Superposed assembly type structure subway station and assembly construction method thereof

A prefabricated, subway station technology, applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve problems such as environmental water pollution, noise pollution, air pollution, etc., achieve support system optimization, reduce site demand, reduce The effect of site occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

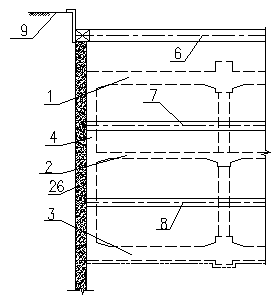

[0058] Introduction to Structural Node Connections

[0059] A superimposed prefabricated structure subway station, which consists of: a roof 1, a middle plate 2, a bottom plate 3, a side wall 4 and a heat exhaust air duct 5, and the structural nodes are connected:

[0060] Bottom plate and side wall connection

[0061] (1) The construction joint 12 from the bottom plate to the bottom of the negative second floor is a cast-in-place reinforced concrete structure, and the leaking grouting sleeve 13 is pre-embedded at the construction joint to connect the stressed steel bars of the upper side wall;

[0062] (2) The inner skin of the side wall is a prefabricated block with truss bars (both the stress bars and the distribution bars are carried), and at the same time, it is used as the inner formwork, the bottom is inserted into the grouting sleeve, and the stress bars are connected by pouring high-efficiency grouting materials. The width of the longitudinal block About 2m, strength...

Embodiment 2

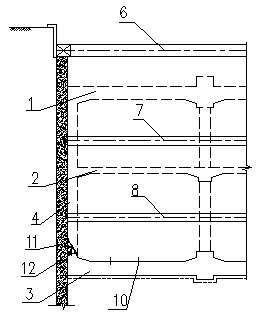

[0065] Middle plate and side wall connection

[0066] (1) The concrete of the side wall of the negative second floor is poured to the construction joint at the top of the negative second floor, and a steel bar connector is reserved for the stressed steel bar of the side wall at the construction joint to connect the upper steel bar;

[0067] (2) The bottom skin of the middle slab is a prefabricated block with truss reinforcement, which is also used as a template for the bottom skin. The width of the longitudinal block is about 2m. Reinforcement connection holes for later installation of heat exhaust air duct;

[0068] (3) The concrete of the middle slab is poured to the construction joint at the bottom of the negative floor to form a superimposed structure of the middle slab, and the leaking grouting sleeve is pre-embedded at the joint to connect the stressed steel bars of the upper side wall;

Embodiment 3

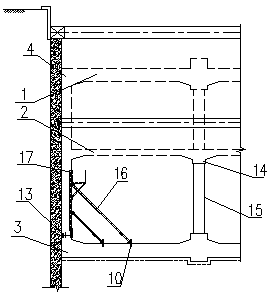

[0070] Roof and side wall connection

[0071] (1) The concrete of the side wall of the negative first floor is poured to the construction joint at the top of the negative first floor, and a steel bar connector is reserved for the stressed steel bar of the side wall at the construction joint to connect the upper steel bar;

[0072] (2) The bottom skin of the roof is a prefabricated block with truss reinforcement, which is also used as a bottom skin formwork. The width of the block is about 2m.

[0073] (3) The roof concrete is poured to form a roof superimposed structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com