Shear connecting part, mounting structure and construction method of UHPC waffle slab combined beam bridge

A technology of connectors and waffle plates, applied to bridge parts, bridges, bridge materials, etc., can solve the problems of large vertical and horizontal slippage, large tensile stress, etc., and achieve improved shear bearing capacity, overall bearing capacity, and good The effect of economic benefit and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

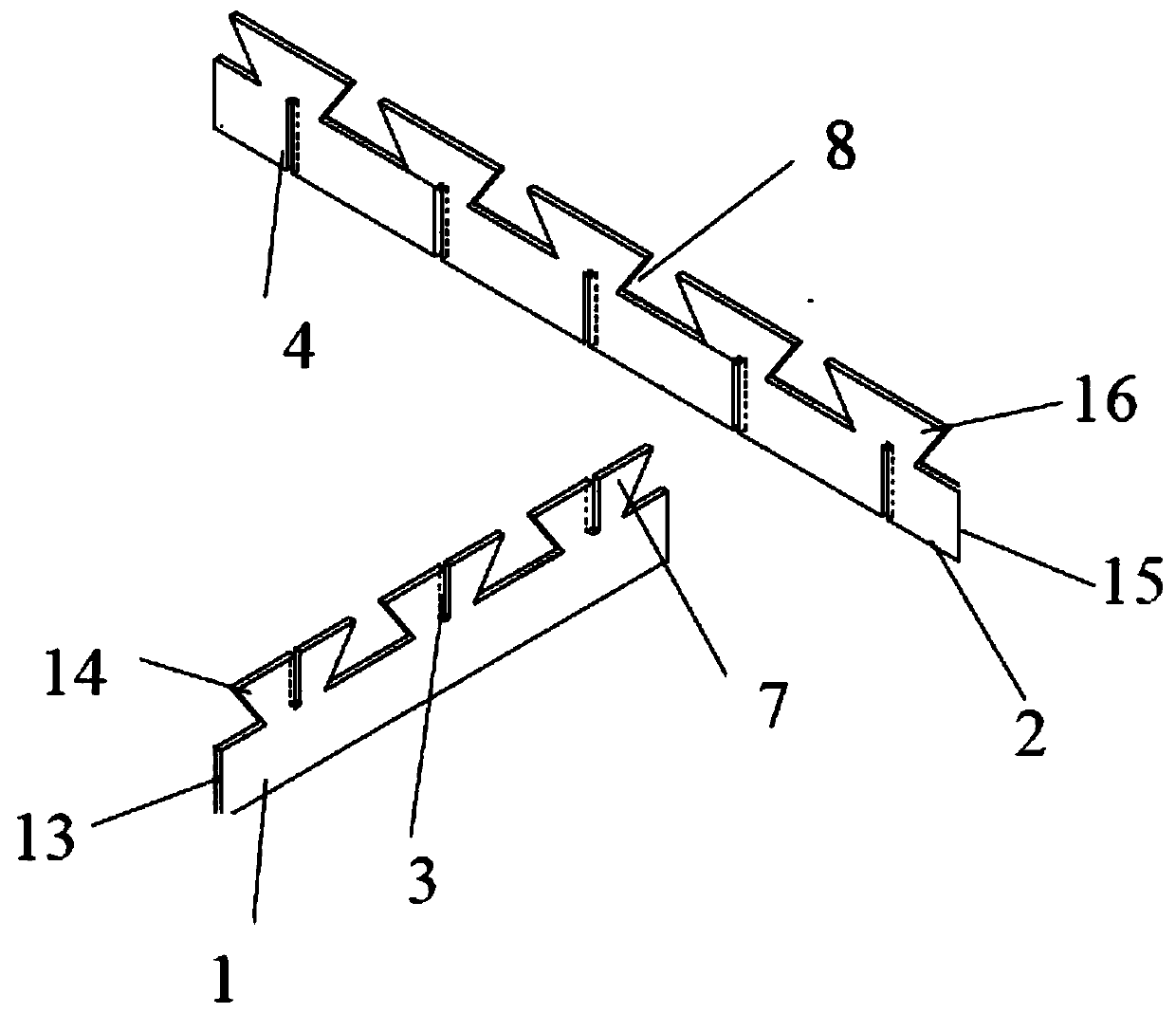

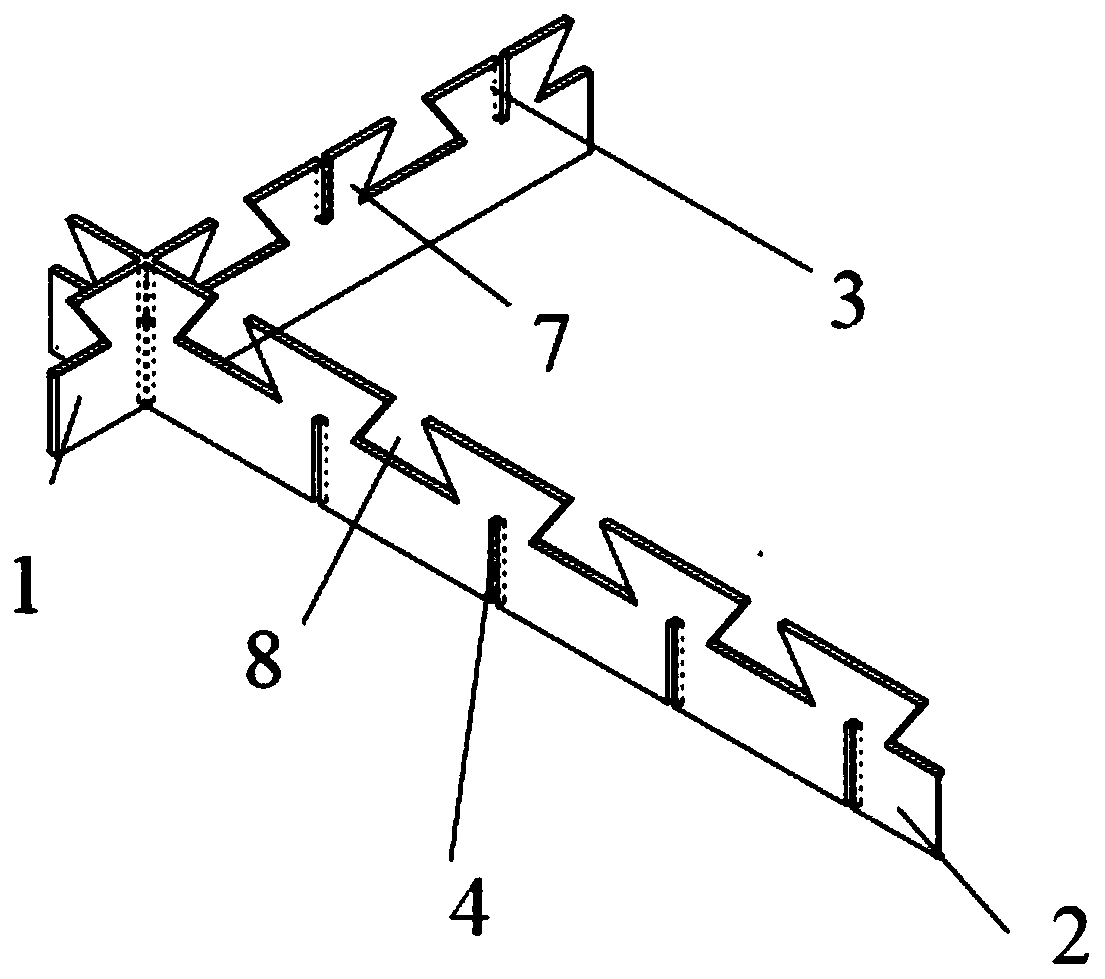

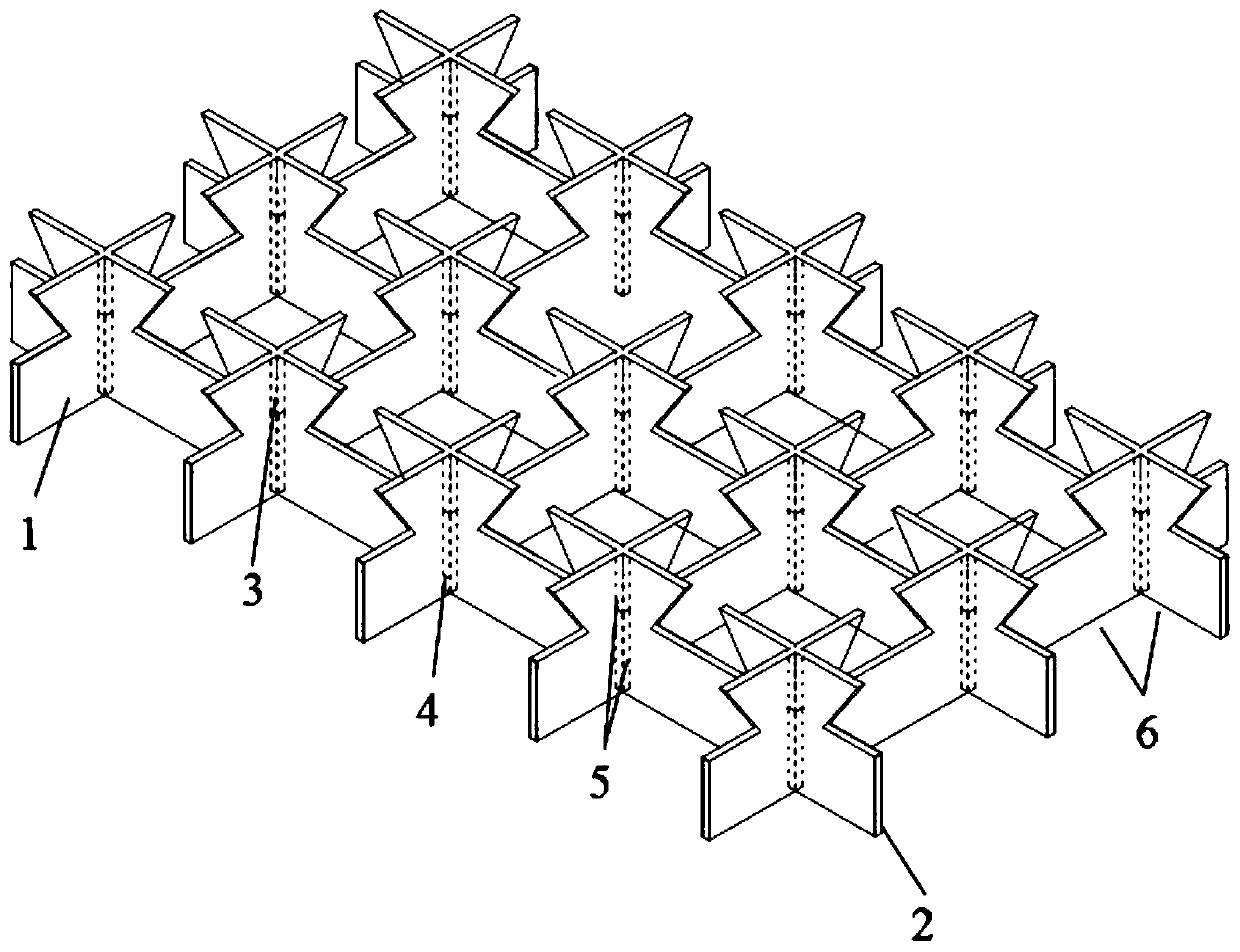

[0044] A shear connector of a UHPC waffle plate composite beam bridge, such as figure 1 , 2 , 3, which includes:

[0045]Horizontal tenon-type standard unit: it is composed of several horizontal tenon-type standard parts 1 arranged at intervals. Each horizontal tenon-type standard part includes an integrated lower tenon board body 13 and upper tenon board body 14. Several upper mortise joint openings 3 with intervals;

[0046] Longitudinal tenon-type standard unit: it is composed of several longitudinal tenon-type standard parts 2 arranged at intervals. Each longitudinal tenon-type standard part includes an integrated lower tenon board body 15 and upper tenon board body 16. There are lower mortise openings 4, the lower mortise openings co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com