Construction method for roof steel grid frame

A construction method and technology for steel grids, which are applied to truss structures, joists, girders, etc., can solve the problems of long construction time, long influence time period, long construction period, etc., so as to reduce the time for high-altitude work and reduce the cost of auxiliary materials. , the effect of less space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

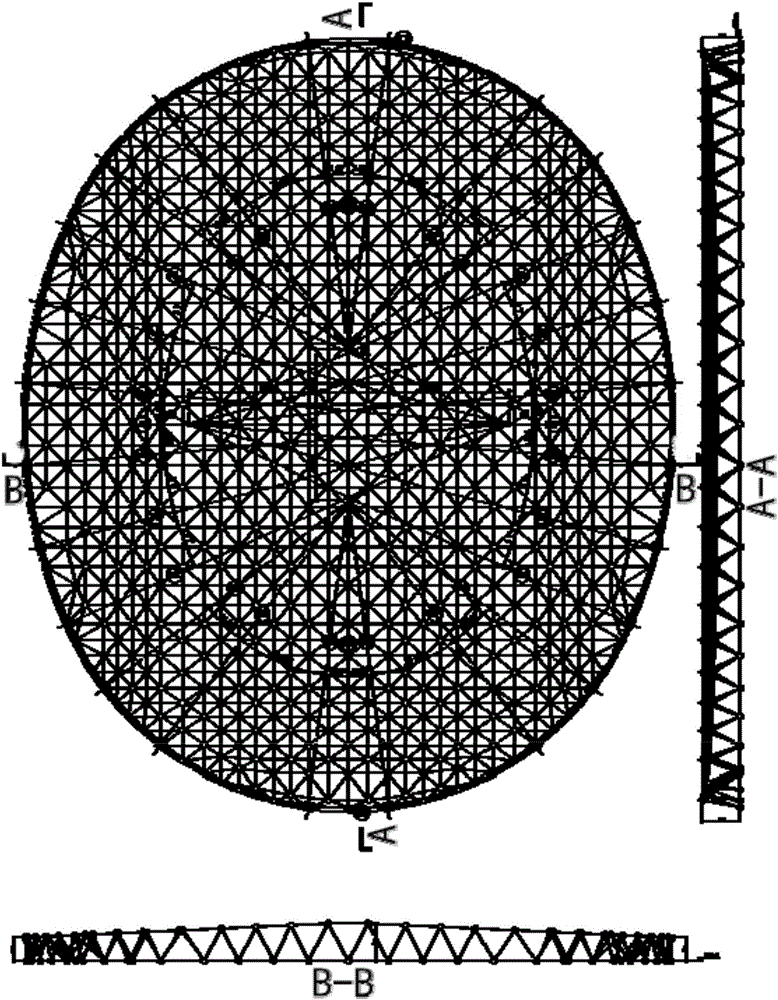

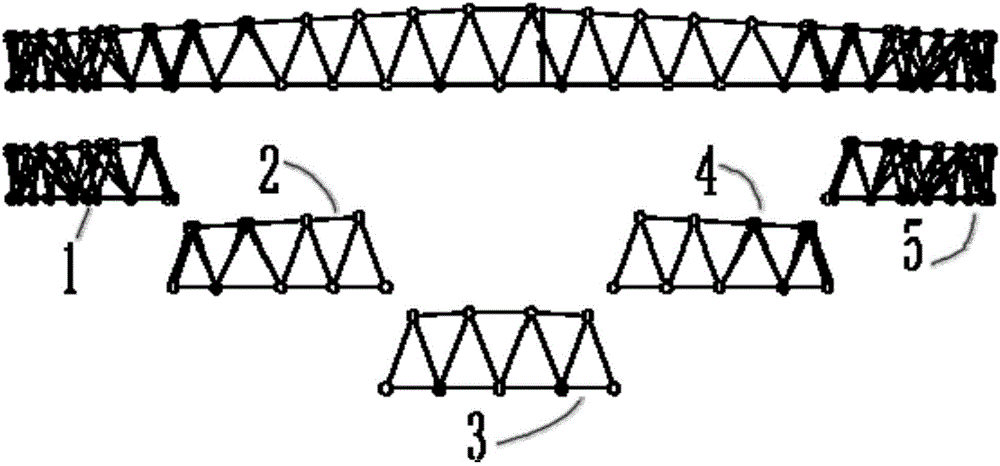

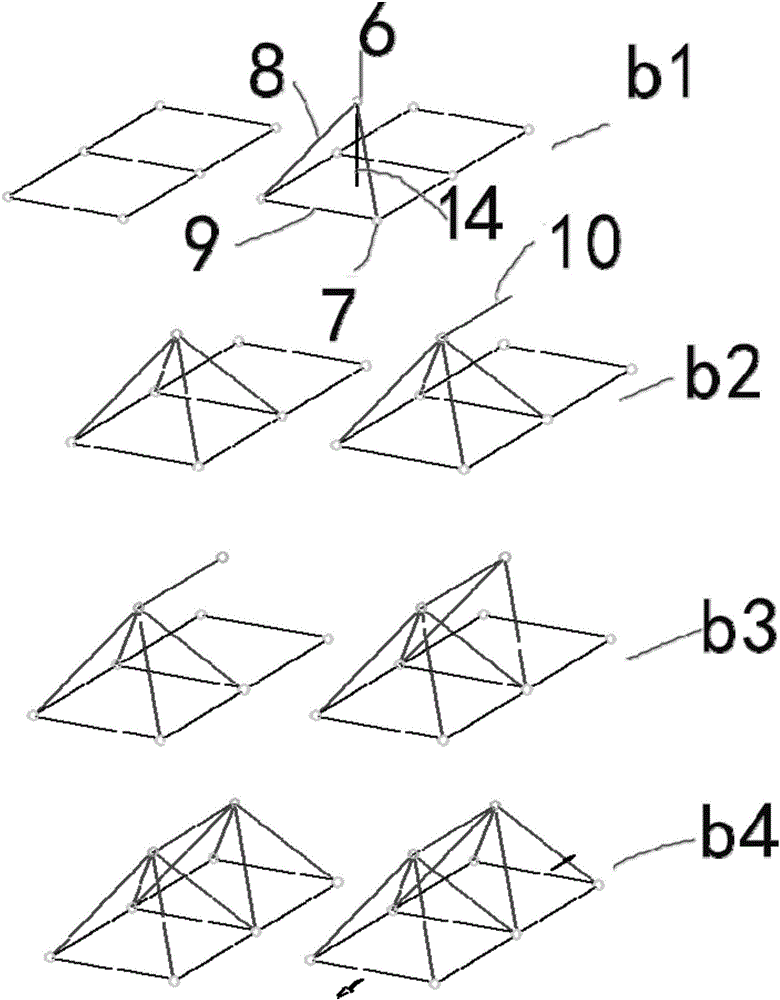

[0052] Such as figure 1 , a construction method of a roof steel grid, characterized in that the steel grid is spliced by several steel grids with different lengths to form an elliptical structure, and each steel grid is composed of upper chords 10, The lower chord 9 and the web 8 are spliced by several quadrangular pyramid units; the upper chord 10, the lower chord 9, and the web 8 are connected by bolt balls between each bar 16, and the bolt balls are divided into Upper and lower bolt balls 7, the upper bolt ball 6 is connected to the web 8 and the upper chord 10, and the lower bolt ball 7 is connected to the web 8 and the lower chord 9;

[0053] Such as Figure 1-Figure 4 As shown, the steel grid construction method may further comprise the steps:

[0054] A1 Arrange cranes along the elliptical plane circumference and inside of the roof steel grid frame, set up two scaffolding work platforms 12 with a width of 10 meters from the east and west atrium lines to the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com