Prefabricated machine room assembly construction method and system based on BIM

A construction method and technology for a refrigeration machine room, which are applied in industrial buildings, office automation, computer parts, etc., can solve problems such as the construction period and project quality cannot be guaranteed, reduce the amount of construction waste, avoid potential safety hazards, and shorten the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

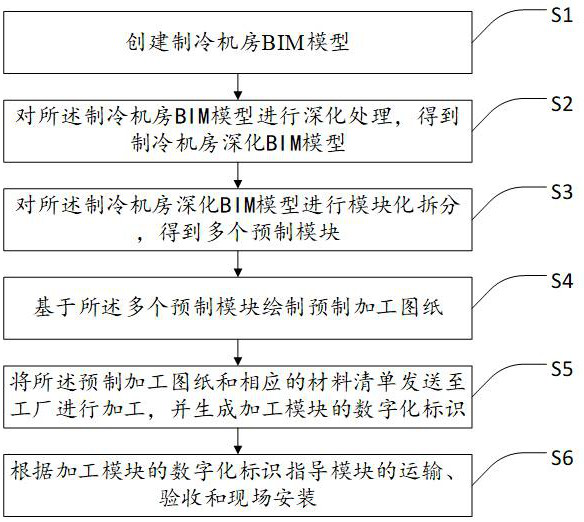

[0033] Additional aspects and advantages of embodiments of the invention will be set forth in the description which follows, and in part will be obvious from the description, or may be learned by practice of embodiments of the invention. figure 1 It is a flow chart of a BIM-based prefabricated machine room assembly construction method provided according to an embodiment of the present invention, as shown in figure 1 As shown, the method includes the following steps:

[0034] S1: Create a BIM model of the refrigeration room;

[0035] S2: Deepen the BIM model of the refrigerating machine room to obtain the deepened BIM model of the refrigerating machine room;

[0036] S3: Perform modular splitting on the deepened BIM model of the refrigeration room to obtain multiple prefabricated modules;

[0037] S4: Drawing prefabricated processing drawings based on the plurality of prefabricated modules;

[0038] S5: Send the prefabricated processing drawing and the corresponding material...

Embodiment 2

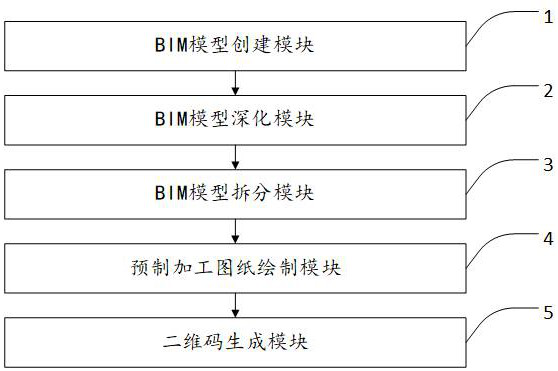

[0047] The embodiment of the present invention also provides a BIM-based prefabricated computer room assembly construction system, including:

[0048] BIM model creation module 1, used to create the BIM model of the refrigeration plant;

[0049] The BIM model deepening module 2 is used to deepen the BIM model of the refrigeration plant to obtain the deepened BIM model of the refrigeration plant;

[0050] The BIM model splitting module 3 is used to modularly split the deepened BIM model of the refrigeration plant to obtain multiple prefabricated modules;

[0051] The prefabrication drawing drawing module 4 is used to draw the prefabrication drawing drawing according to the plurality of prefabrication modules;

[0052] The two-dimensional code generation module 5 is used to generate the two-dimensional code label of the processing module.

[0053] The present invention uses BIM technology to disassemble and design prefabricated modules, combined with the size of construction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com