Assembling and adjusting device and method thereof of F-shaped track panels

The technology of an adjustment device and a level adjustment device, which is applied in the directions of track, track laying, track maintenance, etc., can solve the problems of difficult adjustment, low work efficiency, and difficulty in assembly accuracy meeting design requirements, so as to improve adjustment accuracy and reduce labor costs. , adjust the quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Combine below Attached picture The present invention is described in detail:

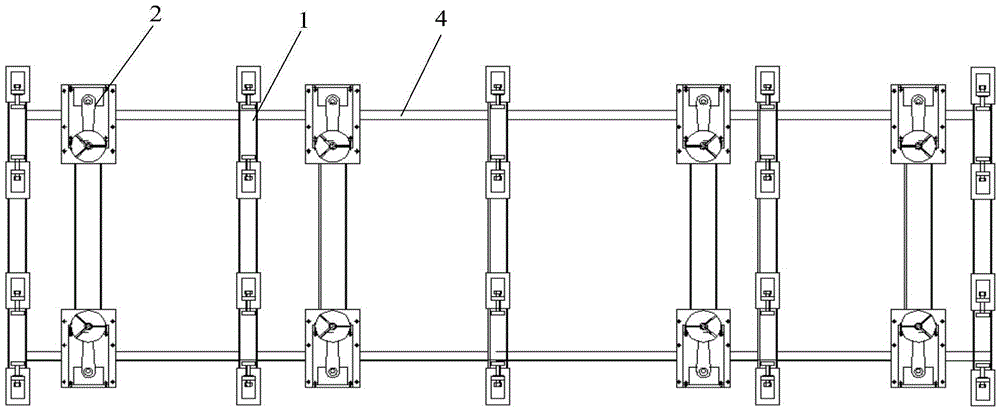

[0030] Such as figure 1 As shown, the present invention provides an assembly adjustment device for an F-shaped rail row, including a horizontal adjustment device 1 and a longitudinal pressing device 2 .

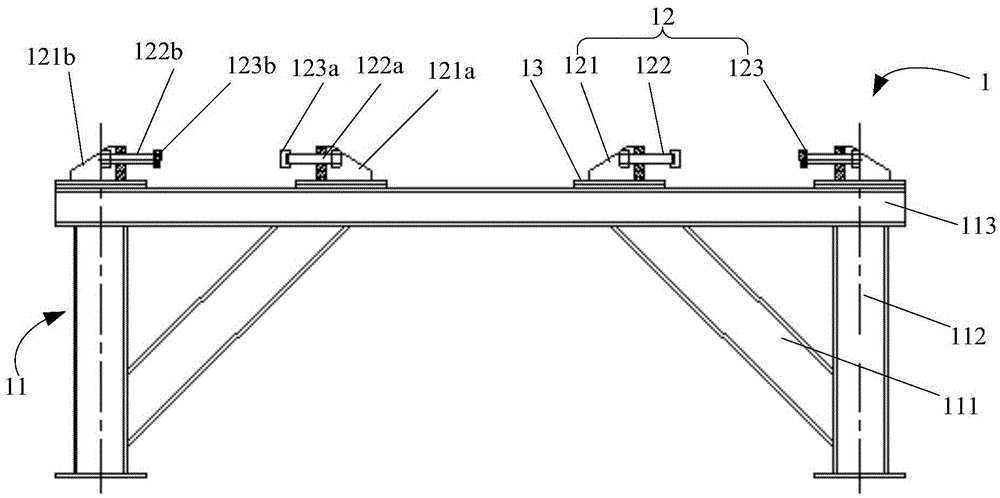

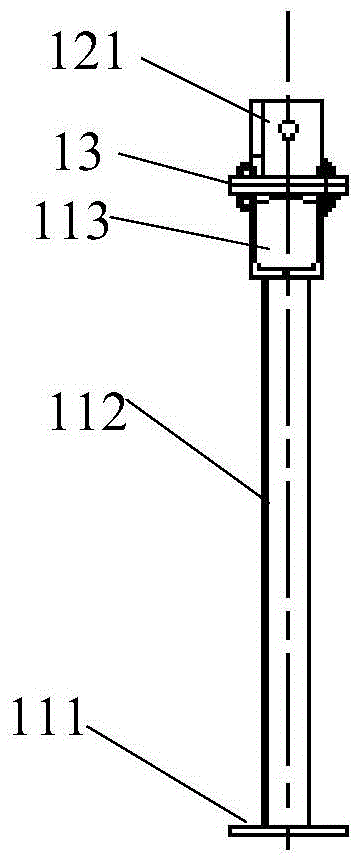

[0031] Figure 2 As shown in a-2c, the horizontal adjustment device 1 includes a first door-shaped bracket 11 and a above table The horizontal adjustment assembly 12 on both sides of the surface, the horizontal adjustment assembly 12 is provided with two groups, respectively located in the first door-shaped bracket 11 above table The left and right sides of the surface, and the distance between the two groups of horizontal adjustment components 12 matches the set value of the spacing of the F-shaped rail row. The matching here is not exactly the same, but corresponding adjustments are made according to the actual situation; preferred , the horizontal adjustment assembly 12 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com