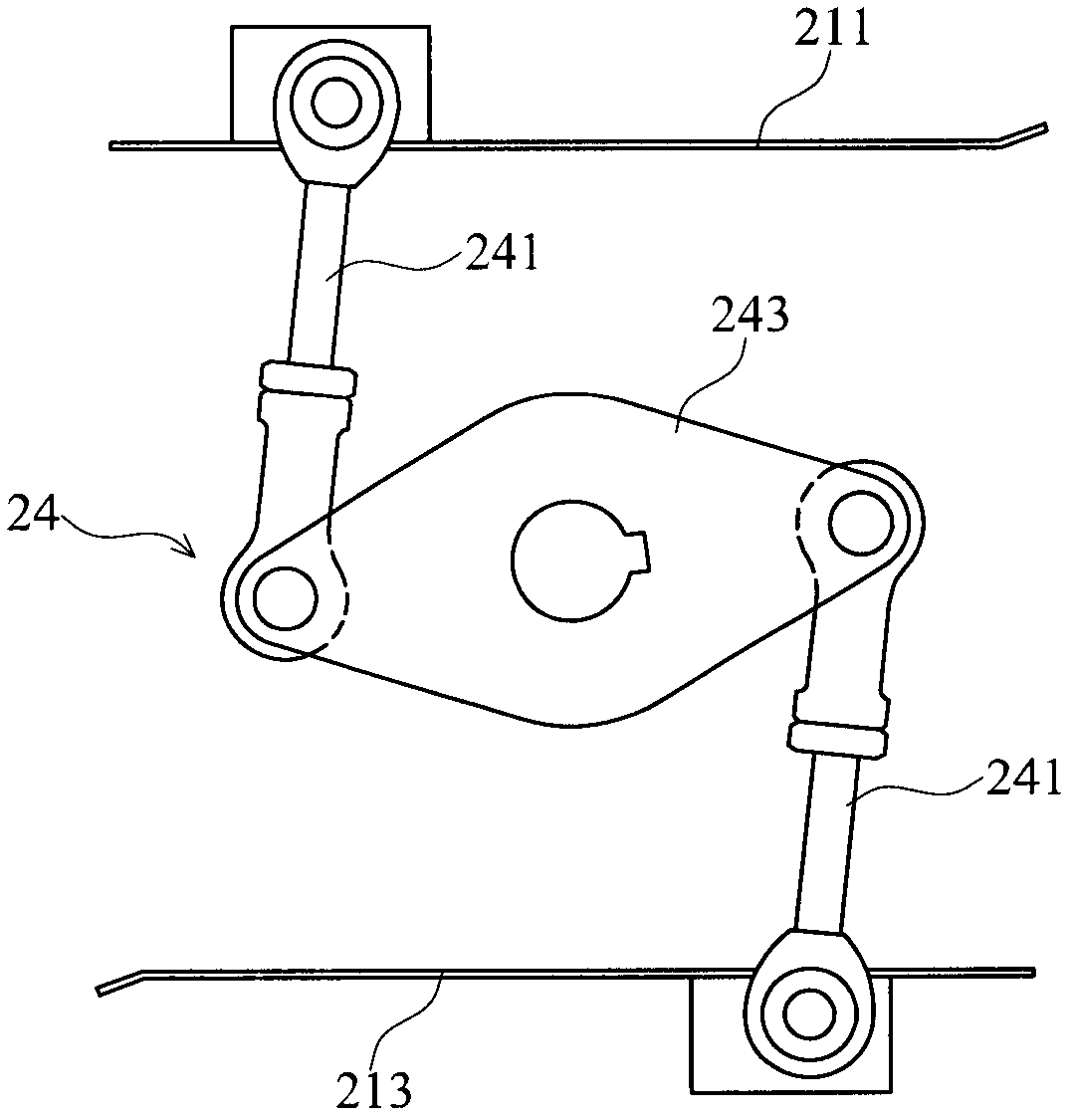

[0043] The two interlocking units 24 respectively include a rotating unit 241 and two connecting units 243 , wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com