Assembled type double-pipe seepage and drainage blind ditch and construction method of roadbed seepage and drainage structure

A seepage and drainage, prefabricated technology, applied in drainage structures, water/sewage treatment, side ditch/curbstone, etc., can solve the problems of slow construction, short service life, poor drainage capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

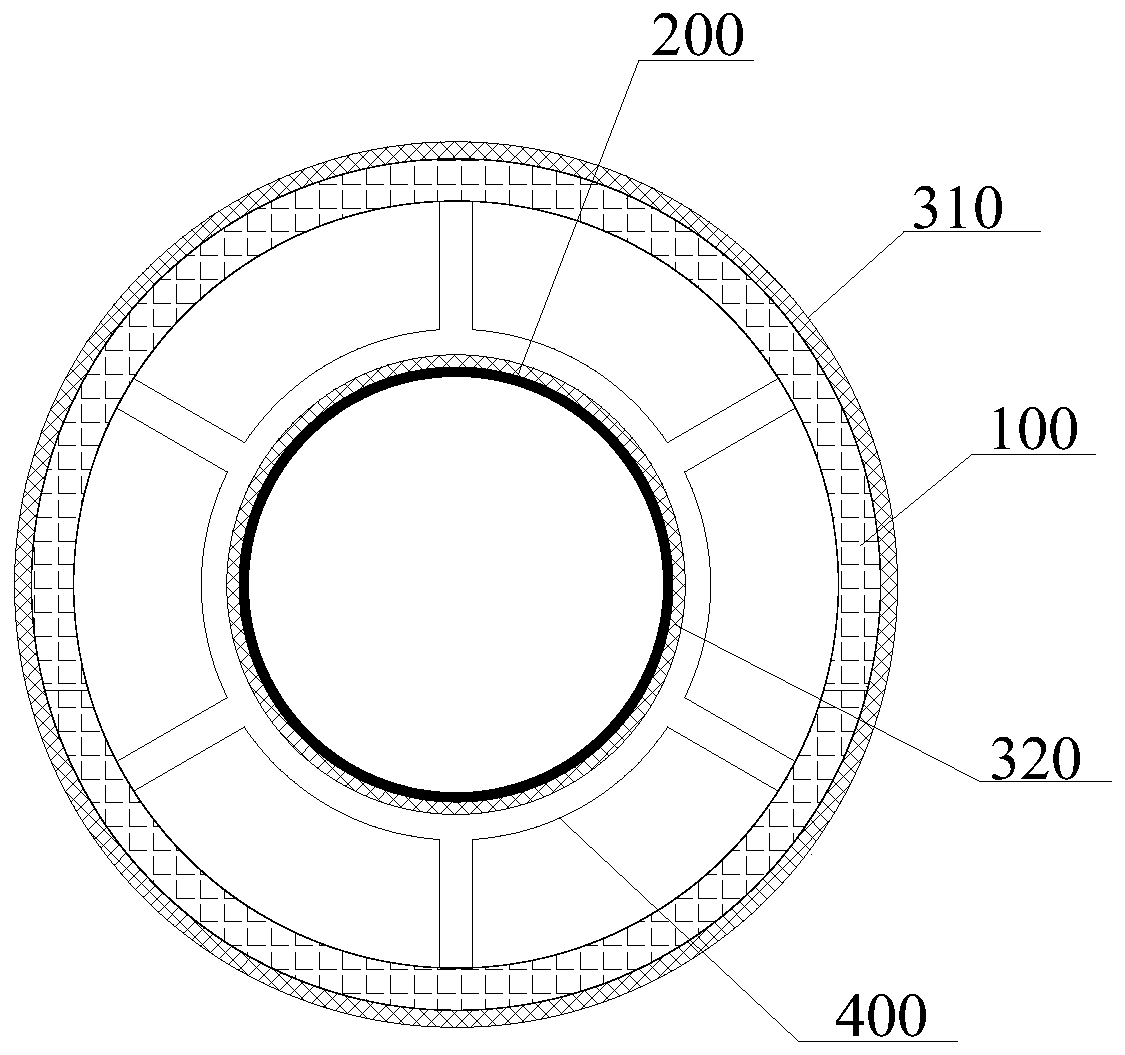

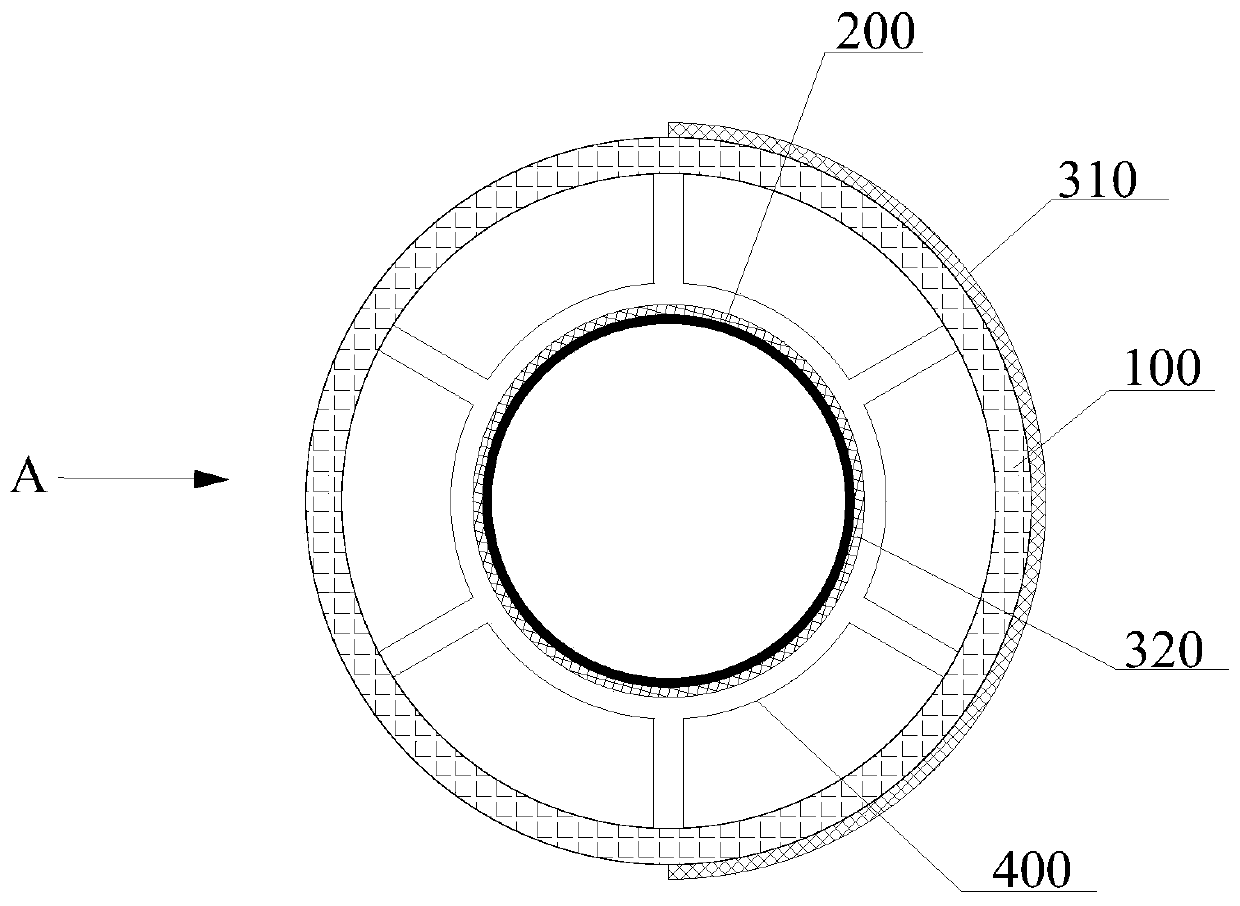

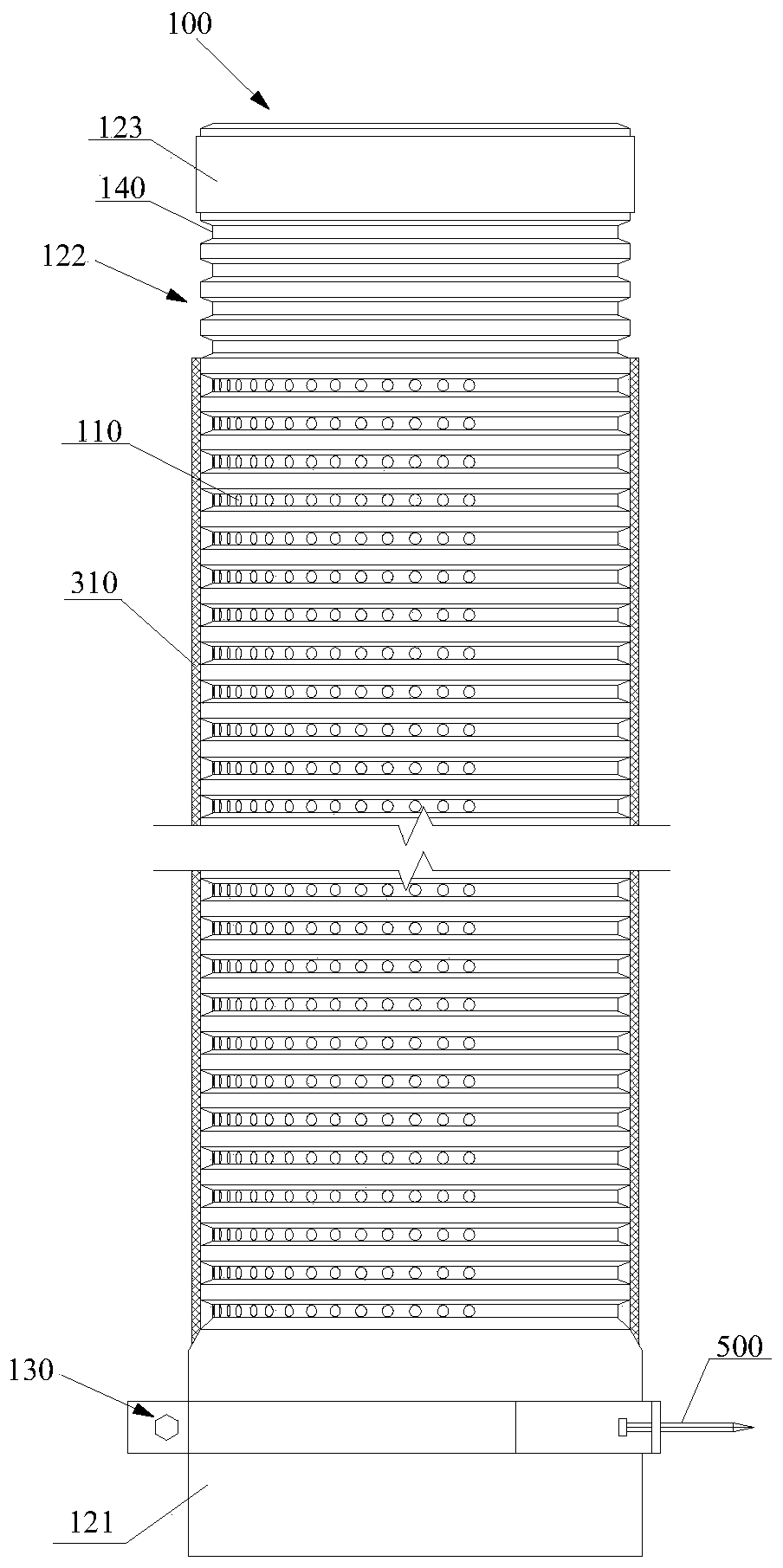

[0084] The prefabricated double-pipe drainage blind ditch of this embodiment includes end-to-end connected drainage units, such as figure 1 As shown, the drainage unit includes a first drainage pipe 100, a first filter layer 310, a second drainage pipe 200, a second filter layer 320 and a support assembly 400, and the wall of the first drainage pipe 100 is provided with a second A seepage hole 110, the first filter layer 310 is wrapped on the outside of the first drain pipe 100, the second drain pipe 200 is arranged inside the first drain pipe 100, and the second drain pipe 200 The pipe wall is provided with a second seepage hole 210, the second filter layer 320 wraps the outside of the second drain pipe 200 and forms a cavity between the inner wall of the first drain pipe 100 and the second filter layer 320 The first clear liquid filtered by the first filter layer 310 enters the cavity through the first water seepage hole 110, and part of the first clear liquid is filtered by...

Embodiment 2

[0093] Such as Figure 10 The subgrade seepage and drainage structure shown includes:

[0094] The blind ditch 20, the blind ditch 20 is the assembled double-pipe drainage blind ditch of embodiment 1 or embodiment 2, and the blind ditch 20 is installed at the bottom of the ditch 10;

[0095] The first backfill layer 30, the first backfill layer 30 is located around the blind ditch 20 and the backfill height is higher than the height of the blind ditch 20 by more than 15cm;

[0096] The third filter layer 40, the third filter layer 40 is located around the first backfill layer 30;

[0097] The second backfill layer 50 is located above the first backfill layer 30 and the height of the backfill matches the height of the trench 10 .

[0098] The construction method of the subgrade seepage and drainage structure comprises the following steps:

[0099] (1) Assemble the drainage unit of the assembled double-pipe drainage blind ditch;

[0100] (2) the third filter layer 40 is inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com